FI002K0018v1530hUK – THS/21 Instruction manual for installation, use and maintenance

4 ORIGINAL INSTRUCTION

3.2.2.1Handling and moving the package

device ................................................. 68

3.2.2.2Unpacking procedure ......................... 68

3.2.2.3Packing list ......................................... 69

3.2.2.4Moving the Metal Detector.................. 69

3.2.3THS-RB.................................................... 69

3.2.3.1Handling and moving the package

device ................................................. 69

3.2.3.2Unpacking procedure ......................... 70

3.2.3.3Packing list ......................................... 70

3.2.3.4Moving the Metal Detector.................. 70

3.3Mechanical installation............................ 71

3.3.1Probe ....................................................... 71

3.3.1.1THS Models........................................ 71

3.3.1.2THS/G models.................................... 71

3.3.2Power supply unit..................................... 72

3.3.3Integrated systems................................... 73

3.3.3.1External signalling unit (beacon)......... 73

3.4Pneumatic installation ............................. 73

3.4.1Minimum requirements............................. 73

3.4.2Pneumatic circuit diagrams ...................... 74

3.4.2.1Ejector cylinder................................... 74

3.4.2.2Air jet ejection system......................... 74

3.4.2.3Ejector cylinder................................... 74

3.4.3Connecting up to the compressed air

supply....................................................... 75

3.4.3.1Ejector cylinder................................... 75

3.4.3.2Air jet ejector ...................................... 75

3.4.3.3Retracting belt .................................... 75

3.4.4Pressure adjustment ................................ 76

3.4.5Flow adjustment ....................................... 77

3.4.5.1Ejector cylinder................................... 77

3.4.5.2Air jet ejector ...................................... 78

3.4.5.3Retracting belt .................................... 78

3.4.6Padlocking the compressed air ................ 79

3.5Electrical Installation ............................... 79

3.5.1Installing connecting cables ..................... 79

3.5.2Description of inputs................................. 80

3.5.3Description of outputs .............................. 81

3.5.4Description of I/O interfaces..................... 82

3.5.5Connection of the CEIA Conveyor belt

Emergency circuit..................................... 83

3.5.6Connecting to the mains power supply .... 85

3.5.6.1Connection to earth ............................ 86

3.5.6.2Power Switch...................................... 86

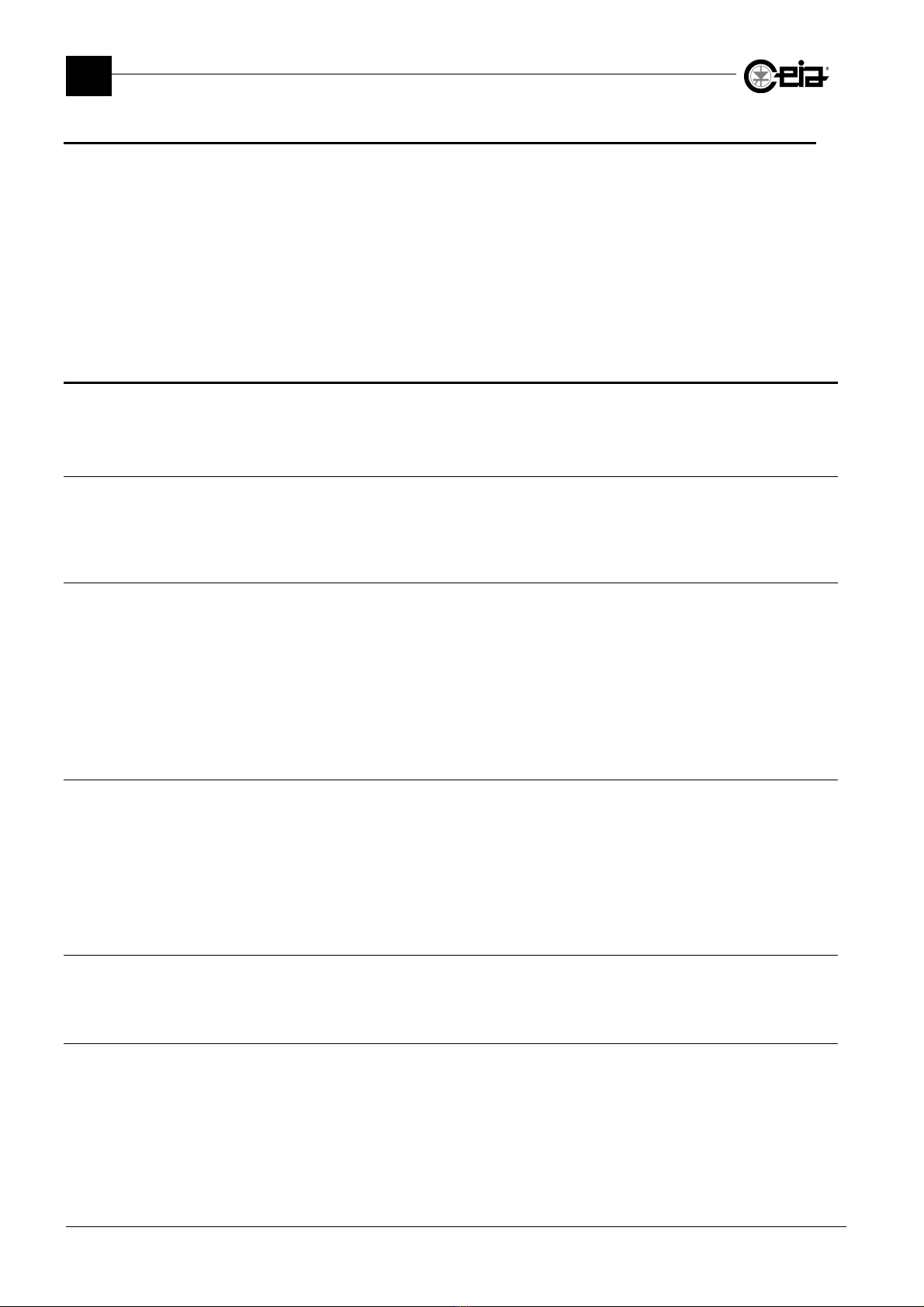

3.6Electrical diagrams.................................. 87

3.6.1Functional diagrams................................. 87

3.6.1.1Control Power Box .................... 87

3.6.1.2Conveyor Control System ......... 88

3.6.2Power Supply units .................................. 89

3.6.2.1Control Power Box .................... 89

3.6.2.2Small Size Power Supply ................... 91

3.6.2.3Field Generator for THS/MN21 . 92

3.6.2.4Conveyor Control System –

ALM card ............................................ 94

3.6.3SCD card ................................................. 98

3.6.3.1THS/xx21E ......................................... 98

3.6.3.2THS/xx21E-3F ....................................99

3.6.3.3THS/xx21 ..........................................100

3.6.3.4THS/xxMS21.....................................101

3.6.3.5THS/MN21 ........................................102

3.6.3.6Input for speed control through a 0-

10V analogic signal........................... 102

3.6.4IXC card (available on request) .............. 103

3.6.5Integrated Systems.................................104

3.6.5.1THS-FBB, THS-MBB, THS-FBV,

THS-FBBV without SCN board ......... 104

3.6.5.2THS-FBB, THS-MBB, THS-FBV,

THS-FBBV with SCN board .............. 106

3.6.5.3THS-MBR..........................................108

3.7Description of electrical connections .... 110

3.7.100211ALM card ......................................110

3.7.2Settings of SW1 minidip..........................114

3.7.300211AL_ card .......................................114

3.7.4Connection of push-buttons or sensors ..115

3.7.4.1Sensor positioning ............................116

3.7.5Connection of an ejection system...........117

3.7.6Synchronization photocell.......................117

3.7.7Ejection check photocell ......................... 117

3.7.8Connection to other in-line devices or

machines ................................................118

3.8Communication connections ................ 119

3.8.1RS232 Serial port connections ...............119

3.8.2BT Wireless Communication ..................119

3.8.3Ethernet / WiFi connections (on request,

with IXC card) .........................................119

3.9Configuration ........................................ 120

3.9.1System start-up ......................................120

3.9.2Preliminary settings ................................120

3.9.3Checking the input and output

connections ............................................121

3.9.4Motor (only with Conveyor Control

System) ..................................................121

3.9.5Transit speed.......................................... 122

3.9.5.2Application with Conveyor Control

System ..............................................122

3.9.6Encoder ..................................................123

3.9.7Synchronization photocell.......................123

3.9.8Ejection check photocell ......................... 124

3.9.9Ejection mode......................................... 124

3.9.9.1Ejection with manual reset (EM=B) ...125

3.9.9.2Photocell synchronized ejection, with

manual reset (EM=SB)......................126

3.9.9.3Reversing belt (EM=R)...................... 127

3.9.9.4Automatic ejection (EM=F)................128

3.9.9.5Automatic ejection with photocell

synchronization (EM=S).................... 129

3.9.9.6Automatic ejection for high-speed

applications (EM=FS)........................ 131

3.9.10Barcode reader....................................... 133

3.9.10.1With change of Detection Mode or

Band between two products..............133

3.9.10.2Without change of Detection Mode or

Band between two products..............134