9

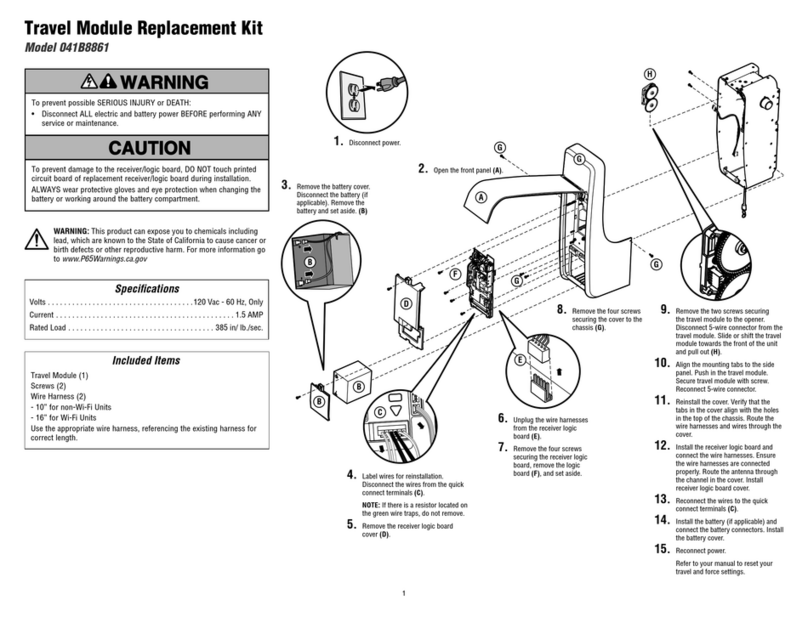

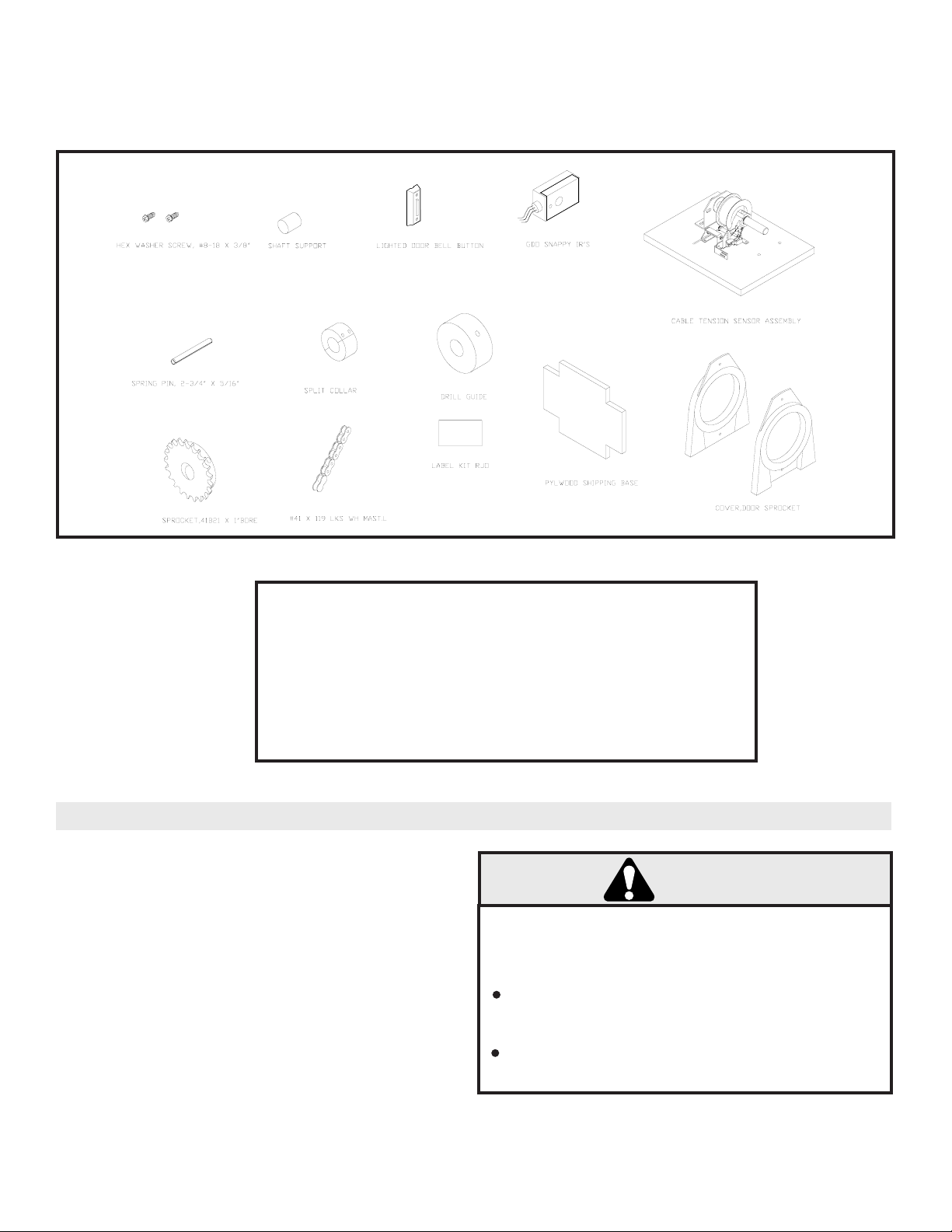

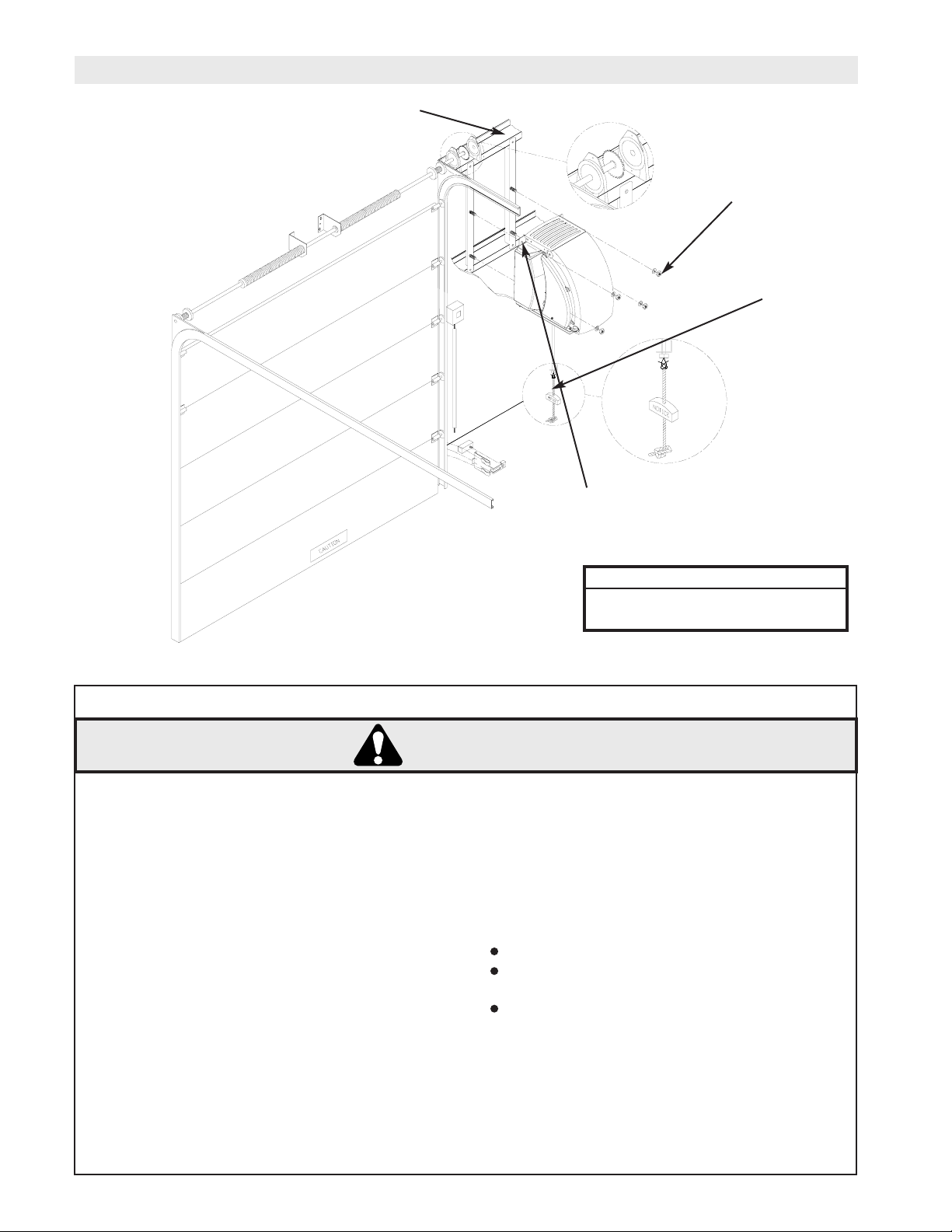

CABLE TENSION SENSOR ASSEMBLY AND INSTALLATION INSTRUCTIONS

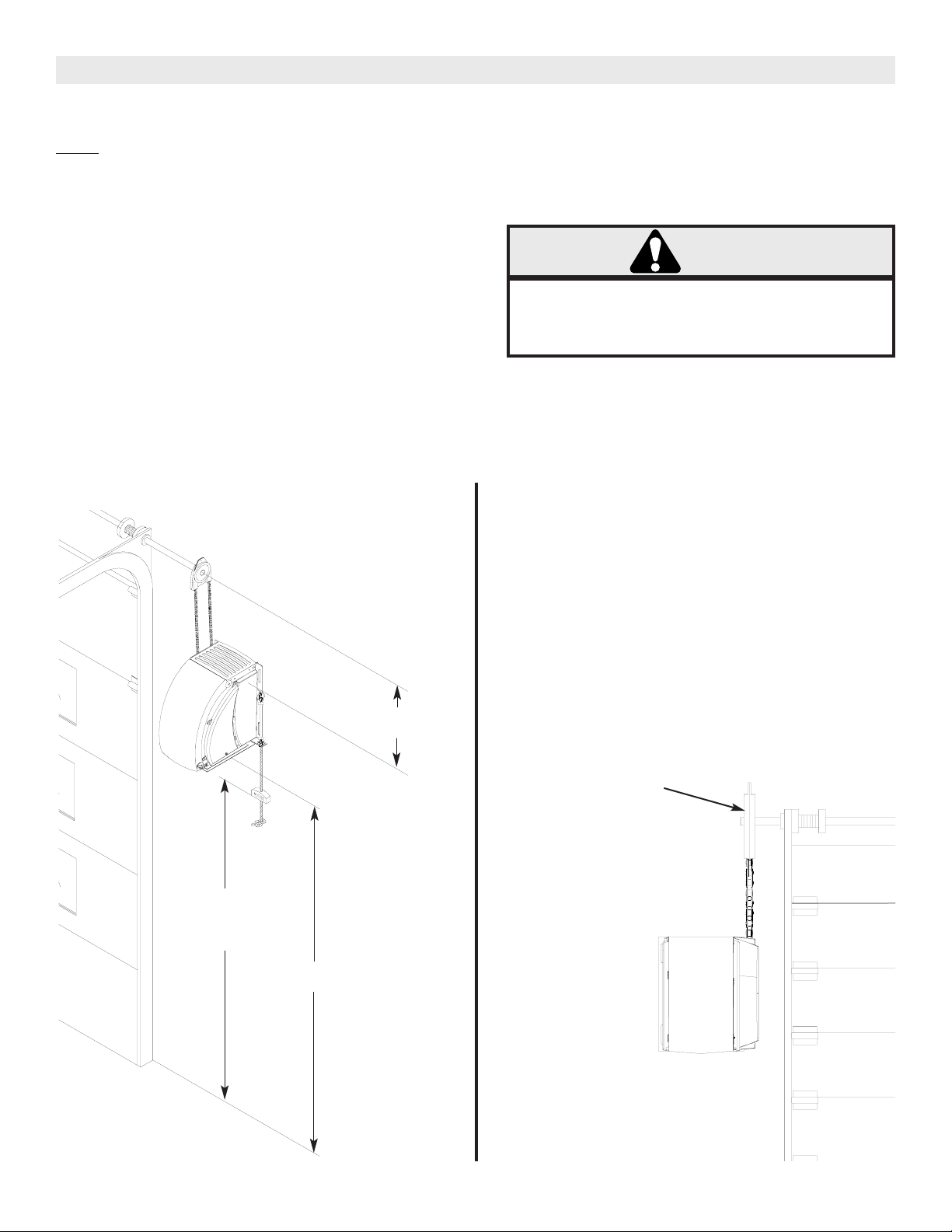

NOTE: Left hand assembly shown, for right hand assembly,

orientation will be opposite.

1. Introduce cable slack on the side of the door where the

CTS will be installed (Left side of door from inside of garage

looking out for left hand unit and right side of door for right

hand unit).

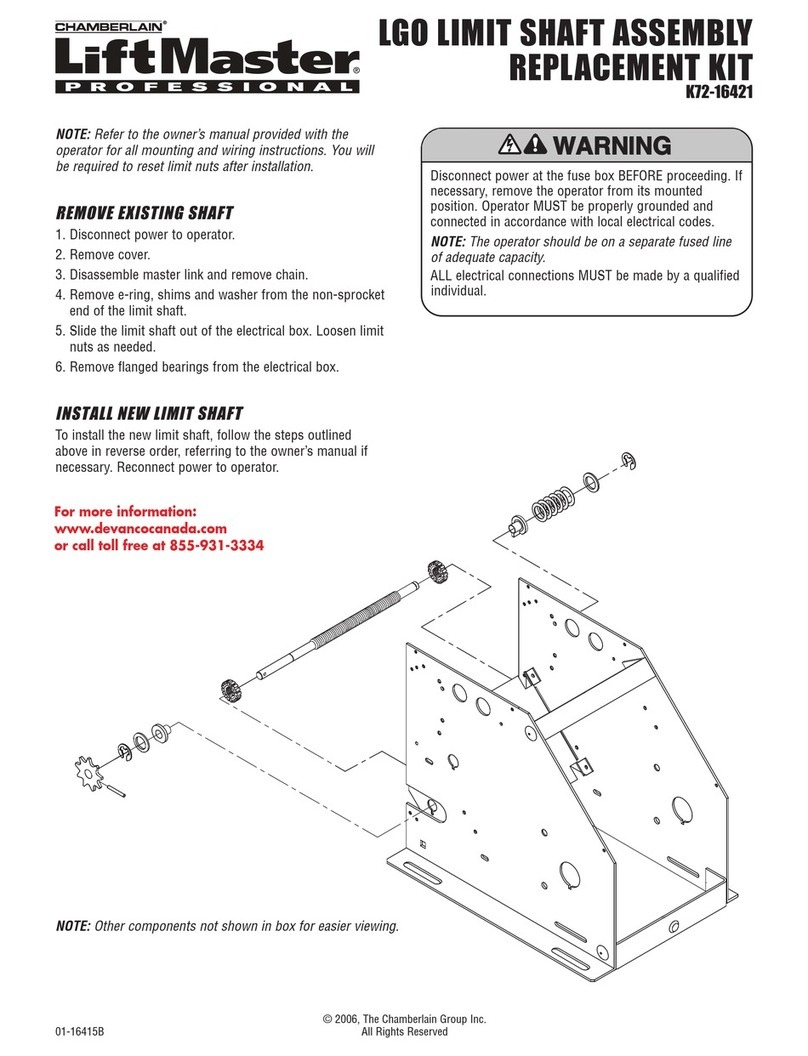

2. Use a 5/32” alan wrench to remove the socket head cap

screw from the pivot arm assembly. Place the pivot arm

assembly around the torsion shaft as shown, reinstall the

socket head cap screw and tighten.

3. Slide the pivot arm towards the cable drum and feed the

door cable over the front side of the pivot arm roller. Place

the assembly against the side of the drum.

4. Use a 3/16” alan wrench to remove the socket head cap

screws from the split shaft collar. Place the collar

around the torsion shaft and reinstall screws. Do not tighten.

5. Slide the collar towards the pivot arm and touch the side of

the pivot arm lightly. Tighten the screws in the collar.

NOTE: Make sure that the pivot arm is free to rotate after

the collar is tightened. The collar must hold the pivot

arm as close as possible to the cable drum, however, not

so tightly that the arm is not free to rotate on the torsion

shaft.

6. Place the CTS assembly into position. Make sure

that the roll pin on the pivot arm extends through the angled

slot on the CTS. Rotate pivot arm down towards header side

of the angled slot. With the roller on the CTS over the front

side of the door cable and the assembly in position, mark the

location of the 5 CTS assembly mounting holes and then

remove the assembly.

NOTE: Measure the distance from the center of the torsion

shaft to the header where the CTS will be mounted. The

optimum distance is 2-3/4”. If your measurement is

more than the 2-3/4” the CTS must have a backer

installed to make up the difference.

EXAMPLE: If you measure 2-7/8” you will need a 1/8” thick

backer. If you measure 3” you will need to install a 1/4”

thick backer, etc. Repeat step 6 if a backer was installed.

7. Drill pilot holes for the 5 CTS lag bolt mounting screws.

To prevent possible SERIOUS INJURY OR DEATH,

SECURELY mount the operator for proper operation

of the Cable Tension Sensor Assembly.

WARNING

8. Reinstall the CTS and attach to the header using the 1/4” x

1” lag screw provided.

NOTE: If it is necessary to use longer screws, due to

backer or other conditions, to securely fasten the

assembly, obtain them at local hardware store. 1/4”is

the required size.

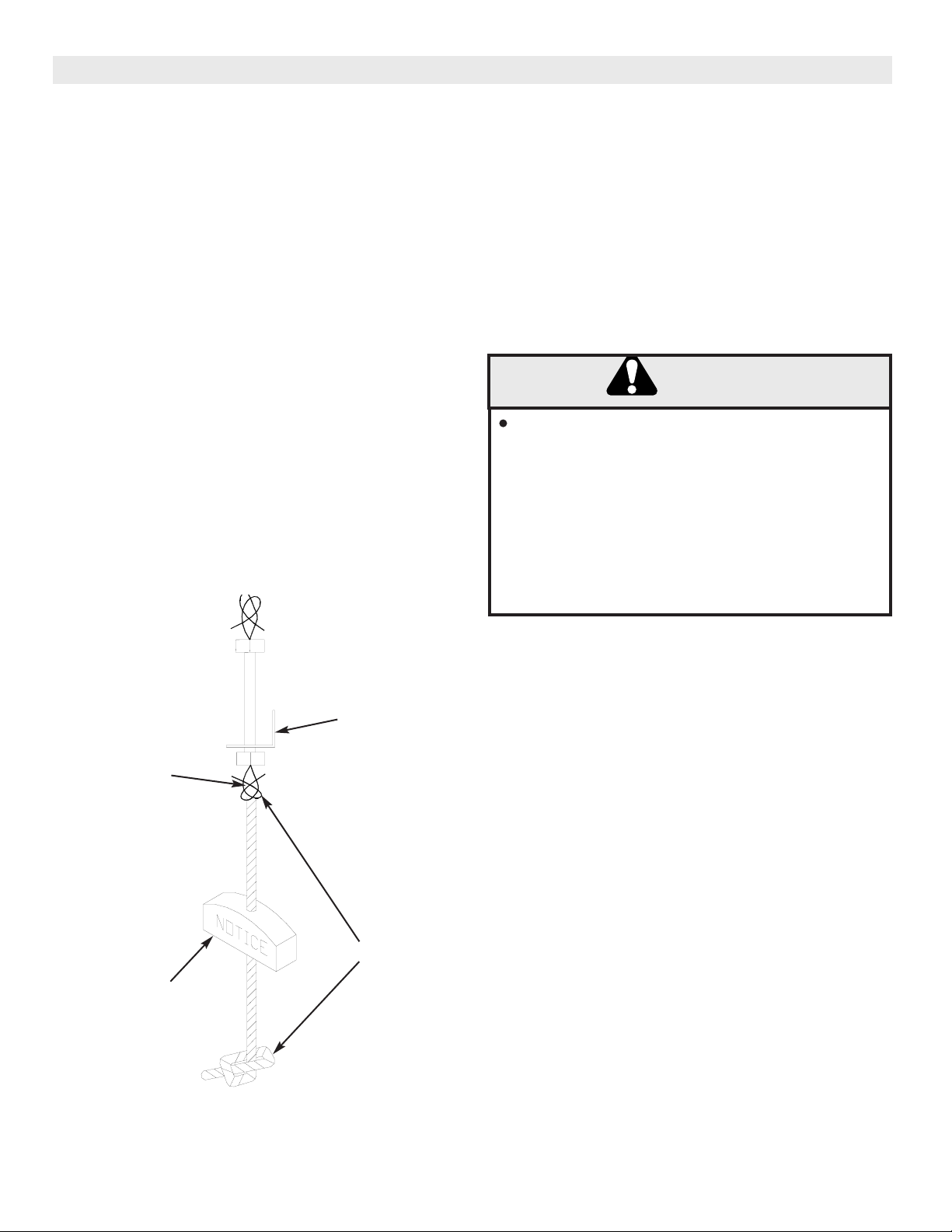

9. Rotate the pivot arm out away from the header. Maintain the

pivot arm in this position. Rotate the torsion spring counter

clockwise and place the end of the spring beneath the pivot

arm roll pin.

NOTE: Make sure that the other leg of the spring hooks

onto the tab extending from the CTS as shown. (Had this

been a right hand assembly, the spring would have been

rotated clockwise as viewed.)

10. You may now remove the slack that was introduced into the

door cable.

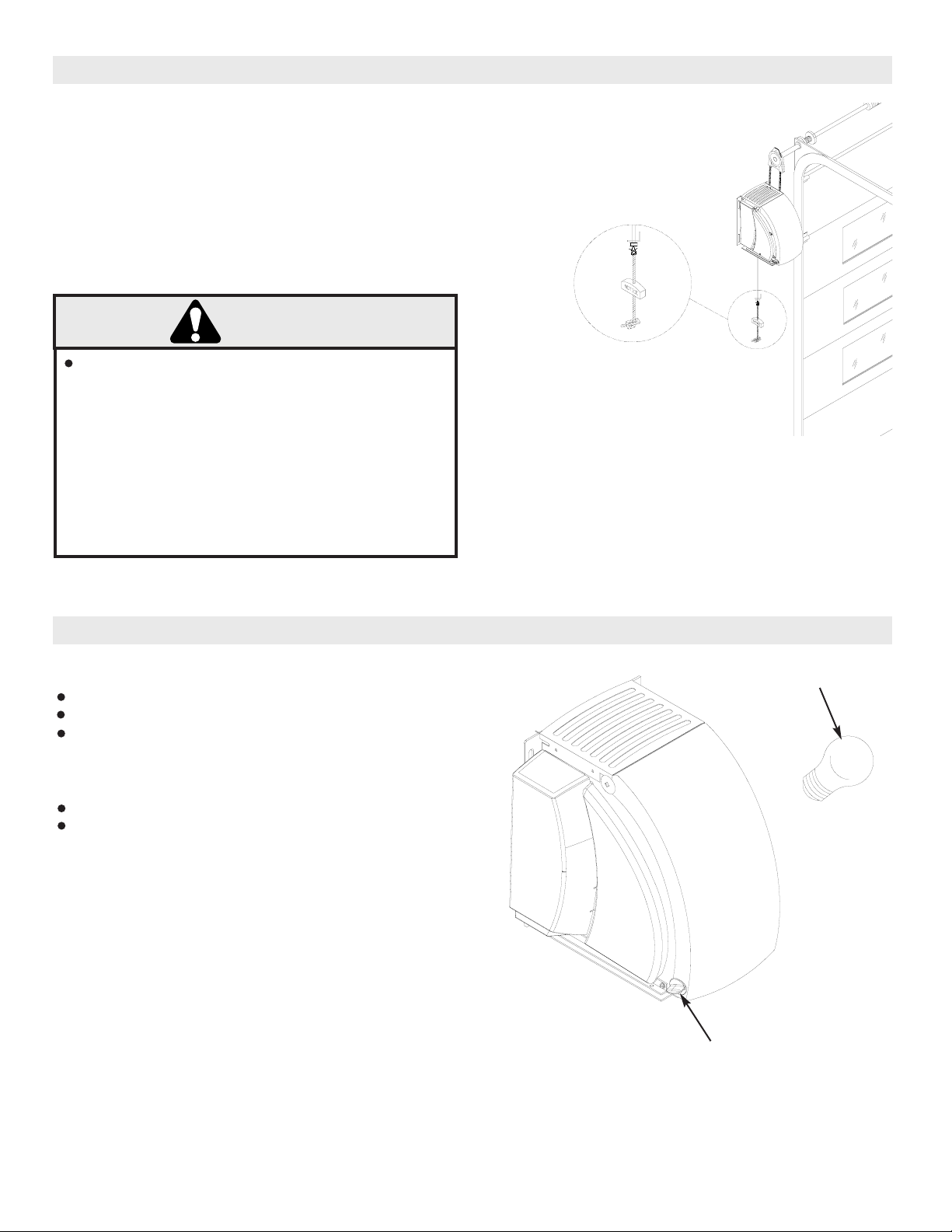

11. Attach the door stopper bracket to the CTS by removing

the 2 mounting screws with a 5/16” wrench. The bracket can

be mounted with the long leg or the short leg attached to the

CTS. This will depend on the distance from the CTS to the

top of the top door section. Tighten the 2 mounting screws.

Apply the self adhesive bumpers supplied to the bottom side

of the door stopper bracket.

12. Try to raise the door manually and check to make sure that

the door stopper bracket contacts the top of the top door

section when this is done. Loosen, adjust and relighten as

needed to accomplish this.

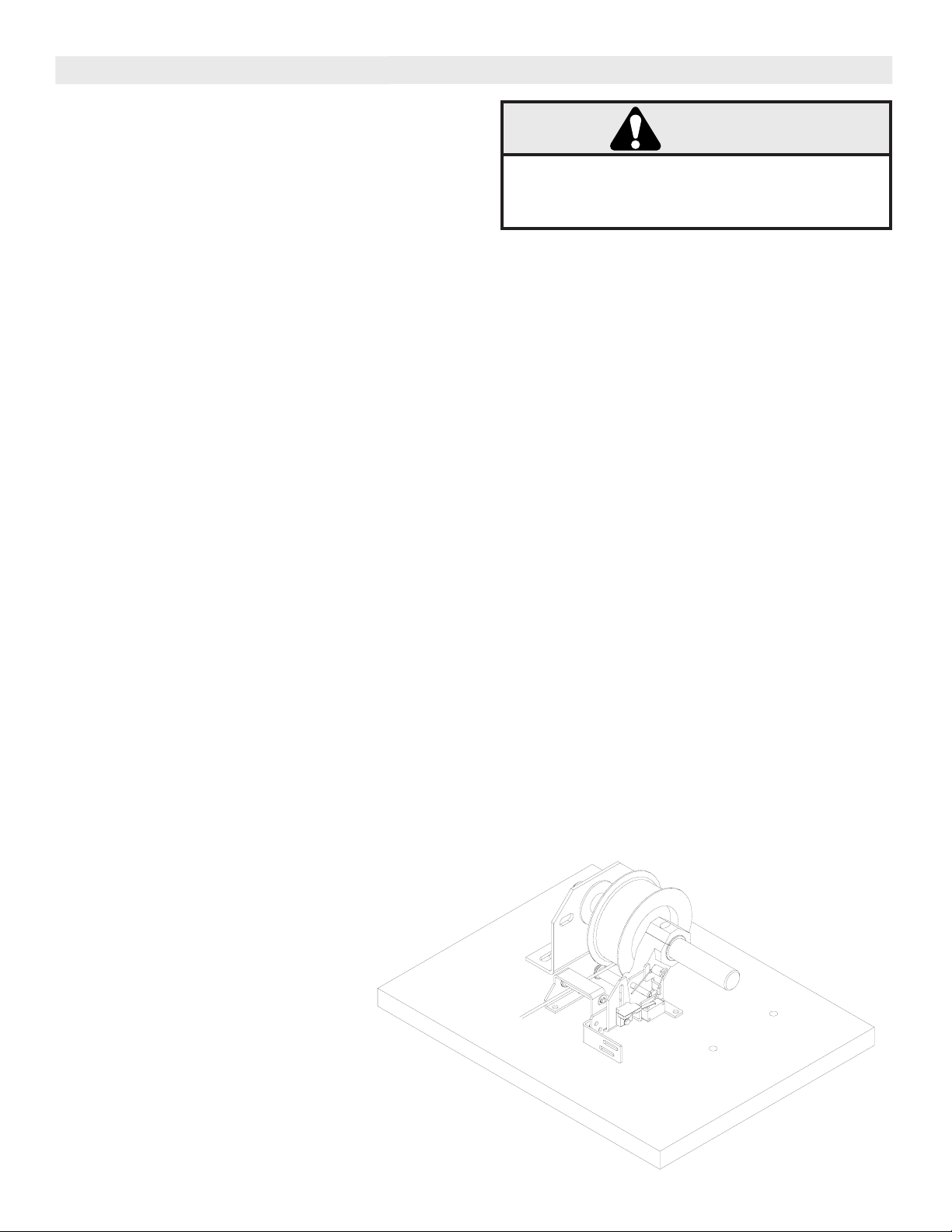

13. Wire the common and the normally open contacts of the

CTS switch in series with one of the wires from the receiving

photo eye. Flag style terminals have been provided to make

your connections. Refer to the wiring diagram in the back of

the owner’s manual.

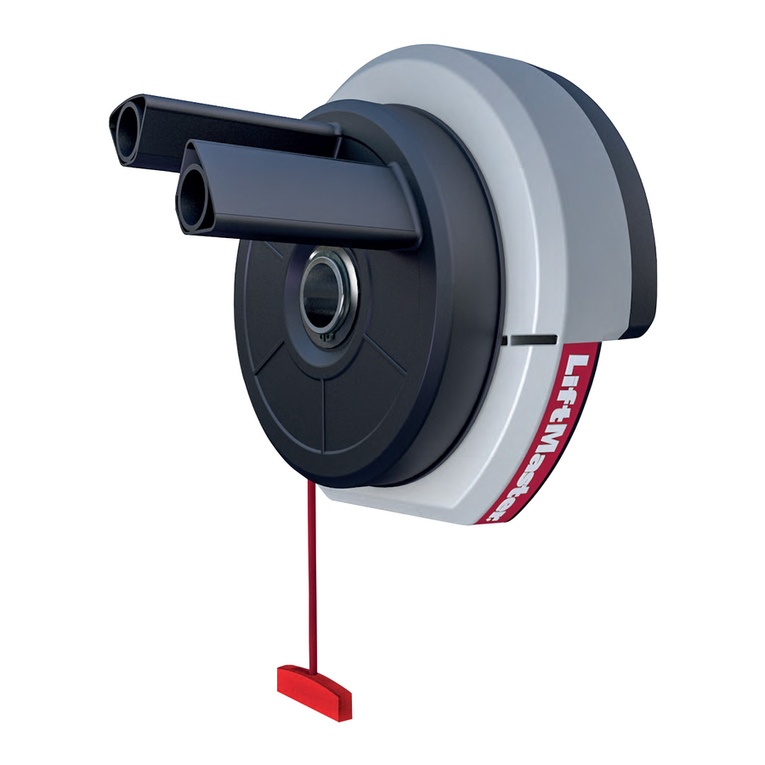

CABLE TENSION

SENSOR ASSEMBLY

(CTS)