Page 3

Important Safety InstructionsImportant Safety Instructions

To ensure the safety of people, it is important that you read all the

following instructions. Incorrect installation or incorrect use of

theproductcouldcauseseriousharmtopeople.

ATTENTION

The installer, being either professional or DIY, is the last person on the site that can ensure that the

operatorissafelyinstalled,andthatthewholesystemcanbeoperatedsafely.

WARNINGS FOR THE INSTALLER

1. CAREFULLY READ AND FOLLOW ALL INSTRUCTIONS supplied with the product, or by Centurion Systems (Pty)

beforebeginningtoinstalltheproduct. Ltd.

2. This appliance is not intended for use by persons 14. Make sure that the earthing system is correctly

(including children) with reduced physical, sensory or constructed, and that all metal parts of the system are

mental capabilities, or lack of experience and knowledge, suitablyearthed.

unless they have been given supervision or instruction 15. Safety devices must be fitted to the installation to guard

concerninguseof the appliance*by a personresponsible against mechanical movement risks such as crushing,

fortheirsafety. draggingandshearing.

3. All installation, repair, and service work to this product 16. It is recommended that at least one warning indicator light

mustbedonebyasuitablyqualifiedperson. befittedtoeverysystem.

4. Donot activateyour gateopenerunless youcan seeit and 17. Always fit the warning signs visibly to the inside and

candeterminethatitsarea oftravelis clearofpeople, pets, outsideofthegate.

orotherobstructions. 18. The installer must explain and demonstrate the manual

5. NO ONE MAY CROSS THE PATH OF A MOVING GATE. operation of the gate in case of an emergency, and must

Always keep people and objects away from the gate and handtheUser/Warningsguideovertotheuser.

itsareaoftravel. 19. Explain these safety instructions to all persons authorized

6. NEVER LET CHILDREN OPERATE OR PLAY WITH THE to use this gate, and be sure that they understand the

GATE CONTROLS, and do not allow children or pets near hazardsassociatedwithautomatedgates.

thegatearea. 20. Do not leave packing materials (plastic, polystyrene, etc.)

7. Securealleasily accessedgateopenercontrols inorderto within reach of children as such materials are potential

preventunauthorizeduseofthegate. sourcesofdanger.

8. Do not in any way modify the components of the 21. Dispose of all waste products like packaging materials,

automatedsystem. wornoutbatteries,etc,accordingtolocalregulations.

9. Do not install the equipment in an explosive atmosphere: 22. Always check the obstruction detection system, and

the presence of inflammable gas or fumes is a serious safetydevicesforcorrectoperation.

dangertosafety. 23. Centurion Systems (Pty) Ltd does not accept any liability

10. Before attempting any work on the system, cut electrical caused by improper use of the product, or for use other

poweranddisconnectthebatteries. thanthatforwhichtheautomatedsystemwasintended.

11. Themainspower supplyofthe automatedsystemmust be 24. This product was designed and built strictly for the use

fittedwith an all-poleswitch with contactopening distance indicated in this documentation. Any other use, not

of 3mm or greater. Use of a 5A thermal breaker with all- expressly indicated here, could compromise the good

polecircuitbreakisrecommended. condition/operation of the product and/or be a source of

12. Make sure that an earth leakage circuit breaker with a danger.

thresholdof30mAisfittedupstreamofthesystem. 24. Everything not expressly specified in these instructions is

13. Never short circuit the battery and do not try to recharge notpermitted.

the batteries with power supply units other than that

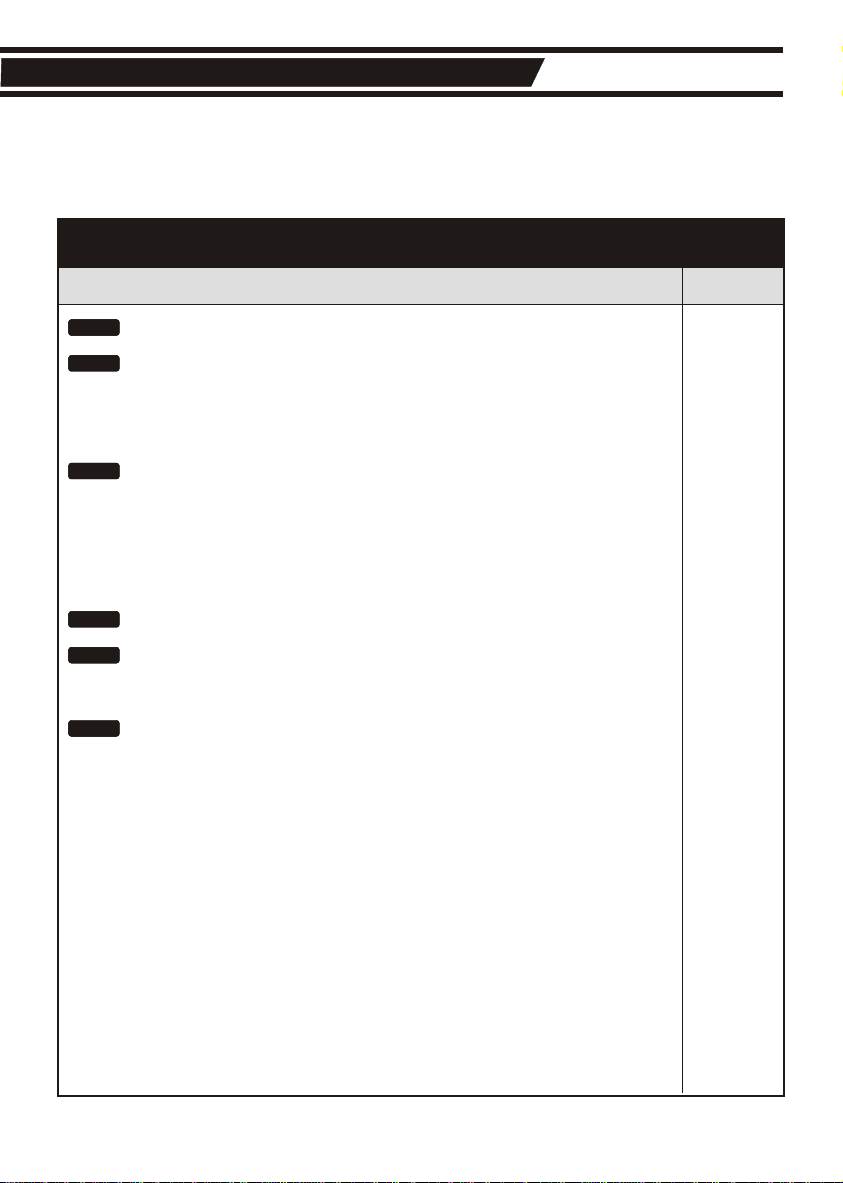

MOVING GATE CAN CAUSE

SERIOUS INJURY OR DEATH

KEEP CLEAR. GATE MAY MOVE AT

ANY TIME. DO NOT ALLOW

CHILDREN TO PLAY IN AREA OR

OPERATE GATE .

WARNING

Appliance should be product described in manual

*