8

Note:

1- The machine has also been designed for use in envi-

ronments with a pollution rating of 1. (See EC 60664).

2- This equipment complies with EC 61000-3-12 provided

that the maximum permissible system impedance ZMAX

is less than or equal to 0,137 (Art. 328) and 0,081 (Art.

335) at the interface point between the user's supply and

the public system. t is the responsibility of the installer or

user of the equipment to ensure, by consultation with the

distribution network operator if necessary, that the equip-

ment is connected only to a supply with maximum per-

missible system impedance ZMAX less than or equal to

0,137 (Art. 328) and 0,081 (Art. 335).

2.3 DESCRIPTION OF PROTECTIVE DEVICES

2.3.1 Thermal protection

This equipment is protected by a thermostat. When the

thermostat is tripped, the machine stops delivering cur-

rent but the fan continues to run. The yellow LED (B)

lights to indicate when it is tripped. Do not shut off the

welding machine until the LED has gone off.

3 INSTALLATION

Make sure that the supply voltage matches the voltage

indicated on the specifications plate of the welding

machine.

When mounting a plug, make sure it has an adequate

capacity, and that the yellow/green conductor of the

power supply cable is connected to the earth pin.

The capacity of the overload cutout switch or fuses

installed in series with the power supply must be equiv-

alent to the absorbed current 1 of the machine.

3.1. START-UP

Only skilled personnel should install the machine. All

connections must be carried out according to current

regulations, and in full observance of safety laws (regu-

lation CE 26-23 / EC-TS 62081).

3.2 DESCRIPTION OF THE EQUIP ENT

A) Setting knob

During A welding it adjusts the “hot-start” current

time , expressed in hundredths of a second; essentially, it

sets an overcurrent that serves to improve striking. t

does not make any adjustment during continuous TIG

welding.

n pulsed TIG welding, it adjusts the pulse frequency in

Hz.

During welding processes in which the knob is active,

the value of the adjustment is shown on the display I.

Two seconds after the last adjustment the display

returns to showing the figure previously selected using

the selector switch O.

B) Thermostat LED

(see 2.3.1. Thermal protection).

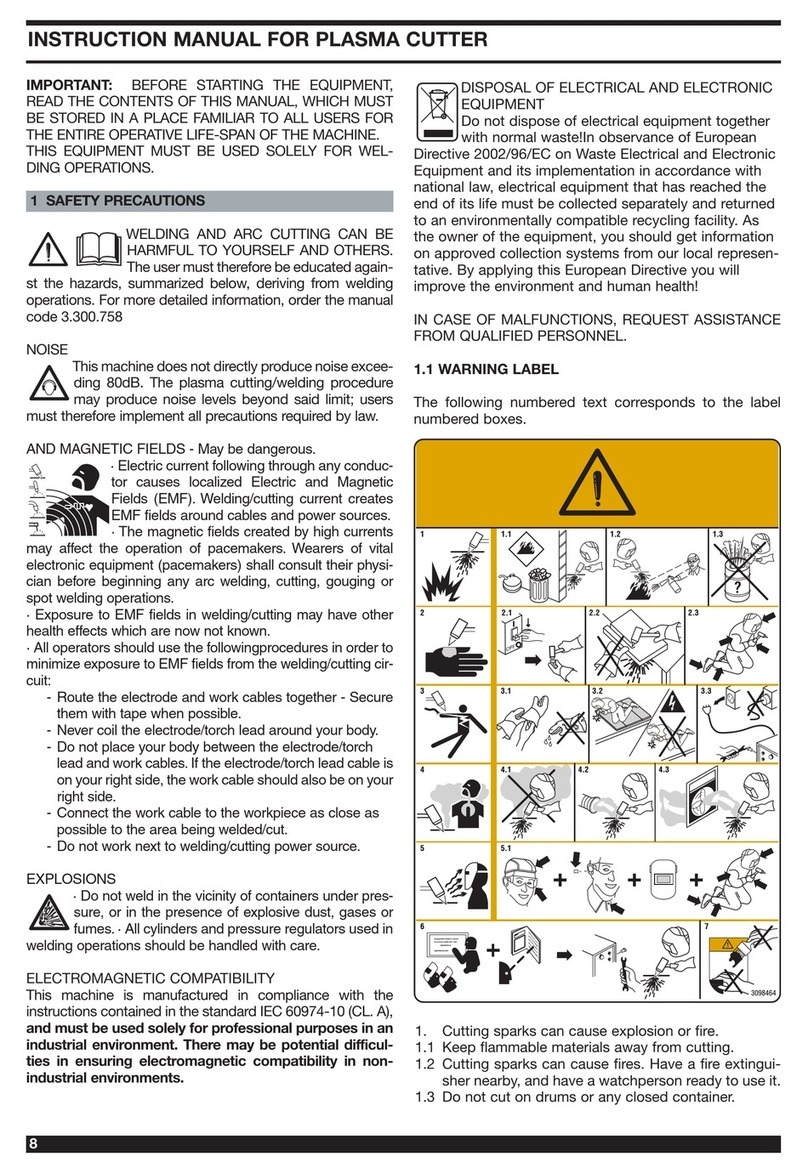

1.3 Disconnect input plug or power before working on

machine.

2 Breathing welding fumes can be hazardous to your

health.

2.1 Keep your head out of fumes.

2.2 Use forced ventilation or local exhaust to remove

fumes.

2.3 Use ventilating fan to remove fumes.

3 Welding sparks can cause explosion or fire.

3.1 Keep flammable materials away from welding.

3.2 Welding sparks can cause fires. Have a fire extinguish-

er nearby and have a watchperson ready to use it.

3.3 Do not weld on drums or any closed containers.

4 Arc rays can burn eyes and injure skin.

4.1 Wear hat and safety glasses. Use ear protection and

button shirt collar. Use welding helmet with correct

shade of filter. Wear complete body protection.

5 Become trained and read the instructions before

working on the machine or welding.

6 Do not remove or paint over (cover) label.

2 GENERAL DESCRIPTIONS

2.1 SPECIFICATIONS

This welding machine is a constant current power source

built using NVERTER technology, designed to weld cov-

ered electrodes (not including cellulosic) and for T G pro-

cedures, with contact starting and high frequency.

T MUST NOT BE USED TO DEFROST P PES.

2.2 EXPLANATION OF THE TECHNICAL SPECIFI-

CATIONS LISTED ON THE ACHINE PLATE.

This machine is manufactured according to the following

international standards: EC 60974.1 - EC 60974.10 CL. A

- EC 61000-3-11 - EC 61000-3-12 (see note 2).

N°. Serial number, which must be indicated on any

type of request regarding the welding machine.

Three phase static transformer-rectifier frequency

converter.

Drooping-characteristic.

MMA Suitable for welding with covered electrodes.

T G Suitable for T G welding.

U0. Secondary open-circuit voltage

X. Duty cycle percentage. % of 10 minutes during

which the welding machine may run at a certain

current without overheating.

2. Welding current

U2. Secondary voltage with current 2

U1. Rated supply voltage

3~ 50/60Hz 50- or 60-Hz three-phase power supply

1 max. This is the maximum value of the absorbed current.

1 eff. This is the maximum value of the actual current

absorbed, considering the duty cycle.

P23S Protection rating for the housing.

Grade 3as the second digit means that this

machine may be stored, but it is not suitable for

use outdoors in the rain, unless it is protected.

Suitable for hazardous environments.

S