Chandler Systems DROP CS125 Series User manual

Chandler Systems

Commercial

Control Valve Manual

CS125 & CS150 Series

2

INTRODUCTION

Thank You for Purchasing a DROP System

We know you’ll love your improved water quality, leak detection ability and water conservation benefits of

your new DROP Water Management System from Chandler Systems. You’ll soon wonder how you ever

lived without it. Improving your water and protecting your home are just a few of the ways that the DROP

Water Management System can improve your water system.

Be sure to check out the dropconnect.com website periodically for more information about additional DROP

products as they are released.

888.363.9434 dropconnect.com

To further help you operate your new DROP system, we have provided you with many other resources for

you to learn more. Feel free to call Chandler Systems when you need additional help. We also have many

resources located on our website including instructional videos, and images.

DROP Connect is also active on various social media pages! Feel free to follow us for the most up to date

information and news!

@dropconnect

FCC Compliance Statement:

https://dropconnect.com/sites/default/files/FCC_Compliance_Statement.pdf

Industry Canada Compliance Statement:

https://dropconnect.com/sites/default/files/Industry_Canada_Compliance_Statement.pdf

Privacy Statement

For more information about privacy, visit our privacy policy online.

(https://dropconnect.com/sites/default/files/DROP-Privacy-Statement.pdf) online.

DROP Patents

For the most up-to-date list of patents, visit our patents on our website: https://dropconnect.com/patents.

3

TABLE OF CONTENTS

Introduction................................................................................................................ 2

Table of Contents....................................................................................................... 3

DROP Valves............................................................................................................ 4

Operations................................................................................................................. 5

Valve Description............................................................................................. 6

Valve Operation............................................................................................... 7

Lights - Regeneration....................................................................................... 8

Advanced Configuration................................................................................... 9

Quick Reference Table.................................................................................... 11

Injectors........................................................................................................... 12

Connections..................................................................................................... 13

CS125 Valve Breakdown............................................................................................ 14

CS125 Brine Connection............................................................................................ 15

CS125 Injector Assy................................................................................................... 16

CS150 Valve Breakdown............................................................................................ 17

CS150 Drain Connection............................................................................................ 18

CS150 Brine Connection............................................................................................. 19

CS150 Injection Assy................................................................................................. 20

CS125 & CS150 Powerhead...................................................................................... 21

Valve Body Flow Diagrams........................................................................................ 22

DROP Warranty......................................................................................................... 28

4

DROP VALVES

DROP CS150 Commercial Softener Valve

DROP CS125 Commercial Filter Valve

5

OPERATIONS

DROP Models

Model Number Description Piston Type Injector / Plugs Valve Body

20125X500

Softener Valve,

Rear Inlet/Outlet, for

Single Tank

Operation with

Manual Bypass

Hard water

bypass during

regeneration with

integrated water

shutoff

Injector CS125

20125X600

Filter Valve, Rear

Inlet/Outlet, for

Single Tank

Operation with

Manual Bypass

Hard water

bypass during

regeneration with

integrated water

shutoff

Plugs in Injector

Port and Refill

Port

CS125

20125X550

Softener Valve,

Rear Inlet/Outlet, for

Multi-Tank

Operation with

Manual Bypass

No Hard water

bypass during

regeneration with

integrated water

shutoff

Injector CS125

20125X650

Filter Valve, Rear

Inlet/Outlet, for

Single Tank

Operation with

Manual Bypass

No Hard water

bypass during

regeneration with

integrated water

shutoff

Plugs in Injector

Port and Refill

Port

CS125

20150X500

Softener Valve, Side

Inlet/Outlet, for

Single Tank

Operation

Hard water

bypass during

regeneration with

integrated water

shutoff

Injector CS150

20150X600

Filter Valve, Side

Inlet/Outlet, for

Single Tank

Operation

Hard water

bypass during

regeneration with

integrated water

shutoff

Plugs in Injector

Port and Refill

Port

CS150

20150X550

Softener Valve,

Side Inlet/Outlet, for

Multi-Tank

Operation

No Hard water

bypass during

regeneration with

integrated water

shutoff

Injector CS150

20150X650

Filter Valve, Side

Inlet/Outlet, for

Single Tank

Operation

No Hard water

bypass during

regeneration

with integrated

water shutoff

Plugs in Injector

Port and Refill

Port

CS150

6

OPERATIONS

Detailed Valve Description

The DROP 1.25” and 1.5” valves are fully automatic control mechanisms to direct and regulate all cycles

of the water treatment unit. The control valve has been designed to make it easily serviceable. The inlet,

outlet, drain and access to the water meter are all hand only tighten nuts making them quick and conve-

nient to service. Accessing the injector or the brine port plug is quick access plug-in style with a clip, pos-

sibly only needing a flat head screwdriver to open the plug. Accessing the piston and seals only requires

removing 5 Philips head screws and separating a few plastic clips by hand. All of this means that the

valve is quick and simple to service and you do not need any specialized tools to work on the valve.

The control valve has two piston options. The first is a hardwater bypass piston, which allows hard water

to be bypassed from inlet to outlet during the valve regeneration cycle. This is typical on a single tank

softening system. The other option is a non-hardwater bypass piston option, which does not bypass

hardwater from the inlet to the outlet during the valve regeneration cycle. All pistons have a patented

water shutoff position (U.S. Patents 9714715 & 10012319), which can be used by a DROP system to

protect properties from the risk of water damage from leaks and water breaks. When combined with the

non-hardwater bypass piston type, this feature allows the commercial DROP valves to be used in paral-

lel without the need of external shut-off valves. When used in this way, the DROP system can provide

continuous treatment of water. The DROP hub can command valves to be in service, providing treated

water, or in stand-by with outlet water shut off waiting for when it is needed. During the regeneration

process, inlet water is used to perform the steps of the regeneration of the softener tank and the outlet

water port is shut off. For more detailed information about multiplexing DROP valves, see our “Multiplex-

ing Filters and Softeners” Application Manual. The control valves / pistons are only available in downflow

regeneration.

The DROP valves include a turbine flow meter that is integral to the valve body. The meter is quick to

access without having to separate any plumbing in case of needing to service the meter. Simply turn

the bypass valve to bypass or turn the water off in the DROP App and loosen the nut securing the water

meter, if necessary, use a flathead screwdriver under the edge to remove the flow meter from the outlet

port of the valve. The meter is calibrated in Chandler Systems lab and has excellent accuracy at all flows

above 0.75 gallons per minute. The meter allows the DROP system to properly protect a property and to

notify the end user of usage and potential problems.

There is also a combination turbine flow meter and pressure sensor that is optionally available. The com-

bination meter can directly replace the standard flow meter as it plugs directly into the same wire connec-

tion. Once installed, the DROP system can then monitor the system water pressure at the outlet of the

valve. The water pressure can then also be viewed by the user in the DROP App.

Combining these control valves with a DROP control system creates a water treatment system that is the

easiest in the industry to install, setup and maintain. The DROP system gives the end user easy control,

information, and history of the water treatment system. DROP is a unique water management system.

Using the DROP Hub, DROP monitors water usage and manages the water-related devices throughout

the entire installation. DROP can operate locally without an internet connection or has the added ability to

send mobile alerts when connected to a WiFi network. This advanced system can allow remote monitor-

ing and adjustments—all from your mobile device.

7

Valve Operation

The DROP Users Guide (https://dropconnect.com/knowledgebase-resources) gives general information

and help with connecting your DROP system to a WiFi network and connecting devices to your DROP

Hub. It also gives some general information about making settings and navigating the user interface in

your DROP app. It is also helpful to know that throughout the app’s user interface there are small info

icons to help explain all the features in the app. The settings that are relevant for a DROP system with

the 1.25” and 1.5” valves installed are found on the System > Settings page and the Devices >

Softener or Devices > Filter pages in the DROP app.

Service Bypass Off

OPERATIONS

CS125 Bypass Operation

8

OPERATIONS DROP VALVE - LIGHTS - REGENERATION

DROP Lights - During Regeneration

When a treatment valve is in regeneration the lights will change color for each step in the regeneration

process. While the valve is sitting in a step of the regeneration process the lights will be slowly fading from

side to side (wobble). If the valve is moving to a position the lights will rotate according to the direction of

the motor movement to get to that position. The colors for each position are as follows:

Position Color

Service Green

Backwash Purple

Brine Draw Light Pink

2nd Backwash

(Optional) Purple

Rapid Rinse Light Blue

Brine Fill Spring Green

Position Color

Service Blue

Decompress Pink

Air Release Lime

Backwash Purple

Rest Light Yellow

Air/Chlorine

Draw Light Pink

Rapid Rinse Light Blue

Position Color

Service Blue

Backwash Purple

Rest Light Yellow

Rapid Rinse Light Blue

Softener

Aeration Filter

Backwashing Filter

9

OPERATIONS ADVANCED CONFIGURATIONS

Advanced Conguration of Valve Device Components

The DROP 1” valve board is used on several configurations of DROP products. These products will

come with the board already setup, ready to use for most installations.

Valves from the factory are preset as follows:

• Softeners are set to device #1

• Backwashing filters are set to device #2

• Aeration valves are set to device #3

These factory presets allow for simple setup without the need for Advanced programming in a majority of

installations. Some situations, however, may cause you to need to change the configuration of the board.

There are up to three settings available on the commercial valve board configuration.

1. The valve type. The options are: Softener, Backwashing filter, Aeration filter.

2. The device number, which can be set from 1-4. Every stage of water treatment that you have

needs to have a unique device number. (Note: The physical water treatment order of the

devices in the system is unrelated to the device number.)

3. The softener resin capacity. This is available if the first option is set to Softener. The

capacity can be set to 45k, 60k, 75k, 90k, 120k, 150k, 210k, 300k and 450k. These are quick

common settings, that should be set according to the amount of resin in the media tank. Full

control of the resin capacity setting is available in the Devices > Softener > Advanced

page in the App.

There are two main situations that might cause you to need to change the device configuration on a

DROP valve control board. The first situation that may cause the need to change the device configura-

tion is in the case of replacing a board in the system. If a generic DROP valve board is used, it may need

configured to match the system that it is being installed into.

A less common reason to change this setting is as follows. A simple system will typically have 1 to 2 treat-

ment stages each with only one tank. For example, a softener and a Sidekick filter. These will come from

the factory already set up with a unique device number. Also, if you want to use two of the same type of

treatment device in parallel to treat your water, the DROP system will automatically know to set up two

softeners (which would have the same device number from the factory) as parallel units. However, the

factory default value will not work properly when you have a system that needs two treatment steps using

the same type of treatment device. For example, a backwashing carbon filter and a backwashing neutral-

izer filter that are used in series with each other. In this case the device number of one of the backwash-

ing filters will need to change and it cannot be the same as any other valve device number already on

the DROP system. Only DROP Softener and Filter devices have device numbers. This does not apply to

other types of DROP devices.

10

OPERATIONS ADVANCED CONFIGURATIONS

Steps for advanced conguring of valve device components

Follow the steps below to change the device configuration of a board, or these steps can be followed to

find out what the current configuration of a board is set to.

1. If the valve is powered up, unplug it (and remove the battery if installed).

2. Depress the pushbutton on the valve board while plugging in the valve. The board will begin

throbbing the LEDs white. Release the pushbutton.

3. The valve will display a light code to identify its configuration. Repeatedly give a short press on

the button to select the correct device type according to this list:

a. 1 green LED: Softener

b. 1 blue LED: Backwashing filter

c. 2 blue LEDs: Backwashing filter with Aeration

d. 3 blue LEDs: Sidekick filter

e. 1 cyan LED: Cartridge filter

4. With the correct device type code displayed, hold the button down for 2 seconds and the LEDs

will all turn green to indicate the selection is accepted.

5. Next, you will see 1 to 4 white LEDs. Repeatedly give a short press on the button to select the

valve device number for the board with 1 to 4 lit LEDs. All the device components in the same

logical device must use the same device number. (Example: a softener with multiple tanks).

Device components of different types must use different device numbers. (Example: a softener

and a filter). Hold the button for two seconds to accept the selection.

6. If the device type was selected to be a Softener in step 3, then one or more LEDs will be lit

yellow. Repeatedly give a short press on the button to select the correct resin capacity

according to this list:

a. 1 yellow LED: 40,000 grains capacity (1 ½ cu. ft. of softener resin is in media tank).

b. 2 yellow LEDs: 60,000 grains capacity (2 cu. ft. of softener resin is in media tank).

c. 3 yellow LEDs: 75,000 grains capacity (2 ½ cu. ft. of softener resin is in media tank).

d. 4 yellow LEDs: 90,000 grains capacity (3 cu. ft. of softener resin is in media tank).

e. 1 red LED: 120,000 grains capacity (4 cu. ft. of softener resin is in media tank).

f. 2 red LEDs: 150,000 grains capacity (5 cu. ft. of softener resin is in media tank).

g. 3 red LEDs: 210,000 grains capacity (7 cu. ft. of softener resin is in media tank).

h. 4 red LEDs: 300,000 grains capacity (10 cu. ft. of softener resin is in media tank).

i. 1 purple LED: 450,000 grains capacity (15 cu. ft. of softener resin is in media tank).

7. With the correct capacity LED code displayed, hold the button down for 2 seconds and the

LEDs will all turn green to indicate the selection is accepted. When the button is released, the

valve will restart and is ready for use.

11

OPERATIONS QUICK REFERENCE TABLE

Valve Series - Piston Type

Tank Opening

CS125 – NHWB

– 2.5” with

Bypass Valve

CS125 – HWB –

2.5” with Bypass

Valve

CS150 – NHWB

– 4”

CS150 – HWB

– 4”

Service Flow Rate @ 15 psig (with

meter)

24.1 26.1 32.4 35.6

Service Flow Rate @ 25 psig (with

meter)

31.3 33.3 42.3 45.9

Backwash Flow Rate @ 25 psig 23.3 20.5 26.9 23.7

Min./Max. Operating Pressure 20 – 125 psig

Min./Max. Operating Temperature 40°F – 120°F

Outlet water state during regeneration Shut-off Inlet Bypassed Shut-off Inlet Bypassed

Brine Refill Rate 3.0 gpm Brine Line Flow Control

Drain Line Flow Controls 2.4 / 3 / 3.5 / 4 / 5 / 8 / 9 / 10 / 12 / 15 / 20 / 25 gpm

Brine Draw Injector Rates @ 60 psi

(see injector charts for details)

Red #0 (p/n: CS125-0#) – 0.25 gpm

White #1 (p/n: CS125-1#) – 0.35 gpm

Blue #2 (p/n: CS125-2#) – 0.5 gpm

Yellow #3 (p/n: CS125-3#) – 0.63 gpm

White #3 (p/n: CS150-3#) – 1.0 gpm

Green #4 (p/n: CS150-4#) – 1.7 gpm

Blue #5 (p/n: CS150-5#) – 2.0 gpm

Distributor Tube Opening 1.32” O.D. (1” NPS) 1.90” O.D. (1 ½” NPS)

Tank Thread 2 ½” – 8 NPSM 4” – 8 NPSM

Drain Line Connection 1” NPT Male

Brine Line Connection ½” Push-Lock

Default Inlet / Outlet Connections 1 1/4” NPT Male, 1 1/2” NPT Male

DROP Commercial Control Board EVB-029

Power Adapter 12 VDC, 2.5mm x 5.5mm Barrel, Center Positive, 1000 mA Min.

Valve specications, Quick Reference Table

12

CS125 Injectors

OPERATIONS INJECTORS

CS150 Injectors

13

OPERATIONS CONNECTIONS

Valve Control Board Connections

The valve board wiring connections are labeled clearly according to their function. “Ext. Input” and “Ext.

Mtr.” are normally unused. For specific installations, the Ext. Mtr. output can be used to run an external

valve.

Brine Line Push-Lock Connection

To connect the brine tubing to the brine port on the valve:

1. Make sure the 3/8” brine tubing is cut squarely on the end.

2. Push the tubing into the fitting 7/8” to be sure it is past the O-ring seal.

To release the brine tubing from the brine port on the valve:

1. Remove the orange locking clip from the brine port fitting.

2. Push in on the gray ring surrounding the brine tube, at the same time pull out on the brine tube.

14

CS125 VALVE PARTS - VALVE BREAKDOWN

No. Part No. Description Qty.

1 20125X001 Encoder Wheel and Piston Rod Assy. 1

2 20125X002 Valve Body Seal Plate with O-Ring 1

3 20125X003 Piston Spacer / Stall Ring 1

4

20125X004 Softener Piston (Hardwater Bypass)

1

20125X005 Softener Piston (No Hardwater Bypass)

20125X023 Filter Piston (Hardwater Bypass)

20125X024 Filter Piston (No Hardwater Bypass)

5 20125X006 Seal & Spacer Stack 1

6

20125X007 Water Meter

1

20125X007-P Water Meter / Pressure Sensor Combo

(Optional)

7

20125X008 CS125 Valve Body (HW)

1

20125X013 CS125 Valve Body (NHW)

8 20125X009 Flow Straightener 1

9 20125X010 Tank Seal O-ring 1

10 20125X011 Riser Tube O-ring 1

11 CS125-BP 1.25” CS Bypass (Optional) 1

12 20125X022 1.25” NPT Yoke for Inlet / Outlet 1

DRAWING A

(Pg._____)

DRAWING B

(Pg._____)

5

4

3

2

1

6

8

7

10

9

11

12

(On Separate Page)

(On Separate Page)

15

CS125 VALVE PARTS

-BRINE CONNECTION

3

2

1

4

Drawing A

5

No. Part No. Description Qty.

1 20125X012 ½” Push-Lock Brine Line fitting 1

2 CS-BLFC-3 Brine Line Flow Control, 3.0 gpm 1

3 20125X014 Brine Line Flow Control Retainer 1

4 20125X015 Red Locking Clip 1

5 20125X025 Optional Brine Plug for Filter Valves 1

16

1

2

3

4

5

Drawing B

No. Part No. Description Qty.

1

CS-DLFC-2.4 Drain Line Flow Control, 2.4 gpm

1

CS-DLFC-3 Drain Line Flow Control, 3 gpm

CS-DLFC-3.5 Drain Line Flow Control, 3.5 gpm

CS-DLFC-4 Drain Line Flow Control, 4 gpm

CS-DLFC-5 Drain Line Flow Control, 5gpm

CS-DLFC-8 Drain Line Flow Control, 8 gpm

CS-DLFC-9 Drain Line Flow Control, 9 gpm

CS-DLFC-10 Drain Line Flow Control, 10 gpm

CS-DLFC-12 Drain Line Flow Control, 12 gpm

CS-DLFC-15 Drain Line Flow Control, 15 gpm

CS-DLFC-20 Drain Line Flow Control, 20 gpm

CS-DLFC-25 Drain Line Flow Control, 25 gpm

2 20125X016 DLFC Retainer 1

3 20017X284-1 1” NPT Drain Line Elbow 1

4

CS125-0# Red #0 Injector, with screen and cap, CS125

1

CS125-1# White #1 Injector, with screen and cap, CS125

CS125-2# Blue #2 Injector, with screen and cap, CS125

CS125-3# Yellow #3 Injector, with screen and cap, CS125

20125X026 Brine Injector Plug for Filters, with screen and cap

5 20125X015 Red Locking Clip 1

CS125 VALVE PARTS - INJECTOR ASSY.

17

CS150 VALVE PARTS

-VALVE BREAKDOWN

No. Part No. Description Qty.

1 20125X001 Encoder Wheel and Piston Rod Assy. 1

2 20125X002 Valve Body Seal Plate 1

3 20125X003 Piston Spacer / Stall Ring 1

4

20125X004 Softener Piston (Hardwater Bypass)

1

20125X005 Softener Piston (No Hardwater Bypass)

20125X023 Filter Piston (Hardwater Bypass)

20125X024 Filter Piston (No Hardwater Bypass)

5 20125X006 Seal & Spacer Stack 1

6

20125X007 Water Meter

1

20125X007-P Water Meter/ Pressure Sensor Combo (Optional)

7

20150X001 CS150 Valve Body (HW)

1

20150X003 CS150 Valve Body (NHW)

8 20125X010 Tank Seal O-ring 1

9 20150X002 Riser Tube O-ring 1

10 20150X004 1.5” NPT threaded couplers 1

DRAWING A

(Pg._____)

DRAWING B

(Pg._____)

DRAWING C

(Pg._____)

1

2

3

4

5

67

8

9

10

(On Separate Page)

(On Separate Page)

(On Separate Page)

18

CS150 VALVE PARTS

- DRAIN CONNECTION

No. Part No. Description Qty.

1 20017X284-1 1” NPT Drain Line Elbow 1

2 20125X016 Drain Line Flow Control Retainer 1

3

CS-DLFC-2.4 Drain Line Flow Control, 2.4 gpm

1

CS-DLFC-3 Drain Line Flow Control, 3 gpm

CS-DLFC-3.5 Drain Line Flow Control, 3.5 gpm

CS-DLFC-4 Drain Line Flow Control, 4 gpm

CS-DLFC-5 Drain Line Flow Control, 5gpm

CS-DLFC-8 Drain Line Flow Control, 8 gpm

CS-DLFC-9 Drain Line Flow Control, 9 gpm

CS-DLFC-10 Drain Line Flow Control, 10 gpm

CS-DLFC-12 Drain Line Flow Control, 12 gpm

CS-DLFC-15 Drain Line Flow Control, 15 gpm

CS-DLFC-20 Drain Line Flow Control, 20 gpm

CS-DLFC-25 Drain Line Flow Control, 25 gpm

Drawing A

3

2

1

19

CS150 VALVE PARTS

-BRINE CONNECTION

1

2

3

4

Drawing B

5

No. Part No. Description Qty.

1 20125X012 ½” Push-Lock Brine Line fitting 1

2 CS-BLFC-3 Brine Line Flow Control, 3.0 gpm 1

3 20125X014 Brine Line Flow Control Retainer 1

4 20125X015 Red Locking Clip 1

5 20125X025 Optional Brine Plug for Filter Valves 1

20

1

2

Drawing C

CS150 VALVE PARTS - INJECTION ASSY.

No. Part No. Description Qty.

1

CS150-3# White #3 Injector, with screen cap, CS150

1

CS150-4# Green #4 Injector, with screen cap, CS150

CS150-5# Blue #5 Injector, with screen cap, CS150

20150X005 Brine Injector Plug for Filters, with screen and cap

2 20125X015 Red Locking Clip 1

This manual suits for next models

9

Table of contents

Other Chandler Systems Control Unit manuals

Popular Control Unit manuals by other brands

Advantech

Advantech MOS-2110Z-1201E user manual

HCL

HCL PT-CB-02 Operation, parts and safety manual

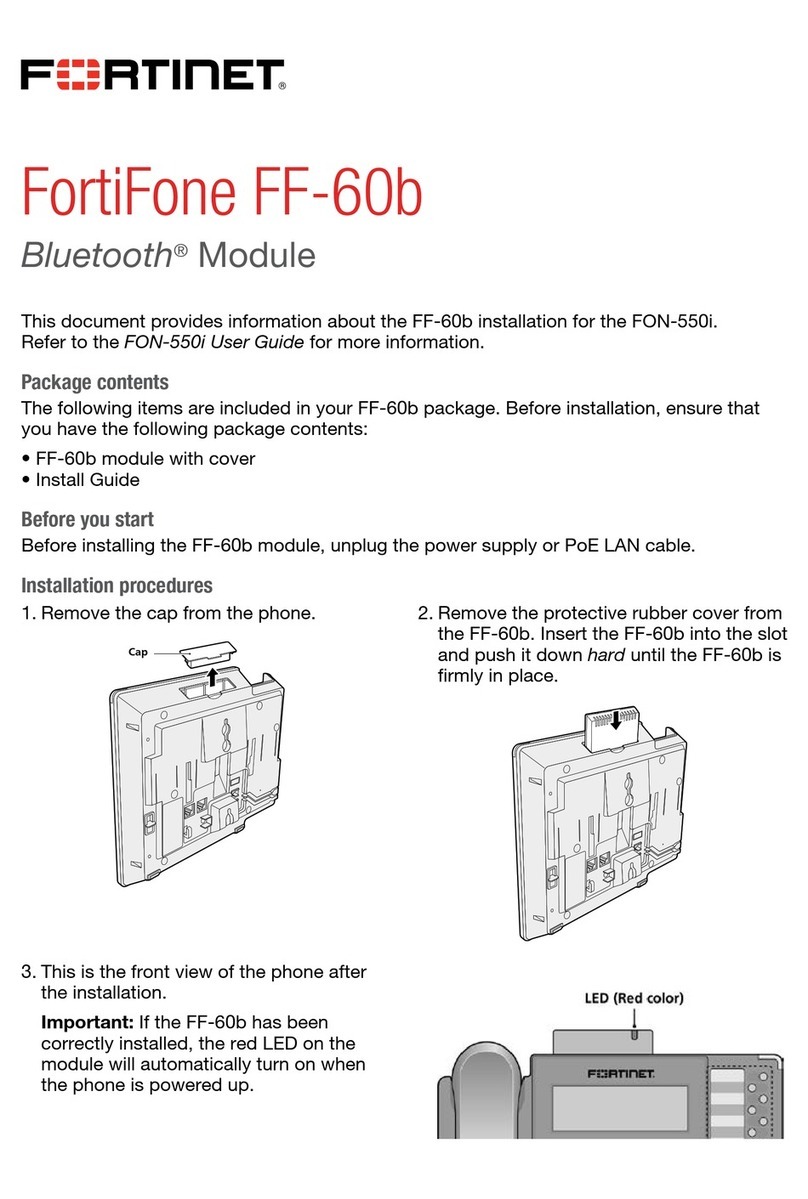

Fortinet

Fortinet FortiFone FF-60b user guide

National Instruments

National Instruments BNC-208X Series user manual

Pilz

Pilz PSSu E F 2DI 60-R operating manual

Optimus

Optimus AV-4 Installation and operating instructions