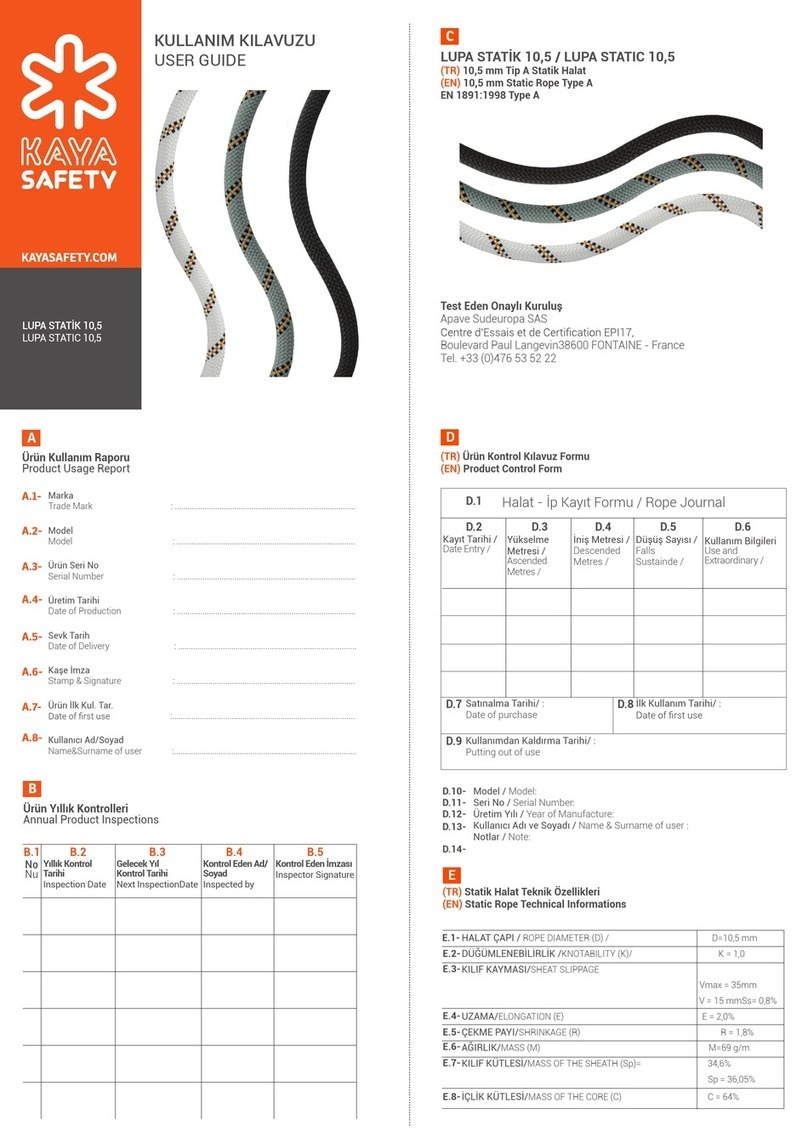

.........................................................................................................................................................................................................................................................................................................................................................................................................................................................

1- Usage Area

*Personal Protective Equipment (PPE)

*Vertical Lifeline System is a permanent system and can be installed on

a vertical ladder or similar structures

*Vertical Lifeline System provides users hands free fall protection on

ladders and other climbing tools by creating continuous access to suitable

anchorage points

* This system is not designed for weight-lifting purposes.

*Vertical Lifeline System is manufactured and certified in accordance with

2016/425 EU regulation and EN 353-1:2014+A1:2017 norm

*Operating Temperature for Lifeline and rope Grab is minimum -30°C

2- Responsibility

*Working at height is acknowledged as one of the most dangerous

activities that cause fatal accidents. Prior to use, the user must read and

understand the user guide and be properly trained by their employer prior

to use. Failure to follow all instructions and limitations on the use of the

Vertical Lifeline System may result in serious personal injury or death. The

guide should not be considered as any form of training.

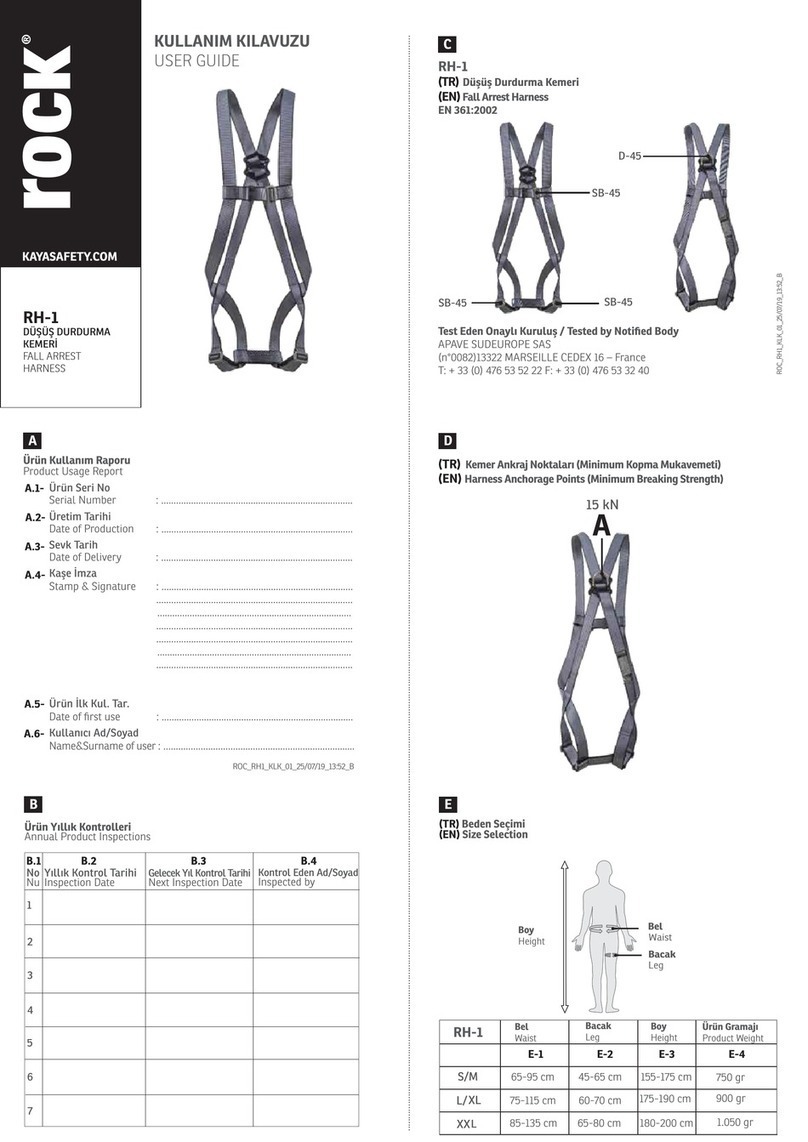

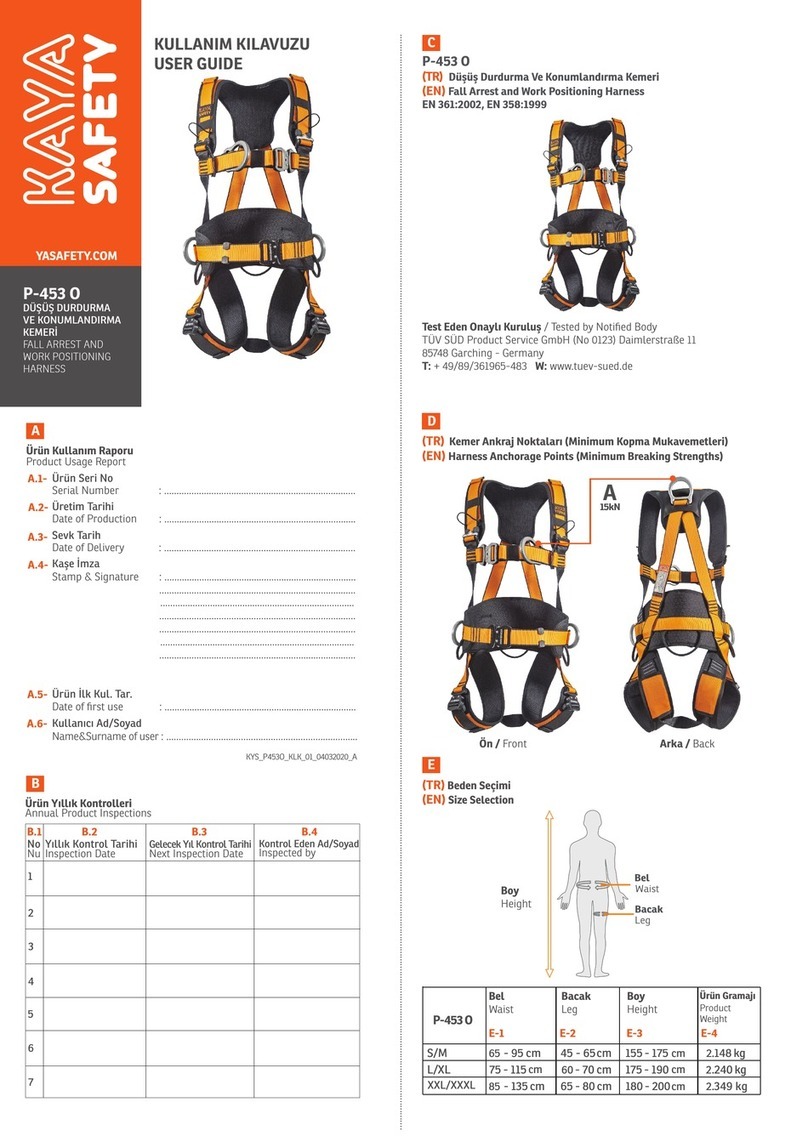

* A full body harness is the only acceptable body holding device that can be

used in a fall arrest system.

*The guided type fall arrester (Rope Grabe) should be connected to a

full body harness conforming to EN 361equipped with a front fall arrest

attachment point, including a clear statement on the required position of

the harness attachment point.

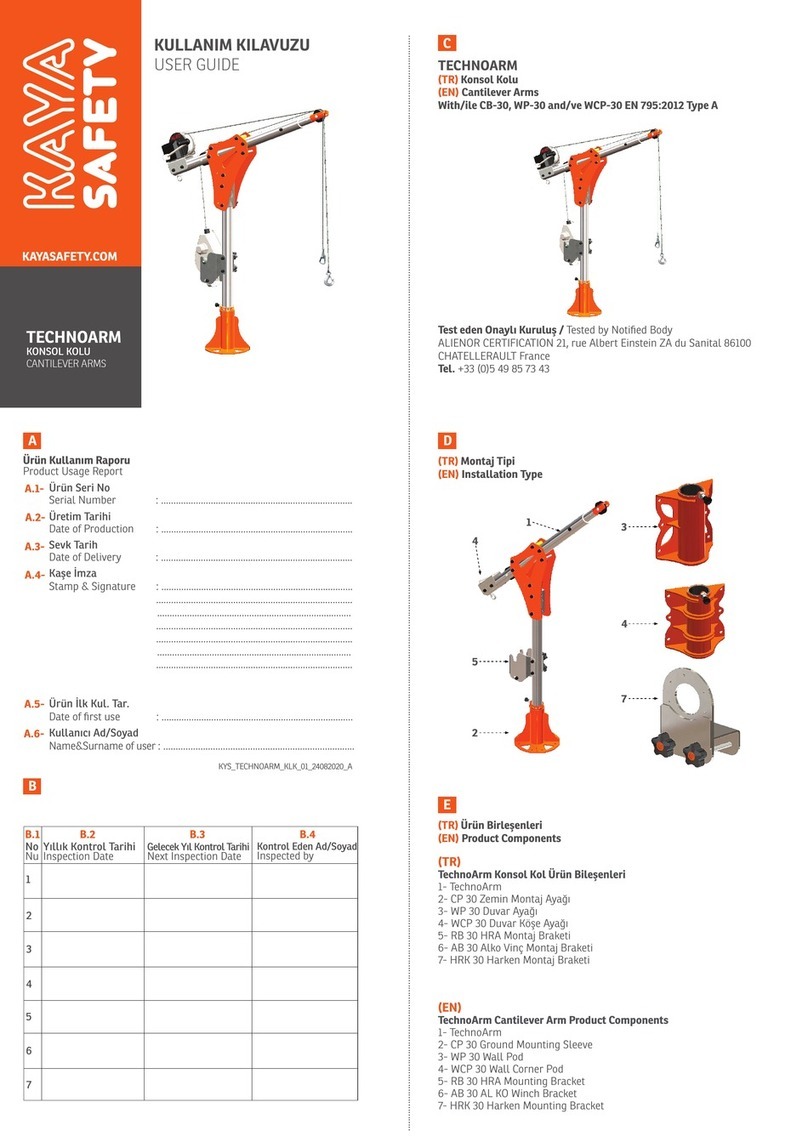

3. Installation

Vertical Lifeline System must be installed by competent persons who have

working at height training certificate and have been trained & authorized by

KAYA for installation. KAYA will not be liable for any installation performed

by unauthorized person. Please refer to installation manual for installation

instructions.

* Tested only on sideways angle at 15°.

* A full body harness is the only acceptable body holding device that can be

used in a fall arrest system

4- Product Usage (EN 353-1:2014+A1:2017)

*Vertical Lifeline System is designed for use only one user.

*If the system is planned to be used in areas where the environmental

hazards are concerned users must take extra precautions to prevent himself

from possible injuries or to protect equipment from damage. Environmental

hazards can be listed as high temperature caused by welding or metal

cutting, sea water, high voltage power lines, explosive or toxic gases, caustic

chemicals, moving machinery, and sharp edges

* The minimum load must be at 50kg without equipment.

* The maximum load must be at 150kg with equipment.

*System should not be used by users who’s total weight (including clothing,

tools, etc.) is less than 50 kg.

*Vertical lifeline has integrated energy absorber RA-50 S. Make sure that

RA-50 S energy aborber has not experienced any shock and it is in working

condition.If the system experienced a fall red colour indicator on the energy

abosrber appears. In this case system must not be used untill RA-50 S energy

absorberis replaced.RA-50 S energy absorber is replaced.

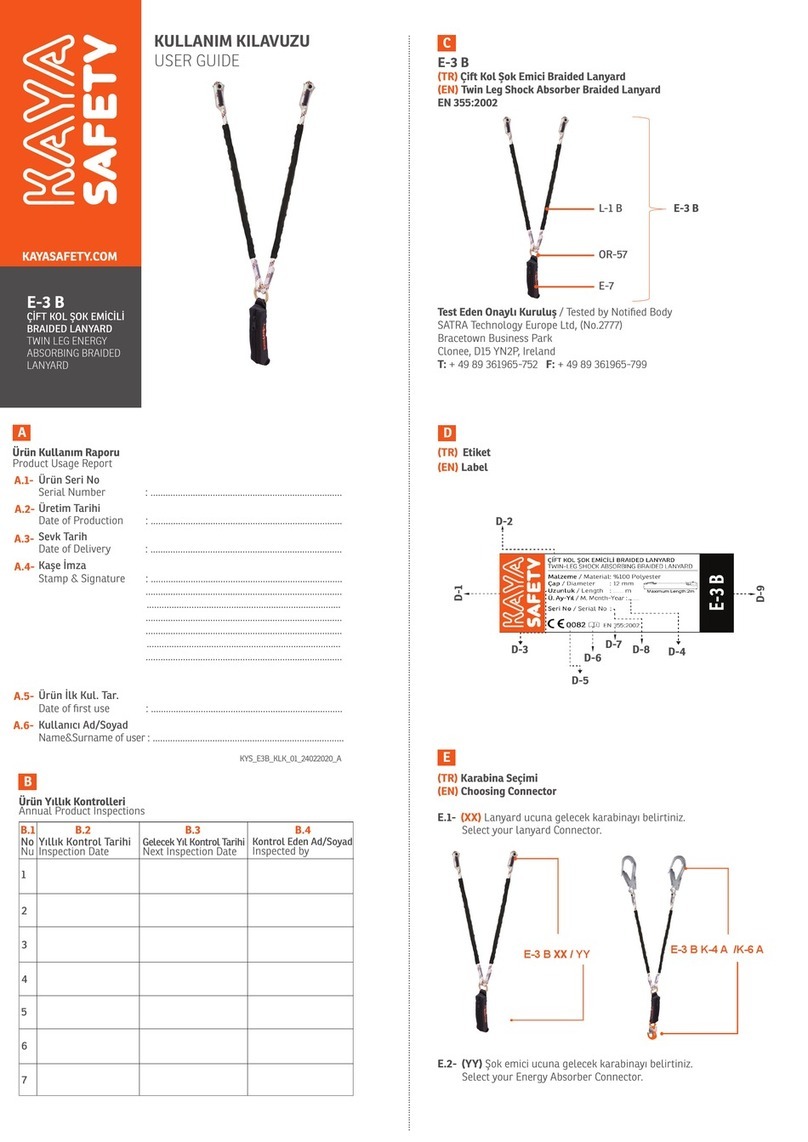

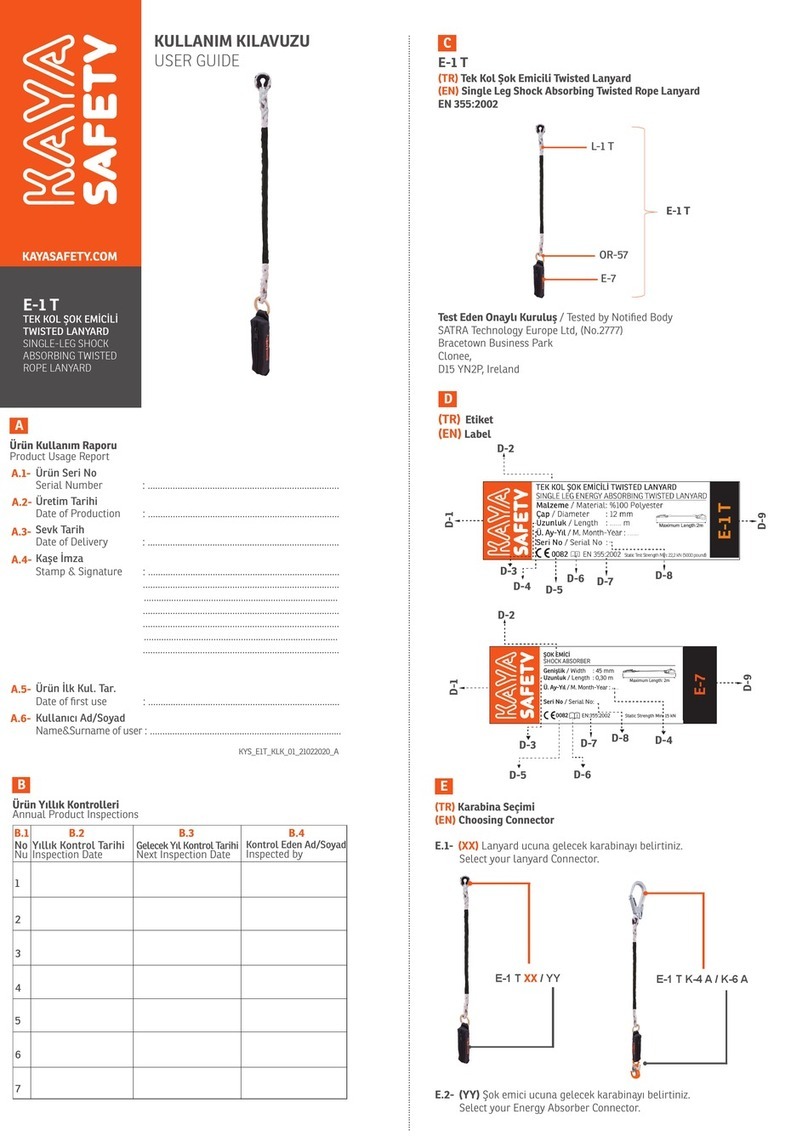

4.1 Connecting Rope Grab onto Full Body Harness

* A guided type F-5 Rope Grab (fall arrester) must be used when working on

the Vertical Lifeline

* F-5 fall arrester must be used with orginal K-2 /3ACP type carbine full

body harness should be connected to a full body harness conforming to EN

361equipped with a front fall arrest (A) attachment point, including a clear

statement on the required position of the harness attachment point

* Full body harnesses should be properly adjusted to fit the body before each

use.

* The full body harness should be properly adjusted to a snug fit and should

not be used if loose

* If the harness becomes loose during ascent or descent, it should be correctly

adjusted again to a secured position

* The length of the connecting element shall not be extended or shortened,

e.g. by adding or subtracting aconnector.

4.2 Installing Rope Grab

* K-2030 A Vertical life line have a shock absorber on the line and a F-5 fall

arrester should beused with this model

* F-5 fall arester as shown should be installed and removed on the line as

shown in Figure-1,

* The arrow on the rope grab must point upward.

* Rope Grab is a personal equipment and so it needs to be removed from the

system after each use. If it is left on the system, it may not work properly due

to environmental sources such as dust, dirt, oil, chemicals etc.

4.3 Climbing with Rope Grab

* To ascend with a F-5 Rope grab climb up the ladder normally. The

detachable rope grab will follow the user.

*Use caution when climbing. Avoid carrying tools or equipment that do not

allow your hands to be free for climbing. Ensure items are carried securely

to drop below.

*Climb within your ability. Long climbs may require several rest stops

during ascent or descent to avoid exhaustion.

*Avoid climbing in high winds or severe weather whenever possible.

*To descend, climb down smoothly in a normal position.

*Allow the detachable rope grab to lead the user down.

*Climbing down out of position (leaning back excessively) will cause the

detachable rope grab to lock on the cable. If the detachable rope grab

locks, move upward slightly to release, then continue down the ladder.

*When climbing is completed and the user is in a safe location remove the

carabiner from rope grab and remove the rope grab from the cable.

4.4 Fall Clearance

For equipment intended for use in fall arrest systems, it is essential for

safety to verify the free space required beneath the user at the workplace

before each occasion of use, so that, in the case of a fall, there will be no

collision with the ground or the other obstacle in the fall path.

*A minimum fall clearance of 2 meters is required between the user’s

feet and surface below. The user may not be protected against hitting

the ground or landing during the first 2 meters of ascent or 2 meters of

descent.(Figure-2)

*Use proper climbing procedures (e.g., maintain 3 points of contact with

hands and feet) when ascending or descending any portion of the ladder

unprotected by the system.

4.5 Work Positioning

* Rope Grab should not be used as work positioning purpose.

*If the work positioning is required on the system, additional relevant

equipment needs to be used such as WPL Work Positioning Lanyard.

*There are hazards associated with connecting and disconnecting from

the system. Use secondary fall arrest protection. Ensure adequate anchor

points, landing platforms, or other means are available at connection and

disconnection points to allow safe transitions to and from the system.

* Identify hazards in the work area that could cause injury to the user or

damage to the system, such as: high heat, electrical hazards, chemical

hazards, falling objects, or moving machinery.

5 General information on the EN 365 standard

5.2.1 Rescue Plan

*The user must have a rescue plan in place and the ability to implement

the plan and to communicate that plan to users, authorized persons, and

rescuers in the event of a fall.

5.2. 2 Anchorage Point

* Anchorages to which personal fall arrest equipment is attached should

always be placed above the position of the user and shall be capable of

supporting 12 kN (EN 795) per employee attached.

5.2.3 General Warnings

*Compatibility of different fall protection equipment must be considered as

it can result in a dangerous situation

*A verticcal life line and fall arrester is intended for use as a component in

a personal fall arrest system.

*There must be sufficient clearance below the user to arrest a fall before

the user collides wtih the ground or any other obstacle. Thus, the user

must check for enough free space on each use.

*The user must be medically fit condition to use the equipment

6. Control and Validation

6.1 Before each use:

All components of the Vertical Lifeline shall be inspected by the authorized

person or rescuer prior to each use. Additionally, annual inspections shall

be conducted by a factory authorized “competent person” other than the

user. Findings should be recorded in the “Inspection and Maintenance Log”

.Inspection must be performed based on following criterias;3

* All markings must be legible and attached to the product.

* All equipment must be free of corrosion, chemical attack, alteration,

excessive heating or wear.

* All hardware shall be free of cracks, sharp edges, deformation, corrosion,

or any evidence of defect or damage to.

* Cable must be inspected for kinks, broken strands, corrosion, abrasion, or

other signs of wear and damage.

* Energy absorber in line should be use.