CHARLY DIAMONDcross 100 Basic Instruction Manual

Models

DIAMONDcross 100 / 125 / 160 / 220 Basic

DIAMONDcross 100 / 125 / 160 / 220 ST

DIAMONDcross 160 ST Tandem

DIAMONDcross 125 / 160 / 220 HG

Certication standards EN 12491 and LTF NFL II 91/09

Version 07/2022 | Valid from year of manufacture 2017

OPERATING & PACKING INSTRUCTIONS

Reserve parachute DIAMONDcross

Thank you for your condence!

Thank you for choosing a CHARLY product!

These operating and packing instructions provide important information on the use of

your rescue system. It has been written to inform you comprehensively about the correct

use and must be read before installation!

If you have any questions related to the use of this rescue system, please contact CHARLY

directly. If you need professional packing or repair service, please contact your certied

dealer or CHARLY.

For more information about this and other CHARLY products, please visit our website. We

wish you great ights and always safe landings.

CHARLY product design / test pilot

Tom Grabner

Operating & packing instructions | DIAMONDcross03

TABLE OF CONTENTS

STRUCTURAL SETUP

TECHNICAL DATA

INTENDED USE & GENERAL SAFETY INSTRUCTIONS

PERMISSIBLE OPERATING TIME

INNER CONTAINER & INSTALLATION OF THE RESERVE IN THE HARNESS

Constructional features of CHARLY inner containers

Connecting the reserve to the harness

Connecting the inner container to the release handle

Repacking into third-party inner containers

Compatibility test of reserve, harness & pilot

PRE-FLIGHT CHECK

INFORMATION FOR WINCH TOWING

FEATURES OF THE DIAMONDCROSS CANOPY & FLIGHT CHARACTERISTICS

GENERAL ADVICE FOR THE USE OF A STEERABLE RESERVE

MAINTENANCE

Packing & inspection record booklet

Packing & inspection intervals

Care & cleaning

Storage & transport

Repairs

Disposal

Optional riser cover

PACKING INSTRUCTIONS

Packing preparation

Packing procedure

05

06

08

08

08

08

10

12

13

16

16

17

17

19

20

20

20

21

21

21

22

23

25

25

26

Operating & packing instructions | DIAMONDcross 04

Stabilo

Stabilo

Rear vent

Main & center lines

Control lines

Control riser

Flight direction indicator (red marking)

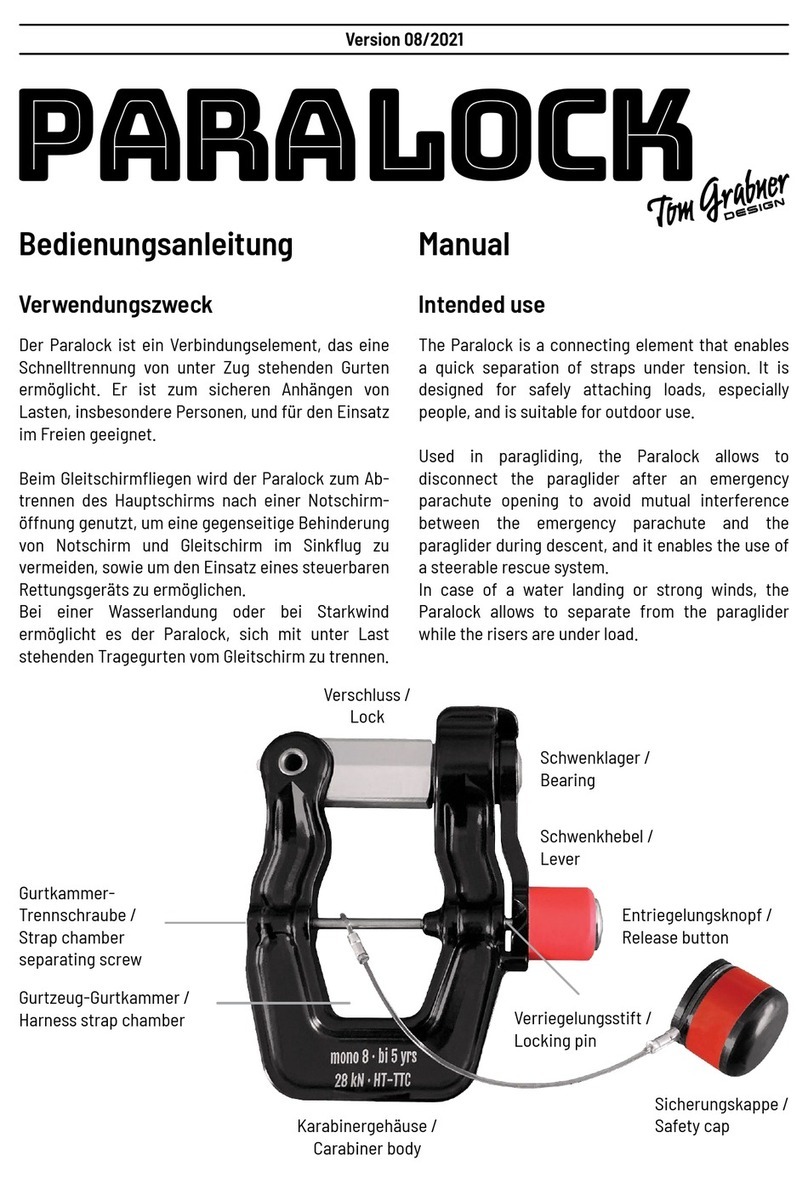

STRUCTURAL SETUP

The gure shows the structural setup of the steerable DIAMONDcross ST. The steerable

Basic and HG versions are not equipped with control risers.

Control handle

Main riser

Lower center lines

Suspension points

Operating & packing instructions | DIAMONDcross05

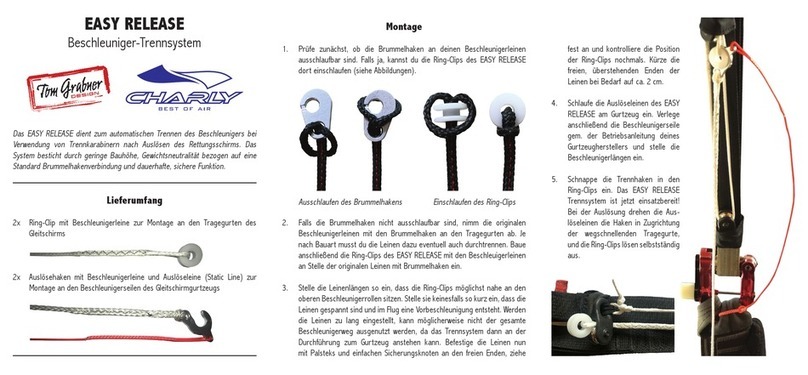

As an additional safety feature for the DIAMONDcross HG versions, we strongly

recommend the use of a swivel (Rotor), as hang gliders in emergency situations often get

into rotating twisting motions, which can entangle the rescue parachute.

The Rotor (CHARLY art.no. HFa160) has been tested and approved for a breaking load of

up to 50 kN. The DIAMONDcross HG can be purchased directly ex works with the Rotor

looped in, but it is also possible to loop it in at a later date between the reserve lines and

the main riser as shown in the picture below.

Please note that for the connection between the suspension lines and the Rotor, the

special swivel line loop is required (CHARLY art.no. HFa161s).

Suspension lines Swivel line loop Swivel Main riser

Surface

Load max. / min.

Sink rate

Max. use speed

Certication

Approval no. ST

Basic

ST Tandem

HG

Weight ST

Basic

ST Tandem

HG - without Rotor

HG - incl. Rotor

Volume

DC100

25,2 m2

100 / 50 kg

4,6 m/s @ 100 kg

3,6 m/s @ 70 kg

115 kmh / 32 m/s

EN / LTF

EP 157.2016

EP 178.2017

---

---

1,17 kg

1,14 kg

---

---

---

3.900 ccm

DC125

30,7 m2

125 / 60 kg

4,5 m/s @ 125 kg

3,5 m/s @ 85 kg

115 kmh / 32 m/s

EN / LTF

EP 158.2016

EP 179.2017

---

EP 184.2016

1,39 kg

1,35 kg

---

1,43 kg

1,60 kg

4.700 ccm

ST = steerable, Basic = not steerable, HG = hang glider (not steerable)

TECHNICAL DATA

Operating & packing instructions | DIAMONDcross 06

DC160

41,0 m2

160 / 80 kg

4,8 m/s @ 160 kg

3,5 m/s @ 110 kg

115 kmh / 32 m/s

EN / LTF

EP 173.2017

EP 180.2017

EP 225.2018

EP 185.2017

1,78 kg

1,75 kg

1,85 kg

1,83 kg

1,97 kg

5.300 ccm

DC220

59,2 m2

220 / 100 kg

4,6 m/s @ 220 kg

3,6 m/s @ 160 kg

115 kmh / 32 m/s

EN / LTF

--

EP 182.2017

EP 181.2017

EP 186.2017

--

2,46 kg

2,57 kg

2,57 kg

2,71 kg

7.300 ccm

Surface

Load max. / min.

Sink rate

Max. use speed

Certication

Approval no. ST

Basic

ST Tandem

HG

Weight ST

Basic

ST Tandem

HG - without Rotor

HG - incl. Rotor

Volume

ST = steerable, Basic = not steerable, HG = hang glider (not steerable)

Operating & packing instructions | DIAMONDcross07

This rescue system is certied according to the standards EN 12491 and LTF NFL II

91/09, and has been specially developed as a manually deployable rescue parachute for

paragliding, powered paragliding and hang gliding. Its use in connection with other ying

activities, such as parachuting, skydiving or base jumping, is not permitted!

The use of this rescue system requires appropriate ight training.Before each take-off, the

pilot must check all parts of the ight equipment for airworthiness.

The permissible operating time of the rescue system is ten years, starting with the rst

commissioning.This also applies if the rescue system has never been deployed.

The date of the rst commissioning must be noted on the approval label on the reserve

riser at the time of purchase. This date is decisive for the ten-year operating period as well

as the regular packing intervals, which are documented in the packing and inspection

record booklet.

After ten years, the operating time can be extended by the manufacturer for a further two

years. For this, it is required that the rescue system undergoes a factory inspection, and

is extensively tested and re-measured. If the condition proves satisfactory, the two-year

operating time extension will be guaranteed and documented.

Depending on the intended use, two different inner containers are available for the

DIAMONDcross:

• Standard at container for harnesses with integrated container compartment

• Inner container for external containers and front containers

Both containers are designed as pocket containers with separate compartments for

the lines and the canopy, so that the canopy is released only after the lines have been

stretched. This ensures a controlled opening of the canopy and reduces the risk of

the reserve becoming entangled in the glider, especially when deploying in SAT-like

rotations.

Inside the CHARLY pocket container, the canopy is protected from dirt in the best possible

way, and unintentional release of the line bundles is reliably excluded.

PERMISSIBLE OPERATING TIME

INTENDED USE & GENERAL SAFETY INSTRUCTIONS

CAUTION: When practicing air sports, the pilot bears sole responsibility for

all risks, up to and including injury and death.Neither the manufacturer nor

the seller of a rescue system can be held responsible, nor can they guarantee

the safety of the pilot.

INNER CONTAINER & INSTALLATION OF THE RESERVE IN THE HARNESS

Constructional features of CHARLY inner containers

Operating & packing instructions | DIAMONDcross 08

In addition, CHARLY inner containers are equipped with fabric-protected rubbers diameter

3 mm, which can be easily replaced as they age. Closure rubbers without protection have

often led to accidental deployments in the past.

The CHARLY standard flat container has been developed on the G-Force trainer

and is the result of years of experience with reserve deployments under centrifugal

force.

The deployment tests have shown that pulling out the rst third of the container requires

the most energy, as the inner container often gets caught in the container compartment

during this rst phase of the deployment. The very at and in the front area conical shape

with a small cross-section of the CHARLY standard at container counters this danger in

the best possible way.

The tests prove that the at container can be pulled out of the reserve compartment in the

harness much better and with less effort than a cube-shaped container - even if the latter

has a signicantly smaller volume.

Thanks to its centered, triangular pull tab, the CHARLY at container will slide out of the

harness even if the deployment handle is intuitively pulled upward instead of outward.

The alternative CHARLY front inner container has the conventional round shape, which

is ideal for front outer containers.

A detailed description for repacking from the standard at container to the front inner

container is available on CHARLY’s website.

S = red

For DC100

M = blue

For DC125

L = black

For DC160

S = red

For DC100

M = blue

For DC125

L = black

For DC160

XL = orange

For DC220

Operating & packing instructions | DIAMONDcross09

Harnesses with attachment points on the shoulder straps

Harnesses with an integrated container have the reserve compartment either under the

seat or on the side of the back. Such harnesses usually have attachment points for the

rescue system on the shoulder straps. From there, a V-line is led through a dedicated

channel at the harness to the reserve compartment, where the main riser of non-steerable

rescuers (e.g. the DIAMONDcross Basic) is looped in.

The steerable DIAMONDcross ST has two separate risers that are attached directly to the

shoulder attachment points. The V-line is not needed and its weight can be saved. If a

V-line is attached to the harness ex factory, it can be removed.

The risers of the DIAMONDcross ST, marked with the colors green (right) and red (left),

are connected to the shoulder straps of the harness by means of connecting links with

a suitable breaking load (e.g. CHARLY art.no. Be31) or with “soft links” (usually made of

Dyneema material) at the attachment points provided for this purpose. From there, they

are led to the reserve container via the dedicated channel which is otherwise used for the

V-line.

Attachment to the carabiners

For paraglider harnesses with outer container or front container, where the attachment

points on the shoulder straps are missing, the riser of the DIAMONDcross Basic is

connected to the carabiners of the harness using a V-line.

With the steerable DIAMONDcross ST, the V-line is obsolete, but please note that the right

and left risers have to be extended by means of special front container extension loops

(CHARLY art.no. HFa165) before they are each hooked to the corresponding paragliding

carabiner. Otherwise problems may arise with the red connection line between the risers

(see information below).

Removal of the connection line is not recommended, but may be considered if

necessary, e.g. if a harness does not allow the installation of the DIAMONDcross ST

in another way. The connection is not required by construction regulations, therefore

removing it does not invalidate the approval.

For the DIAMONDcross HG, the riser is connected directly to the main suspension of the

harness using a suitable connecting link (breaking load min. 2.5 t).

Note: The red connection line between the two risers of the DIAMONDcross

ST has the purpose that the reserve parachute remains functional, at least to

a limited extent, should one of the two suspension points on the harness fail

(e.g. due to carabiner breakage). In addition, it helps to untangle possible

line twists more easily. CHARLY explicitly points out that if the connection

line is removed, an additional safety and backup feature is lost! The Tandem

version does not have the connection line due to characteristics of the

system.

Connecting the reserve to the harness

Operating & packing instructions | DIAMONDcross 10

Twists are often unavoidable

when deploying the reserve.

However, the described

installation method helps avoid

them as much as possible.

Position the harness and

container as shown on the left.

Then turn the container over so

that the closure points to the

ground. When installing the

container on the right side of the

harness as seen in direction of

ight, the rotation must be made

to the left (from the perspective

of the photo), when installing the

container on the left side of the

harness as seen in direction of

ight, the rotation must be made

to the right.

Avoiding twists when installing the inner container in the harness

Then move the container to the harness as shown, attach the release handle to it

as described below, and nally install the inner container according to the harness

manufacturer’s instructions.

Container compartment

Operating & packing instructions | DIAMONDcross11

Outer containers and front containers as well as harnesses with integrated container

compartment are equipped with a release handle, which must be connected to the inner

container of the reserve. The use of original release handles is mandatory.

Release handles with possibility of looping in the original inner container

If there is a possibility of looping in the deployment handle, it is recommended to attach

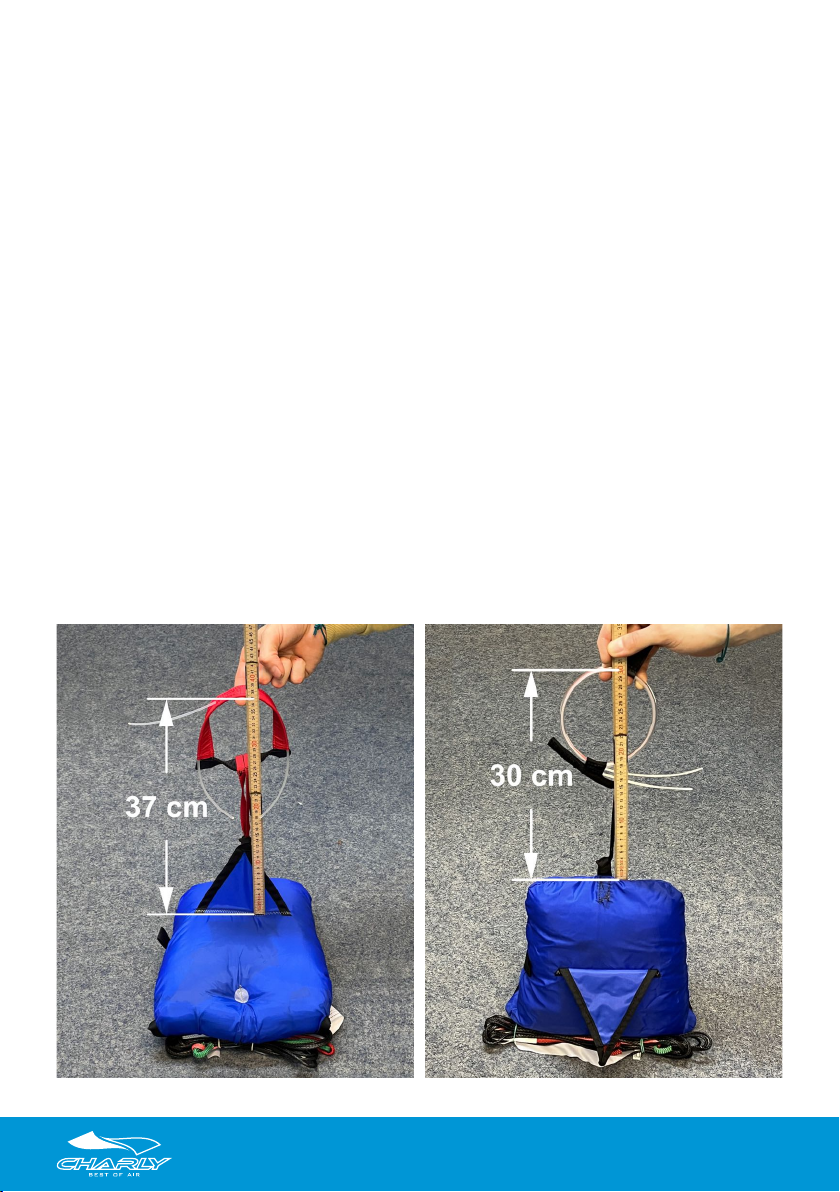

the CHARLY inner container to it. It is then very important to check the length between the

handle and the inner container.

The shorter the connection from the release handle to the inner container, the easier it is

to pull out and throw the reserve. However, the connection must be at least long enough

to ensure that that the locking pins are released when the handle is pulled. To prevent an

entanglement of the release handle in the suspension lines while they are stretching, the

maximum length of the connection from the release handle to the inner container must

not exceed 37 cm.

There are three loop-in options on the CHARLY standard at container:

• The attachment to the triangular pull tab is preferable, as it is the best prevention

against the container getting stuck during the extraction from the harness.

• The attachment point on the side is intended for harnesses with a rear container

compartment.

• The bottom attachment point is used when the 37 cm would be exceeded when using

the triangular pull tab. How to measure the length of the connection is shown in the

pictures.

Connecting the inner container to the release handle

Operating & packing instructions | DIAMONDcross 12

Please contact the harness manufacturer if the release handle connection is too long. If it

is necessary to shorten the connection between the handle and the inner container, this

must be done by the handle manufacturer or another qualied specialist. It is required to

use a high-strength sewing thread (Art.No. HNae40) for this purpose.

Release handles and third-party inner containers

In modern harnesses with integrated container compartment, the release handle and

inner container usually are a single unit, which has been specially tested during the

approval of the harness or front container. The CHARLY pocket container can no longer

be used for these harnesses. Rather, it is necessary that the reserve is repacked into the

harness manufacturer’s inner container. CHARLY permits this, provided that it is a standard

cloverleaf inner container and its volume is not less than that of the CHARLY rescue system

(see technical data). If the design of the third-party inner container differs signicantly

from the usual cloverleaf containers, the handle-inner container combination must be

sent to CHARLY for approval.

The following steps describe the repacking of a DIAMONDcross ST from the CHARLY

standard at container into the GIN Genie Lite 3 cloverleaf inner container (CHARLY Art.

No. HFa1952).

It is not a problem that third-party containers usually have only one closure for the two line

bundles. The bundles can simply be put together in the closure rubber.

Unpacking from the CHARLY standard at container

Please note: The following steps for repacking the reserve into a third-party

cloverleaf inner container are to be understood as an example only. Detailed

instructions must be obtained from the respective manufacturer of the third-

party container.

Repacking into third-party inner containers

Reserve packed inside the CHARLY

standard at container

Tie both line bundles together with

packing cords

Operating & packing instructions | DIAMONDcross13

Tie the central line bundle together with a

packing cord

Gently pull the line bundles from the

closure loops

Gently pull the central line bundle from its

closure loop

Open the line compartment

Open the inner container aps Carefully remove the cap from the inner

container

Operating & packing instructions | DIAMONDcross 14

Packing into the cloverleaf inner container

Inser the looped line bundles Close the container and make sure that all

packing cords have been removed

Carefully insert the cap into the cloverleaf

container and remove the 3 packing cords

Guide the closure loop through the central

eyelet, and secure it with the line bundle

Reserve packed inside the cloverleaf inner

container from GIN

When lifting the reserve up by its lines,

the closure must open under the its own

weight

Operating & packing instructions | DIAMONDcross15

There have been several issues reported associated with the recombination of reserves

with harnesses with an integrated container compartment. Also special characteristics

of the pilot, e.g. his strength or arm length, or a changed packing volume after the rst

repacking of the reserve can cause problems related to the deployment of the rescue

system. A compatibility check by a qualied specialist is therefore mandatory. Qualied

specialists are active ight instructors and authorized employees of ight schools who

have received comprehensive instruction in the task of compatibility testing. The reserve-

harness-pilot combination must be tested in a realistic arrangement. That is, the pilot is in

normal ight position while the harness is hooked to its main carabiners.

It has to be checked:

• That the release handle is easy to reach and grasp.

• That the inner container can be pulled out of the outer container easily and effortlessly.

The pulling power on the release handle should be between 4 and 8 daN. During the

release test, the inner container must be fully extracted.

• That the conguration of the release handle, the inner container and their connection

allows for the powerful throwing away of the inner container in one pull with the

extraction.

• Which pilot position results with the selected harness settings when the harness is

hooked to the attachment points of the reserve.

After the compatibility check has been completed and passed, the rescue parachute

inside its inner container is reinstalled in the harness container compartment or external

outer container in accordance with the operating instructions. Particular attention must be

paid to the following:

• That the packing volume indicated on the CHARLY reserve’s approval label is consistent

with the allowed volume indicated in the operating instructions of the harness/

container.

• That the volume of the packed reserve can vary signicantly depending on the quality

of packing, and often differs greatly from the volume of a factory-packed reserve

compressed by the harness.

• That the rescue system has not been installed in the wrong direction/arrangement

inside the reserve compartment. The instructions for the harness/container must be

strictly followed in this regard.

It must be ensured that the compatibility test is documented in the packing and inspection

record booklet!

In addition to the usual pre-ight check (see operating instructions of the paraglider, the

harness, possibly the tow release etc.), make sure that the reserve container is properly

closed and the release handle is correctly positioned before every take-off.

If the reserve connection line is unhooked after each ight (for example with a front

Compatibility test of reserve, harness & pilot

PRE-FLIGHT CHECK

Operating & packing instructions | DIAMONDcross 16

container system), the pre-ight check must additionally include the correct attachment

of the riser!

For winch towing, the instructions of the harness, paraglider/hang glider and winch

manufacturer must be followed! When using a front container, it must be ensured that the

deployment of the rescue parachute is possible at all times.

Its S-shaped canopy trim provides a high righting moment, so that the DIAMONDcross

is in a stall for a short time imediately after opening. This reliably prevents a downplane

position of the reserve. The paraglider is quickly unloaded and dives down. This prevents

the danger of a scissor position between the rescue system and the paraglider, facilitates

the recovery of the main glider and even allows the unhooking of one riser with CHARLY

Pinlock or even conventional carabiners.

The sinking of the DIAMONDcross during stall corresponds to that of a conventional cross

canopy. The then beginning forward movement in the direction of the red marked corner

further reduces the sink rate signicantly.

Since the S-shaped canopy trim additionally ensures high pendulum stability, also the

hang glider versions of the DIAMONDcross benet from its advantages.

Steerability is an optional feature of the paraglider ST versions of the DIAMONDcross. If it

is not used after deployment, e.g. due to low altitude, the landing will be the same as with

a conventional cross canopy.

If required, the paraglider Basic versions of the DIAMONDcross can be converted to be

steerable by the manufacturer at a later date.

Forward motion

Signicant forward speed only occurs after the paraglider has been pulled in or separated.

The trim of the DIAMONDcross canopy results in a ying speed of up to 15 km/h or a glide

ratio of about 1:1,5. This gives the pilot the possibility, e.g. at 500 meters above ground,

to target a landing area of about 1,7 km² for landing. At lower deployment altitudes, it is at

least still possible to avoid obstacles; at higher altitudes, it is even possible to steer from

the ridge down into the valley or towards a safe landing area.

The horizontal drift of the DIAMONDcross also helps to reduce the risk of injury, because

the deceleration path to reduce the impact speed is shortest in the case of a vertical impact

on a at surface, while lower forces act on the body in the case of an angular impact. In

addition, the human body is not equally resilient in all axes. The most sensitive axis is the

one in the direction of the spine, which has to cushion an impact on the buttocks.

Twists with steerable reserves

Since after deployment, the inner container package is thrown more or less uncontrolled

into the open airspace, and rotations of the container before the canopy unfolds cannot

be completely avoided, a steerable reserve sometimes opens twisted. Steerable rescue

systems have the characteristic that the main glider will always be turned away from the

ight direction due to the air resistance. Even if the main glider still has open surface, a

FEATURES OF THE DIAMONDCROSS CANOPY & FLIGHT CHARACTERISTICS

INFORMATION FOR WINCH TOWING

Operating & packing instructions | DIAMONDcross17

twist (at least 180°) is usually unavoidable. The pilot ies backwards. The DIAMONDcross

then behaves like a conventional cross canopy, but with increased forward movement,

higher pendulum stability and a reduced sink rate.

Twists have basically no negative inuence on the DIAMONDcross’ sink rate or pendulum

stability, and can be considered uncritical in contrast to twists of the paraglider. However,

the benets of a steerable reserve can only be fully realized if the main glider is completely

disconnected. An uncontrollable, partially open surface of the main glider always has a

disadvantageous effect on the ight characteristics of the reserve parachute. This also

applies to all non-steerable systems, which is why it is generally advisable to use separation

carabiners (e.g. CHARLY Paralock) instead of conventional carabiners.

Resolving twists

If the paraglider is disconnected, even multiple twists can be resolved quickly and

easily with the right technique. By making leg kicks in an upright position (slow in one

direction, fast in the other), the pilot turns about 90° per stroke in the desired direction.

This technique is standard in skydiver training, and should be practiced on a suspension

using the reserve attachment points at the harness.

While resolving twists, the pilot should look upwards to the reserve and check whether the

leg kicks are made in the right direction for the respective direction of rotation.If necessary,

the direction of the leg kicks and thus the direction of rotation must be changed.

Spiraling

The DIAMONDcross can be steered using the brake loops on the rear risers. This is most

effective when one side is pulled through quickly and to full deection to y a turn. After

about ve seconds, the brake can be released briey to resume full speed. Then it can be

pulled fully again for directional correction. With this method, the canopy turns into the

curve most quickly and in a dened manner.

The control forces of the DIAMONDcross are relatively high and the system reacts much

slower to direction changes than a paraglider. There is no danger of a stall - not even with

impulsive and deep control inputs at the brakes.

Flyback

By pulling the brake loops fully on both sides, the canopy can be brought into a “yback“.

The reserve will then y backwards until the brakes are released.

Side slip

By holding one brake long and far down, the DIAMONDcross can also be brought into a

“side slip”. The reserve then pushes stably over one of the two lateral corners. This ight

state is terminated by counter-braking and releasing. The side slip can be helpful to avoid

obstacles or to turn just above ground still against the wind. Pulling the brake too deep

or too hard will not cause a stall, which is very important for the pilot’s safety, especially in

stress situations.

Landing approach

The DIAMONDcross’ minimized sink rate resulting from its canopy trim gives the pilot

more time to prepare for landing and provides optimal conditions for an injury-free

landing. The ight tests have shown that the DIAMONDcross is best landed when the

Operating & packing instructions | DIAMONDcross 18

approach and landing are done completely unbraked.

1. In an air emergency situation, pull the release handle rmly so that the release pins

are pulled out of the release pin loops. Throw the inner container holding the reserve,

which is attached to the release handle, powerfully into clear air. As the suspension

lines stretch, the inner container opens and the canopy is inated by the air current.

The reserve unfolds and the inner container is lost. Perform the throwing action as

quickly and as powerfully as possible, and practice it on the ground before each

repack of the reserve. It is important to also mentally practice the procedure several

times.

2. Check: Is the canopy inated? What is the height above ground?

3. Check: Orientation - what is the direction of ight (indicated by the red corner)?

4. Adjust the direction of ight: If there is an imminent collision with an obstacle,

immediately change the ight direction by pulling the brake loop (side does not

matter). Immediately try to do this even when the reserve is twisted.

5. Pull in or separate the paraglider (optional). Separation can be done by:

• Separation carabiners

• Unhooking the risers from conventional carabiners (a separation system for the

speed system is strongly recommended)

• Using a crosscut knife and cutting the paraglider risers or the main lines in case

of emergency. Material damage is preferable to physical damage, so every pilot

should always carry a crosscut knife in ight!

6. Direction check: Correct the direction of ight again, if necessary.

7. Resolve twists

GENERAL ADVICE FOR THE USE OF A STEERABLE RESERVE

Operating & packing instructions | DIAMONDcross19

8. Heading for the landing area: In the remaining time, head for the nearest possible

area where a safe, injury-free landing appears possible. Do not attempt to y over

power lines or other obstacles in low altitude if your position is in front of the

obstacle!

9. If possible, turn the canopy against the wind: If you are above an obstacle and sinking

towards it due to increased headwind speed, try to turn off and reach a more suitable

landing site with tailwind.

10. Landing: At least 20 m above the ground, release the brakes completely and land

unbraked, without aring (even in the case of a tailwind landing). An exception is the

attempt to initiate a side slip to avoid an obstacle. In this case, one brake can also be

held fully pulled until landing.

11. Notify emergency services: It is highly recommended to contact the police or rescue

services immediately after landing via an emergency call. This applies even if there is

no personal injury, as search operations are often initiated by observers after a rescue

parachutes deployment.

A packing and inspection record booklet must be kept as proof of care and for reasons of

insurance coverage and warranty maintenance.

The following shall be noted therein:

• On the part of the manufacturer: The routine test

• On the part of the seller: the date of purchase and the compatibility test

• On the part of the service companies: packings, repairs and inspections

The reserve must be opened,ventilated and then repacked six months after commissioning

and every 12 months thereafter.

The required packing interval may be shortened in the event of extreme environmental

inuences such as humidity, sand, water and other factors. The packing procedure is

described from page 22.

In the event of a water landing, the rescue system may only be repacked after it has dried

completely in the air. For this purpose, it is best to hang it upside down in a symmetrical

position.

After contact with salt water, the reserve should be immediately rinsed several times with

fresh water and then dried.

If the reserve has been incompletely dried (canopy or lines), it may shrink

asymmetrically!

No other heat sources or machines may be used to accelerate the drying process.

MAINTENANCE

Packing & inspection record booklet

Packing & inspection intervals

Operating & packing instructions | DIAMONDcross 20

This manual suits for next models

11

Table of contents

Other CHARLY Safety Equipment manuals

Popular Safety Equipment manuals by other brands

IKAR

IKAR HAS 9 Log book and instructions for use

Sperian

Sperian MILLER Grip 497 Operation and instruction manual

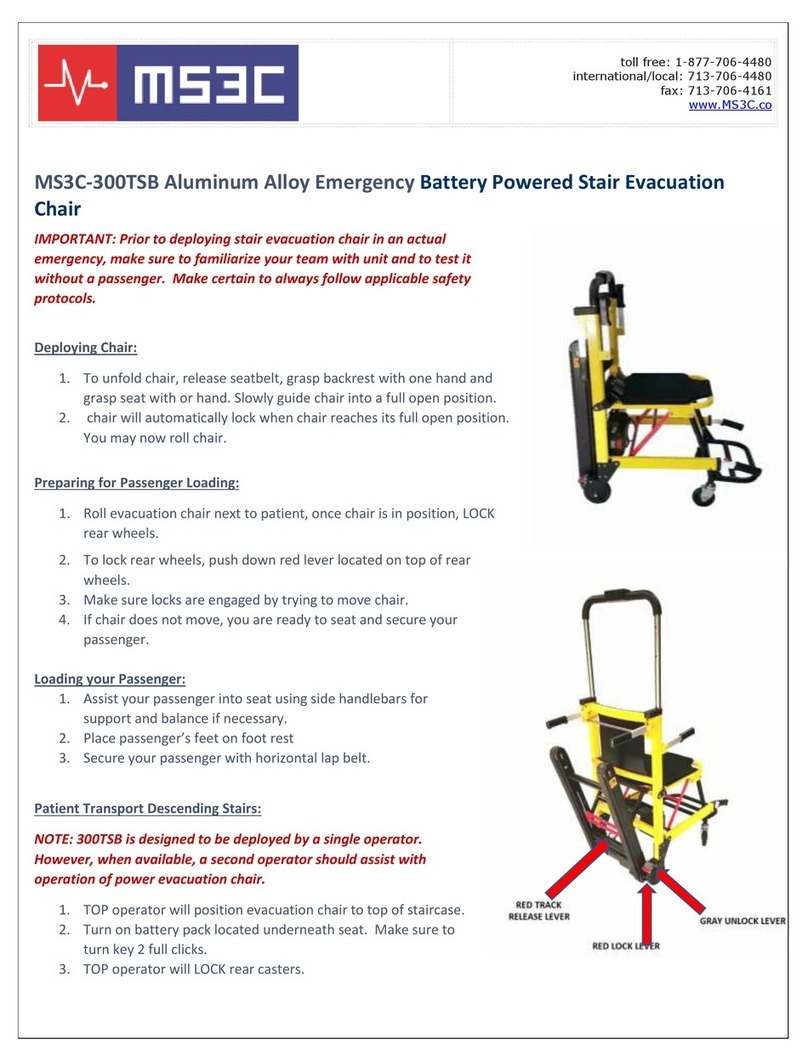

MS3C

MS3C MS3C-300TSB manual

Omron

Omron F3S-AP Series manual

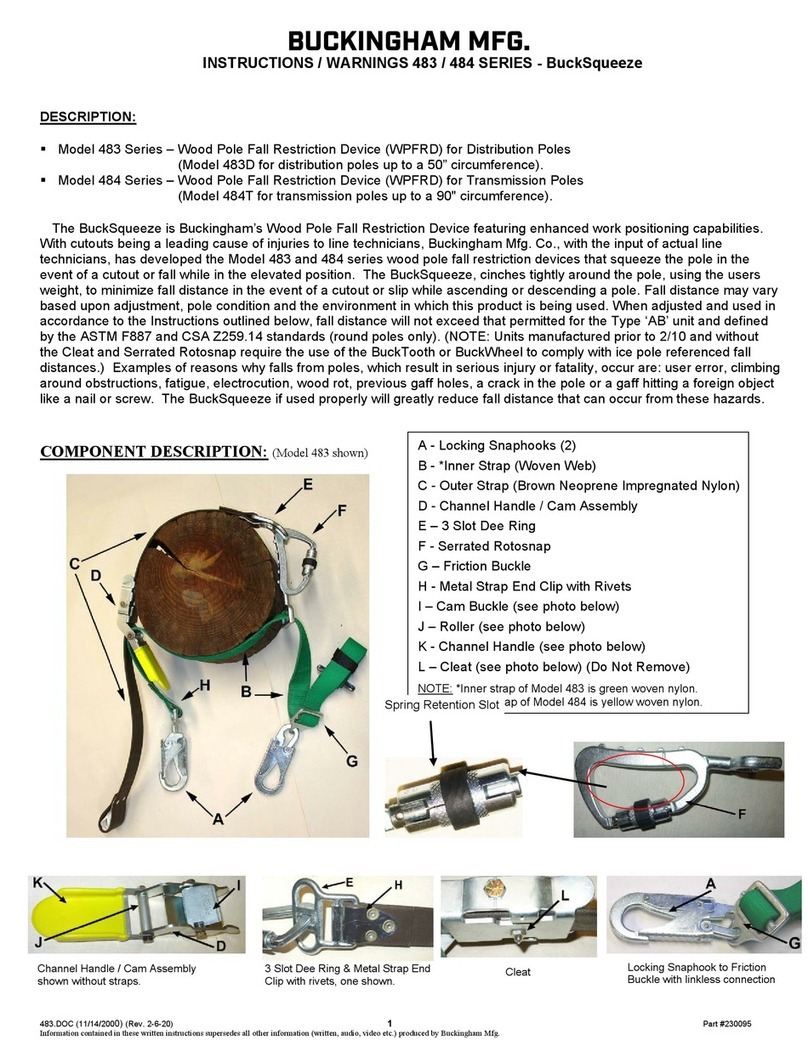

BUCKINGHAM MFG

BUCKINGHAM MFG BuckSqueeze 483 Series Instructions & warnings

Buckingham

Buckingham GLIDE Series Instructions & warnings

Capital Safety

Capital Safety PROTECTA AM211 Specific instructions

Guardian Fall Protection

Guardian Fall Protection 15026 instruction manual

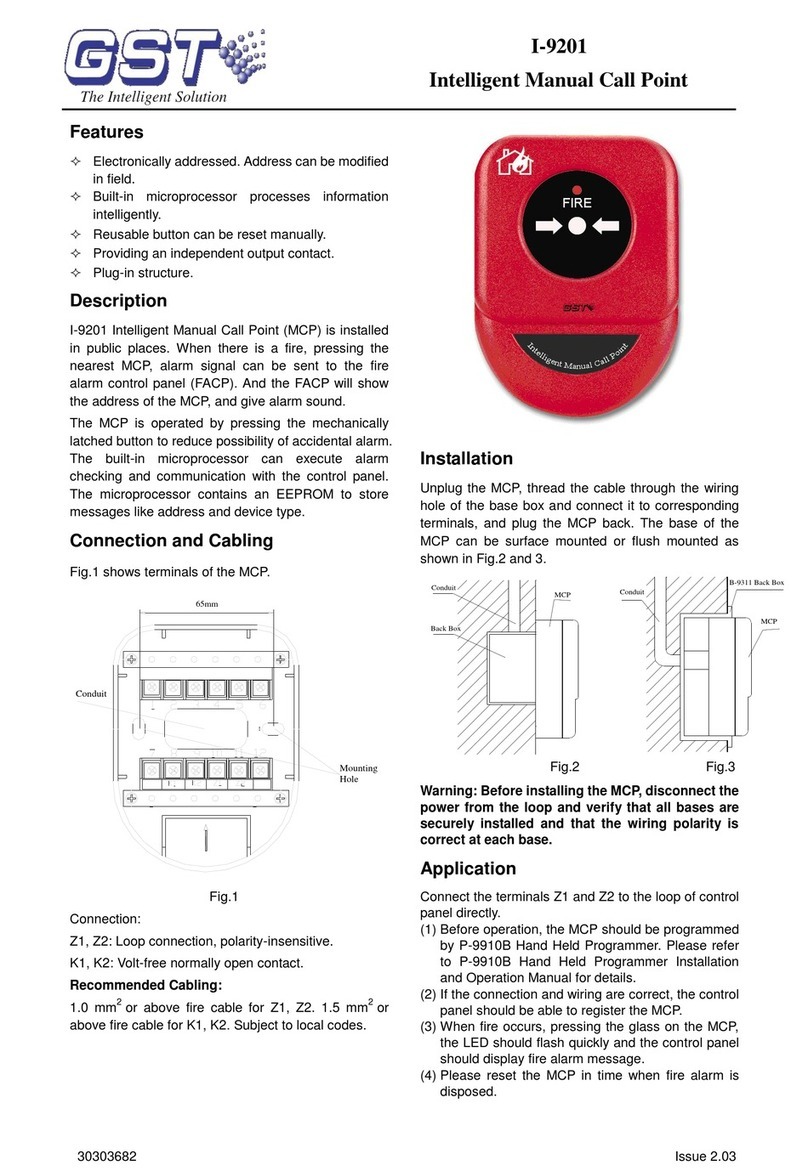

GTS

GTS I-9201 manual

BARRON

BARRON Exitronix CH900X Series installation instructions

CMC

CMC RESCUE & PROTECH PULLEYS manual

Clevertronics

Clevertronics L10 Jumbo LJELED-40 Series Installation & maintenance instructions