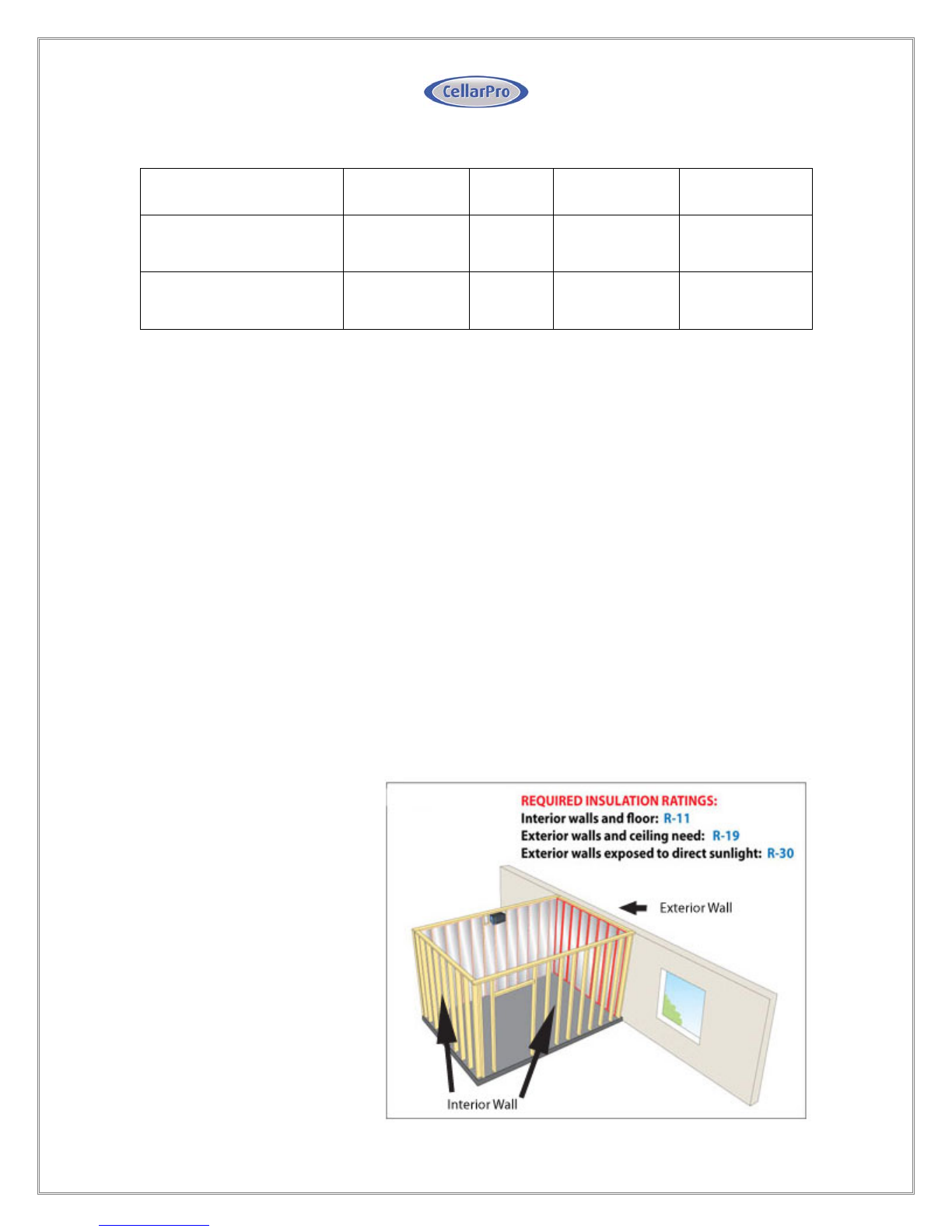

recessed lighting, which can allow air to leak into the cellar. Please note: The R-values

above are the MINIMUM recommended amounts of insulation. It is advisable to use as

much insulation as possible inside your walls, ceiling and floor.

It is critical that all walls, joints, doors and windows, electrical outlets and/or switches,

pipes, vents and light fixtures be sealed to prevent air and moisture from entering the

cellar. If there is a leak in the cellar, the cooling unit will build up excess condensation

that eventually may damage the internal components and shorten the life of the

cooling unit, and may cause water to leak from the cooling unit.

We offer a Wine Cellar Modification for cooling

units that will be installed in wine cellars (as

opposed to wine cabinets.) The Wine Cellar

Modification provides a fitting and condensate

tube at the back of the cooling unit to relieve

excess moisture that may condense inside the

cooling unit. For installations in warm

environments and/or cellars without airtight

seals, we strongly recommend this modification.

However, the modification does not replace the requirement for a cellar to have proper

insulation, moisture barriers and airtight seals from the environment outside the cellar.

If your cooling unit has the wine cellar modification, please make sure that the tube has

a condensate trap that is slightly filled with water, as follows:

As shown above, the drain line should drop, then rise (but stay below the height of the

fitting), and then drop again into a drain or bucket. Then, fill the trap with water. The

condensate trap will allow any excess moisture inside the cooling unit to overcome the

static pressure and flow out of the drain line. Please note: If you do not use a trap, you

will see little – if any – condensation, for the same reason that water stays inside a straw

when one end is sealed.

V9.14

7