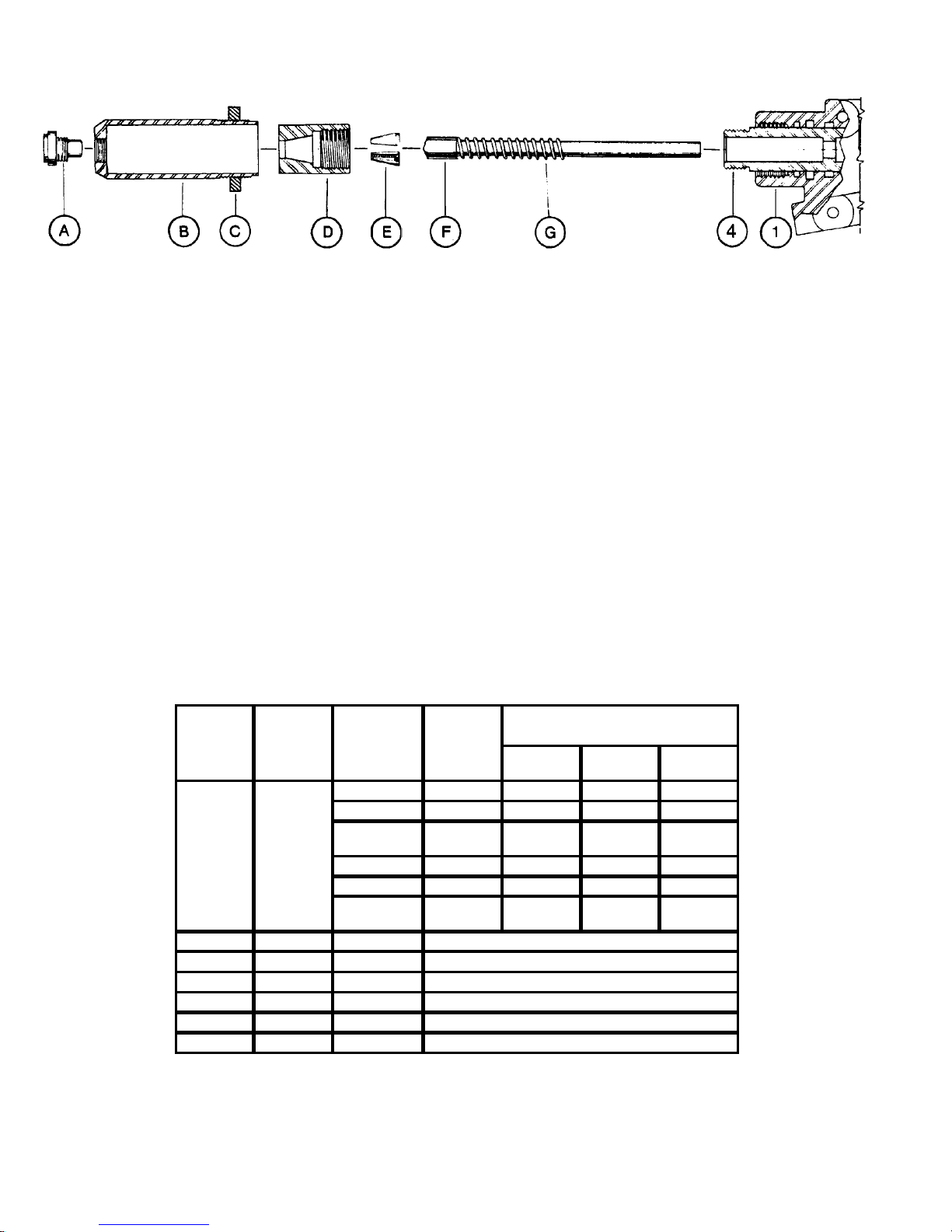

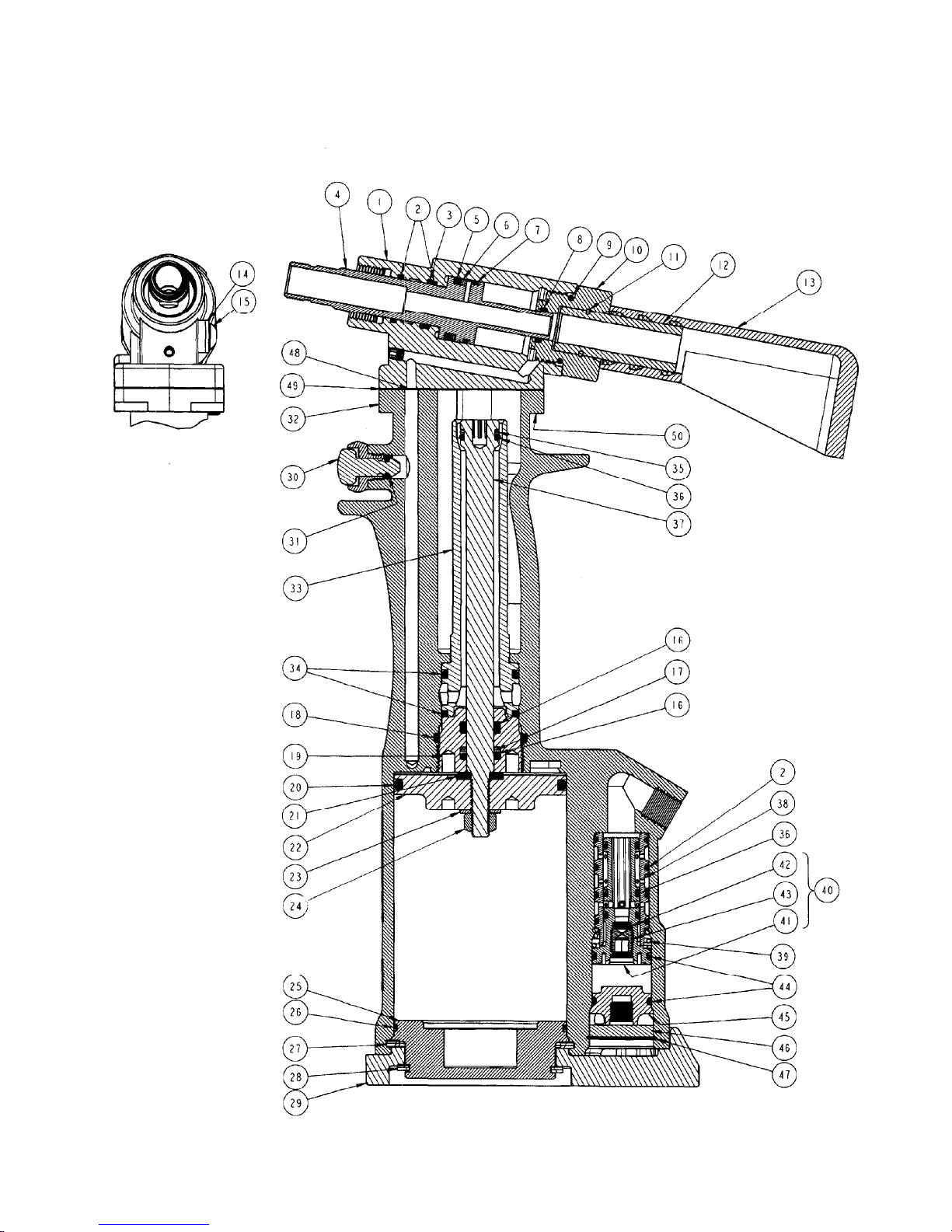

PART LIST FOR THE GH-702A RIVETER ASSEMBLY

"Not furnished with riveter. Must be ordered separately if desired.

**No substitutions.

***These parts can not be ordered separately, but must be ordered as a sub-assembly.

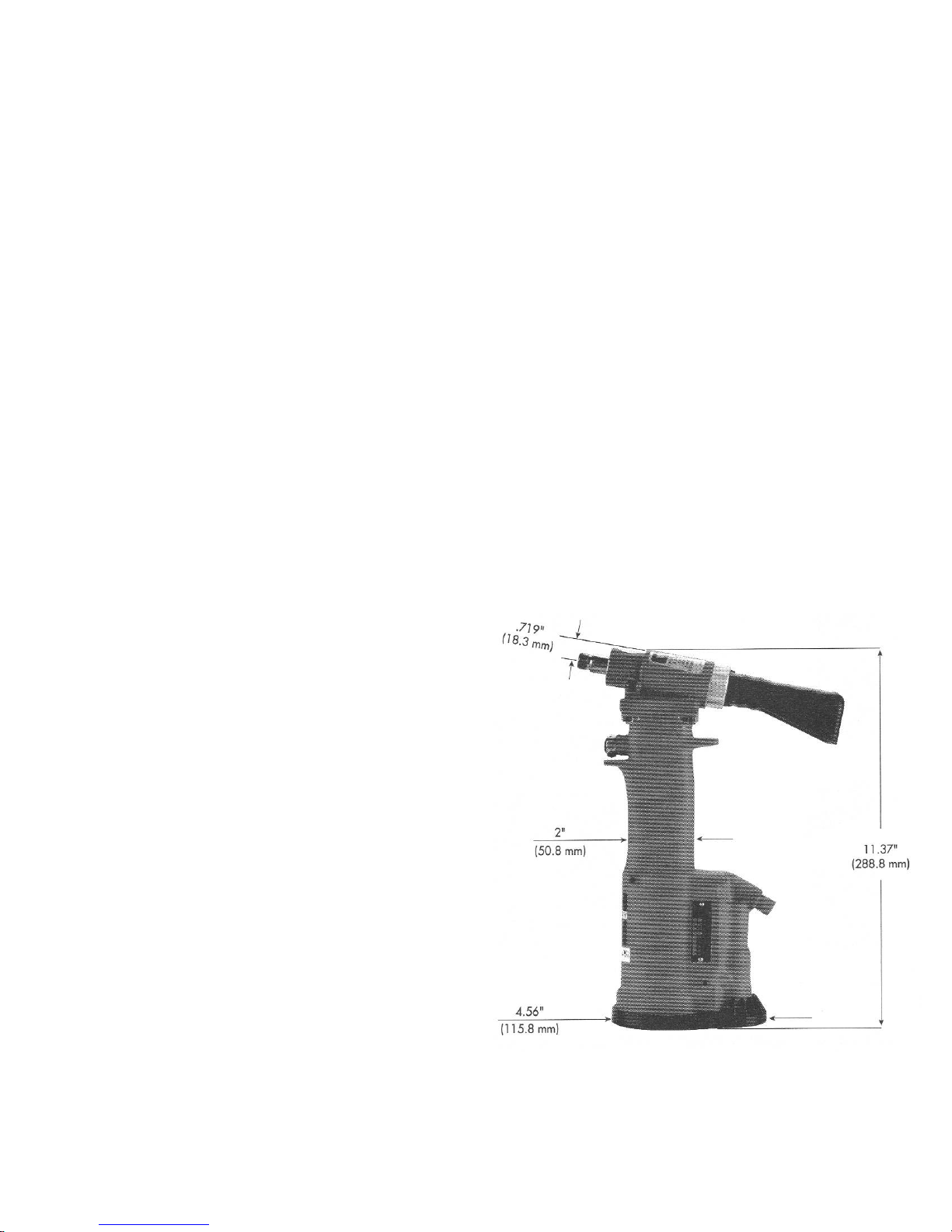

All dimensions are in inches.

QTY.

11

26

31

41

51

61

71

81

91

10 1

11 1

12 1

13 1

14 1

15 1

16 2

17 2

18 1

19 1

20 1

21 1

22 1

23 1

24 1

25 1

26 1

27 1

28 1

29 1

30 1

31 P-223 O-RING (.285, .145, .070) 1

32 1

33 1

34 2

35 1

36 4

37 1

38 1

39 1

40 1

41 SPOOL, VALVE*** 1

42 FILTER*** 1

43 SCREW, METERING*** 1

44 2

45 1

46 1

47 1

48 1

49 1

50 4

51 ASSEMBLY, MANDREL CATCHER BAG* 1

52 1

702-054 (G702A RIVER ASSEMBLY)

702B15 SUB-ASSEMBLY, HEAD

702C2 SUB -ASSEMBLY, HEAD CYCLINDER

P-653 O-RING (.691, .551, .070)

P-883 RING, BACK-UP (.686, .580, .053)

702B16 PISTON, HEAD

P-216 RING, QUAD (.880, .674, .103)

P-209 RING, BACK-UP (.864, .688, .088)

P-654 O-RING (.879, .739, .070)

P-112 0-RING (.504, .364, .070)

P-848 O-RING (.941, .801..070)

702B17 CAP

P-880 RING, RETAINING (NON-STANDARD)

703A13 FITTING, DEFLECTOR

530A16 DEFLECTOR, PIN

P-572 STAT-O-SEAL (.430, .180, .125)

P-573 SCREW, BUTTON HEAD SOC., 10-32 X 1/4

702-053 SUB-ASSEMBLY, HANDLE

P-838 O-RING (.568, .362_1 03)**

P-115 RING, BACK-UP (.551, .375, .088)

P-727 O-RING (1.318, 1.112, .103)

700B93 PLUG, PACKING

P-893 O-RING (2.387, 2.109, .139)

700A21 WASHER

747-013 PISTON, AIR

P-1387 WASHER, STEEL

P-737 NUT, CONEL K, 1/4-20

747-015 BASE, HANDLE

P-894 O-RING (2.254, 2.114, .070)

P-895 RING, RETAINING (INT. Ø 2.440)

P-1386 RING, RETAINING (EXT. Ø 2.062)

747-011 COVER, URETHANE BASE

703A33 SUB-ASSEMBLY, TRIGGER

747-018 HANDLE

747-019 CYLINDER, POWER

P-833 O-RING, DISOGRIN (1.068, .862, .103)

P-919 RING, BACK-UP (.528, .422, .053)

P-829 O-RING, DISOGRIN (.504, .364, .070)**

747-017 PISTON, POWER

700B73 SLEEVE, VALVE

700A67 SPRING

700A15 SUB-ASSEMBLY, VALVE SPOOL

700D15-2

700A18

700A69

P-834 O-RING (.816 .676, .070)**

700A16 PLUG, VALVE

GASKET

700A17 MUFFLER

P-279 RING, RETAINING (INT. Ø .906)

HOSE

PART NO. DESCRIPTION

670-037-1

P-948

P-27 SCREW, SOC. HD. CAP, 8/32 X 1/2

P-832 O-RING (.379, .239, .070)**

702A22

9