9

II. Installation Instructions

Configuration Options

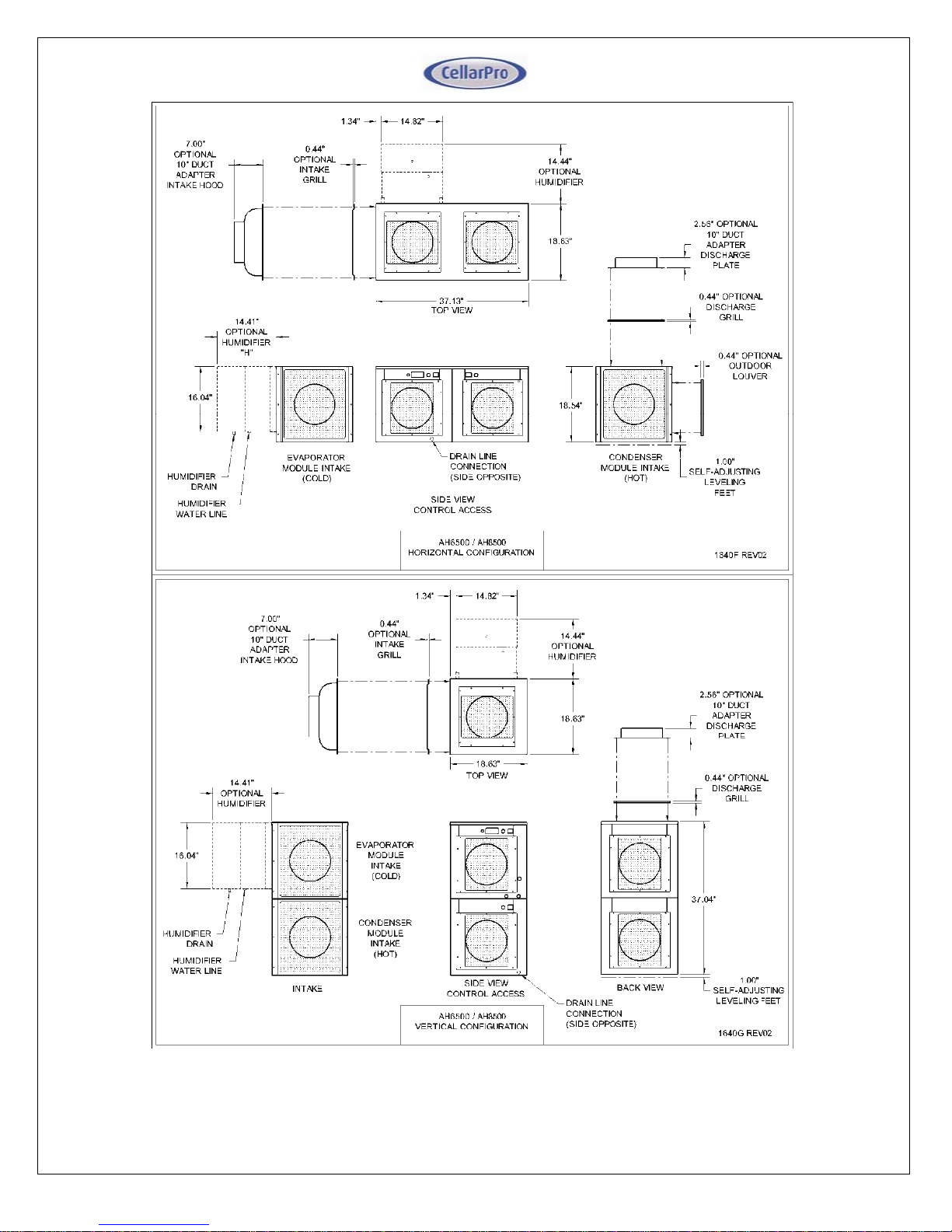

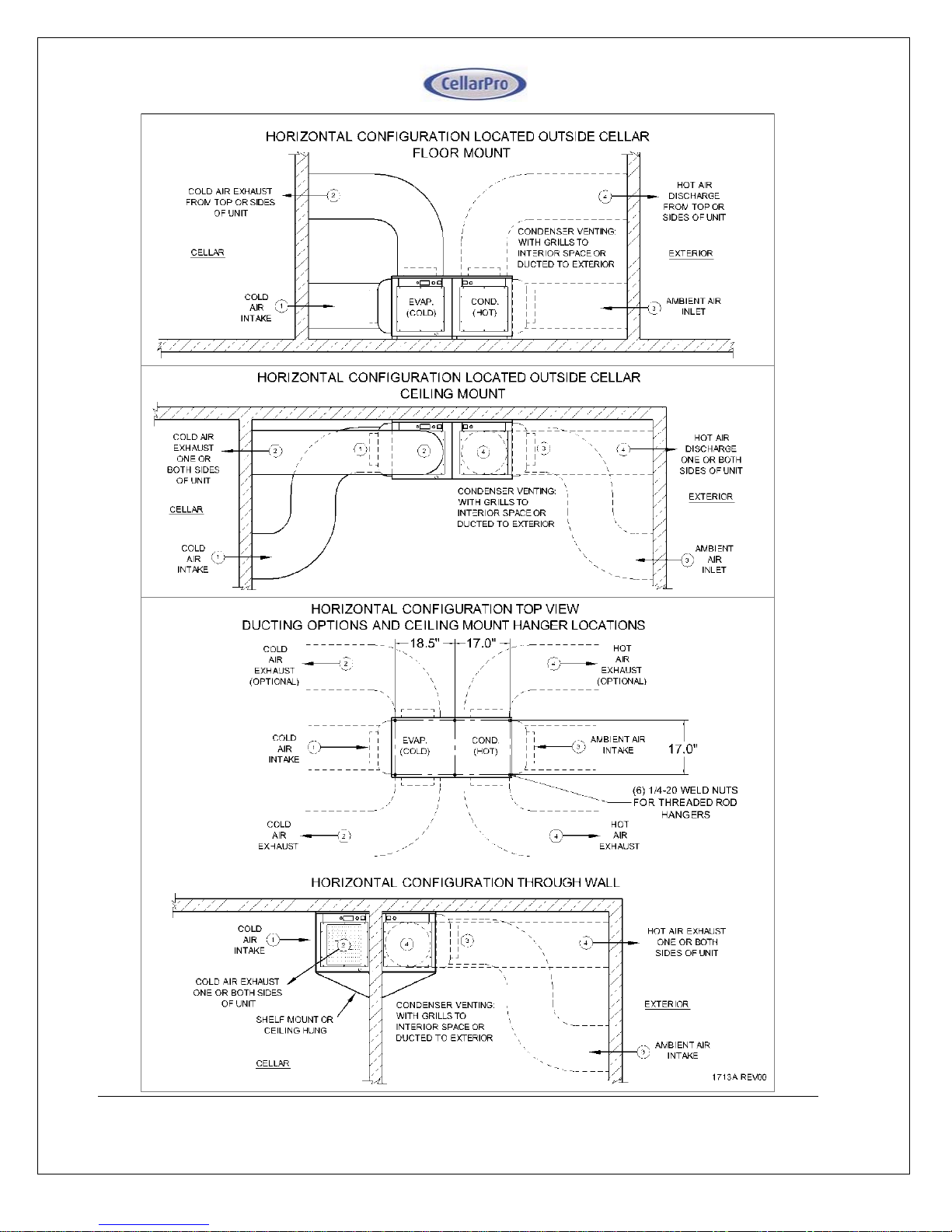

The Air Handler comes in three basic configurations:

Horizontal configuration - which can be installed inside or outside the cellar.

Additionally it can be installed through the wall with a portion of the unit in the cellar

and outside the cellar.

Vertical configuration – this is the ‘stacked’ option which is a space saving approach.

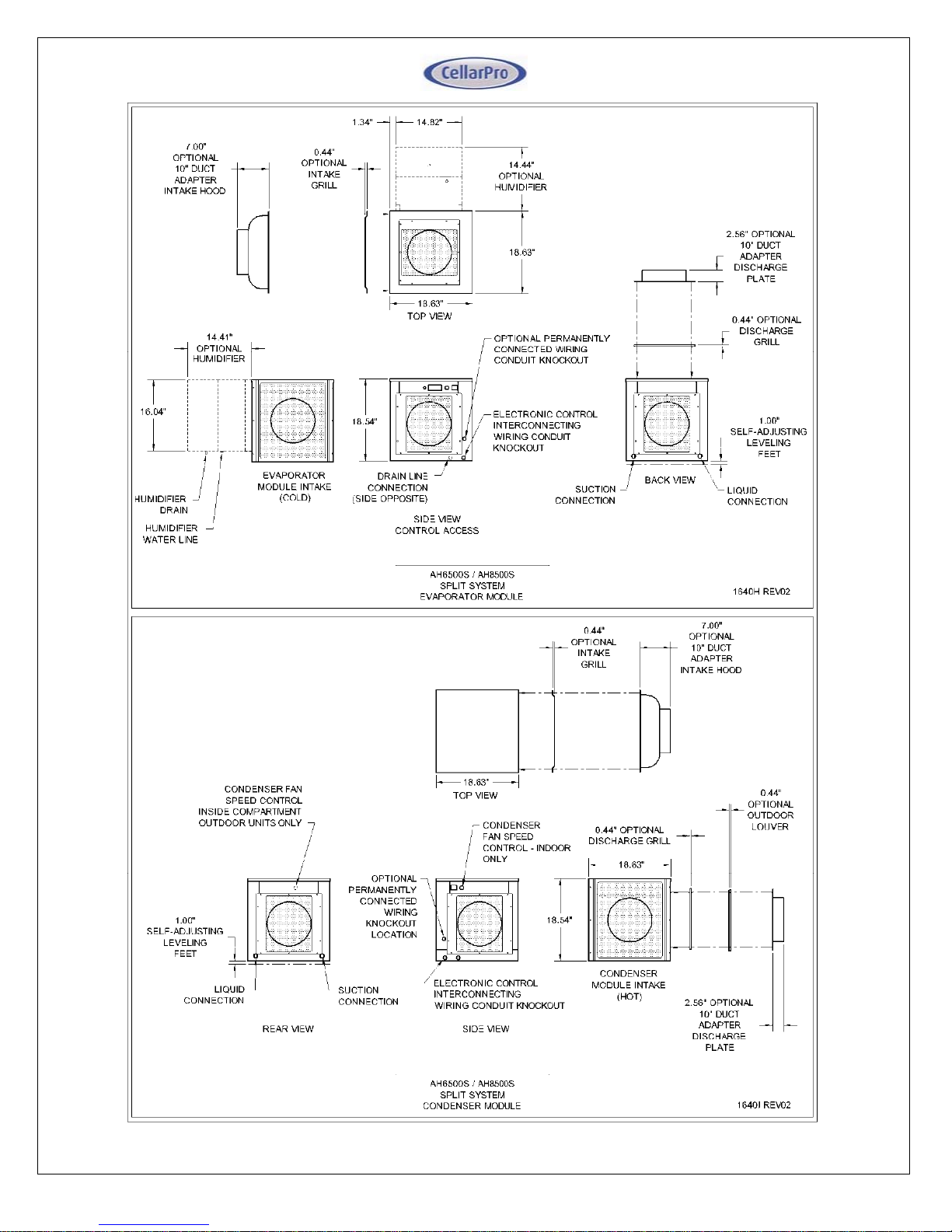

Split configuration – with the evaporator in the cellar (ductless) or outside (ducted)

and with the condenser either inside or outside the house or building.

Horizontal Configuration.

Through wall: The unit is installed through the cellar wall with the evaporator module

inside the cellar, and the condenser module outside. The unit requires a mounting shelf,

sized to fit the width and depth of the unit and strong enough to support the weight of the

unit. The unit is secured to the mounting shelf using (4) 1/4-20 bolts secured to captive

nuts located in the bottom corners of the unit (note: the provided leveling feet must be

removed). The condenser can be provided with grills to vent the air, or duct adapters to

duct the intake, discharge, or both. The condenser module can also pass through the

cellar wall to an outdoor exposure by installing optional outdoor louvers to the intake and

discharge air panel openings.

Remote ducted: The unit is mounted remote to the cellar, and the evaporator module

intake and discharge air are ducted to the cellar. The condenser can be provided with

grills to vent the air, or duct adapters to duct the intake, discharge, or both. The

condenser module can also pass through an exterior wall to an outdoor exposure by

installing optional outdoor louvers to the intake and discharge air panel openings. The

unit may be floor mounted on the leveling feet provided, or flush to the floor with the

leveling feel removed. The unit may be ceiling hung using six 1/4-20 threaded rods (field

provided), attaching to captive nuts provided in the top corners and middle edges of the

unit.

Inside cellar: The unit can be mounted inside the cellar, provided that the condenser

intake and discharge are ducted to a suitably ventilated area outside the cellar.