6

Ambient Environment

CellarPro cooling units are designed to operate in ambient temperatures between

10.0°C and 29.4°C. They are designed for internal use only, and are not designed for

exposure to the exterior.

CellarPro cooling units are designed to maintain temperatures inside the cellar up to

16.6°C below the ambient temperature of the condenser air intake. For example, if

the ambient temperature of the condenser air intake is 29.4°C, the cooling unit

should be able to maintain temperatures of 12.8°C inside the cellar. Similarly,

CellarPro cooling units do not have heating elements, so if temperatures inside the

cellar drop below proper wine storage temperatures, the cooling unit cannot create

heat inside the cellar.

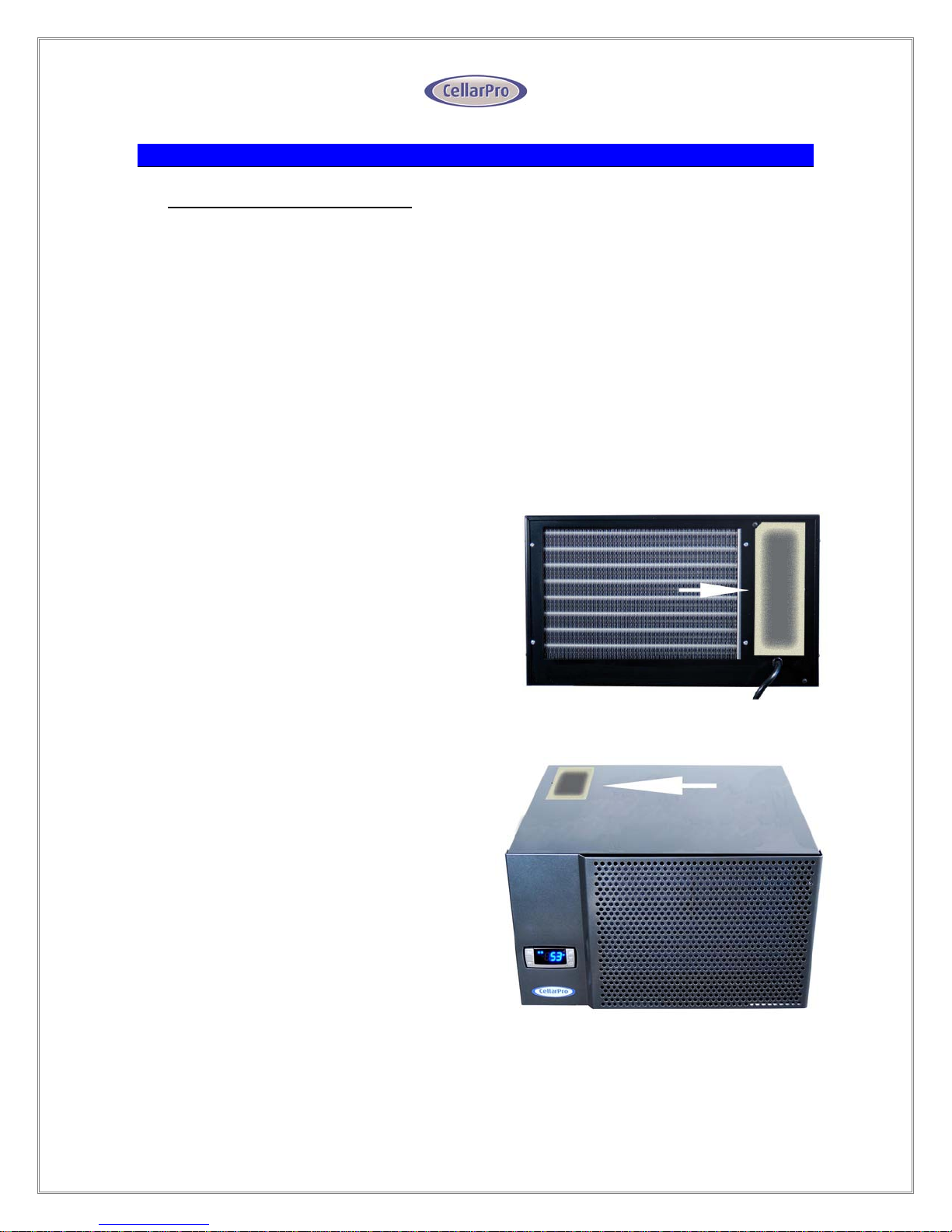

Proper temperatures are maintained by transferring heat from inside wine cellars

and exhausting heat through the top (top-vent) or rear (rear-vent) of the cooling units.

Insulation

CellarPro cooling units are designed to be installed inside wine cellars that have

proper insulation, moisture barriers and an airtight seal from the environment

outside the cellar.

Interior walls and floor

should have a minimum of

R-11 insulation, and a vapor

barrier on the warm side of

the insulation. The ceiling

should have a minimum of

R-19 insulation and a vapor

barrier on the warm side of

the insulation. Doors also

should be insulated and

tightly sealed with weather

stripping around the

perimeter of the door.

Surface-mounted fixtures

are recommended over

recessed lighting, which can

allow air to leak into the

cellar.

It is critical that all walls, joints, doors and windows, electrical outlets and/or

switches, pipes, vents and light fixtures be sealed to prevent air and moisture from

entering the cellar. If there is a leak in the cellar, the cooling unit will build up excess

condensation that eventually may damage the internal components and shorten the

life of the cooling unit, and may cause water to leak from the cooling unit.