10

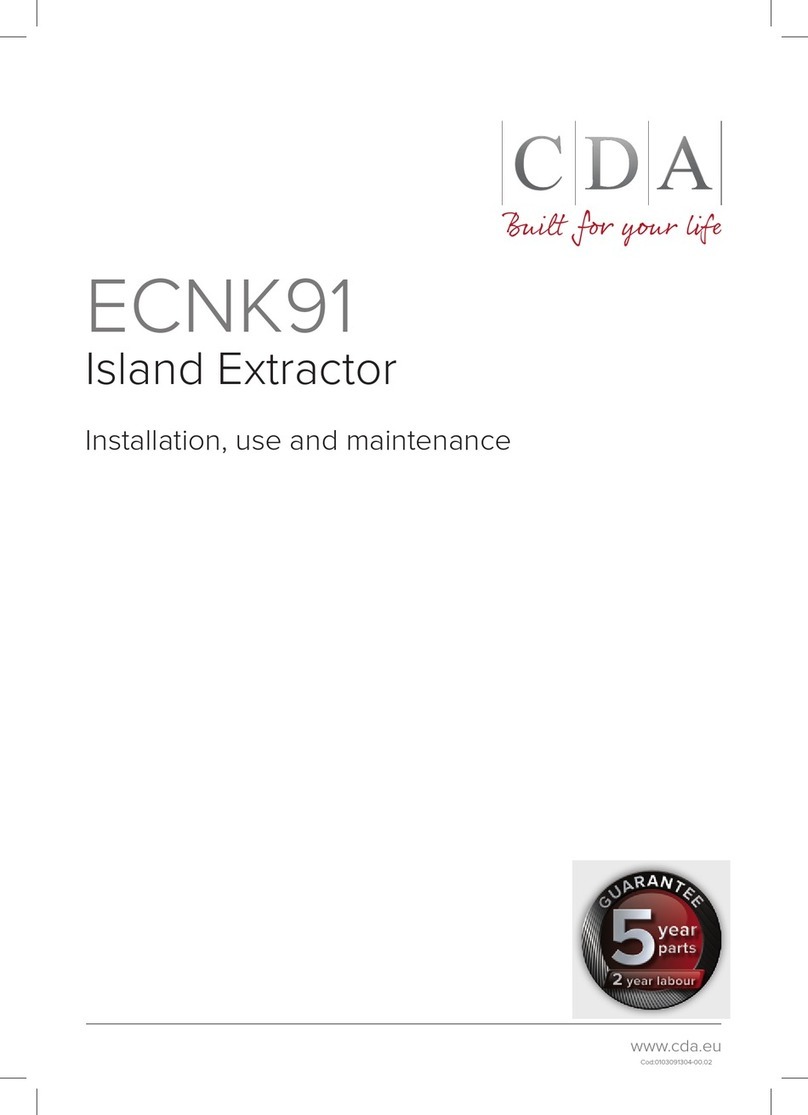

Installation - height

When the extractor is to be

installed above a CDA electric

hob, the minimum distance

between the hob and extractor

must exceed 650mm.

When the extractor is to be

installed above a CDA gas hob,

the minimum distance between

the hob and extractor must

exceed 750mm.

If the instructions provided with your gas hob state that the required

distance between the hob and extractor must be greater than 750mm,

then that is the distance that should be observed; this is a legal

requirement and may lead to your hob being disconnected from the

gas supply and the installation being reported under RIDDOR.

Note: The height should be measured from the top of the hob’s

burners to the grease filter.

•IN THE ABSENCE OF ANY INSTRUCTIONS SUPPLIED WITH

THE GAS HOB, THE MINIMUM DISTANCE BETWEEN THE HOB

AND EXTRACTOR MUST BE AT LEAST 760mm.

•The width of any hob must not be greater than the width of the

extractor installed above it.

•Always bear servicing in mind. The extractor should always be

easily accessible or removeable after installation.

CDA Electric

hob - 65cm

CDA Gas

hob - 75cm

Fig. 3