Certified Power Freedom series User manual

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 1

FREEDOM2QuickStartGuide

DOCUMENTP/NSG07230026

REV:EDATE:08/28/14

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 2

InstallationGuidelines

Equipmentrequired.

Afterunpackingtheequipmentcheckeachitemagainstthepackinglist.Youshouldhavethefollowing

parts:

1. Freedom2spreadercontroller

2. Mountingbrackets

3. Wireharnessoradaptorifthisisaretrofit.

4. BasictoolstomounttheFreedom2controller.

MounttheFreedom2controller(bracketoption1)

1. Therearethreebracketkitsavailable.Alwaysusethemountinghardwaresuppliedinthekits.If

longerthanspecifiedscrewsareused,thescrewscouldtouchthecircuitboardcausingashortand

irreparabledamage.

U‐Bracketkitpart#SG07010468‐001(1)

Use¼‐20x3/8screwspart#HDW0001‐000062(3)

Use1/4in.externaltoothlock‐washerpart#HDW0003‐00027(4)

BesuretoinstallUSBcoverplatepart#SG07070557(2)

FastenUSBcoverplatewith6‐32x1/4inscrewpart#201020(5)

2. MounttheF2controllersoitdoesnotobstructthevisibilityofthevehicleoperator.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 3

RAM™Mounting(Bracketoption2)

1. Thisisthesecondofthreemountingkitsavailable.Alwaysusethemountinghardwaresuppliedin

thekits.Iflongerthanspecifiedscrewsareused,thescrewscouldtouchthecircuitboardcausinga

shortandirreparabledamage.

RAM™mountbracketkitpart#SG07010468‐003(1)

Use10‐32x7/16orshorterscrewspart#HDW0001‐000074(3)

Use#10externaltoothlock‐washerpart#HDW0003‐00001(2)

BesuretoinstallUSBcoverplatepart#SG07070557(5)

FastenUSBcoverplatewith6‐32x1/4inscrewpart#201020(4)

2. MounttheF2controllersoitdoesnotobstructthevisibilityofthevehicleoperator.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 4

FlushConsoleMounting(Bracketoption3)

1. Thisisthelastmountingoption.Ifyouarereplacingalegacyproductthatismountedinaconsole.

Alwaysusethepartsspecifiedinthekits.Ifthewronglengthscrewsareused,thescrewcouldturn

intothecircuitboardcausingashortandirreparabledamage.

Flushmountbracketkitpart#SG07010468‐002(1)

Use10‐32x3/8orshorterscrewspart#HDW0001‐000003(2)

Use#10externaltoothlock‐washerpart#HDW0003‐00001(3)

Use8‐32x1/2screwspart#73049tomountthebracketintotheconsole(4)

2. MounttheF2controllersoitdoesnotobstructthevisibilityofthevehicleoperator.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 5

InstallingthewireHarness

1. PicturedbelowisatypicalwireharnessusedontheF2Spreader.Therearevariationsofthisharness

suppliedbyCertifiedPower.ContactyourCertifiedPowerSalesRep.forhelpobtainingfull

documentationanddrawingsoryourSystemOwner’smanual.

2. AttachRedB+wiretoa8‐16Vcircuit.

Useaswitchedorcontinuous10ampprotectedcircuit.

Closed‐loopsystems(feederorliquid)mustuseaswitched10ampcircuit.

Use16AWGwirewhenadditionalwireisneeded.

3. Attachthe(2)Groundwiresdirecttochassisgroundordirecttobatterypost.

Chassisgroundsmustbemadetobarecleanmetal.

4. Disconnectbatterysupplyandgroundbeforeweldingonthevehicle.

5. AttachtheMPHwiretothevehiclesMPHsignalsource.Checkwiththevehiclemanufacturerbefore

splicingintoanywiretoavoiddamagingthevehicleelectronics.

6. Attachanyremoteinputsthatarerequired.Thestandardinputsarelistedbelow.

Input1WT/BK,REMOTEPAUSE

Input3WT,REMOTEBLAST

7. AttachAux.outwireifrequired.Thiswireprovidesa+Bat200mA.Source.

IftheAux.wireisNOTused.Tieupandinsulatethewirefromchassisground.

Typicallythiswireisusedtocontrolarelayorlampindicator.

8. Attachanyexternalwiringandcablesusingtheprovidedinstallationdrawing.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 6

TypicalSystemOV

1. Picturedbelowisagenericsystemoverview.Usethisasabasicillustrativeguidetoinstallthe

appropriateharnessingontothevehiclechassis.

Yourharnessingmayvaryfromthepicture.

DonotusedielectricgreaseonM12connectors

Allharnessingshouldbetiedupsecurelyandawayfrommovingparts.

Avoidroutingharnessingnearareasofexcessiveheatsuchasengineexhaustpipe.

Minimumbenddiameterbehindamoldedconnectorshouldbe>3inches.

LIQUID

TANK

LIQUID

FLOAT

SWITCH

1

2

#2

#1

LIQUID

PUMP

F2 HARNESS

SPINNER(A)

LIQUID

FEEDER(B)

FLOW-METER

MPH INPUT

WT/BL

VALVE

FEEDER

MOTOR

FEEDER

SENSOR

10A

10

20

30 40 50 60

70

200

MPH

FEEDER/SPINNER VALVE

LIQUID VALVE

LIQUID FLOW-METER

FEEDER SENSOR/LIQUID FLOAT

GROUND

BK

GROUND

BK

BAT+

RD

DETENT

SWITCH

INPUT 1

WT/BK

PAUSE

NOTE:

IF LIQUID FLOAT SWITCH

IS USED WITHOUT

FEEDER SENSOR, IT STILL

MUST BE CONNECTED TO

SPLITTER PORT #2. IF

LIQUID FLOAT SWITCH IS

NOT USED, THE SPLITTER

MAY BE REPLACED WITH

A MALE-FEMALE

EXTENSION TO THE

FEEDER SENSOR.

NOTE:

REFERENCE

ENCLOSED DRAWING

FOR OPTIONAL

PROPORTIONAL

ELECTRIC PREWET

OPTION

POWER

RELAY

MOMENTARY

SWITCH

WT

INPUT 3

BLAST

AUX. OUT (+12V.) 200mA.

BL/VT

INSULATE

WIRE END

IF NOT

USED.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 7

SystemOptions

Closed‐loopsystems(feederorliquid)musthaveamainpowerdisconnect.Picturedbelowisa

typicaldiagramforignitionswitchedpower.

Electricproportionalliquidpumpswilltypicallyrequireahighcurrentrelayassemblyandwiringas

shownbelow.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 8

Atypicalanti‐iceonlywiringdiagramispicturedbelow.

MPH INPUT

WT/BL

FLOW-METER

10A

10

20

30 40 50 60

70

200

MPH

BALL VALVE

LIQUID VALVE

LIQUID FLOW-METER

LIQUID FLOAT

GROUND BK

GROUND BK

BAT+ RD

F2 ANTI-ICE

HARNESS

LIQUID

TANK

LIQUID

FLOAT

SWITCH

DETENT

SWITCH

INPUT1WT/BK

PAUSE

POWER

RELAY

BALL

VALVE

LIQUID

VALVE

P/NSG07010479 OptionalextensionP/NSG07051136 P/NSG07051115

Laneswitchesboxandharnessing.

*Ratechangerequiredbyoperatortomaintaingallonsperlanemileoutput.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 9

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 10

StandardHarnesslist

PART#DESC.LENGTH

SG0705069618AWGTPEMALEM12TOFLYLEAD3M

SG0705073218AWG.TPEMALEM12TOFLYLEAD10M

PART#DESC.LENGTH

SG0705063918AWG.TPESPLITTERM12TOFLYLEAD5.2M

PART#DESC.LENGTH

SG0705099718AWG.TPEMALETOFEMALE.3M

SG07050731‐00118AWG.TPEMALETOFEMALE1M

SG0705068418AWG.TPEMALETOFEMALE3M

SG07050731‐00218AWG.TPEMALETOFEMALE5M

SG0705048518AWG.TPEMALETOFEMALE7M

PART#DESC.LENGTH

SG0707005218AWG.TPEMALESTTOFEMALE90LED2.5M

PART#DESC.LENGTH

SG0705050918AWG.TPEMALETOFEMALESTLED2M

SG0705041118AWG.TPEMALETOFEMALESTLED3.7M

SG0705054618AWG.TPEMALETOFEMALESTLED7M

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 11

PART#DESC.LENGTH

SG0705063818AWG.TPEMALETO2XFEMALE6.4M

1

2

#2

#1

PART#DESC.LENGTH

SG0705048818AWG.TPEMALETOFEMALEBPMW/CAP1M

SG0705050318AWG.TPEMALETOFEMALEBPM.3M(12in.)

SG07050722‐00218AWG.TPEMALETOFEMALEBPMW/CAP5M

SG07050722‐00318AWG.TPEMALETOFEMALEBPMW/CAP7M

SG07050722‐00118AWG.TPEMALETOFEMALEBPMW/CAP10M

PART#DESC.LENGTH

SG07070374MALETOFEMALETHREADEDBULKHEADN/A

PART#DESC.LENGTH

SG07070121PLASTICHORZ.FLOATSWITCH.6MMALETPE.6M

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 12

PART#DESC.LENGTH

SG0705064322AWG.DINCORDSETDUAL.6M

SG0705030222AWG.DINCORDESTSINGLE.6M

SG0705064422AWG.AMPJR.TIMERDUAL.6M

SG0705041422AWG.AMPJR.TIMERSINGLE.6M

SG0705035522AWG.WEATHER‐PAKDUAL.6M

SG0705030622AWG.WEATHER‐PAKSINGLE.6M

SG0705043222AWG.FLYLEADDUAL.6M

SG0707004822AWG.FLYLEADSINGLE.6M

FULL-DIN AMP JR TIMER WEATHER-PAK FLYLEAD

..643 ..302 ..644 ..414 ..355 ..306 ..432 ..048

PART#DESC.LENGTH

SG07050294ANTI‐ICEBALLVALVEHARNESS1.8M

PART#DESC.LENGTH

SG07050808ANTI‐ICEFLOWMETERHARNESS2.5M

Anti‐iceswitchboxandharnessingrefertopage8.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 13

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 14

BasicControloperation

2. ThebasicUserControlsaredefinedbelow.

Gainingaccesstothemainmenu

1. Withthevehiclesafelyinpark,holdthe“mode/menu”buttonin.

TheMainmenushouldappearafterholdingthemenubuttonfor3seconds.

Touchthescreenover“Userlevel”.

Usingthedropdownselect“Technician”or“Admin”

ThePasswordfieldisleftblankfromthefactoryforTechnician.

ThePasswordfieldfor“Admin”is“admin”.

Touchthepasswordfieldtoenterapasswordifloggingin“Admin”.

Touch‘OK’tologinTechorAdminafterenteringthePassword.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 15

UsingF.I.R.S.TtoperformsystemsetupandCalibration.

1. “FIRST”isainteractiveSetupguideintendedtohelptheUsersetupandcalibratetheF2controller

foruse.

YoumustbeloggedinastechnicianorAdmintouseF.I.R.S.T.

Touchthescreenoverthe“F.I.R.S.T.Guide”button

2. Usethe“FIRST”GuidetocompletesetupandcalibrationoftheF2control.

Assetupstepsarecompletedcheckmarkswillappearforeachsection.

THISDRAWINGISCOPYRIGHTEDAND

ISTHEPROPERTYOFCERTIFIEDPOWERINC. 16

BasicDiagnostics/troubleshooting(commonerrorsandtheirmeanings)

1. ErrorsseenwhileSavingTrims

“SettingnotSaved,MinexceedsMax”,Thisisacommonmessageseenwhilesavingtrims.

Usuallyoccursifsavingaminimumtrimpercentthatisoverthemaximumtrimpercent.Try

settingmaxtrimfirstthensetminimumtrimlast.Theerroralsoappearsifnofeedbackisbeing

receivedfromtheclosed‐loopsensorwhenaSaveisapplied.

“SettingnotSaved,Valveopen”,ThiserrormessageappearswhenSavingtrimsandtheF2

cannotdetectcurrentflowingthroughtheHydraulicvalveelectricalcircuit.Suspectaconnector

orbrokenwirebetweentheF2controlandValvecoilconnectiononthehydraulicvalve.

2. Errorsseenwhilecalibratingground‐speedMPH(SpeedCal)

“GroundSpeedError”,ThiserrorappearsiftryingtoSavea“SpeedCal”andnothavingany

groundspeedsignalpresentattheMPHGroundSpeedinput.Tryadifferent“SpeedType”and

watchforthe“PulsesPerminute”valuetoreflectafrequencyindicatingagoodgroundspeed

signalattheinput.

3. Commonon‐screenoperatingerrors.

“SensorPowerError”,Ifthesensorpowersupplylineisshortedtogroundorhasmorethan

750mA.ofcurrentdrawthesensorpowersupplyfromtheF2isbeingoverloaded.Suspecta

faultyFeedersensororLiquidFlow‐metersensor.Alsosuspectapinchedorcrushedwire,

corrodedconnectororanyfaultthatmaycauseashorttochassisground.

“FeederRatelimited”,IftheFeederisrunningatmaxspeedandthecurrenttargetapplication

rateisNOTbeingmet,thiserrorwilldisplay.Sometimesthiserrorwouldbeindicativeofa

systemthathasnotbeencalibratedorhasbeencalibratedimproperly.Thiserroralsoappliesto

Liquid,andtheSpinner.Thiserrorclearsitselfwhenthetargetrateisbeingmet.

“FeederRateOverrun”,IftheFeederisrunningatitslowestspeedandthecurrenttarget

applicationrateisNOTbeingmet,thiserrorwilldisplay.Sometimesthiserrorwouldbe

indicativeofasystemthathasnotbeencalibratedorhasbeencalibratedimproperly.Thiserror

alsoappliestoLiquid,andtheSpinner.Usuallythiserrorwillonlydisplayatverylowsustained

vehiclespeedsofusually5mphorlessandlowtargetrates.Thiserrorclearsitselfwhenthe

targetrateisbeingmet.

“Sensorfault”and“FeederOverride,ThiserroroccurswhentheF2wasoperatinginclosed‐loop

modeandwasnotreceivingsensorfeedback.TheF2automaticallydefaultsintoopen‐loopafter

thiserroroccurs.Suspectastalledmotororconveyor,dragchainordryorstalledliquidpump.

Thiserroroccursforanyclosed‐loopfunction.Theerrorconditionisclearedwithapowercycle.

Other manuals for Freedom series

1

This manual suits for next models

1

Popular Controllers manuals by other brands

BECS

BECS BECSys5 Operation and maintenance manual

Iron logic

Iron logic Z-5R NET user manual

Heath Zenith

Heath Zenith Lighting Controls 598-1306-02 owner's manual

Welbilt

Welbilt Frymaster YUM K3000 Operation manual

Aqua Medic

Aqua Medic Qube control Operation manual

Alphawave Photonics

Alphawave Photonics AWCL-300-6P Series user manual

Krom Schroder

Krom Schroder GDJ 15 operating instructions

Ebmpapst

Ebmpapst RM-ECv Operating and maintenance instructions

Corsair

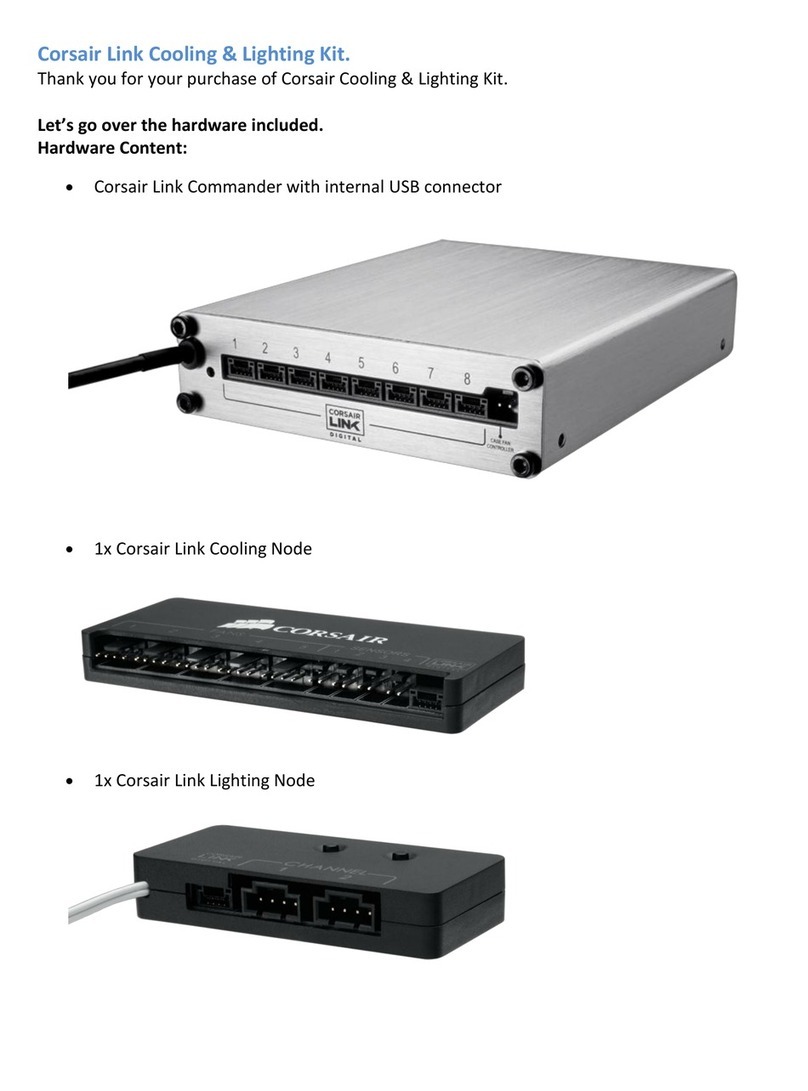

Corsair Link Hardware installation guide

TracoPower

TracoPower TSP-BCM24 operating instructions

Delta

Delta DZNT-104T installation guide

Aqua Medic

Aqua Medic Ocean Light LED Operation manual