Sollatek FreoCom FCA 3 Series User manual

A3 CMYK

Important: This manual contains important safety instructions. Before using this product please read

all instructions carefully. Keep this manual handy for reference.

FCAx3

Advanced Electronic Temperature Controller With Energy

Saving, Defrost, and Plug-in Connectivity Options

USER MANUAL

FCAx3 USER MANUAL

A3+ CMYK

2+44 (1753) 214 500

Please read the following warnings to maintain the safe function and continued performance of your Sollatek

device.

INSTALLATION

The mounting of the unit must be in accordance with orientation as specied in this manual. The device must only be installed

and congured by trained and authorized staff.

TEMPERATURE

The Sollatek device must only be subjected to temperatures as specied in this manual.

VIBRATION AND IMPACT

The device MUST be installed in such a way as to be protected from impact in operation. Do not hit or drop the device.

NO SERVICEABLE PARTS

There are no serviceable parts inside the device. Do NOT open the housing.

VOLTAGES

The Sollatek device must only be connected to power supplies that comply with the acceptable voltage ranges as specied in

this manual.

VOLTAGE FLUCTUATIONS AND SURGES

The Sollatek device has surge protection as specied in this manual. Exposure to surge voltages outside these limits, or

excessively repeated surges within the limits may cause damage to the electrical circuits.

CURRENTS

Outputs should not be connected to short circuits or to loads that exceed the currents as specied in this manual. Care must be

taken to ensure that cables and terminations are safely terminated.

SEGREGATION OF POWER AND SIGNAL CABLING

Correct segregation of power and signal cabling must be followed. Do not run power and signal cables together in the same

conduit. Induction from power cables may corrupt data signals, leading to incorrect operation.

CONSEQUENTIAL FAILURES

The Sollatek device includes features to protect both itself and connected components. However, failure of connected

components may cause damage to the controller and/or connected components. Critical or vulnerable components should be

protected independently against failure.

FIT FOR PURPOSE

The Sollatek device must only be used for the purpose and functions described in this manual. As each application requires a

different conguration and setup, no liability is accepted by Sollatek UK Ltd for the correct operation of the nal equipment.

Failure to comply with the warnings may result in the device becoming damaged leading to

premature failure or unsafe operation. In extreme cases failure to comply may cause a risk

of electrocution or re.

FCAx3 USER MANUAL sollateksupport@sollatek.com3

A3+ CMYK

SAFETY PRECAUTIONS

Precautions should be taken when installing or disconnecting the device. Isolate the power supply

before installation or servicing.

Trained and Authorised personnel only should install/service this equipment.

THE DANGERS OF ELECTRICITY

Harm can be caused to any person when they are exposed to ‘live parts’ that are either touched directly or indirectly by means

of some conducting object or material. Voltages over 50 volts AC or 120 volts DC are considered hazardous.

Most electrical accidents occur because of individuals:

1. Are working on or near equipment, which is thought to be dead, but which is, in fact, live.

2. Are working on or near equipment, which is known to be live, but where those involved are without adequate training or

appropriate equipment, or they have not taken adequate precautions.

3. Misuse of equipment or use of electrical equipment which they know to be faulty.

REDUCING THE RISK OF ELECTRIC SHOCK

To reduce the risk of electric shock:

1. Install the device in an area free of conductive contaminants. The ambient temperature must not exceed 60°C.

2. Isolate the power to the device before installation, repair, or removal.

3. Use tools with insulated handles.

FIRST AID

Before commencing any work:

1. Find out the location of a suitably stocked rst aid box.

2. Find out the arrangements that exist on-site for rst aid, and who is responsible for taking charge of these.

DISPOSAL

Sollatek devices are subject to the EU directive 2012/19/EU and may also be subject to other national legislation for

the safe disposal of e-waste.

1. The device cannot be disposed of as municipal waste, and such waste should be collected and disposed of

separately.

2. The device can be disposed of through an approved WEEE collection point, or alternatively can be returned to

Sollatek UK Ltd at the end of its working life.

3. The device may contain hazardous substances, which if disposed of incorrectly may cause harm to the

environment and/or human health.

4. Penalties may be applicable for incorrect disposal, as specied by local legislation.

Sollatek devices comply with EU directive 2011/65/EU (RoHS).

FCAx3 USER MANUAL

A3+ CMYK

4+44 (1753) 214 500

CONTENTS

1. INTRODUCTION 5

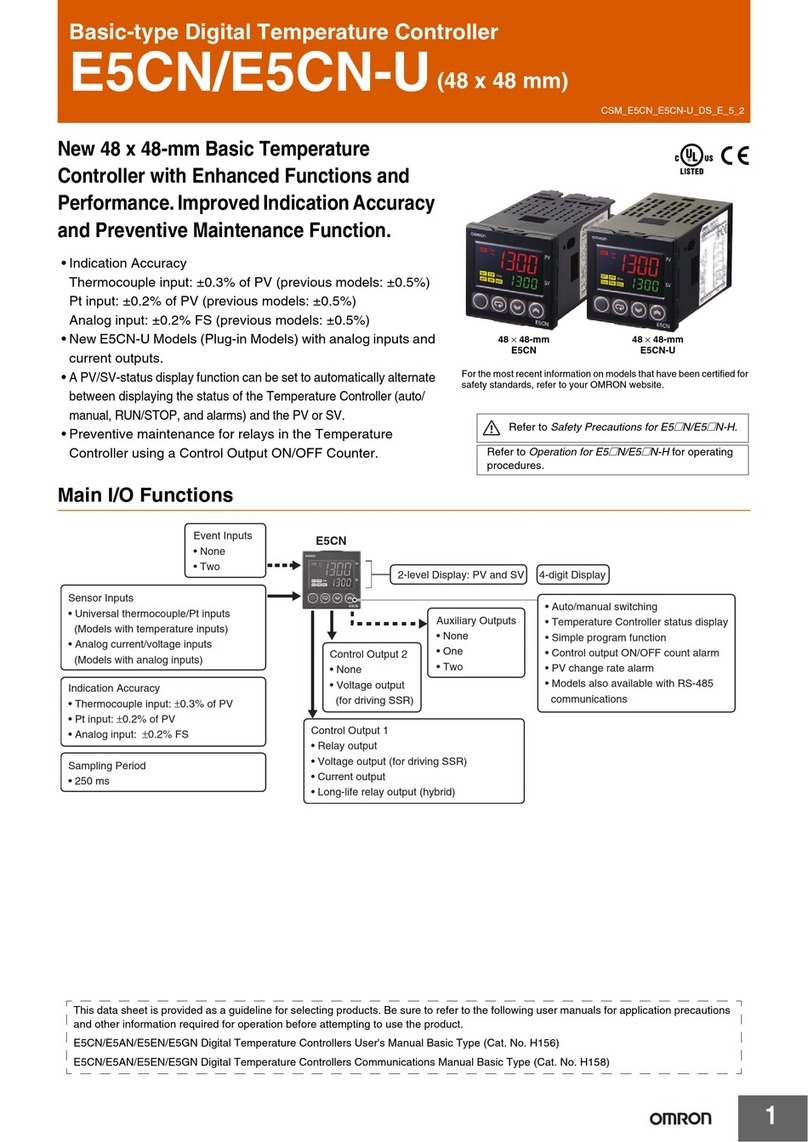

1.1 DESCRIPTION 5

1.2 MODEL VARIANTS 5

1.3 LED INDICATORS 6

2. FUNCTION 7

2.1 TEMPERATURE CONTROL 7

2.2 ENERGY SAVING 7

2.3 DEFROST CONTROL 7

2.4 VOLTAGE AND COMPRESSOR PROTECTION 7

3. OPERATION 8

3.1 STANDARD REGULATING MODE 8

3.2 DEFROST MODE 10

3.3 ENERGY SAVING MODE 11

4. FEATURES 12

4.1 TEMPERATURE BLIND TIME 12

4.2 BAD VOLTAGE BLIND TIME 12

4.3 TIMESAVE™ FUNCTION 13

4.4 INTELLIGENT TIME DELAY 13

4.5 INTELLIGENT BLACKOUT TIME DELAY 14

4.6 TEST PINS 14

4.7 DIAL POSITION & CONTROLLER OFF 14

4.8 BLUETOOTH CONNECTIVITY 14

4.9 CONNECTIVITY DEVICE 15

4.10 DIGITAL DISPLAY MODULE 15

5. INSTALLATION 16

5.1 FCAx3 DIMENSIONS 16

5.2 MOUNTING INSTRUCTIONS 16

5.3 WIRING CONNECTIONS 16

6. TESTING PROCEDURE 18

6.1 THERMOSTATIC FUNCTION 18

6.2 DEFROST FUNCTION 18

6.3 VOLTAGE PROTECTION FUNCTION 19

7. ALARMS & ERRORS 20

7.1 FREQUENCY MONITORING & ERROR DETECTION 20

7.2 REGULATION PROBE ERROR DETECTION 20

7.3 DEFROST PROBE ERROR DETECTION 21

7.4 INTERNAL FAULT DETECTION 21

8. CONFIGURATION 22

8.1 DESKTOP CONFIGURATION 22

8.2 REMOTE CONFIGURATION 24

9. PROGRAMMING 25

10. PARAMETERS 27

10.1 HARDWARE CONFIGURATION 27

10.2 RELAY CONFIGURATION (RELAY #2/#3) 27

10.3 TEMPERATURE CONTROL 29

10.4 ENERGY SAVING (TEMPERATURE SET-BACK) 31

10.5 DELAYS AND TIMERS 31

10.6 DEFROST FUNCTION 32

10.7 VOLTAGE PROTECTION 35

10.8 DOOR SWITCH OPERATION 35

10.9 HEATER FUNCTION 36

10.10 PROBE FAULT DETECTION (PROBE #1/#2/#3) 36

11. SPECIFICATION 37

12. ACCESSORIES 39

13. VERSION HISTORY 39

FCAx3 USER MANUAL sollateksupport@sollatek.com5

A3+ CMYK

1. INTRODUCTION

1.1 DESCRIPTION

The FCAx3 is an electronic refrigeration controller designed to be a direct replacement for electro-mechanical thermostats

to provide precise and efficient refrigeration control for up to 3 outputs using up to 3 inputs (temperature sensor and/or door

switch). The FCAx3 provides advanced defrost modes as well as energy saving during periods of low demand using a door

switch.

The FCAx3 is built to last meeting industry benchmarks and offering complete voltage protection including high/low voltage

to all connected outputs. To also help protect and extend the operating life of the connected outputs the FCAx3 provides zero

voltage crossing.

The FCAx3 has internal Bluetooth (optional) or can be connected to an external Bluetooth module (GBR) allowing remote

access via the Smart Device App to authorized service personnel to access controller data logs and control parameters. BLE also

transmits Eddystone and iBeacon for proximity marketing (nearby customer engagement).

The FCAx3 can be connected to a connectivity device to provide always-on connectivity to send telemetry and performance

data to the portal, and Wi-Fi asset location or a digital display to provide live temperature reading, parameter and mode

configuration and alarms/errors.

DEVICE OVERVIEW

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

1Mains and Output Connectors

2User Adjustable Temperature Dial

3Data Port - Connectivity / Programming

4Test Pins - Time Delay Bypass

5LED Indicator

6 Temperature/door Sensor Connector

7Temperature Sensor Connectors

1.2 MODEL VARIANTS

The “x” in the part number FCAx3 indicates the number of controllable outputs. There are three models available:

FCA13 = 1 relay, 16 Amp (Compressor)

FCA23 = 2 relays, 16 Amp (Compressor) + 5 Amp (Aux1)

FCA33 = 3 relays, 16 Amp (Compressor) + 2x 5 Amp (Aux1 & Aux2)

FCAx3 USER MANUAL

A3+ CMYK

6+44 (1753) 214 500

1.3 LED INDICATORS

Dial in “OFF” position

Test Mode

Blink Once. Probe #1 Fault.Compressor Off or Cycling

*

LEDs Mains Voltage Compressor Description

R Y G

Off. Voltage Bad. Cooling Demand

Wait Period (intelligent time delay). Cooling Demand

On. Voltage Good. Cooling Demand

*

Defrost Mode

Blink Twice. Probe #2 Fault.Compressor Off or Cycling

*

If the Red LED turns ON momentrily, the controller is in under/over voltage blind time

On. Compressor Off due to Door Switch Operation

*

Wait Period. No Cooling Demand

Wait is Over. No Cooling Demand

KEY On/good Off/bad Flashing (1 second interval) Cycling (1 second interval) OffBlink (2 seconds interval)On

Blink Three Times. Probe #3 Fault.Compressor Off or Cycling

*

*

Cycle every 0.5 seconds. Bad Frequency

Pre-defrost Mode

Drip Down Mode

Post Defrost Recovery Mode

Not Relevant

Off. Voltage Bad. No Cooling Demand

Blink Once. Probe #1 Fault and Bad Voltage

Blink Twice. Probe #2 Fault and Bad Voltage

Blink Three Times. Probe #3 Fault and Bad Voltage

Cycle 5 times a second. Internal Power Supply Failure

FCAx3 USER MANUAL sollateksupport@sollatek.com7

A3+ CMYK

2. FUNCTION

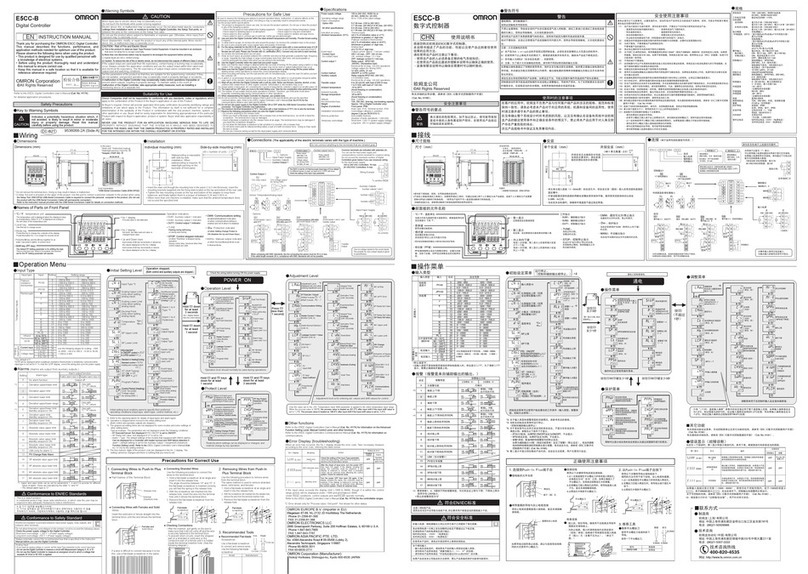

2.1 TEMPERATURE CONTROL

The FCAx3 is a microprocessor-based temperature controller utilising up to two NTC (Negative Temperature Coefficient)

probes. The cooler temperature is determined by measuring the temperature of either the return airflow or evaporator

temperature depending on where the customer prefers to fit the probe. This probe should be connected to the probe #1

connector.

The FCAx3 is a closed-loop temperature controller, turning the compressor OFF once the Cut-out set point has been reached

and then turning the compressor ON when the Cut-in temperature is reached. Users can set both the cut-in and cut-out values.

2.2 ENERGY SAVING

Commercial refrigeration is energy-hungry; With rising energy costs and growing environmental concerns, the FCAx3 allows

you to reduce energy consumption. You can:

• Cycle the Evaporator Fan: set the fan to cycle during operation as opposed to ON all the time.

• Temperature Setback Mode: Reduce the cooling demand by increasing the set temperature values. This will reduce how

hard the compressor must work and therefore reduce energy.

The setback is designed to be initiated when the store is closed. To activate Setback there must be no door activity for a

configurable set period.

2.3 DEFROST CONTROL

One of the primary functions of the FCAx3 controller is defrost management. The defrost cycle can be initiated or terminated

by either time or temperature (active).

Every system is different but usually, for the most efficient and satisfactory refrigeration operation, you would set the controller

parameters to initiate the fewest amount of defrosts in a day, for the shortest amount of time needed to clear the evaporator

of ice.

Usually, parameters will be set to terminate due to temperature with a fail-safe time backup to prevent prolonged defrost

because of defective defrost components or failures.

The FCAx3 supports Natural or Forced Defrost:

• Natural Defrost turns off the compressor and allows the evaporator to warm up normally.

• Forced Defrost turns the compressor and evaporator fan off and then turns a reverse fan to warm up the evaporator

quicker than natural defrost.

Standard operation during Defrost:

Natural Defrost Forced Defrost

Compressor: OFF Compressor: OFF

Evaporator Fan: ON Evaporator Fan: OFF

Reverse Fan or Heater: ON

2.4 VOLTAGE AND COMPRESSOR PROTECTION

The FCAx3 has built-in voltage protection including High / low voltage, spikes/surges, and frequency monitoring to protect

the controller and connected outputs to reduce equipment damage and downtime. The FCAx3 continually senses the mains

supply, on sensing bad voltage (voltage is higher or lower than the present acceptable limits) the FCAx3 will disconnect the

compressor and other connected outputs. Once the voltage becomes good, the FCAx3 will ensure the voltage remains good

for a set period (TIMESAVE™) before reconnecting power to the compressor and other connected outputs.

A minimum OFF period is essential in allowing compressor gases to neutralise, ensuring that the mains have stabilised before

re-connection and avoiding a locked rotor condition, however, any prolonged off time can affect cooler efficiency and or the

contents of the cooler. The FCAx3 will automatically adjust the reconnection period meaning the cooler will never be off for

longer than required.

FCAx3 USER MANUAL

A3+ CMYK

8+44 (1753) 214 500

3. OPERATION

3.1 STANDARD REGULATING MODE

ON

Time

Compressor

OFF

ON

Evaporator Fan

OFF

CUT IN

CUT OUT

Pull

down

HVD

LVD

Mains Voltage

ON

OFF

Defrost

Defrost Mode

HVD Disconnect

LVD Disconnect

Intelligent Time Delay

Intelligent Time Delay

Temperature Probe

FCAx3 USER MANUAL sollateksupport@sollatek.com9

A3+ CMYK

3. OPERATION

3.1 STANDARD REGULATING MODE

ON

Time

Compressor

OFF

ON

Evaporator Fan

OFF

CUT IN

CUT OUT

Pull

down

HVD

LVD

Mains Voltage

ON

OFF

Defrost

Defrost Mode

HVD Disconnect

LVD Disconnect

Intelligent Time Delay

Intelligent Time Delay

Temperature Probe

FCAx3 USER MANUAL

A3+ CMYK

10+44 (1753) 214 500

3.2 DEFROST MODE

3.2.1 STANDARD DEFROST

Depending on the requirement, defrost can be triggered by either using the temperature or/and by time, when both settings

are enabled, whichever event happens first will trigger or end the defrost cycle.

The FCAx3 has a minimum defrost duration and minimum duration between defrost cycles which must be satisfied before

it will act no matter the status of the other parameters. This is to ensure the defrost cycle is not stopped too early or defrost

cycles are not initiated too close together.

3.2.2 ADVANCED DEFROST MODES

The FCAx3 has optional advanced pre- and post-defrost settings that provide extra protection to the controller and

compressor as well as maximising defrost efficiency.

Time

Pre Defrost

Mode

Defrost is activated

by temperature or

time

Defrost Mode Drip Down

Mode

Post Drip Down

Recovery Mode

Defrost ended by

temperature or

time

Aux 1 & 2

configurable

Aux 1 & 2

OFF

Aux 1 & 2

OFF

Aux 1 & 2

configurable

Compressor OFF during

ALL defrost modes

ON

OFF

Compressor

ON

OFF

Evaporator

Fan

ON

OFF

Defrost Relay

Post Drip Down

Recovery ended

by temperature

or time

FCAx3 USER MANUAL sollateksupport@sollatek.com11

A3+ CMYK

3.3 ENERGY SAVING MODE

The FCAx3 has an Energy Saving mode that provides reduced compressor operation when the outlet is closed and no

customer demand by setting the cut-in and cut-out temperatures higher than in normal mode. When the FCAx3 does not

sense a door opening for the pre-set duration, then the FCAx3 will enter Energy Saving Mode and run using the energy-saving

cut-in and cut-out temperature. When the door is opened or the maximum energy-saving timer has elapsed, the FCAx3 will

resume normal operation.

CUT IN

CUT OUT

Eco Mode

Temperature

Time

Engery Saving Max Duration

OPEN

CLOSE

Door Switch

Energy Saving Mode

Door Close Duration

to Start Energy Saving

Door Open Duration to Exit Engery Saving

Energy Saving is activated Energy Saving is terminated

CUT IN

CUT OUT

ON

OFF

Compressor

Normal Mode

Temperature

FCAx3 USER MANUAL

A3+ CMYK

12+44 (1753) 214 500

4. FEATURES

4.1 TEMPERATURE BLIND TIME

The software will ignore the sensor temperature reading for the first few seconds (a pre-set value of 10 seconds) after the

compressor is switched on. This is to prevent short-term thermal effects such as those caused by the fan starting to operate

causing disconnection.

Cut in

Average

Cut out

On

O

Less than

Temperature

Blind Time

Temperature

Compressor

4.2 BAD VOLTAGE BLIND TIME

The software permits high and low mains voltages transitions for short periods of time preventing inadvertent compressor

stop-starts. Present values of 0.5 and 2 seconds (configurable) respectively are implemented.

However, if the mains voltage becomes too extreme (HVD + 10%) and (LVD - 20%), the FCAx3 will immediately disconnect the

compressor.

IDH

HVD

LVD

IDL

On

O

Intelligent time delay

Less than 0.5 secs

Less than 2 secs

Intelligent time delay

High limit

Low limit

Mains power

Compressor

IDH= Immediate Disconnect High

IDL= Immediate Disconnect Low

FCAx3 USER MANUAL sollateksupport@sollatek.com13

A3+ CMYK

4.3 TIMESAVE™ FUNCTION

The FCAx3 has a built-in sensing period after a bad voltage event. When the voltage returns to good after a bad voltage

period the FCAx3 will only reconnect power to the compressor and other connected outputs once it has sensed the voltage

remains within set limits for at least 10 seconds.

4.4 INTELLIGENT TIME DELAY

The FCAx3 controller has a built-in intelligent time delay of up to 5 minutes (customer configurable). After a compressor

disconnection period, either from cycling OFF, defrost, or HVD/LVD the FCAx3 will automatically adjust the time delay on

the disconnection period before allowing the compressor to turn ON. For example, if the Time delay is set to 3 minutes, a

2-minute disconnection will result in only a 1-minute additional delay, making the total delay 3 minutes. Any disconnection of 3

minutes or over and the FCAx3 will immediately turn the compressor ON.

The time delay is essential in allowing compressor gases to neutralise, ensuring that the mains have stabilised before

re-connection and avoiding a locked rotor condition.

Operation of time delays during normal operation:

Intelligent Time

Delay (1 min)

Disconnection Period

(2 mins)

Disconnection Period

(7 mins)

ON

OFF

Compressor

ON

OFF

Compressor

Operation of time delays during a brownout (bad voltage):

Intelligent Time

Delay (1 min)

Disconnection Period

(2 mins)

Disconnection Period

(7 mins)

ON

OFF

Compressor

ON

OFF

Compressor

Voltage GOOD Voltage BAD Voltage GOOD

TIMESAVE

™

TIMESAVE

™

Voltage GOOD Voltage BAD Voltage GOOD

*Above illustrations use intelligent time delay set to 3 minutes

FCAx3 USER MANUAL

A3+ CMYK

14+44 (1753) 214 500

4.5 INTELLIGENT BLACKOUT TIME DELAY

The FCAx3 also has an Intelligent Blackout delay, meaning depending on the disconnection period, caused by no power i.e.

power cut or mains being turned off, the FCAx3 will adjust the wait period before allowing the compressor and other outputs

to turn on. For example, if the Time delay is set to 3 minutes, a 2-minute disconnection will result in only a 1-minute additional

delay, making the total delay 3 minutes. Any disconnection of 3 minutes or over and the FCAx3 will immediately turn the

compressor ON. Time delay is configurable (intelligent time delay and blackout time delay are set as the same value).

Intelligent Time

Delay (1 min)

OFF Period

(2 mins)

OFF Period

(7 mins)

ON

OFF

Compressor

ON

OFF

Compressor

Voltage GOOD Voltage BAD Voltage GOOD

TIMESAVE

™

TIMESAVE

™

Voltage GOOD Voltage BAD Voltage GOOD

4.6 TEST PINS

Next to the LED, the FCAx3 has two test pins. The test pins can be shorted by touching both pins with

a conducting object such as a small screwdriver.

When the FCAx3 is first turned ON and the test pins are shorted, the time delay is bypassed and will

force the FCAx3 to operate immediately according to the current temperature demand.

If the test pins are shorted during operation when there is no cooling demand, the FCAx3 will force the

compressor ON for 10 seconds to allow technicians to check the compressor operation.

4.7 DIAL POSITION & CONTROLLER OFF

The dial setting point on the FCAx3 is pointing downwards when the power/output connectors are on the left. When moving

the dial into or away from the OFF position the dial will click in and out respectfully.

When the dial is set to OFF and Enable Potentiometer Off Position is enabled, the FCAx3 turns off all outputs regardless of

the temperature, allowing forced defrost or cleaning. The outputs are enabled when the dial position is changed to any other

value.

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

Dial Setting Point

4.8 BLUETOOTH CONNECTIVITY (INTERNAL OR EXTERNAL)

FCAx3 controllers are equipped with Bluetooth capability, enabling them to connect to the Sollatek Smart device Application.

The Sollatek App has extensive cooler management capabilities providing technicians with all the tools to view and upload

controller status and event data.

• Real-time Data Analysis - View real-time telemetry data, operational status, and performance data.

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

FCAx3 USER MANUAL sollateksupport@sollatek.com15

A3+ CMYK

• Cooler Event Log - Access all historical data that has occurred between store visits to identify any issues or problems.

• Manage Settings and Parameters - View and configure predefined FCAx3 controller parameters for cooler optimisation.

Set BLE Beaconing protocols and event logging.

• Connect to the Cloud - Upload data to the cloud for access on the online portal for further analysis.

The FCAx3 controller also features iBeacon and Eddystone Beacon capabilities allowing proximity marketing to send engaging

and interactive content to consumers’ smartphones while they buy in real-time.

4.8.1 RECHARGEABLE BATTERY (INTERNAL BLUETOOTH MODEL ONLY)

The internal battery allows the FCAx3 to keep Real Time Clock (RTC) while there is no mains supply. The battery can also be

used to power the Bluetooth so the device can still advertise/beacon.

The battery will last approximately 15 days RTC / 10 days RTC + BLE Advertising.

CAUTION! RISK OF EXPLOSION

It is not recommended for users to replace the battery so please contact Sollatek. The replacement

battery should be of the same type.

Dispose of the used batteries according to national standards and directives.

4.9 CONNECTIVITY DEVICE (GMC4)

4.9.1 CELLULAR FEATURES

The GMC4 is equipped with cellular connectivity capabilities of 2G or Cat-M (depending on the model), enabling it to transmit

data over the secure global network for you to access on the online portal for cooler monitoring. The online portal can be

accessed on any device with an internet connection. The GMC4 is provided with a global roaming SIM pre-installed. Via the

online portal, you can:

• Detailed Reports - View a vast list of controller operational data such as temperature, event history, and faults.

• Intelligent Data Analysis - Monitor technical and operational data in easy-to-read graphs and charts.

• Accurate Sales Performance - view and analyse cooler KPIs for enhanced sales forecasting and strategy.

• Over the Air Parameter Configuration - View and configure predefined GMC4 controller parameters for cooler

optimisation

• Remote Cooler Shut-down - In the event the cooler is stolen, disable the cooler so it cannot be used. Once the cooler is

recovered the cooler can then be enabled.

The transmission interval of cooler health data can be configured via the Sollatek Smart Device Application. Health data will

not be transmitted while being powered by the battery.

4.9.2 GEO-LOCATION

The GMC4 provides Wi-Fi geo-location for precise asset tracking anywhere in the world. The GMC4 collects and sends Wi-Fi

signal strength and WAP information from nearby devices (without connecting to the Wi-Fi network). The system then uses the

leading Wi-Fi location database to determine the location of the GMC4 and cooler. The location can be seen on a dynamic

map on the portal.

• View current and historic cooler locations.

• Real-time tracking of cooler location during movement (depending on transmission interval set).

The transmission interval of Wi-Fi data is fully configurable via the Sollatek Smart Device Application.

4.10 DIGITAL DISPLAY MODULE

The FCAx3 can be connected to the Sollatek FDM3 digital display. This allows you to:

• View and configure controller status/mode.

• Configure pre-set parameters.

• View controller alarms and faults.

FCAx3 USER MANUAL

A3+ CMYK

16+44 (1753) 214 500

5. INSTALLATION

5.1 FCAx3 DIMENSIONS

5.2 MOUNTING INSTRUCTIONS

WARNING!

FCAx3 MUST be mounted with terminals in an isolated area, either in a plastic or earthed metal case.

1. Mark and drill holes for the dial shaft and mounting

screws in the surface where the FCAx3 is to be mounted

according to the panel cut-out. Ensure all holes are free

of burrs and sharp edges.

2. Insert the FCAx3 dial shaft through the hole from the

rear of the panel.

3. align the mounting holes and secure the FCAx3 into

position with the provided screws.

4. Push the dial onto the shaft.

5.3 WIRING CONNECTIONS

DANGER! ELECTRIC SHOCK HAZARD - LIVE TERMINAL

This is a non-isolated product. The sensor inputs and outputs are not electrically isolated from the power terminals

therefore the supply MUST be disconnected from the controller before installing/disconnecting, repairing, or

programming the controller, inputs, outputs, and external devices.

Ensure exposed connectors/wires of connected inputs, outputs and external devices do not touch the frame or

chassis of the cooler or other enclosures otherwise, damage to the controller, equipment, and the cooler will occur.

This equipment is to be installed or serviced by trained personnel only.

FCAx3 USER MANUAL sollateksupport@sollatek.com17

A3+ CMYK

5.3.1 MAINS AND OUTPUT WIRING

DANGER! - LIVE TERMINAL

Isolate the supply before installing/disconnecting or repairing the controller. Failure to do so can result in damage

to equipment and electrical shock.

Ensure the connected load does not exceed the maximum relay rating it is connected to and the total current

rating on at once does not exceed 18 Amps (FCA22/FCA32).

0.25” vertical male spade terminals are used for mains and output connectors. Connections should be made with equivalent

female crimp connectors.

1. Connect the Mains Neutral wire to terminal 1 (labelled Neutral) on the FCAx3.

2. Connect the Mains Live-In wire to terminal 2 (labelled Live in) on the FCAx3.

3. Connect the Compressor Live wire to terminal 3 (labelled Comp) on the FCAx3.

4. Connect the required output (commonly evaporator fan) Live wire to terminal 4 (Relay #2,

labelled Aux1) on the FCAx3, if required.

5. Connect the required output (commonly Lights or heater) Live wire to terminal 5 (Relay #3,

labelled Aux2) on the FCAx3, if required (FCA32 ONLY)

6. Connect all output Neutrals to Mains Neutral.

Note: Output connectors are based on the default relay configuration, if the output configuration is changed via the FCAx3

configuration interface, then the equipment should be connected accordingly.

5.3.2 INPUT SENSOR WIRING

DANGER! - LIVE TERMINAL

Isolate the supply before installing/disconnecting or repairing the controller. Failure to do so can result in damage

to equipment and electrical shock.

WARNING!

If the probes placed in an accessible area have less than 1.4 mm insulation, then the probes need to be sleeved

(greater than 0.4mm thickness) to attain supplementary insulation.

Separate as much as possible the input sensors and cables carrying inductive load and power. Do Not run power

and signal cables together in the same conduit.

0.11” vertical male spade terminals are used for the input connectors on the FCAx3.

Temperature probes and the door switch use a 2-way female crimp terminal connector.

1. Connect the regulating temperature probe (air) to terminal PRB1 on the FCAx3.

2. Connect the defrost temperature probe (evaporator) to terminal PRB2 on the FCAx3.

3. Connect the door switch to terminal D-SW on the FCAx3

Note: Input connections are based on a typical installation. Probe inputs can be configured

according to your requirements in the configuration software. PRB1an PRB2 can only be used

for temperature probes. D-SW can be used for a door switch or temperature probe.

5.3.3 EXTERNAL DEVICE CONNECTION

DANGER! - LIVE TERMINAL

Isolate the supply before connecting/repairing/disconnecting external devices. Failure to do so can result in damage

to equipment and electrical shock.

Do not power the controller with connecting cables unconnected to devices as if exposed connectors were to

touch the frame or chassis of the cooler, damage to the controller, equipment, and the cooler will occur.

WARNING!

Separate as much as possible the input sensors and cables carrying inductive load and power. Do Not run power

and signal cables together in the same conduit.

1. Remove the rubber dust cover from the data port on

the side of the FCAx3.

2. Insert the Micro USB-B connector of the connection

cable into the Micro USB-B port in the FCAx3. Ensure

the connector is fully pushed down.

Note: The port is recessed, and the cable has a rubber boot

so when a device is connected, the IP rating is maintained.

3. Plug the other end of the connector cable into the

connector on the device.

+-

+-

OR

+-

FCAx3 USER MANUAL

A3+ CMYK

18+44 (1753) 214 500

6. TESTING PROCEDURE

6.1 THERMOSTATIC FUNCTION

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

1. Connect the FCAx3 to a source of variable AC voltage such as a Variac and set the temperature dial to 9. Adjust the

output of the Variac to a good starting voltage (within the acceptable limits) and power it on. The yellow LED will turn ON

and stay on if the temperature detected by the regulation temperature probe (Probe#1) is below the cut-in temperature. If

the temperature is above the cut-in value, then the yellow LED will flash.

2. When the Intelligent Time Delay is over, the FCAx3 will connect the mains supply to the compressor (assuming the

temperature sensed by Probe#1 is above the cut-in temperature). The green LED will now turn ON.

3. Once the cabinet has reached the desired temperature (the temperature sensed by Probe#1 drops below the cut-out

temperature), the FCAx3 will disconnect the compressor and the green LED will start flashing which indicates there is no

cooling demand.

6.2 DEFROST FUNCTION

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

1. Connect the FCAx3 to a source of variable AC voltage such as a Variac and set the temperature dial to 9. Adjust the

output of the Variac to a good starting voltage (within the acceptable limits) and power it on. The yellow LED will turn ON

and stay on for the duration of the protection time delay (assuming the temperature is above the cut-in value).

2. When the Intelligent Time Delay is over, the FCAx3 will turn on the compressor and the green LED will turn ON.

3. The unit will go into defrost as soon as one of the defrost start criteria is met. This could be either defrost start time is over

or the evaporator temperature drops below defrost start temperature value, whichever happens first, or is activated. The

green and red LEDs will turn ON, and the compressor and other outputs will act according to the set operation, turning

ON if set to ON.

4. The unit will stay in defrost until one of the defrost end criteria is met. This could be either defrost end duration is over or

the evaporator temperature has risen above defrost end temperature value, whichever happens first, or is activated.

Note: The FCAx3 has two built-in features which force the unit into defrost to reduce the testing time:

Manual Defrost (Temperature dial)

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

1. Connect the FCAx3 to a source of variable AC voltage such as a Variac and set the temperature dial to OFF. Adjust the

output of the Variac to a good starting voltage (within the set limits) and power it on. The green LED will turn ON.

2. Rotate the dial to 4 (within 7.5 seconds and stay there for at least 200mSec). The yellow LED will be ON.

3. Rotate the dial to 2 (within 7.5 seconds and stay there for at least 200mSec). The red LED will be ON.

4. Rotate the dial to 8 (within 7.5 seconds and stay there for at least 200mSec). All LEDs will be ON.

5. Rotate the dial from 8 to any other number and defrost mode will be activated. The green and red LEDs will be ON, and the

FCAx3 USER MANUAL sollateksupport@sollatek.com19

A3+ CMYK

compressor and other outputs will act according to the set operation, turning ON if set to ON.

6. The unit will stay in defrost until one of the defrost end criteria is met. This could be either defrost end duration is over or

the evaporator temperature has risen above defrost end temperature value, whichever happens first, or is activated.

Immediate Defrost at Power UP Enabled (programmed via the configuration software)

1. Connect the FCAx3 to a source of variable AC voltage such as a Variac and set the temperature dial to 9. Adjust the output

of the Variac to a good starting voltage (within the acceptable limits) and power it on.

2. If the defrost enable temperature is met, the FCAx3 will enter defrost. The green and red LEDs will be ON, and the

compressor and other outputs will act according to the set operation, turning ON if set to ON.

3. The unit will stay in defrost until one of the defrost end criteria is met. This could be either defrost end duration is over or

the evaporator temperature has risen above defrost end temperature value, whichever happens first, or is activated.

Note: Ensure to disable this feature and reprogram the FCAx3 before sending the cooler/controller to market.

6.3 VOLTAGE PROTECTION FUNCTION

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

1. Connect the FCAx3 to a source of variable AC voltage such as a Variac and set the temperature dial to 9. Adjust the

output of the Variac to a good starting voltage (within the acceptable limits) and power it on. The yellow LED will turn ON

and stay on for the duration of the protection time delay (assuming the temperature is above the cut-in value).

2. When the Intelligent Time Delay is over, the FCAx3 will turn on the compressor and the green LED will turn ON.

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

3. Slowly decrease the voltage until the red LED turns ON while the green LED is still ON. The LEDs will stay ON for the

duration of the Under Voltage Blind Time (2 seconds),

4. Then the FCAx3 will disconnect the outputs and the green LED will turn OFF so just the red LED is ON. This represents

the Low Voltage Disconnect voltage.

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

2

3

4

5

6

7

8

9

1

D

L

O

C

E

R

OFF

5. Increase the voltage slowly until the yellow LED turns ON. This represents the Low Voltage Reconnect voltage.

6. Wait for the Protection Time Delay, then the green LED will turn ON.

7. Repeat steps 3 to 6 but increase the voltage to test the overvoltage.

• The High Voltage Blind Time is 0.5 seconds.

Note: Low/high Blind Times are Sollatek’s recommended timings. Blind times are configurable in the desktop configuration

interface so actual timings may differ from the times stated depending on your settings.

**Tip: During testing, short the test pins to bypass the set time delay and force the FCAx3 to operate immediately**

FCAx3 USER MANUAL

A3+ CMYK

20+44 (1753) 214 500

7. ALARMS & ERRORS

7.1 FREQUENCY MONITORING AND ERROR DETECTION

The FCAx3 dynamically measures the frequency of the mains supply and reacts accordingly. If the mains supply frequency is

too low or too high, the FCAx3 will then disconnect the compressor and indicate an error signal through the LEDs. The FCAx3

can auto-recover once the frequency is within acceptable limits.

Normal

frequency

35-75Hz

Intelligent time delay

ON

OFF

Compressor

Mains Voltage

High

frequency

>75Hz

Normal

frequency

35-75Hz

Normal

frequency

35-75Hz

Low

frequency

<35Hz

Time

Note: The above illustration assumes that the Mains voltage RMS value is good and there is cooling demand, hence the

compressor comes on after the intelligent time delay is over.

7.2 REGULATION PROBE (PROBE#1) ERROR DETECTION

The FCAx3 will report an error code through the LEDs indicating a sensor fault if it happens. Depending on customer

preferences the FCAx3 will either:

Scenario One: Detect the fault and disconnect the compressor until the problem is resolved and then the system resumes

normal operation.

Cut in

Average

Cut out

faulty

functioning

On

O

Temperature

reading

Probe

Compressor

Probe fault has

been detected.

Compressor

switches o

until the fault

is recovered.

This manual suits for next models

6

Table of contents

Other Sollatek Controllers manuals

Popular Controllers manuals by other brands

Outback Power Systems

Outback Power Systems FLEXnet DC user guide

Intec Controls

Intec Controls MSR PolyGard 2 DGC6 user manual

Janson Controls

Janson Controls FC100 Series manual

Kindermann

Kindermann HDMI Switch 41 automatic 4K60 Commissioning and operating instructions

Eaton

Eaton EC500 Operation handbook

CorroVenta

CorroVenta HomeVision Pro user manual