。

I

﹛﹜

﹛J

I

﹛

﹛﹜

﹛﹜

I

﹛

I

﹛﹜

司月司

﹛

﹛

I

﹛﹜

﹛﹜

附

﹛

:’ 州

:

﹛

。

臼

間,

:

﹛﹜

﹛﹜

:

﹜

:

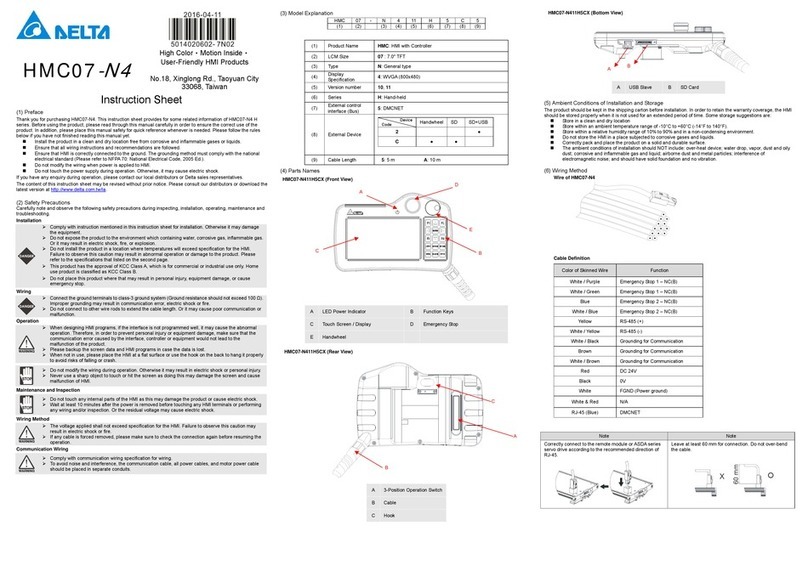

*We reserve the

ight to change the information in this manual without prior notice.

Delta MP句 Series

User Manual (15-inch)

。

DELTA_IA-PAC_MP1 15_UM_EN_20190902

Delta MP1 Series User Manual (15-inch)

■■ ■

■