Checkmate ecoAnch2or User manual

User Manual

®

User Manual

Page 2

Issue 3

ecoAnch

ecoAnch2

2or

or®

Index

Index

Page

Page

1.0 Introduction to ecoAnch2or®&

Scope of Use

2.0 Storage, Issue, Inspection *

Lifespan

3.0 Installation and System Setup

4.0 Anchorage, Compatibility &

Warnings !

5.0 Quality, Legislation & Exclusions

6.0 Record Card

3

4

5-7

8

9

10-11

User Manual

Page 3

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 1.0

Section 1.0

Checkmate Safety - Water Weight Anchor - ecoAnch

ecoAnch2

2or

or®

The Checkmate ecoAnch2or®has been designed for your safety when working

at height. The anchor is a totally unique concept in fall protection & uses

renewable resources for both manufacture & installation.

The ecoAnch2or®is compatible with a large variety of roof surfaces including

composite & mineral felts. It has been independently tested & exceeds the

EN795 Class E standard & even works on roof pitches to 15 degrees.

For a full list of approved surfaces & roof angles please see ecoAnch2or®

supplement available on request from Checkmate.

The anchor is safe to use on wet surfaces but NOT shiny or slippery surfaces.

When collapsed the ecoAnchor weighs just 8Kg & fits into to a small holdall for

easy installation.

Introduction to the

Introduction to the

ecoAnch

ecoAnch2

2or

or®

&

&

Scope of Use

Scope of Use

Principal Features

Material

Neoprene Coated Fabric

Dimensions

1.45m x 1.45m x 0.2m

Weights

Empty = 8kg, Full = 430kg

Pressure Loading

2.7kN/square metre

Puncture Resisitance

Meets FED STD 191 Pt.1520

>700N

User Manual

Page 4

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 2.0

Section 2.0

Storage in a central protected location allows assurance of inspection on issue and return.

This device should be stored in a clean dry place where it can be protected from damage by chemical attack and

sharp objects . It should be stored with its instructions and record card at all times.

Return the device back to it’s original holdall for storage & transportation.

After use return to the store, Never leave the device lying around site.

This and associated equipment must be visually inspected by a competent person when initially delivered to site,

there after the product must be inspected before and after use. A record card is printed on the page 10 of this

manual and should be completed when first put into service, and updated after each routine inspection. Follow the

points laid down in the section headed “Inspection” without deviation.

The supervisor must ensure that the equipment is being used correctly and that the user is aware of its safe use

and inspection.

Inspect the device for damage or leakage.

Inspect the attachment point for signs of wear or damage.

If in doubt quarantine and remove from service.

Check the user instructions are clear & legible.

To clean the anchor, a mild detergent can be used with warm or cold water & left to dry naturally before storing.

Ensure that device certification is current before use, the device must have been serviced within the

last 12 months and 6 months if used in corrosive or off-shore environments.

If for any reason the inspection of this device shows signs for concern or doubt then the device must be

quarantined and removed from service immediately. Qualification should be sought from the supervisor and if still

concerned the device must be sent to the supplier, an approved service agent or the manufacturer for service and

re-calibration.

This device must only be serviced by a trained and competent individual,

Never attempt to service this unit or tamper with its function in any way.

The ecoAnch2or®has an expected life or at least five years exposed, and significantly longer wrapped up and

stored correctly in the bag. The lifespan is dependant upon regular and correct inspection, but is estimated to be

a minimum of five years from when it was first put into service.

Storage, Issue & Inspection

Storage, Issue & Inspection

Storage

Inspection

Issue

Lifespan

User Manual

Page 5

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 3.0

Section 3.0

Before Use

Only ONE person may be attached to the anchor at any time.

Minimum ground clearance 3.5 metres.

Minimum distance from edge 2.5 metres.

The anchor MUST NOT be used in the following conditions:

Where there is a risk of frost or in freezing conditions

Where there is contamination of the roof surface and/or anchor by oil, grease or other

lubricants, or by algae.

The anchor is approved for use ONLY on the following surfaces at a maximum pitch of 5 degrees

(1 in 11) within the scope of the PPE directive EN795 Class E.

Concrete

Tarmac

Felt & mineral

EPDM membrane

Felt & chippings (loose chippings must be removed)

For a full list of approved surfaces & roof angles please see “ecoAnch2or®

supplement” available on request from Checkmate.

Before use ensure that the surface you are working on is capable of supporting the weight

of the anchor. The weight of the anchor when full is 430kg with a distributed load of 273kg

per square metre.

Inspect the anchor for signs of damage or leakage. Inspect the attachment point for signs of wear

or damage. Do not use the anchor if either the bag or attachment point show signs of damage.

If the anchor is used on a roof surface of felt & chippings, loose chippings must be removed from

the area where the anchor is to be positioned (e.g. by sweeping with a stiff brush) before

deployment of the anchor.

Installation & System Setup

Installation & System Setup

User Manual

Page 6

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 3.1

Section 3.1

1. Remove from carry bag, unfold & position the

anchor so as to maximize the contact area

between the base of the anchor & the roof.

2. Avoid areas where there are projections, e.g.

bolts, ridges etc. Do not position the anchor in

areas where water accumulates.

3. The anchor must be positioned as indicated

on the label with the vent at the highest corner &

the drain at the lowest point. The vent allows air

to escape & prevents the over-pressurising.

Incorrect positioning can result in trapped air &

underfilling, making the anchor unsafe.

4. The anchor is filled with cold water by simply

fitting a hose with an outside diameter of 16mm

to 20mm into the filler spout with the rubber

bung removed. Filling is complete when water

begins to flow from the diagonally opposite vent

valve.

To detach the hose, squeeze the spout, remove

the hose & replace the bung.

The anchor should now be completely full of

water, any air that can be felt in the bag can be

exhausted through the vent.

Installation & System Setup

Installation & System Setup

User Manual

Page 7

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 3.2

Section 3.2

Installation & System Setup

Installation & System Setup

Daily Checks

5. If the anchor is left filled and in position for more

than 24 hours, it must be inspected for each working

day for leakage by ensuring the material near the vent

is taut. If neccessary, refill the bag until water is seen

to come out of the vent.

After Use

6. Empty the bag by unscrewing the drain cap.

When almost empty, lift the the bag to remove the

remaining water.

7. If the external surface of the bag is wet leave to dry

before folding.

8. Fold twice as shown in photo, carefully expelling

any remaining air until relatively flat.

9. Roll lengthways until compressed into a small roll

and secure with fitted straps.

10. Stow anchor back into it’s holdall, it is now ready

for reuse.

User Manual

Page 8

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 4.0

Section 4.0

Installation

The Device must not be installed where the following

hazards may endanger the user or prevent the efficient operation

of the system.

The area below the device must be free of obstruction that will

prevent the free pay-out of lanyard or rope or may obstruct the

movement of the user.

The environment must be free of heavy solvents or acids that will

degrade the device.

Install the device so that it is away from the edge, so avoiding

swing hazards, minimum 2.5 metres.

Never install where there is a possibility of electric shock

hazards.

When installing ensure that you are not subjecting your self to

potential fall hazards, wear a full body harness and shock

absorbing lanyard, anchoring yourself whilst installing.

Use

Fall Protection

Follow the inspection routine laid down in this manual.

Do not use the device in situations where there is less than 3.5

metres of ground clearance.

Connect a lanyard from the anchor to the Rear Dorsal “D” ring of

a fall Protection Full Body Harness. Ensure that the hook of the

device is secure in the Harness “D” Ring and that the gate of the

hook is locked.

Never run or jump whilst attached to the anchor.

Compatibility

The anchor is suitable for fall arrest when used with a

Full Body Harness to EN361, such as the Checkmate

PBH range. Suitable lanyards for connection are Type

SAL, PAL and RL2.

This unit is not suitable for use in explosive

environments.

If in doubt contact your approved

Checkmate technical support for further

details.

Warnings!

Read and understand manufacturers instructions before

inspection, installation or use of this product.

Never use this product if you weigh more than 100kg

Only use approved equipment with this product.

If there are any points in this manual that you are unsure of

seek a competent, trained person to advise you before using.

Seek medical advice from a doctor before using this product if,

you have sustained a spinal injury, suffer from a neck or back

complaint, or you are taking prescription medication.

Never use if you are under the influence of alcohol or

recreational drugs.

Extra care should be taken if welding whilst using this product,

protect the anchor from splatter and heat at all times. Never use

this system unattended.

Never use this system unless you are supervised by a trained

and competent person.

Rescue Planning and Training

When using the ecoAnch2or®, users should

always make suitable provisions for rescue.

A full risk assessment should be carried out

to determine the most effective, safe and

quickest form of rescue.

For more information on specialist rescue

systems or training please contact the

Checkmate Safety technical team, where our

dedicated training division,

can offer a full range of training courses.

Anchorage, Compatibility &

Anchorage, Compatibility &

Warnings !

Warnings !

User Manual

Page 9

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 5.0

Section 5.0

5.1 Quality

All Checkmate products are

manufactured under ISO 9001:2000

and to the highest standards. The

scope of use within the certification

held allows Checkmate to design,

manufacture and test Personal

Protection Equipment.

Horizontal tensile test machine,

abrasion testers and dynamic drop

test rig are just part of the full range of

test facilities used to ensure ultimate

safety of our product range.

All Checkmate systems must only be

installed by Checkmate personnel or

an approved installer. Strict training is

given and written exams are

completed before full certification can

be given to installers.

5.2 Legislation and Standards

The ecoAnchor has been designed to

meet BS EN 795 Class E

For clarification on any certification

issues contact Checkmate or SGS UK.

5.3 Exclusions

Checkmate holds global product

liability cover for your safety.

Checkmate will NOT however be

responsible for;

a) users who are out of the scope of

any written manuals of training given.

b) any systems that have NOT been

inspected under the current

legislation.

c) operators who do not use load

limiting devices.

d) devices that have been damaged.

e) when the Max weight in Kg has

been exceeded.

f) devices that have NO serial number

markings, and the manufacturers

name is not present.

Quality,Legislation &

Quality,Legislation &

Exclusions

Exclusions

User Manual

Page 10

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 6.0

Section 6.0

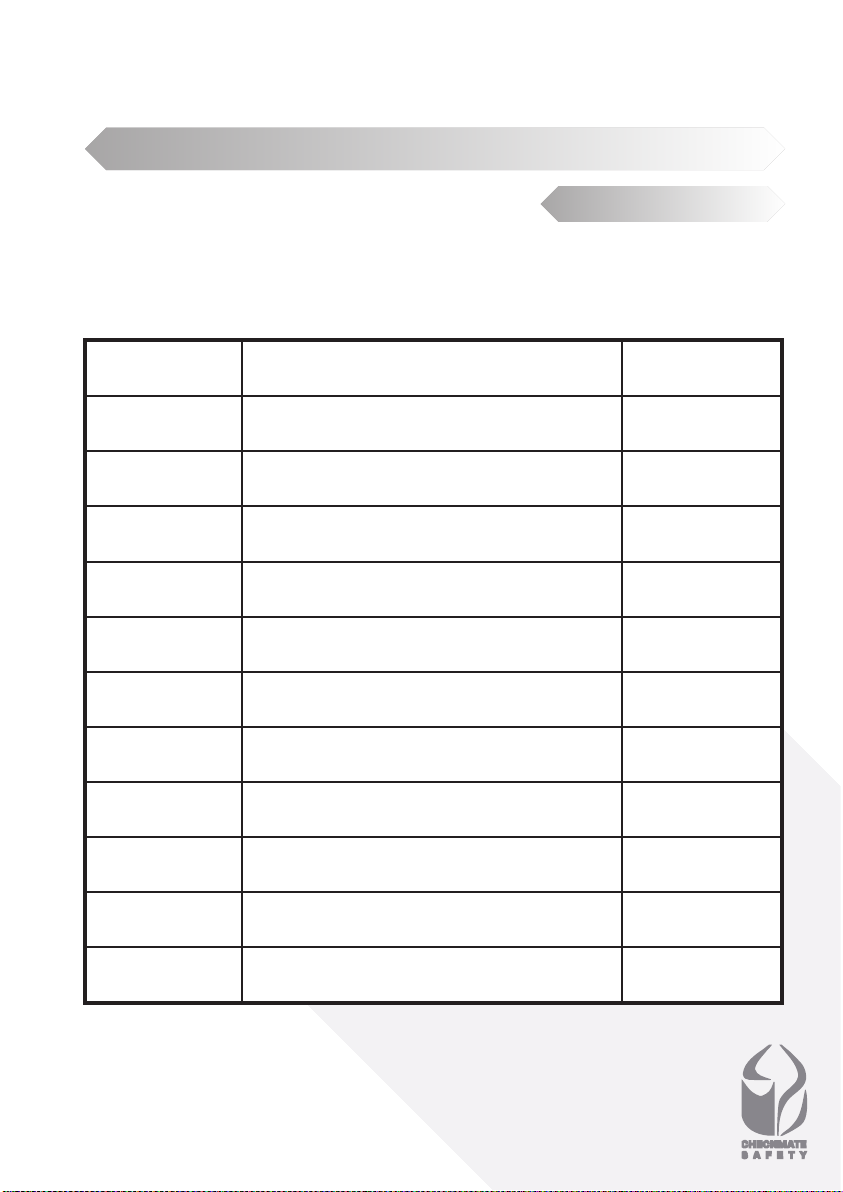

DATE:

DATE:

USER:

USER:

Record Card

Record Card

SERIAL NO:

SERIAL NO:

PRODUCT CODE:

PRODUCT CODE:

DATE

DATE CONDITION OF SYSTEM

CONDITION OF SYSTEM INSPECTED

INSPECTED

BY

BY

User Manual

Page 11

Issue 3

ecoAnch

ecoAnch2

2or

or®

Section 6.0

Section 6.0

Record Card (continued)

Record Card (continued)

DATE

DATE CONDITION OF SYSTEM

CONDITION OF SYSTEM INSPECTED BY

INSPECTED BY

Approved service company:

Checkmate Lifting & Safety LLP, Sheerness, Kent. England. ME12 1PZ, UK

Tel: +44 (0)1795 580333 Fax: +44 (0)1795 668280

[email protected] www.checkmateuk.com

Table of contents

Other Checkmate Safety Equipment manuals