Ceiec Electric Technology

5

Table of Contents

Chapter 1 Introduction ............................................................................................................................7

1.1 Overview ....................................................................................................................................7

1.2 Features......................................................................................................................................7

1.3 PMC-53 series’ application in Power and Energy Management Systems...................................9

1.4 Getting more information ........................................................................................................10

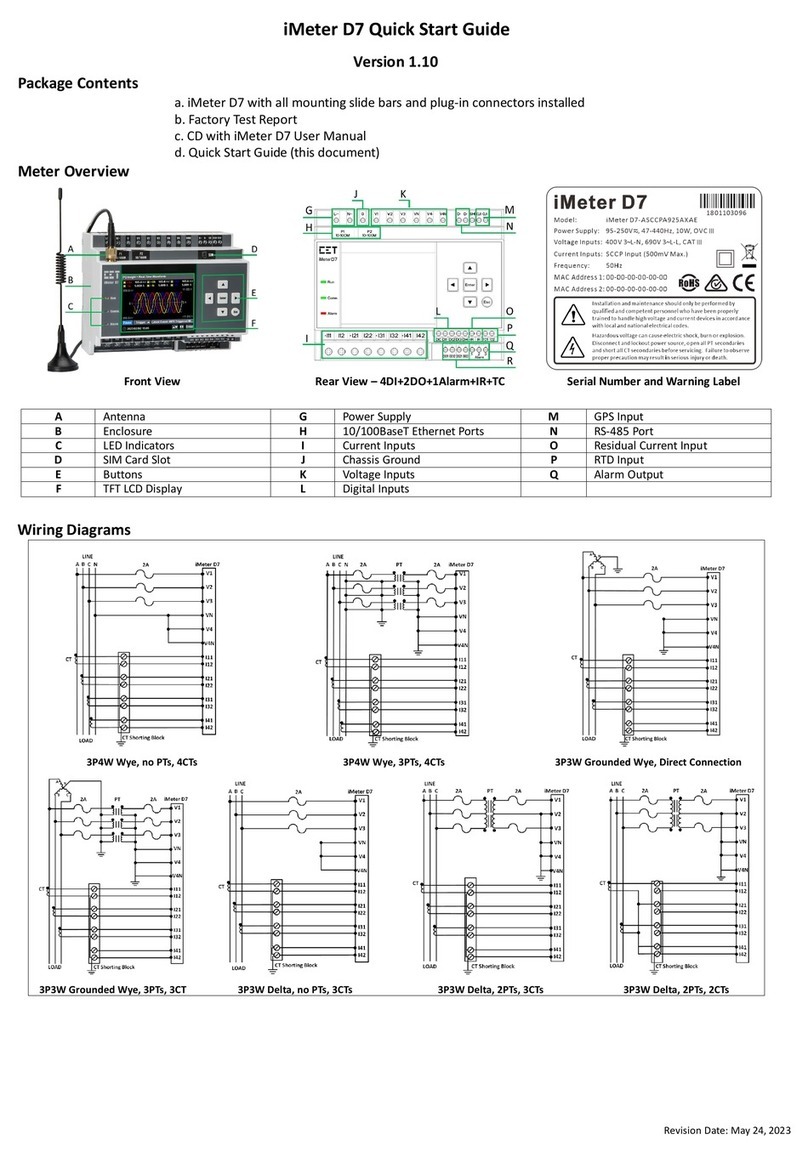

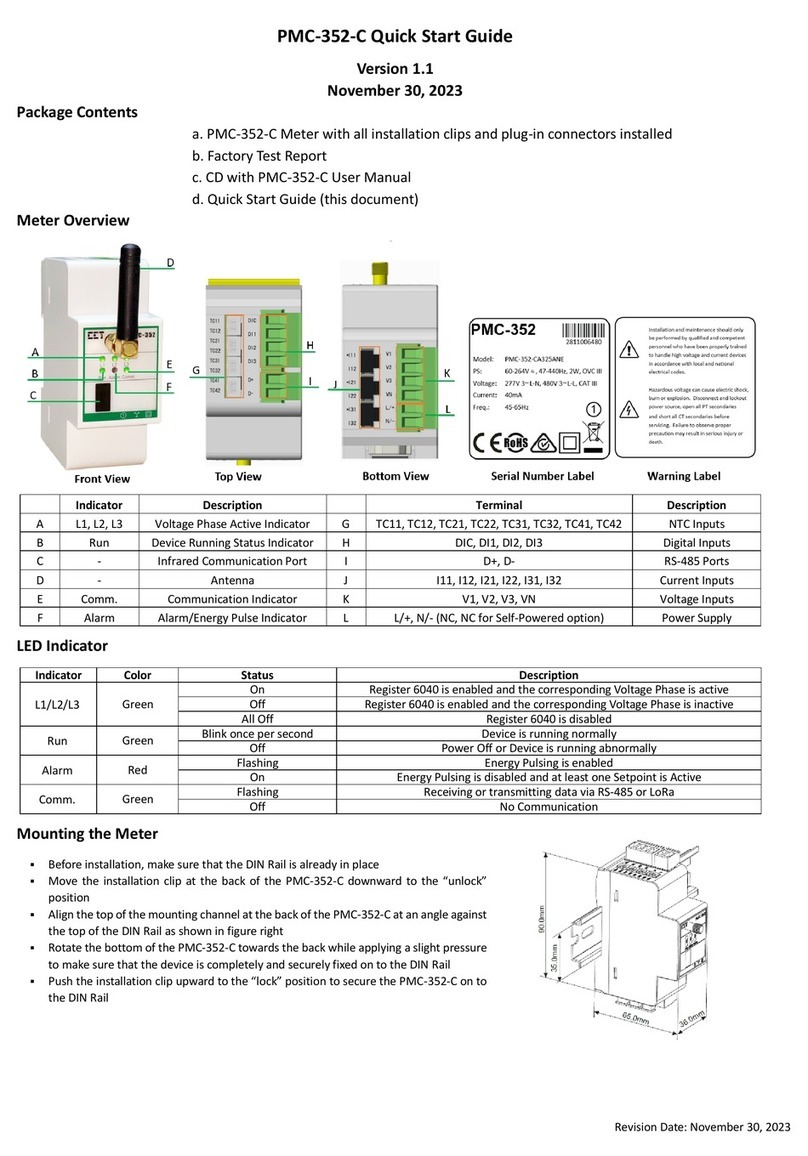

Chapter 2 Installation ............................................................................................................................11

2.1 Appearance ..............................................................................................................................11

2.2 Unit Dimensions .......................................................................................................................12

2.3 Mounting..................................................................................................................................12

2.4 Wiring connections ..................................................................................................................13

2.4.1 3-phase 4-wire Wye Direct Connection ........................................................................13

2.4.2 3-phase 4-wire Wye with 3PTs and 3CTs.......................................................................14

2.4.3 3-phase 3-wire Open Delta Direct Connection .............................................................14

2.4.4 3-phase 3-wire Open Delta with 2PTs and 3CTs............................................................15

2.4.5 3-phase 3-wire Open Delta with 2PTs and 2CTs............................................................15

2.5 Communications Wiring...........................................................................................................16

2.6 Digital Input Wiring ..................................................................................................................16

2.7 Digital Output Wiring ...............................................................................................................16

2.8 Pulse Output Wiring.................................................................................................................17

2.9 I residual Input Wiring..............................................................................................................17

2.10 Temperature Input Wiring......................................................................................................17

2.11 Power Supply Wiring..............................................................................................................17

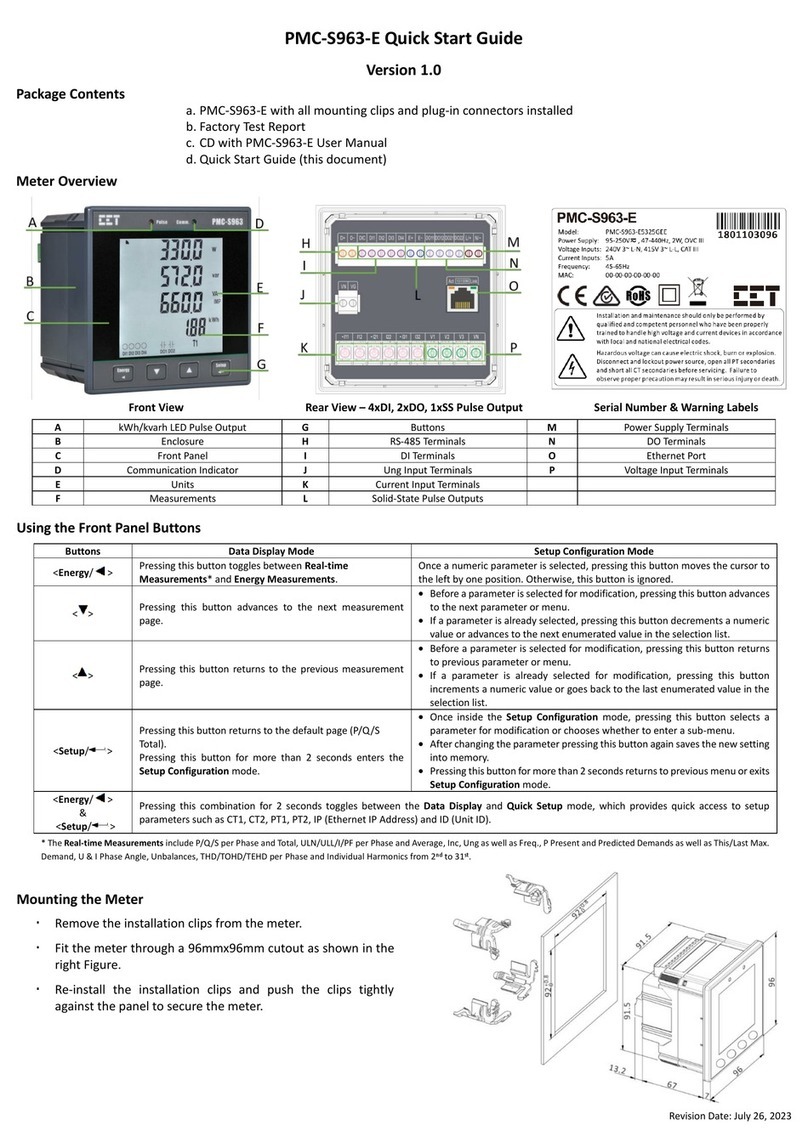

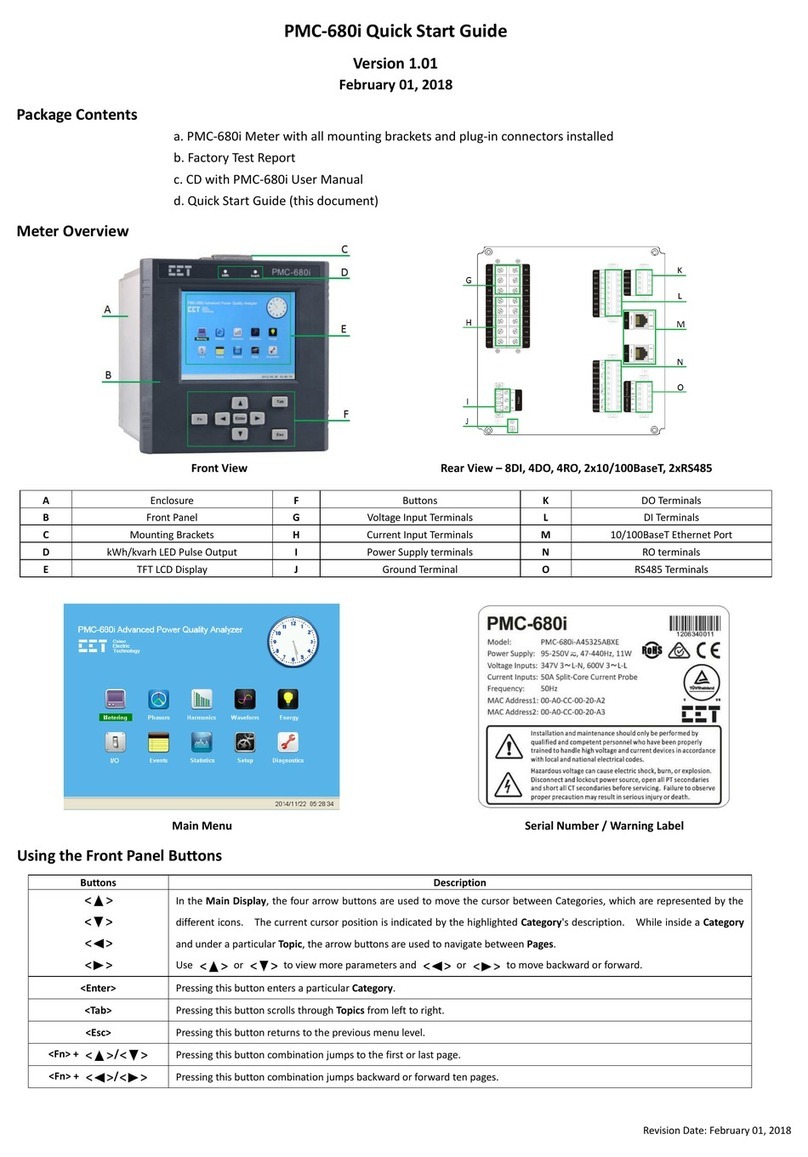

Chapter 3 Front Panel ............................................................................................................................18

3.1 LCD Display...............................................................................................................................18

3.1.1 LCD Testing....................................................................................................................18

3.1.2 LCD Display Areas..........................................................................................................18

3.1.3 Peak Demand Display....................................................................................................20

3.2 LED Indicators...........................................................................................................................20

3.3 Display Screen Types ................................................................................................................20

3.3.1 Default Screen...............................................................................................................21

3.3.2 Data Display ..................................................................................................................21

3.4 Setup Configuration via the Front Panel ..................................................................................22

3.4.1 Functions of buttons .....................................................................................................22

3.4.2 Reset the Alarm LED and Buzzer ...................................................................................23

3.4.3 Setup Menu ..................................................................................................................24

3.4.4 Configuration ................................................................................................................25

Chapter 4 Applications ..........................................................................................................................30

4.1 Inputs and Outputs...................................................................................................................30

4.1.1 Digital Inputs .................................................................................................................30

4.1.2 Digital Outputs ..............................................................................................................30

4.1.3 Energy Pulse Outputs....................................................................................................31

4.1.4 I residual Input ..............................................................................................................31