Chengdu Hangfa Hydraulic Engineering Co., Ltd Compass Q2 User manual

Compass Q2

Four-wheel Omni-directionalRobotPlatform

User Manual V1.2

Chengdu HangfaHydraulicEngineering Co., Ltd

RobotDivision

Feb3rd,2017

1

Safety Warnings

Pleasedonot switch onpower fortherobot beforeyoureadand fully understand thisManual.

Pleasedonot plugordismountany partof therobot whentherobot ispoweredon.

Pleaseswitch themain power off if anyemergency happens.

Originalpoweradaptorshall beusedforcharge.

Therobot platformdoesnotfireprooforwaterproof,thereforepleasekeeprobot platformaway

from fireorwaterasfaraspossible.

Pleasekeepasafedistancefromrobot platform,forerrorsmightoccurwhetherontheprogram

itself orduringmanualoperation.

CopyrightStatement

HangfaCompanyownstheintellectualpropertyrights ofthisManual,and hardware&software

involved. Anyoneoranypartyshall not copy,plagiarize,discloseorreleaserelevantcontents in

any formwithoutwrittenauthorization of HangfaCompany.

2

CATALOGUE

1Description................................................................................................................................3

2Features....................................................................................................................................3

3GettoknowyourDiscovery Q2................................................................................................4

3.1 Exteriorstructure..........................................................................................................4

3.2 Interiorstructure...........................................................................................................5

4LetyourCompass Q2robot platformmove.............................................................................6

4.1 PositionParallelMovementDEMO...............................................................................7

4.2 Self-movementin PlaceDEMO.....................................................................................7

5SystemBrief Introduction.........................................................................................................8

5.1 TypicalResearch and Application Area.........................................................................8

5.2 Specification Parameters...............................................................................................8

6Mechanicalsystems..................................................................................................................9

6.1 Dimensions....................................................................................................................9

6.2 Main structure ..............................................................................................................9

6.3 Motor............................................................................................................................9

6.4 Omni wheel.................................................................................................................11

6.5 Rocker suspension.......................................................................................................11

6.6 Usersextension platform............................................................................................11

6.7 Thethreadhole...........................................................................................................11

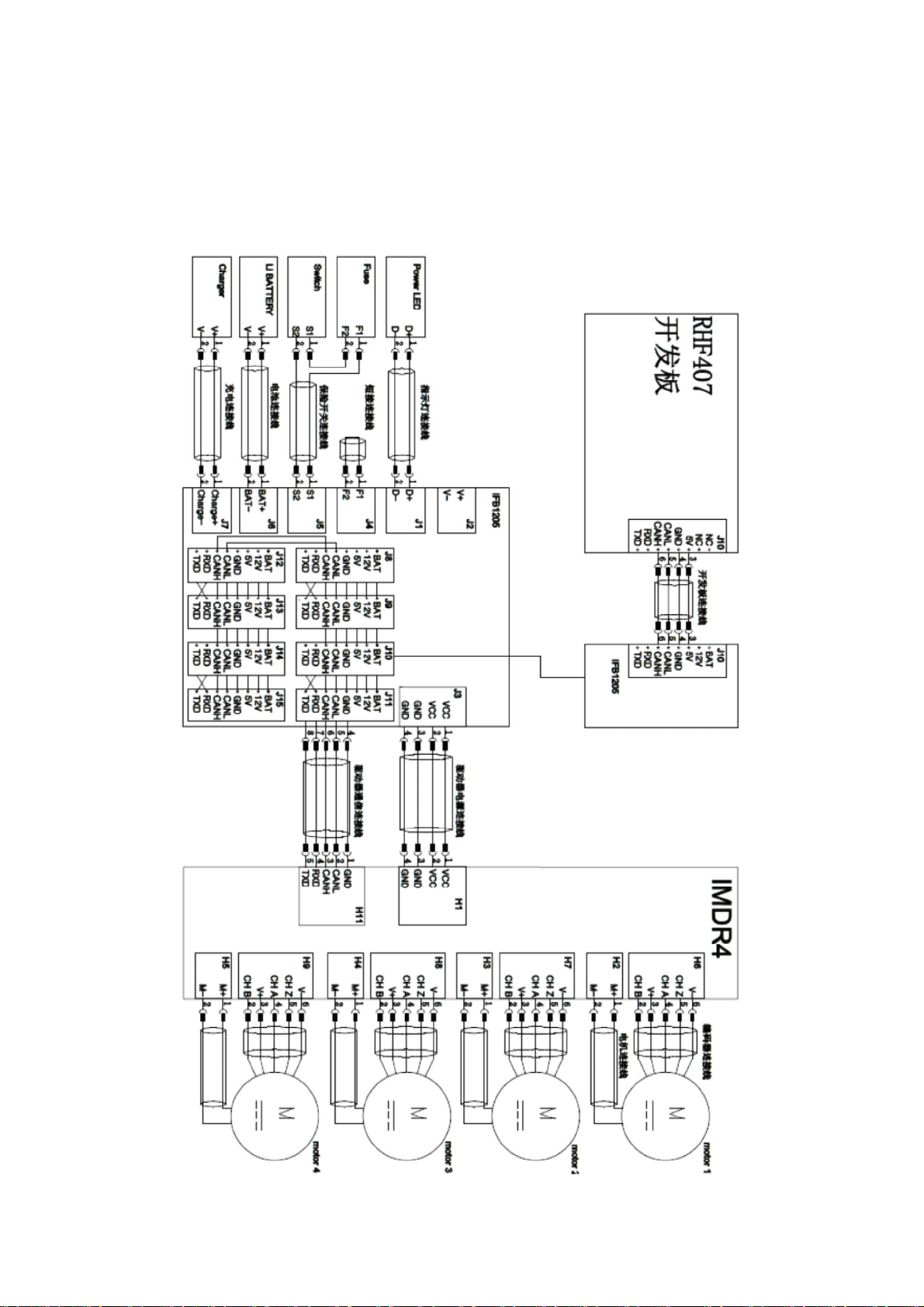

7Electric system........................................................................................................................12

7.1 Electricalprincipledrawing.........................................................................................12

7.2 IMDR4Fourshaftdriver..............................................................................................13

7.2.1 TheModuleoverview.....................................................................................13

7.2.2 Interfacedescription.......................................................................................13

7.3 IFB1205powerand busportmodule .........................................................................16

7.3.1 Modulesummary............................................................................................16

7.3.2 Portdescription...............................................................................................16

7.4 RHF407DevelopmentBoard......................................................................................19

8User Extend ..........................................................................................................................19

8.1 BusExtend...................................................................................................................19

8.2 RHF407Extend............................................................................................................19

8.3 DesignYourOwnMain Control Unit...........................................................................20

8.4 AccessoriesCanBeChoose.........................................................................................21

9PackingList..............................................................................................................................21

10TechnicalSupportand Quality Guarantee......................................................................21

3

1Description

Aseconomicalsmall robot platform,theCompass seriesareaimedatofferingacomplete,

multi-interfacedand highlyreliablemovingrobot systematthebestcost-performance.Compass

Q2issuch aplatformwithfourQMA-10Mecanum wheelswhich are madebyHangfaitself.

Comparedtothetraditionalones,thewheelsareabletomove laterally,rotate,orrotatewhen

move laterally.Therobot platformchassisismadebymold. Compass Q2isdrivenby4high

power coreless servomotorswith4-axisservodriver,and supports CAN busand RS232 serial

ports.SDKisprovidedtotheuserswithcompletecommunication protocol and thesamplesand

demonstration programssourcecodebasedontheSTM32F407,so thattheuserscould getit

startedassoonaspossible.

2Features

360degree free movement

With 4Mecanum wheels,therobot platformisabletomovein all directionshorizontally,and

rotatein thesametime.

Suspension system

Rockersuspension structureenablesthe4wheelstotouch theground and bedrivenevenly.

Thissuspension systemcanhelp reducingvibration whenpassingtheroughground.

Whollycasted chassis

Thisrobot chassisismadebymold withstrongstructure.Ourprocessingcenter keeps

thehighprecisefour-wheelrelativeposition Thischassisismuch stronger thanthewelded

chassiswhich iswithbigerrorand lowprecision.

PreciseMecanumwheel

Theclassic seriesQMA-10Mecanum wheelismadebyHangfawithindustrialgrade

quality.Each wheelroller iswithtwobearingwhich movessmoothly and steadily.

Coreless DC servomotor

The4coreless DC servomotorsrealizethehighpower density,hightorqueandquick

speedresponse.Themotoriswithpreciseplantgearboxand 500RMPencoder.

4-axis servodriver

Such driverenablesthemotortoperformagoodcharacteristic curve.Theusercould

control themotorspeedquickandaccurately,not affectedbythechangesin theloadingand

ground, so thattherobot performs accurately and reliably.

4

DEMOdevelopmentboard

With STM32F407asthecore,theRHF407developmentboardofferstheopensourceC#

programming languageSDK,toaid theuserstooperateontherobot.Highcomputing

performanceand multipleports enabletheusertocarryonitdifferentapplication and

development.

3Gettoknow yourDiscovery Q2

3.1 Exterior structure

1、wire hole

Wirefrom insideof therobot tooutside.

2、Bigcoverplate

3、Wireless receiver module

4、RHF407developmentboard

STM32F407 asthecoreofthedevelopmentboard,itofferstheusersdemonstration

programand application sourcecode.Forthedetails,pleasechecktheRHF407User

Manual.

5、Small cover plate

6、rechargersocket

Forrechargingthe robot;therechargingstateisindependentof powerswitch.

7、powerlight

Thatthelightison/off indicatestherobot ison/off.

8、powerfuse

Thefusewill blow outforprotection, in thecaseof shortcircuitorfalseoperation.

9、powerfuse

5

Thefusewill blow outforprotection, in thecaseof shortcircuitorfalseoperation.

10、Chassisbody

11、QMA-10 Mecanum wheel

3.2 Interior structure

1、PlantGearbox

2、Motor

3、Encoder

4、Driver

5、Lithium Battery

6、Power sourceandbusports modular

6

4LetyourCompass Q2 robotplatformmove.

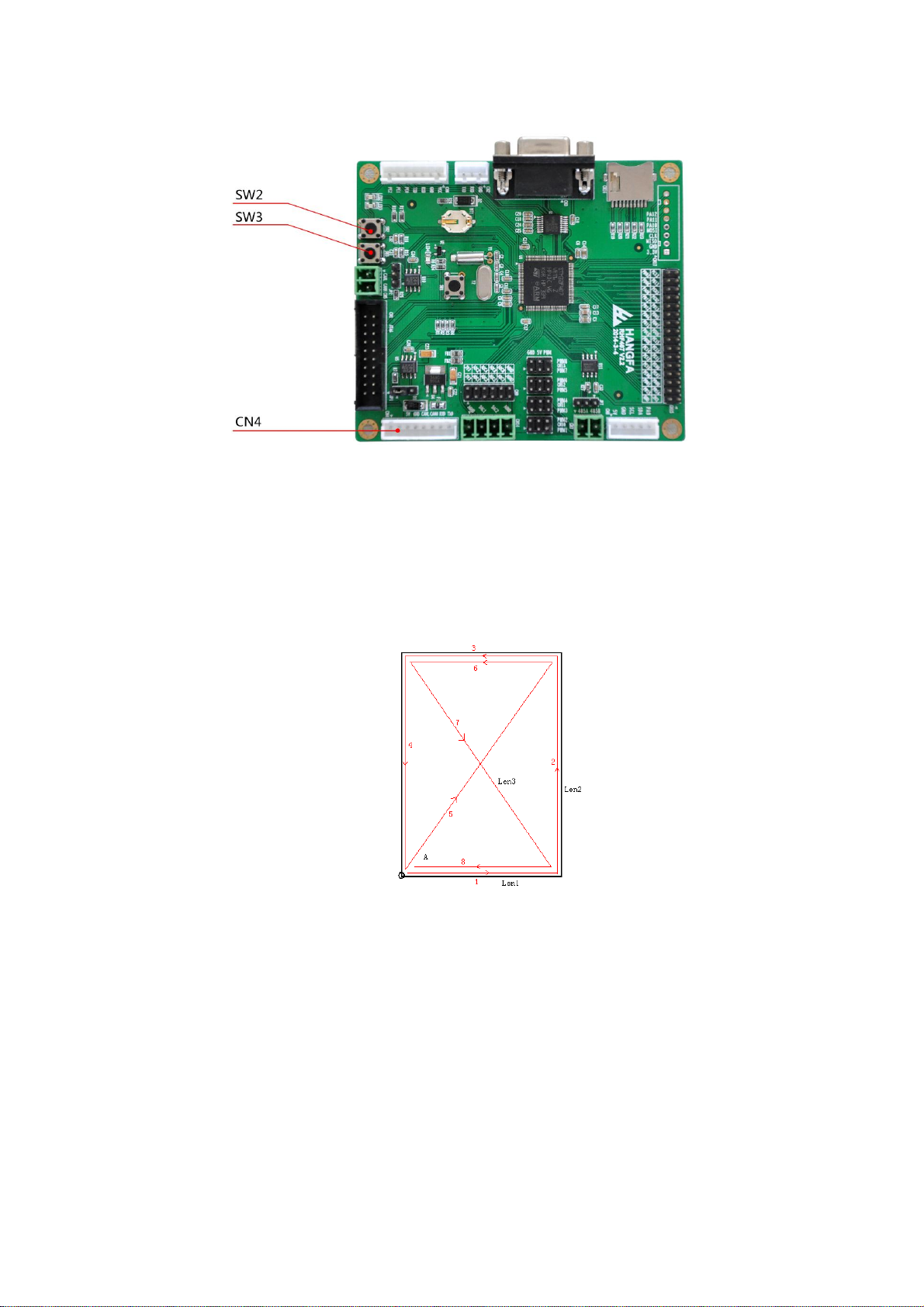

ByRHF407 developmentboard,discoveryQ2pre-buildstwodemonstration programs,

which demonstratetherobotparallelmovementfunction and self-movementfunction The

user canpushSW2andSW3buttonsonthedevelopmentboardtoachieveaction1and

action 2.Itisnecessary toinstall theRHF407develop boardontotherobot, connecttheCN4

porttoany 8pin plugof theIFB1205BIMby incidentalcable, and switch iton

Step1:Disassemblethetoppaneltocheckeach component.

Step2:Connectthebattery plugtotheJ6portof IFB1205board

Step3:Assemblethefuseand turnonthepowersourceswitch.

thepowerindicatorlightshould belightedup,Ifyoupushtherobot platformslightly,you

would feeltheself-lock dragforthtothemotorproducedby servodriver.

Step4:Connectonesideofthesinglegraycablebusin thecasetoany8PINplugof

IFB1205board,and theothersidetotheRHF407boardfrom thetoppanelthread

hole.

Step5:FixtheRHF407 boardonthesetpositionandfixthetoppanelontherobot.Then

connectthegraycablesidewhich isoutofthethreadholetotheCN4portof

RHF407board.

Step6:Positiontherobot ontothevacantflatsurfaceand turnonthepowerswitch. After

that,theLED1ontheRHF407boardwill twinkle.ThenseparatelyclicktheSW2

and SW3buttonontheRHF407boardtomaketwodemonstration movement

programs operate.

IFB1205PowerSourceandBIM

7

RHF407DevelopmentBoard

4.1 Position Parallel Movement DEMO

Click theRHF407SW2button,therobot will makea parallelmovementaccordingto theroute

of thebelowrectangle.Therectanglewidthis0.8m,lengthis1.6m.

4.2 Self-movement in Place DEMO

Click theRHF407SW3button,therobot will makeself-movementin placefor20 seconds.

8

5System Brief Introduction

5.1 Typical Research and Application Area

Research onpatternrecognition technology Electronic EngineeringExperiment

Research onPathPlanningTechnology Mechanicalengineeringexperiment

Research onautomatic drivingtechnology Embeddedsystemdevelopmentand experiment

Research onsensortechnology Research onimageprocessingtechnology

Research onartificialintelligencetechnology Research onmultirobot cooperation technology

Handlingand storageapplications Maprenderingapplication

Monitoringand investigation application Application of flexiblemanufacturingsystem

Robot competition

5.2 Specification Parameters

Table1.Compass Q2SpecificationParameters

Body structure: Aluminum Alloy MoldingWholeShape

Dimension: 450 330 115mm

Drivenwheel: QMA-10 Omni wheel

Diameterof drivingwheel: 101.6mm

Drivenmode: four-wheelindependentdrive

Suspend kind rockerarmsuspension

Minimum spacebetweenrobot toground: 22.5mm

Ratedloadcapacity: 20kg

Maximum translationalspeed: 0.75m/s

Maximum rotation speed: 215°/s

Adaptive ground indoor, bituminousground ,concreteground

withlittledepression

Typicalduration time 10h(loadcapacity10KG,movingspeed

Standby time >30h

Chargingtime4h

Supportelectricity output 5V@2.5A

12V@2.5A

(22~29.2V)@>5A

Battery output24V

Battery capacity7.8Ah

Battery lithium-ion battery

Battery fastchange: Support

Chargerinputvoltage AC100V~240V

Interface directplug-in

Chargingcurrent: 3A

Thedefaultspecification of Thepowerof 5×20/10A

9

insurancetube:

DEMO developmentboardmodel STM32F407

6Mechanical systems

6.1 Dimensions

6.2 Main structure

Compass Q2ismadeby aluminum alloy castingprocess, thebottom and theinsidewitha

protrudingribs, supportear,which will reducetheconnection of platform, so itwill makefull

useof thematerialproperties.Themain structureisone-timeproducingwhich makesitwith

highstrengthand highrigidity;itavoidstheshortcomings such aspoorprecision, poor

integration errorand poorrigidity of theassembly of thesteelplate.

6.3 Motor

Compass Q2usesHFmotor-3230motor.Testparameters:

Ratedvoltage:24V

Ratedcurrent: 1.45A

Ratedoutputpower: 31W

Noloadrotatingspeed:6450rpm

Ratedrotatingspeed:5230rpm

Reduction ratio:24:1

Encoder :500line/rev,A、Bphaseoutput

Encoder ratedvoltage:5V

10

11

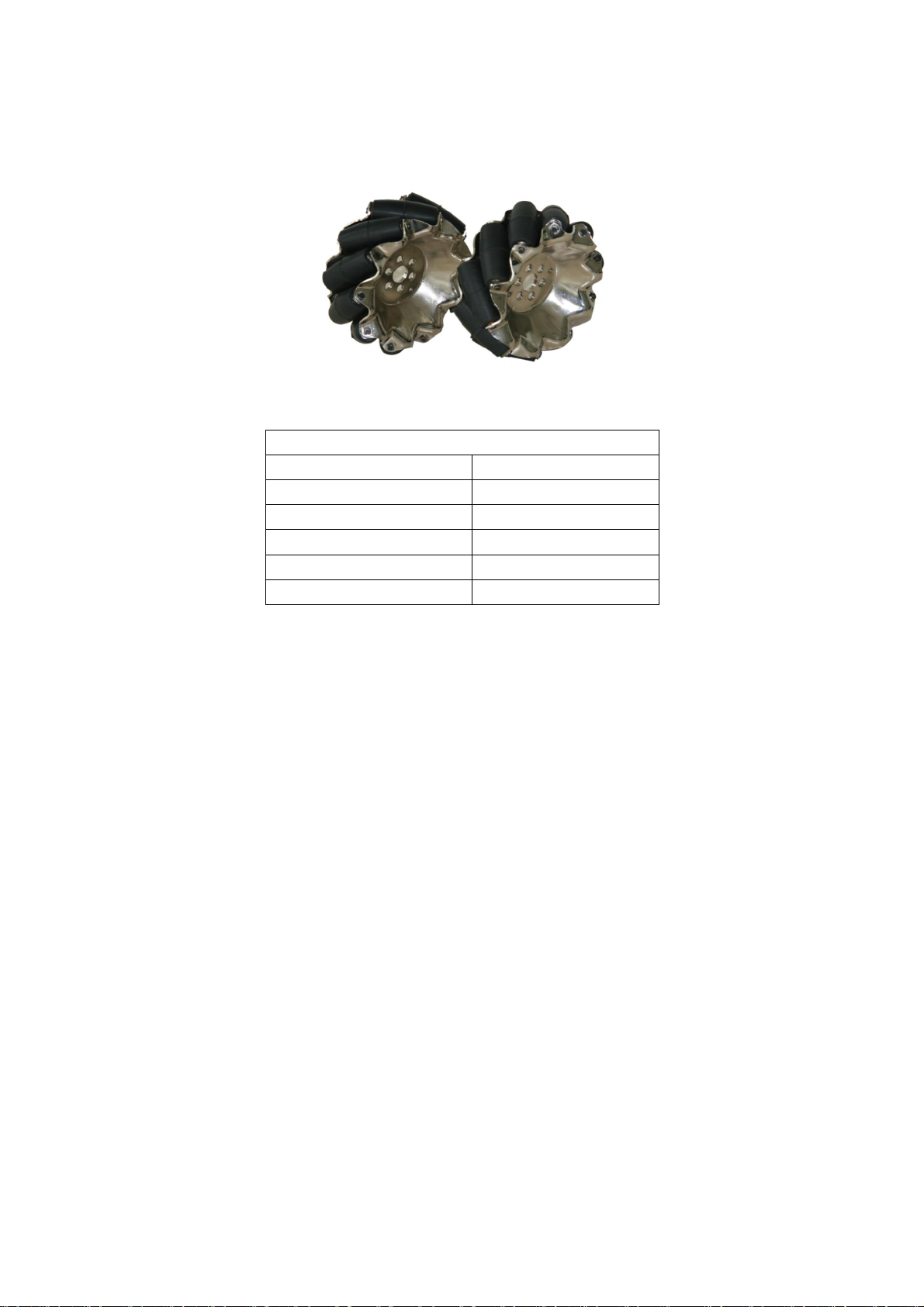

6.4

Omni wheel

Table2Themainparameter ofQMA-10 Omniwheel

Hangfa IndustrialQMA-10Omni wheel

Diameter101.6mm

wide45.7mm

Roller number10

Bearingnumber20

Hub materials steel

Loadcapacity 30kg

6.5

Rocker suspension

Rockersuspension structureenablesthe4wheelstotouch theground andbedrivenevenly.This

suspension systemcanhelp reducingvibration whenpassingtheroughground. ThePolyurethane

shockabsorberhelpsreducingvibration whentheplatformismoving.In thisway,theworking

environmentof theaddedequipmentwould beimproved.

6.6

Users extension platform

Theplateontherobot ismadeofonebigboardandonesmall board. There ispowersource

switch onthesmall board, pleasedonot disassembleit.Thebigboardisforuser toextend. Users

canadd other equipmentandstructuretothisboardasrequired.

6.7

The thread hole

Thereare manythreadholesontheplatewithrubberring.Theholeisforconnection ofthread

outsideoftherobot and insideoftherobot.Thehalf-openedthreadringonlyrequiresthe

threadtobepushedtothethreadring, noneedtocross theplate.

12

7Electricsystem

7.1

Electrical principle drawing

13

7.2 IMDR4 Four shaft driver

7.2.1 TheModuleoverview

Thismoduleisusedtodrivethefourdc servomotorsand provideaccuratespeedclosed-loop

control.Italso integratesmotioncontrol algorithm ofthefouromnidirectionalwheels.Userscan

realizetheoverall chassismotioncontrol ordirectlyforeach motormotion control throughthe

communicationsvia CAN busand RS232interface.

Formoredetails,pleasecheck IMDR4fourshaftdriverCancommunication protocol, and MDR4

fourshaftdriveUART communication protocol .

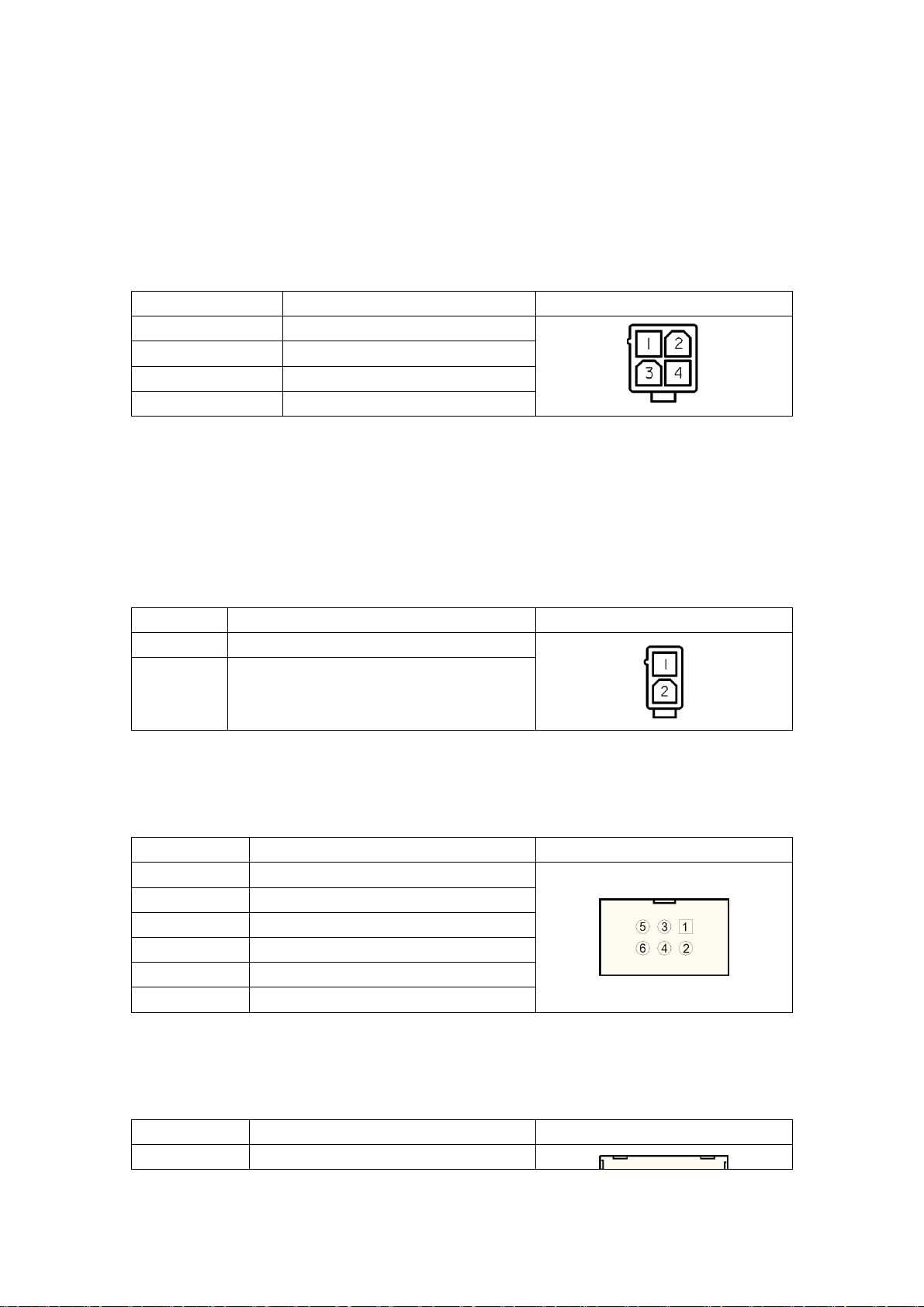

7.2.2 Interfacedescription

7.2.2.1 Interface summary

Table3 IMDR4 Interfacesummary

Interface

serial

number

Description Remark

H1 Power input

H2 Motor1powerinterface

H3 Motor2powerinterface

H4 Motor3powerinterface

H5 Motor4powerinterface

H6 Motor1encoder interface

H7 Motor2encoder interface

H8 Motor3encoder interface

H9 Motor4encoder interface

H11 RS232、CAN businterface

JP2 CAN bus120Ωresistancejump line

14

7.2.2.2 H1,Main power input port.

Table4 IMDR4 mainpower inputport

PinNo.Description note

1 GND

2 GND

3 VCC

4 VCC

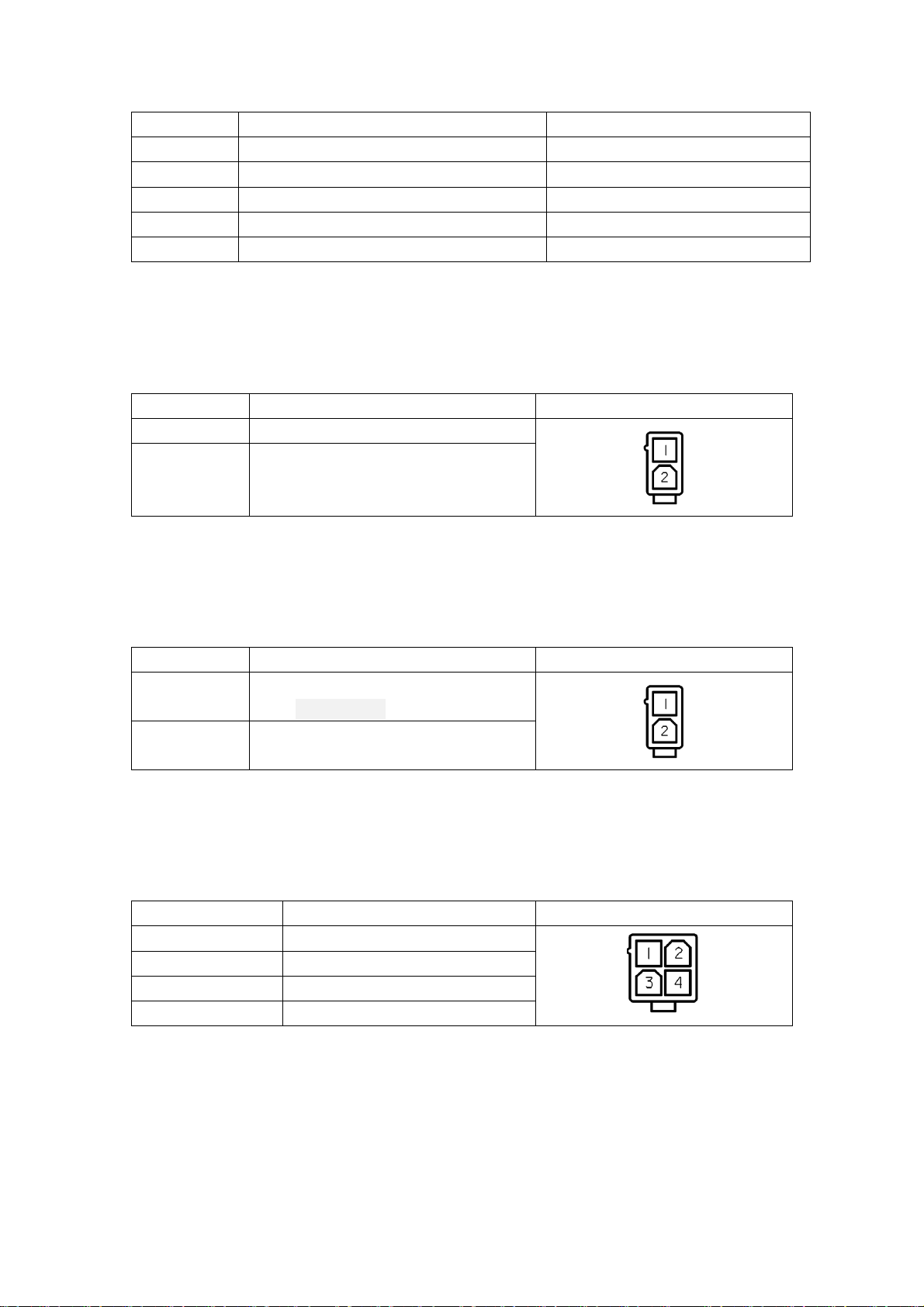

7.2.2.3 H2、H3、H4、H5, Motor 1、Motor 2、Motor 3、Motor 4power input

Table5 IMDR4 motor1,2,3,4 Power interface

PinNo. Description note

1 M+,Motor+

2 M-,Motor+

7.2.2.4 H6、H7、H8、H9,Motor 1、Motor2、Motor3 、Motor4 encoderinterface

Table6 IMDR4 motor1、2、3、4 encoder port

PINnumber

description remark

1 NC

2 CHB

3 5V

4 CHA

5 NC

6 GND

7.2.2.5 H11, communication port

Table7IMDR4 motor1、2、3、4 communicationport

PINnumber

description remark

1 GND

15

2 CANL

3 CANH

4 RXD

5 TXD

16

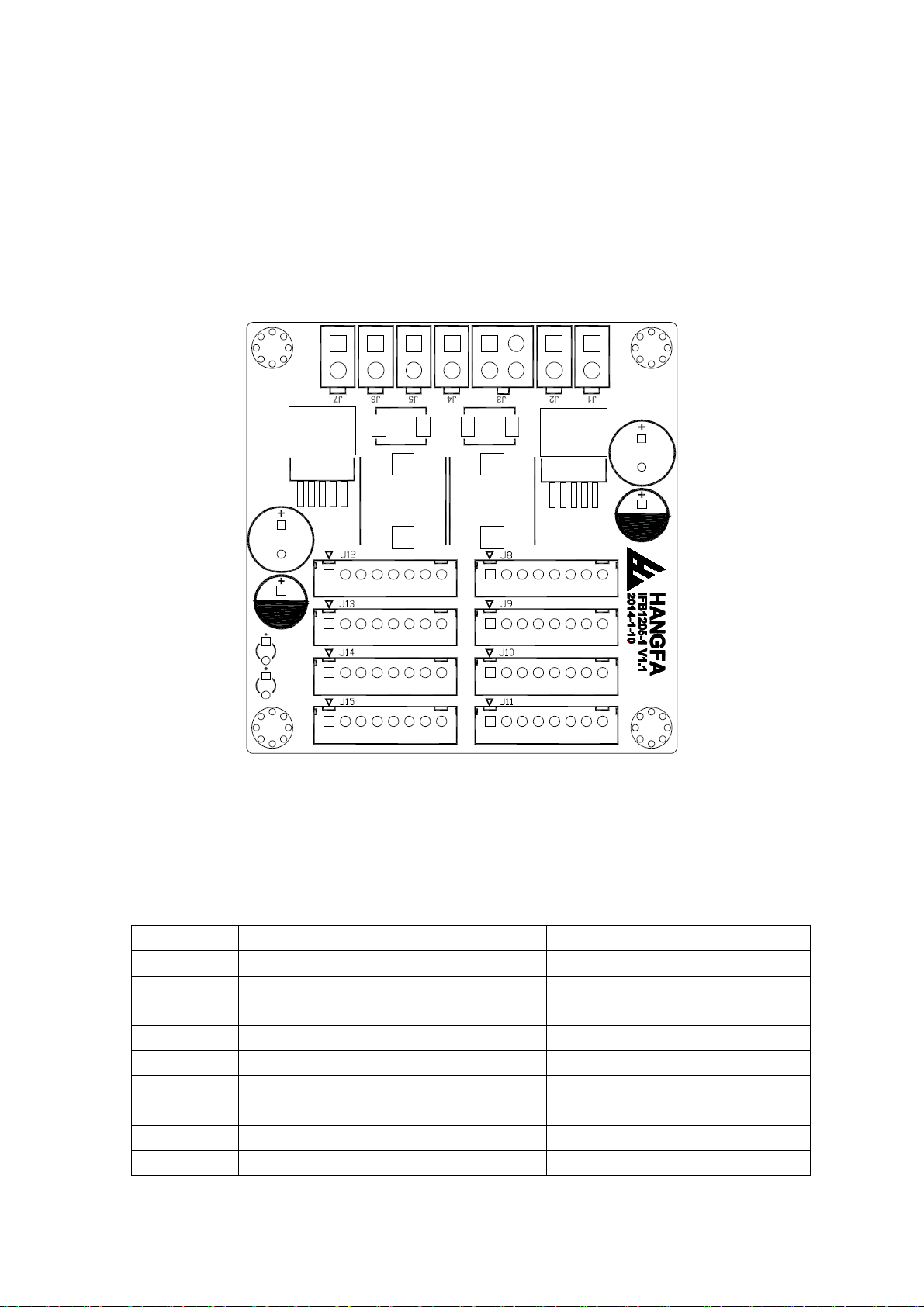

7.3 IFB1205power and busport module

7.3.1 Modulesummary

Thismoduleisusedforpower supplyand line-concentratingofcomponentand

equipment.Supplybatterypowerandtwowaystep-downpowerstousers’equipment.

Themodule output eightwaypowerportand busport,theusers’canuseelectricityand

communication network easily fortheequipmentthroughtheseport.

7.3.2 Port description

7.3.2.1 Port summary

Table8 IFB1205 port summary

Portnumber

Description Remark

J1 Indicatorlightaccess port

J2 user chargeport

J3 IFB1205 poweroutputport UsedforconnectIMDR4drive

J4 Fuseaccess port

J5 powermain switch port

J6 battery access port

J7 Chargeraccess port

J8 Standardpower andbusport J8、J9port’s5、6pin cross connect

J9 Standardpower andbusport

17

J10 Standardpower andbusport J10、J11port’s5、6pin crossconnect

J11 Standardpower andbusport

J12 Standardpower andbusport J12、J13port’s5、6pin crossconnect

J13 Standardpower andbusport

J14 Standardpower andbusport J14、J15port’s5、6pin crossconnect

J15 Standardpower andbusport

7.3.2.2 J1, Indicatorlight access port

Table9IFB1205 Indicatorlight access port

PINnumber

Description Remark

1 D+

2 GND

7.3.2.3 J2, userchargeport

Table10IFB1205 user charge port

PINnumber

Description Remark

1 24V/BAT,voltagechangedalong

with batteryanode

2 GND

7.3.2.4 J3, batterypoweroutput

Table11 IFB1205 batterypower output port

PINnumber Description Remark

1 GND

2 GND

3 24V/BAT

4 24V/BAT

18

7.3.2.5 J4,Fuse Port

Table12.Ifb1205 FuseAccess Port

PIN

number Description Remark

1 F1,FusePIN1

2 F2,FusePIN2

7.3.2.6 J5,Power Main Switch Port

Table13. Ifb1205 Power MainSwitch Port

Pin

number Description Remark

1 S1,Switch PIN1

2 S2,Switch PIN2

7.3.2.7 J6,Battery Access Port

Table14. Ifb1205 BatteryAccess Port

Pin

number Description Remark

1 BAT+

2 BAT-

7.3.2.8 J7,Charger Access Port

Table15. Ifb1205 Charger Access Port

Pin Description Remark

19

number

1 Charge+

2 Charge-

7.3.2.9 J8~J15,Standard Bus Port

Table16.Ifb1205 StandardPower Bus Port

Pin

number Description Remark

1 24V/BAT

2 12V

3 5V

4 GND

5 CANL

6 CANH

7 RXD

8 TXD

7.4 RHF 407 Development Board

Pleasecheck “RHF407usermanual”.

8User Extend

Hardwarein the robot canbeextendingthroughmanyways:

8.1 Bus Extend

Theequipmentwhichhave CANbusportcanaccess busthrough8PINstandard

ports ontheIFB1205board, and realizeequipmentconnection. Meanwhile,itcanrealize

connecttwoeach other which haveRS232portthrough8PINstandardports onthe

IFB1205board.

8.2 RHF407 Extend

TheRHF407developmentboardhaslots ofsource,itcanaccess variousequipment.

Followingsource:CAN×2,RS232×2,TTL*1,RS485×1,SPI×1,I2C×1,ADC×8,

DAC×2,PWM×8,LED×2,button×2,independenceI/O×24,repeatuseI/O×29, TF

cardport×1,RTC spare battery,RepeatuseTFTLCD port×1.

Table of contents