INSTALLATION INSTRUCTIONS

Slide the output shaft out of the Motor Frame from the

output sprocket side. The interior sprockets and shim

washers will slide off the shaft as it is removed. Remove

the two ball bearings from the Motor Frame.

INSTALLING NEW OUTPUT SHAFT:

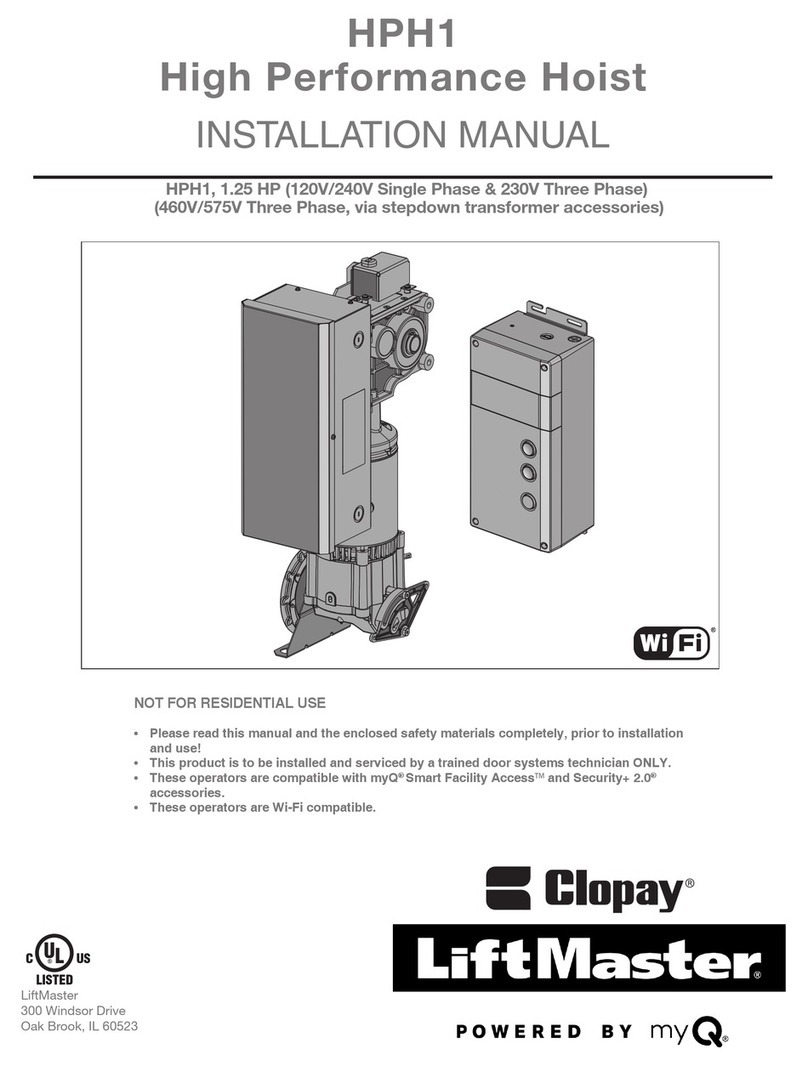

Press the new ball bearings into the motor frame. Referring

to the illustration above, attach new output sprocket to the

new output shaft along with a key using the set screw. Do

not fully tighten the set screw at this time. Refer to the

illustration and the Owner’s Manual as necessary for the

remainder of the installation. Add the necessary shim

washers. Slide the new output shaft into the Motor Frame,

picking up the appropriate washers and sprockets in the

reverse order from how they were removed before. Align

the two interior sprockets by re-attaching the three lengths

of chain connecting the clutch and output shafts. Tighten

the 48B32 sprocket with its set screw and secure the

combination sprocket with push on fasteners. Attach the

new limit sprocket, aligning it before securing it in place

with its set screw. Secure the new output shaft in the Motor

Frame with the shaft collars and washers supplied and re-

attach the Motor Plate.

Replace the limit chain and the drive belt. Restoring power

completes the installation.

NOTE: Refer to the Owner’s Manual supplied with the

operator for all mounting and wiring instructions.

REMOVE EXISTING SHAFT:

Remove the master links from the limit and output chains.

Remove the chains and set them aside. Remove the drive

belt from the clutch and set it aside. Remove the four

screws connecting the Motor Plate to the Motor Frame. Lift

off the Motor Plate and set it aside.

Disconnect and remove the three interior chains connecting

the clutch and output shafts. Remove all push on fasteners

from the output shaft. Remove the output shaft limit

sprocket by first loosening the set screw and then sliding it

off the shaft along with its key. Loosen the set screw of the

48B32 sprocket.

WARNING

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING. IF NECESSARY REMOVE THE

OPERATOR FROM ITS MOUNTED POSITION.

© 2002, The Chamberlain Group, Inc.

01-12570D All Rights Reserved