9

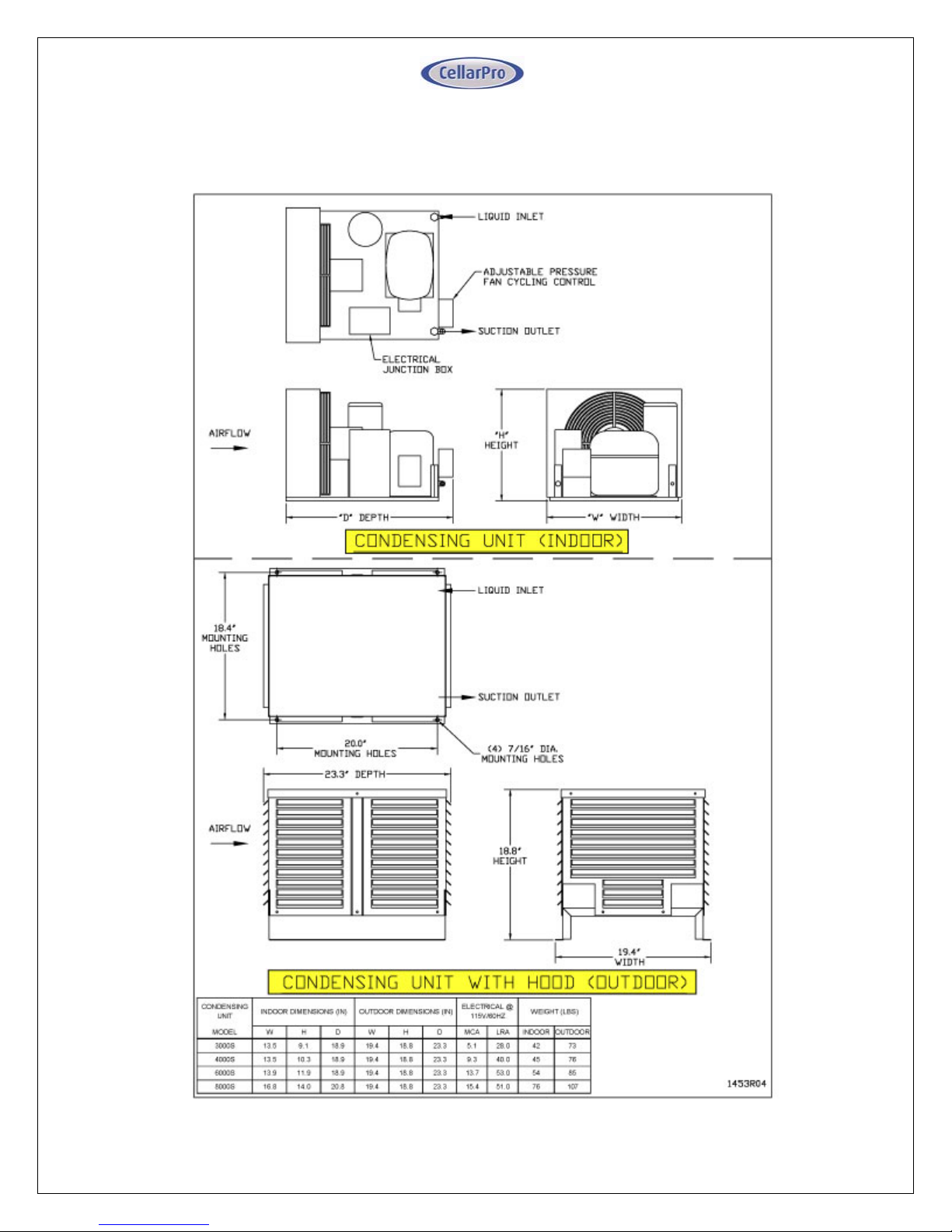

Outside the Cellar

Condensing unit Air Exhaust. Condensing units create significant hot air which

must be exhausted into an appropriately-sized space in order for the heat to

dissipate. If the space is constrained and/or too small, the heat will not dissipate.

In this event, the cooling unit will be forced to re-circulate its hot air exhaust

and/or the static pressure will back up the cooling unit. If this happens, the

cooling unit’s ability to create cold air inside the cellar will be compromised.

Condenser Air Intake. The condenser coils require access to cool air in order for

the cooling unit to produce cold air. In addition, the cooling unit must be installed

so that, after its installation, the condenser coils are accessible for periodic

cleaning.

The Condensing unit cannot be ducted.

Inside the Cellar

Evaporator Air Intake

.

When the warm air passes across the evaporator coils,

heat is removed from the air, and the resulting cold air is exhausted into the cellar.

To ensure proper airflow, minimum clearance of 12” is required in front of the

cooling unit.

Evaporator Air Exhaust.

Cold air is exhausted at the top front of the cooling unit.

Because CellarPro cooling units are located at the highest point inside wine

cellars, the cold air exhaust eventually will drop to the bottom of the cellar. To

ensure proper airflow and reduce temperature stratification inside the cellar, the

space in front of the cold air discharge should be clear of any obstructions,

including wine bottles, wine racks, etc.

Ducting. CellarPro Evaporators cold air exhaust and return can be ducted with a

hood up to 50 equivalent feet with 8” diameter ducting, or 100 equivalent feet with

our auxiliary fan and 8” diameter ducting. We offer a duct kit (sold separately) with

two fitting that attach to the front of the cooling unit and can be ducted.

We also offer a remote control panel kit that can be installed remotely (up to 10

feet) from the cooling unit, either inside or outside the cellar, and a bottle probe

(10 foot cord) that can be plugged into the cooling unit.