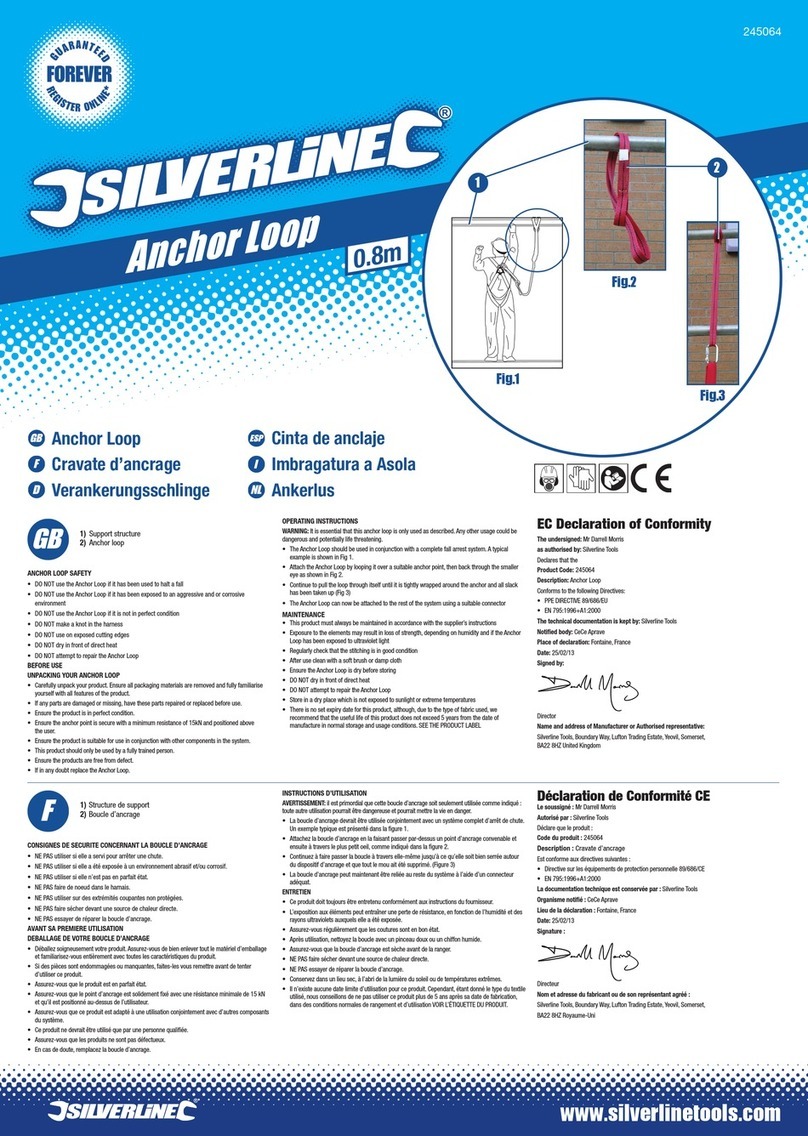

Auto-Locking Oval Karabiner571429

7

silverlinetools.com

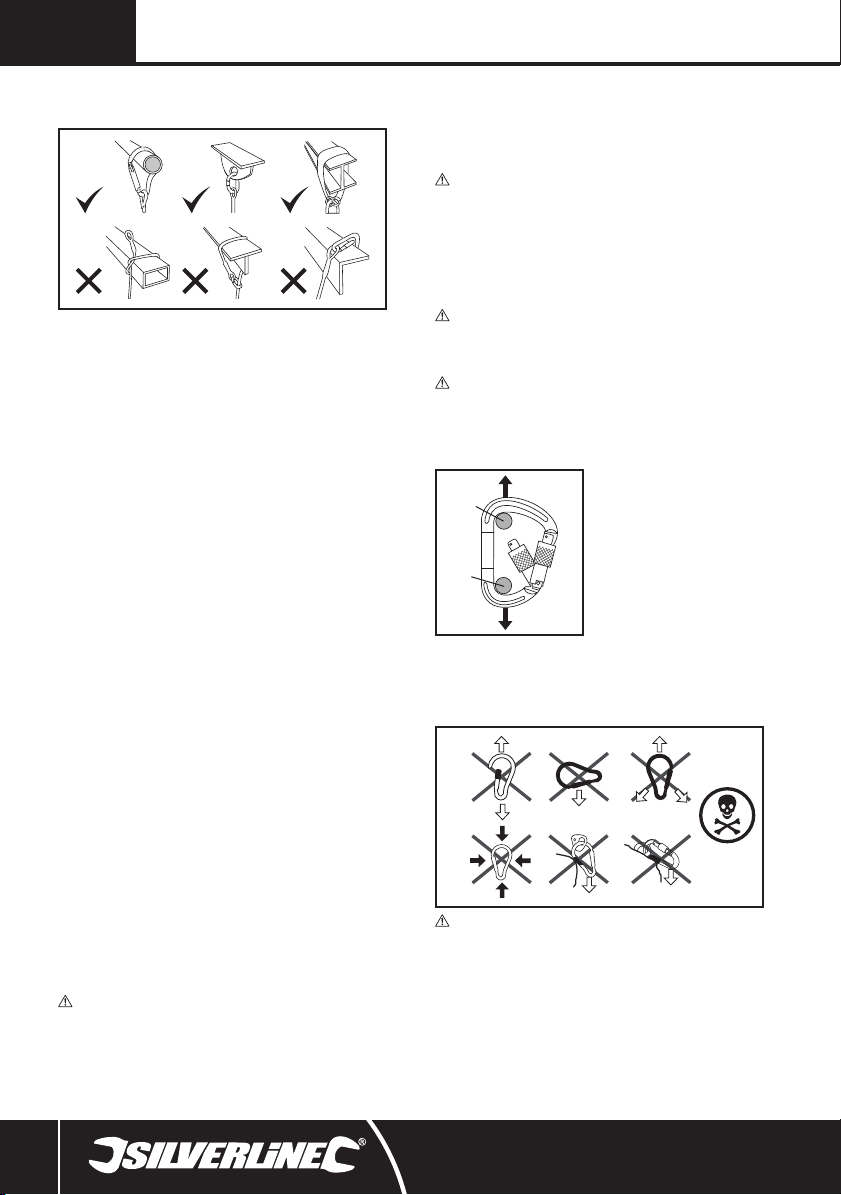

Proper alignment of the karabiner under load

• The karabiner must be installed so that the loads are applied in the area designed for greatest

strength (see marking on the product and Fig.B)

• The anchorage or anchorage connector should be seated in the radius of the karabiner opposite

the Gate (4)

• DONOTapplyloadsacrosstheGate

• Thekarabinermustbeabletomovefreelyandwithoutinterferenceduringuse.ANYconstraintor

external pressure is DANGEROUS

• Beawarethatsomeequipmentcombinationsmayreducetheeffectivestrengthofthekarabiner

(e.g. when connecting to wide straps)

Note: Regularlycheckconnectionswithotherequipmentinthesystemduringuse,andensure

varioussystemcomponentsarecorrectlypositionedwithrespecttoeachother.Thismaysave

yourlife!

Rescue plan

WARNING:Asuitableandsufcientriskassessmentmustbecarriedoutbeforecommencing

withanykindofworkatheight,oranyworkthatrequirestheuseofpersonalprotectiveequipment

(PPE)asacontrolmeasure.

• The user must have a rescue plan and the means at hand to implement it

• Theplanmusttakeintoaccounttheequipmentandspecialtrainingnecessarytoeffectively

conduct prompt rescue under all foreseeable conditions

Accessories

• Additional fall arrest equipment, workwear and other personal protection equipment is available

fromyourSilverlinestockist

Maintenance

Note: Allfallarrestequipmentmustberegularlyinspected,cleanedandmaintainedbya

competent person, in accordance with local laws and regulations.Maintenance must be recorded in

a dedicated service record (see end of this manual).

WARNING:Carryoutavisualandtactileinspectionofallcomponents,everytimethe

equipmentisused.Carryoutadetailedexaminationiftheequipmenthasnotbeenusedforsome

time. Note: Athorough, detailed examination of the equipment must be carried out at regular

intervals,atleastonceannually,ormorefrequentlydependingonuse.

WARNING:ItisILLEGALtocarryoutanykindofrepairormodicationtofallarrestequipment.

WARNING:Shouldanydamagebedetected,removetheequipmentfromserviceimmediately.

Itmustthenberenderedunusableanddiscarded.

Inspection procedure

• Thefollowingprocedurehelpsdetectdefectspotentiallyresultingindegradationand/or

weakening of karabiners:

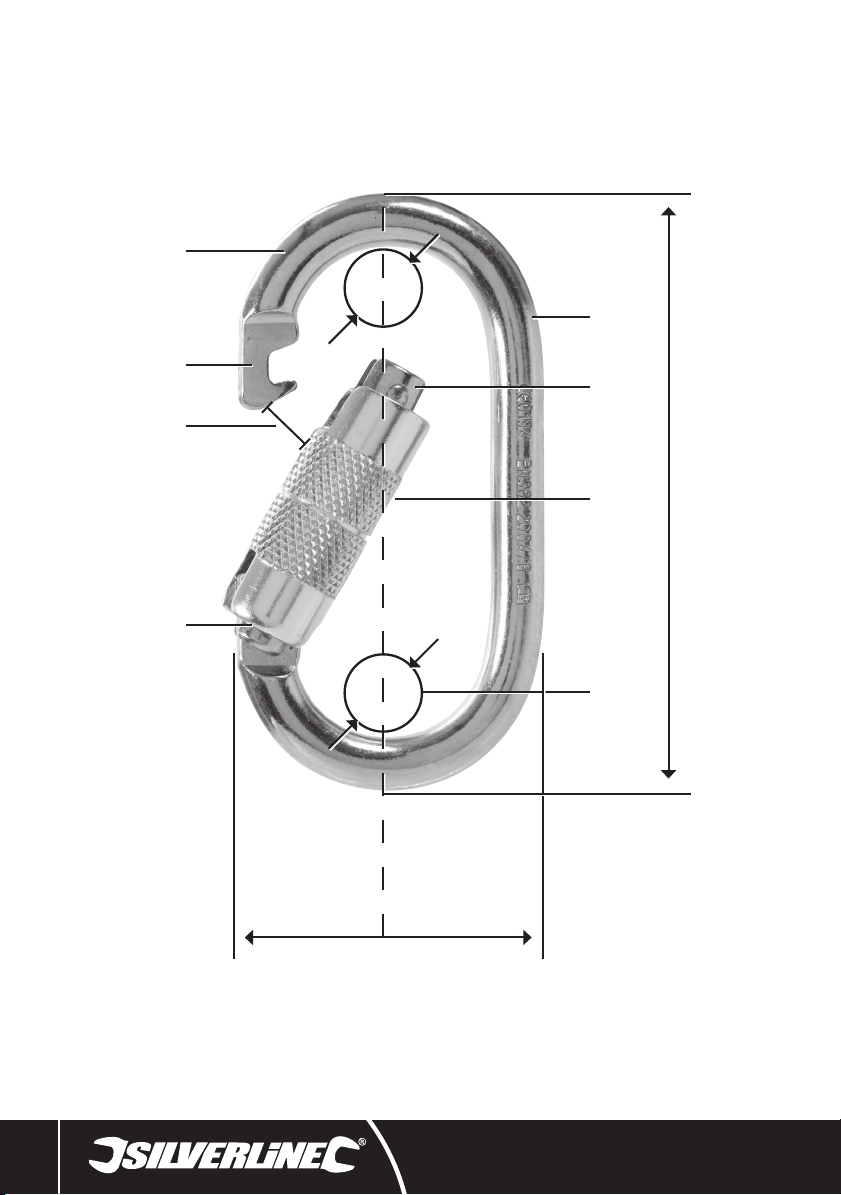

1. Inspectformissingoralteredparts.Refertotheimagein‘ProductFamiliarisation’for

identication.Verifyeachitemispresentandhasnotbeentamperedwith

2. Inspecttheentirekarabinerforcracks,nicksorbreaksinthemetal.Inspecteverymillimetre

Note: Ifnecessary,cleanbeforeinspection,tobeabletodetectevensmallhairlinecracks.

3. Inspectfordeformation,bentsordentedparts.OpentheGateandinspecttheNose(1)ofthe

karabiner for signs of wear, distortion or damage

4. Inspectthemetalsurfaceforanysignsofcorrosion.Steelkarabinersmayshowreddustas

evidenceofcorrosion,aluminiumkarabinersmaydeveloppittingorscales

5. Inspectforheatdamage,whichcanusuallybeseenasdiscolorationordarkeningofthemetal

surfaces

6. Performafunctionaltest:TheLockingSleevemustrotateeasily,andthekarabinermustfully

openandclosesmoothlyandeasily.Whenlocked,theGateMUSTNOTopenunderpressurefrom

anydirection

• Inspectallothercomponentsorsubsystemofthefallarrestequipmentaccordingto

manufacturer's instructions

• Record inspection date and results in a dedicated service record (see end of this manual)

Note:Referto‘Servicelifeandproductobsolescence’ifanydamageorotherdefectsaredetected

during inspection.

Cleaning

Note:Correctcleaningisessentialtoensureintegrityofallsafetyequipment.Followthecleaning

instructions below without deviation.

• Cleanthekarabinerbywipingitwithasoft,lightlyoiledcloth

• Ifthisisnotsufcient,usewarmwaterwithamildpHneutral(pH7)detergent,tocleanoffany

foreignmatter.Drythoroughlyandlubricatemovingpartswithasuitablespraylubricant

• DONOTunderanycircumstancesuseanyabrasivematerials,acids,basicdetergentsorsolvents

• Disinfect parts that come into contact with the operator’s skin, using a disinfectant suitable for

thematerialoftheequipment(see‘Specication’).Strictlyfollowthedisinfectantmanufacturer’s

recommendations and procedures

• ALWAYSallowtheequipmenttodrynaturally,keepitawayfromopenreoranyotherheat

source

Note: This also applies to equipment that has become wet during use.

Lubrication

• Occasionallyapplyasmallamountofasuitablespraylubricant,tothegatemechanism.

Afterwards,performathoroughinspectionasdescribedin‘Inspectionprocedure’

Transport

• ALWAYStransportthisequipmentinsideadedicatedbagorsuitablecontainerthatprotectsit

frommechanicaldamageandshieldstheequipmentfromhightemperatures,humidity,UVrays

and chemicals

Storage

• Storethistoolcarefullyinasecure,dryplaceoutofthereachofchildren

• Storeatmoderatetemperatureandhumidity,awayfromdirectsunlightorchemicals,insidea

dedicated, UV-proof bag or container

• Neverplaceheavyobjectsontopofthisequipment

Disposal

Service life and product obsolescence

WARNING: FallarrestequipmentisdesignedtoarrestafallfromheightONLYONCE!If

subjected to an arrested fall, the equipment must be withdrawn from service and rendered

unusable.

Note:Thedateonwhichtheproductisremovedfromtheoriginalpackagingforthersttime

becomesthe‘dateofrstuse’,whichshouldberecordedontheInspectionRecord(seeendofthis

manual).Thespeciedworkinglifebeginsfromthispoint.

• Thisequipmentissubjecttoamaximumworkinglifeof5yearsfromtherecordeddateof

rstuse,providedtheproducthasbeencorrectlystored,maintainedandsubjectedtoregular

inspectionsbyatrainedandcompetentperson

• Newequipmentmaybestoredforamaximumof5yearsfromthedateofmanufacturingas

indicatedontheproduct,andwillstillgivethepotential5-yearworkinglife-provideditremains

in the original manufacturer's packaging

Note:Otherreasonswhytheproductmaybeconsideredobsoleteincludebutarenotlimitedto

changes of applicable standard, regulations or legislation, development of new techniques or

incompatibilitywithotherequipment.

571429_Manaul.indd 7 10/10/2018 15:04