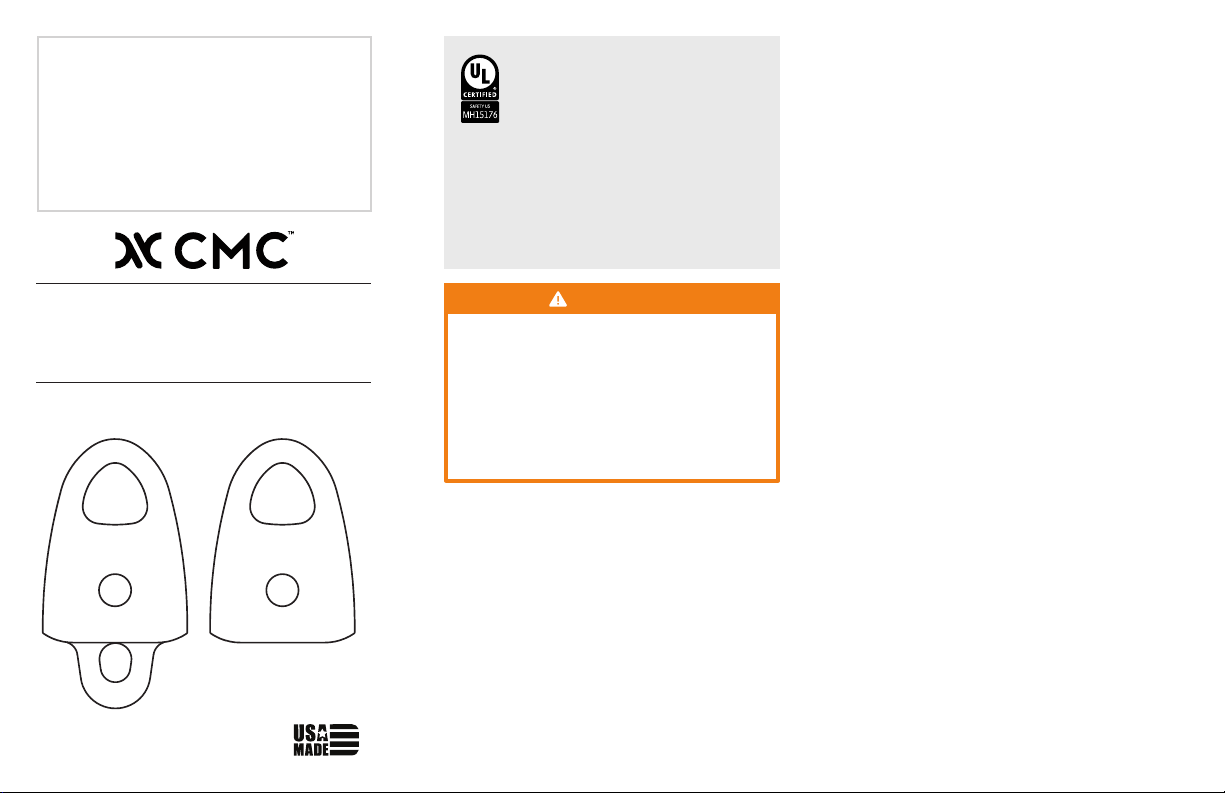

RESCUE & PROTECH

PULLEYS

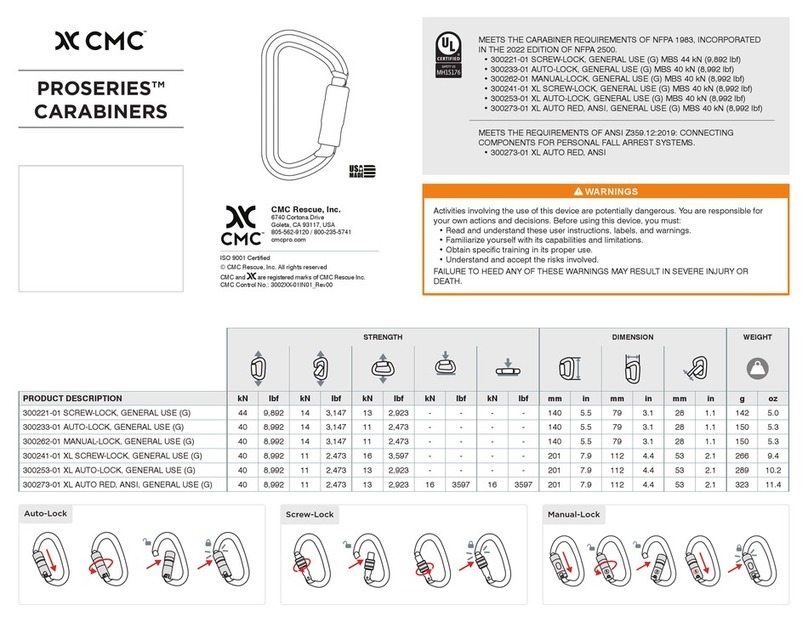

Activities involving the use of this device are potentially

dangerous. You are responsible for your own actions and

decisions. Before using this device, you must:

• Read and understand these user instructions, labels,

and warnings.

• Familiarize yourself with its capabilities and

limitations.

• Obtain specic training in its proper use.

• Understand and accept the risks involved.

FAILURE TO HEED ANY OF THESE WARNINGS MAY

RESULT IN SEVERE INJURY OR DEATH.

WARNINGS

MEETS THE PULLEY REQUIREMENTS OF

NFPA 1983, INCORPORATED IN THE 2022

EDITION OF NFPA 2500.

• 300301-01 RESCUE PULLEY, GENERAL

USE (G)

MBS 52 kN (11,690 lbf)

• 300302-01 RESCUE DOUBLE PULLEY,

GENERAL USE (G)

MBS 45 kN (10,116 lbf)

• 300501-01 PROTECH SINGLE PULLEY,

GENERAL USE (G)

MBS 36 kN (8,093 lbf)

• 300502-01 PROTECH DOUBLE PULLEY,

GENERAL USE (G)

MBS 36 kN (8,093 lbf)

USER INFORMATION

User Information shall be provided to the user of the product.

NFPA Standard 1983, incorporated into the 2022 edition of

NFPA 2500 recommends separating the User Information from

the equipment and retaining the information in a permanent

record. The standard also recommends making a copy of

the User Information to keep with the equipment and that the

information should be referred to before and after each use.

Additional information regarding life safety equipment can

be found in NFPA 1500 and NFPA 1858 and NFPA 1983,

incorporated in the 2022 edition of NFPA 2500.

LIFESPAN / INSPECTION / RETIREMENT

CMC does not specify an expiration date for hardware

because the service life depends greatly on how and where

it is used. The type of use, intensity of use, and environment

of use are all factors in determining serviceability of the

equipment. A single exceptional event can be cause

for retirement after only one use, such as exposure to

sharp edges, extreme temperatures, chemicals, or harsh

environments.

A device must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal

use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation,

standards, technique or incompatibility with other

equipment.

Remove retired equipment from service and destroy it to

prevent further use.

Inspect the equipment according to your department’s policy

for inspecting life safety equipment. CMC recommends a

detailed inspection by a competent person at least once every

12 months depending on current regulations and conditions of

use. Record the date, inspector name, and inspection results

in the equipment log as well as any other relevant information

to track the

usage history.

Before each use, the user should:

• Conrm the device is functioning properly.

• Verify the presence and legibility of the product markings.

• Verify there is no excessive wear or indications of damage

such as deformation, corrosion, sharp edges, cracks, or

burrs. Minor nicks or sharp spots may be smoothed with

emery cloth or similar.

• Check for the presence of dirt or foreign objects that can

affect or prevent normal operation such as grit, sand,

rocks, and debris.

During each use, the user should:

• Conrm all pieces of equipment in the system are

correctly positioned with respect to each other.

• Monitor the condition of the device and its connections to

other equipment in the system.

• Do not allow anything to interfere with the operation of the

device or its components.

• Keep foreign objects out of the device.