CET Electric Technology

5

Table of Contents

Chapter 1 Introduction ............................................................................................................................. 7

1.1 Overview ....................................................................................................................................7

1.2 Features......................................................................................................................................7

1.3 Getting more information ..........................................................................................................8

Chapter 2 Installation ............................................................................................................................... 9

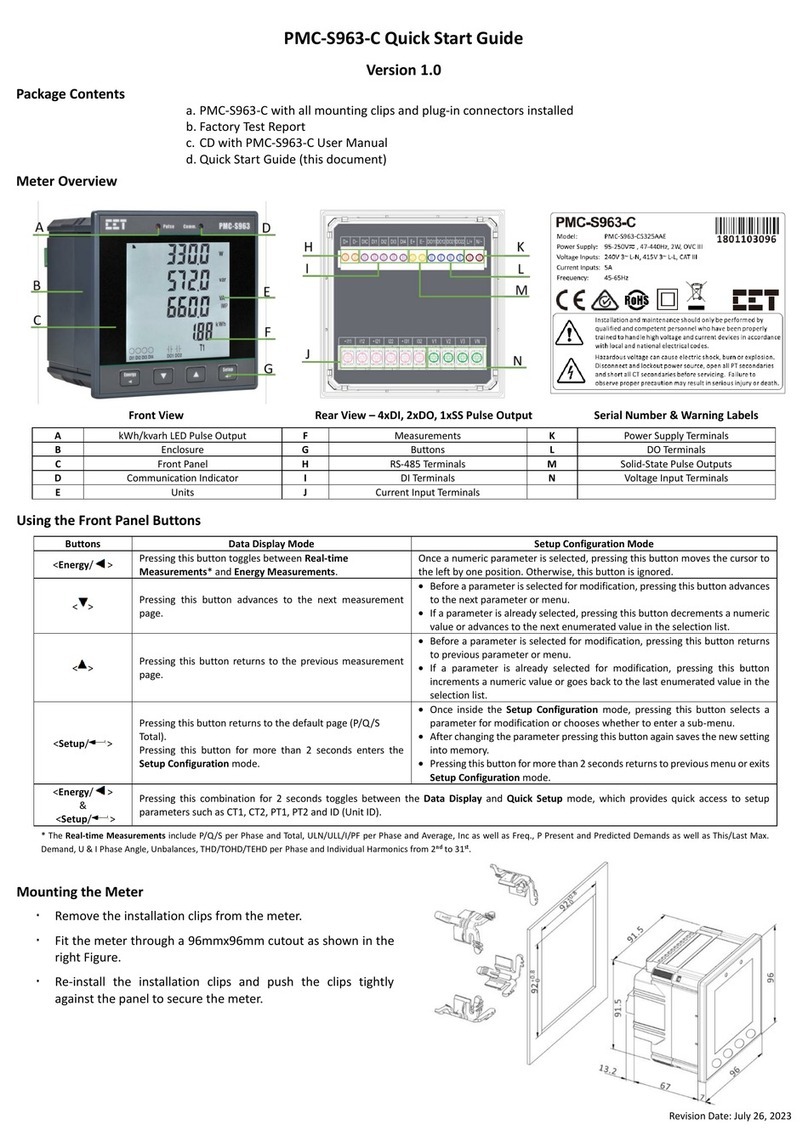

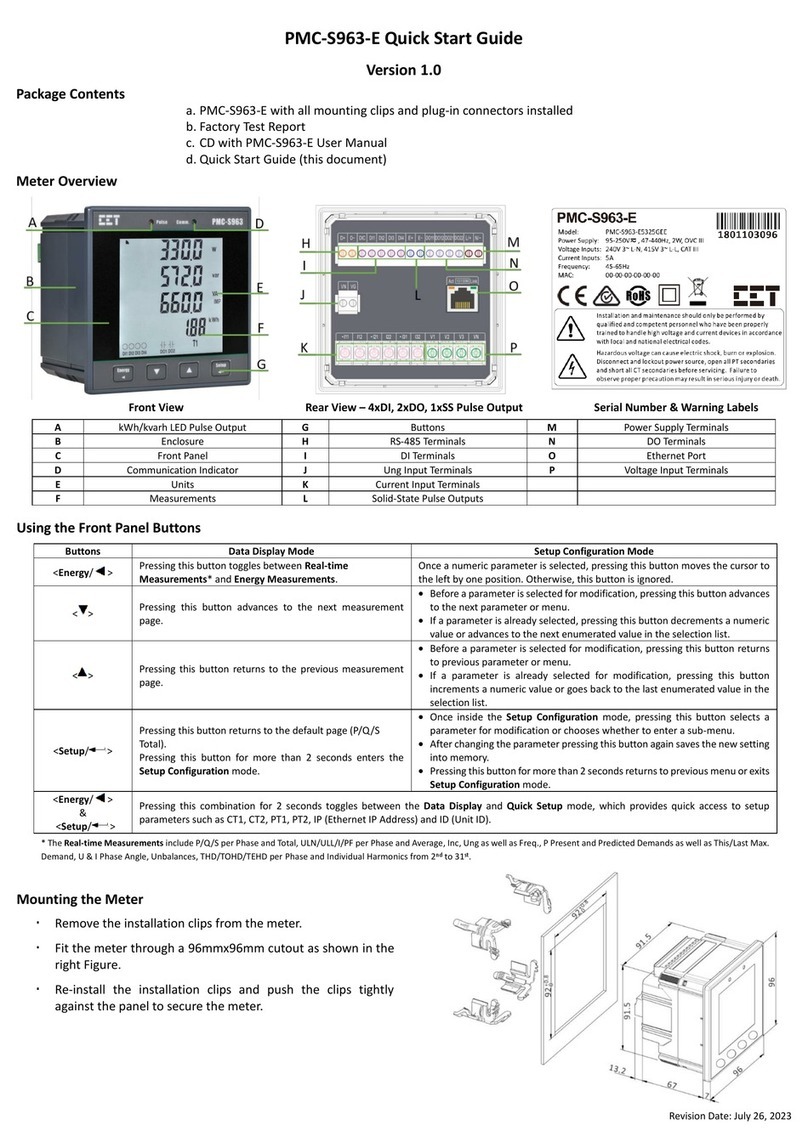

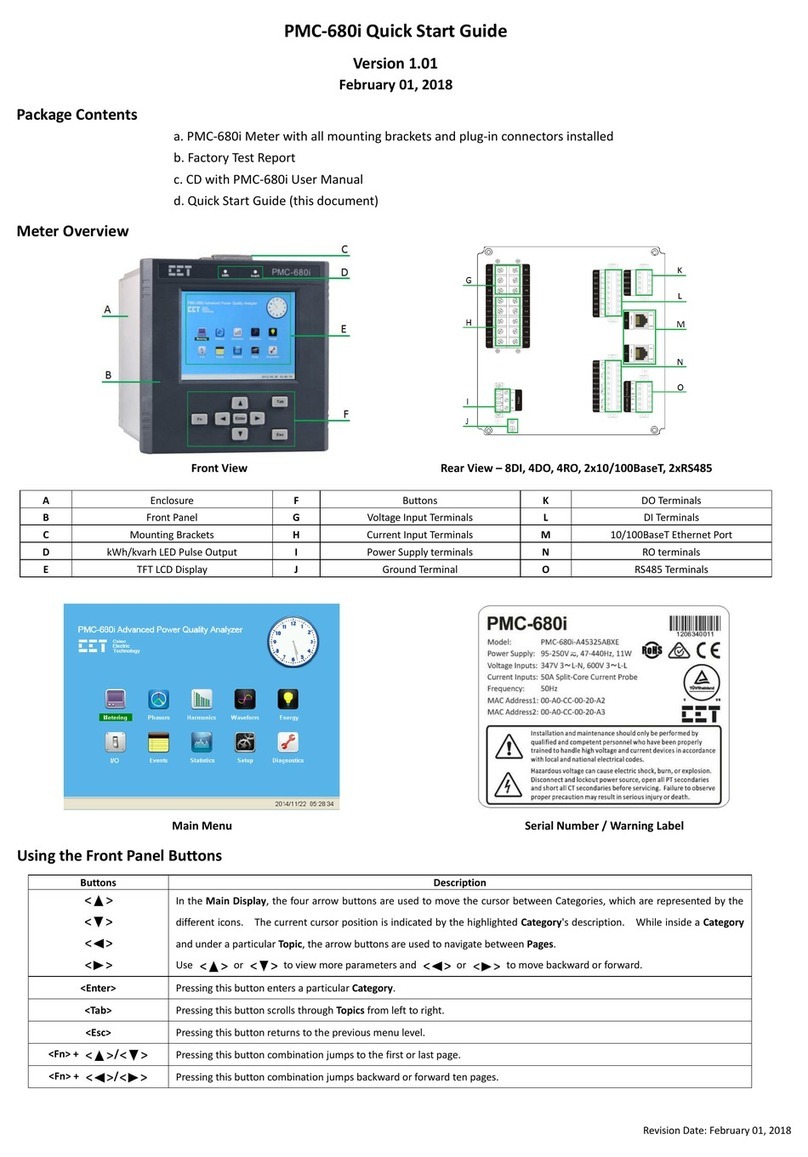

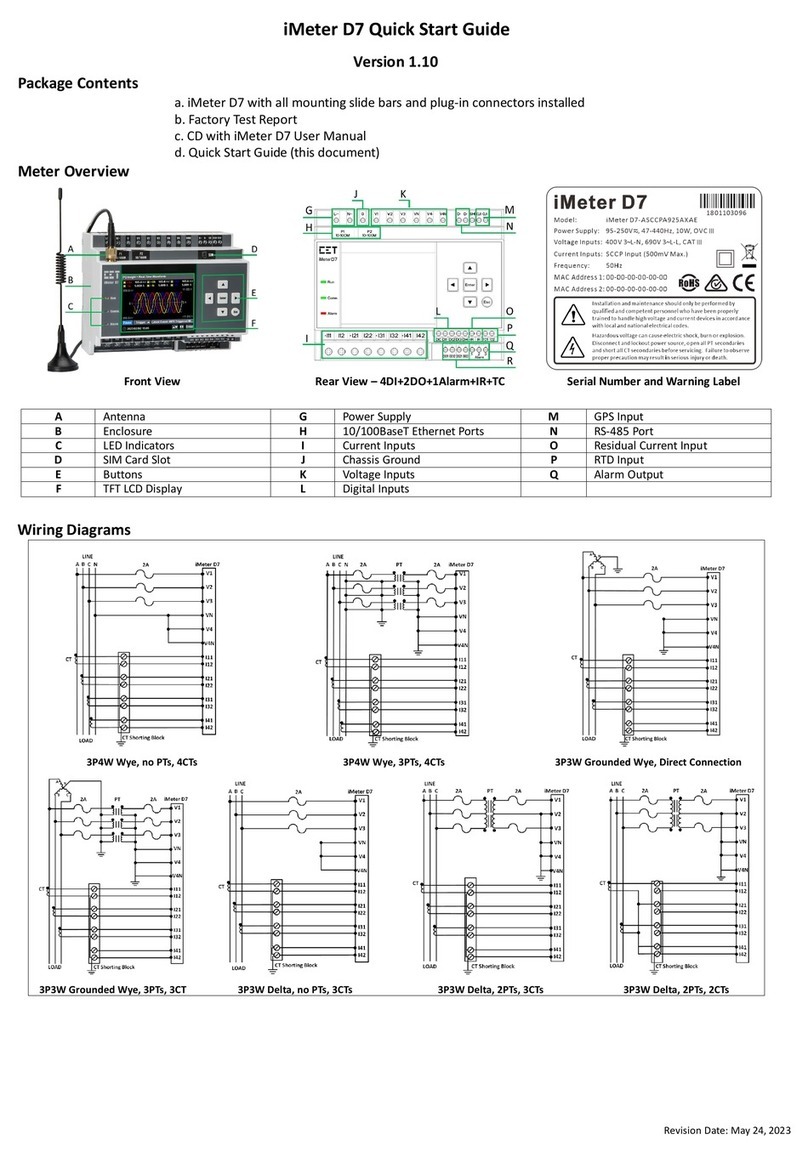

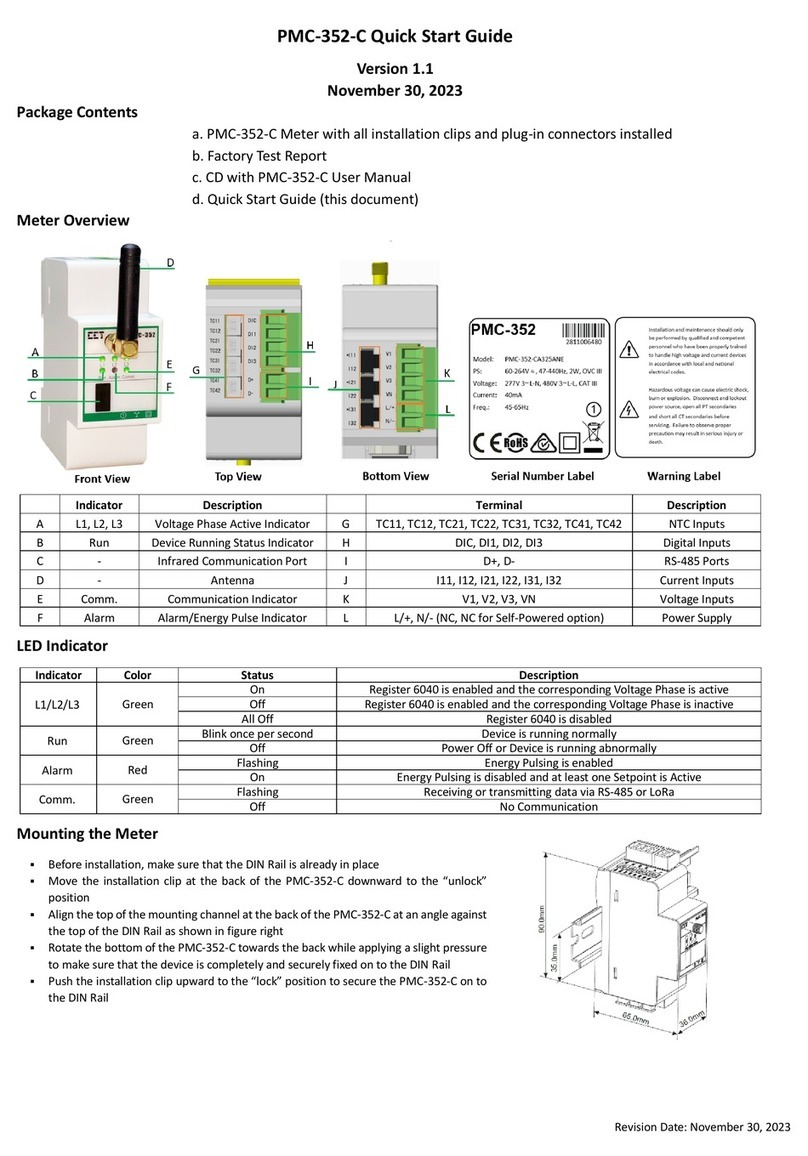

2.1 Appearance ................................................................................................................................9

2.2 Unit Dimensions .......................................................................................................................10

2.3 Mounting..................................................................................................................................10

2.4 Input Wiring .............................................................................................................................11

2.5 Communications Wiring ...........................................................................................................11

2.6 Digital Input Wiring ..................................................................................................................11

2.7 Pulse Output Wiring .................................................................................................................12

2.8 Power Supply Wiring ................................................................................................................12

Chapter 3 Front Panel............................................................................................................................. 13

3.1 Display ......................................................................................................................................13

3.1.1 LCD Testing....................................................................................................................13

3.1.2 LCD Display Areas..........................................................................................................13

3.2 Using the Front Panel Buttons..................................................................................................15

3.3 LED Pulse Outputs ....................................................................................................................15

3.4 Display Screen Types ................................................................................................................15

3.5 Setup Configuration via the Front Panel ..................................................................................15

3.5.1 Making Setup Changes..................................................................................................16

3.5.2 Setup Menu ..................................................................................................................16

3.5.3 Configuration ................................................................................................................17

Chapter 4 Applications ........................................................................................................................... 18

4.1 Digital Inputs ............................................................................................................................18

4.2 Pulse Outputs ...........................................................................................................................18

4.3 Basic Measurement..................................................................................................................18

4.4 SOE ...........................................................................................................................................18

Chapter 5 Modbus Register Map............................................................................................................ 19

5.1 Basic Measurements ................................................................................................................19

5.2 SOE Log.....................................................................................................................................19

5.3 Device Setup.............................................................................................................................21

5.3.1 Basic Setup Parameters.................................................................................................21

5.3.2 I/O Setup Parameters....................................................................................................21

5.3.3 Energy Pulse Setup Parameter......................................................................................21

5.3.4 Communication Setup Parameters ...............................................................................21

5.4 Time..........................................................................................................................................21

5.5 Clear Control ............................................................................................................................22

5.6 Meter Information....................................................................................................................22

Appendix A Technical Specifications....................................................................................................... 24