Warning!!

Do not use incompatible connectors with

any Miller Grip Anchorage. Refer to separate instructions

supplied with your anchorage connectors.

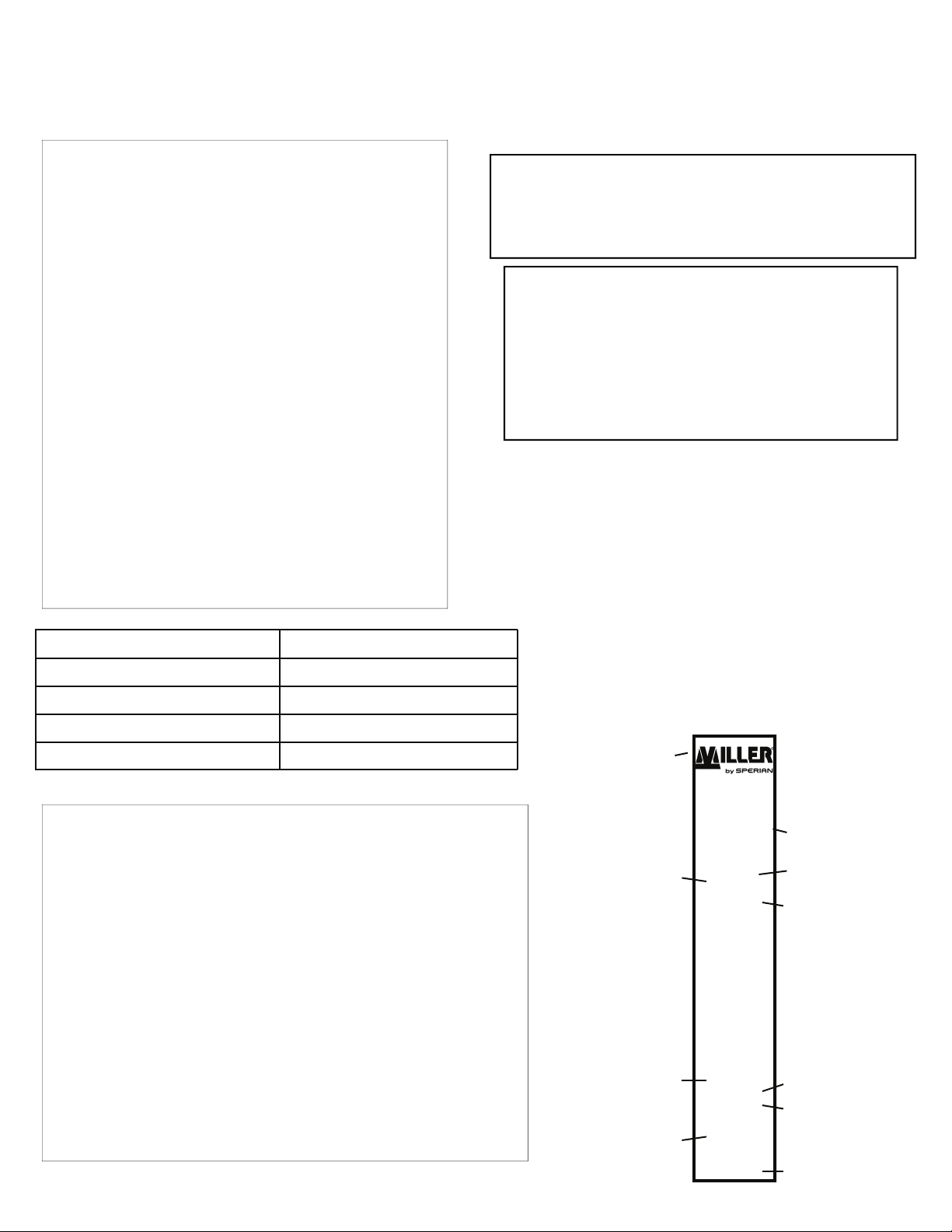

1”

Miller Grip

Use for Fall

Protection Only

Batch # 001

Manufactured on

00/00/0000

Model Miller Grip #499

Tested

ANSI Z359.1

WARNING!

You must read the

operations manual

before using this

product. Only qualified

fall protection

personnel should use

this product.

Company Logo

Hole Diameter/Size

Model Number

Manufactured Date

Product Use

Batch Number

Product Name

ANSI Z359.1 Mark

Warning Instructions

Test Statement

IMPORTANT!!!

Do not drill a hole closer then 10” from any corner.

The concrete substrate must be at least 20” wide and 10” thick.

Main Cable

7x 19 Galvanized Cable Return Wire 1x19 Galvanized Cable

Rotary Swage 304 Stainless Steel Trigger 6061 T6 Aluminum

Spoons 304 Stainless Steel Spring Zinc Coated Spring Steel

Cleaning Bushing 304 Stainless Steel Swage Zinc Coated Copper

Stop Sleeve 304 Stainless Steel Thimble Color Coded Green

• Drill a 1” diameter hole at least 4-1/2” deep.

• Use recommended drill type and size.

• Blow hole clean with compressed air.

• Drill hole straight into substrate.

• When reusing a previously drilled hole always inspect the hole carefully.

• Insert unit 4-1/2 inches deep into hole.

• Set the unit with a slight tug on the anchor loop.

• The stop sleeve must always be partially inserted into the hole.

• Always inspect a previously drilled hole for deformation. Drill another

proper hole if needed.

• Inspect the unit for damage each time you use it. If damage has occurred,

dispose of unit.

• Always dispose of unit after a fall has occurred.

• Never lend your unit to other workers.

• Never rely on a unit placed by unqualified workers.

• Remove your unit at the end of each day.

• Never leave a unit inserted in a hole overnight.

• Never drill hole closer than 10” to any edge or corner.

Only use industrial grade rotary hammer

drills and drill bits.

DO NOT USE masonry drill bits

Inspection:

1. Make sure unit is straight and operates smoothly.

2. Make sure the label is affixed to unit.

3. Make sure trigger stop is not bent or damaged.

4. Make sure cables are not kinked, frayed or damaged.

5. Make sure metal components are not damaged.

6. Make sure metal spoons and conical end fitting operate

smoothly and no metal burrs have occurred.

7. When reusing a previously drilled hole, always inspect the

hole carefully.

Storage and Cleaning:

1. Blow off unit after each use with compressed air.

2. Store in clean dry environment.

3. Store in secure locked area.

4. Store and put away at the end of each day’s work.

5. Do not pile any objects on top of unit during storage.

6. Keep unit free of grease, oils and dirt.

7. Never lend your unit to other workers.

Disposal:

1. Dispose of unit after any fall has occurred.

2. Dispose of unit if cable becomes kinked or bent.

3. Dispose of unit if trigger stop is bent or damaged.

4. Dispose of unit if trigger action is rough or sticky.

5. Dispose of unit if return wire becomes bent or frayed.

6. Proper disposal requires the unit’s spoons be cut off the

return wires and thrown away.

It is important that you drill your Miller Grip hole to the

manufacturer’s required depth and hole structure. All

holes must be 1” in diameter and drilled at least 4-1/2”

into the substrate and the bored hole walls must be

straight and parallel. NOTE: The bored hole must be of

uniform diameter and free of peaks and valleys on the

inner wall surfaces. Only use quality industrial grade

rotary hammers and rotary hammer drill bits.

NEVER USE A BENT DRILL BIT!!