4

Instruction Manual SLB-9000

.

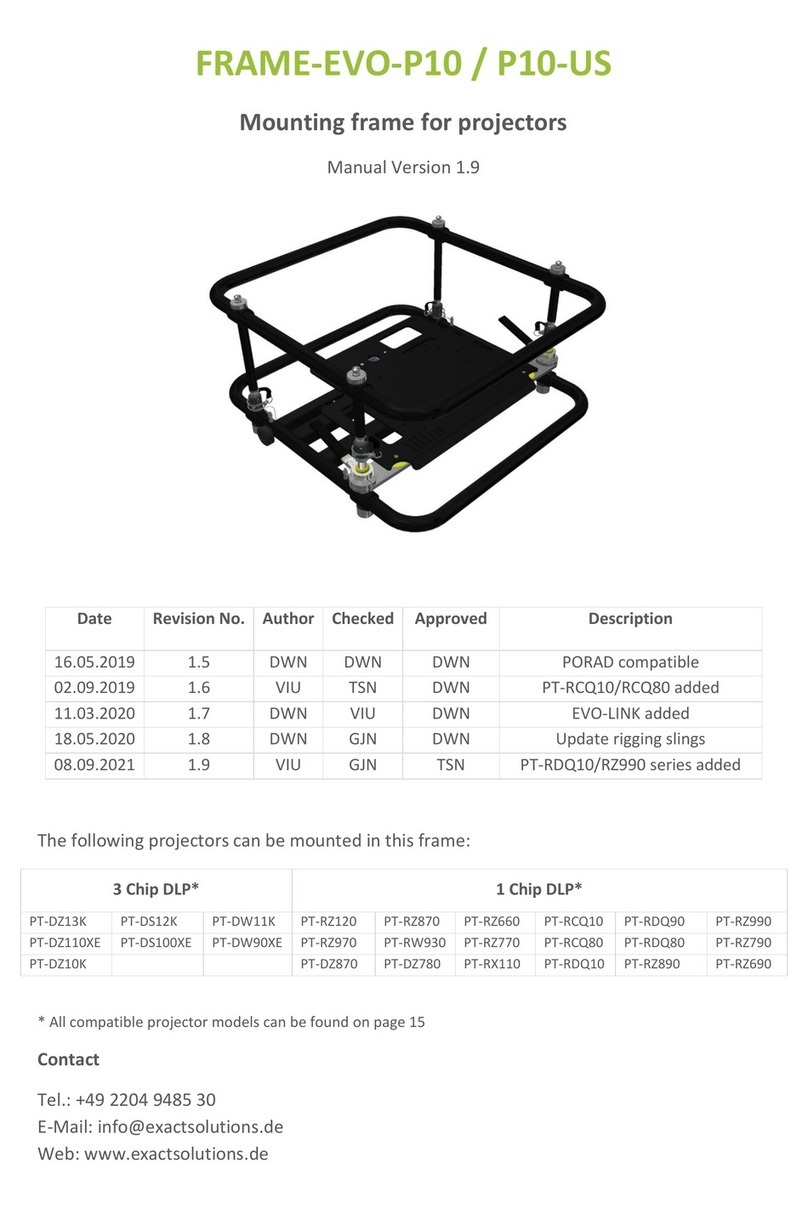

Manufacturer Model

Group

Manufacturer Model

Group

A + K AstroBeam S120 DGeha Compact 280 A

A + K AstroBeam S230 AGeha Compact 290 C

A + K AstroBeam X120 DGeha Compact 690 B

A + K AstroBeam X201 EIBM

A

A + K AstroBeam X211 EIBM iL C200 A

A + K AstroBeam X220 CIBM iL C300 C

A + K AstroBeam X230 AIBM iL V200 A

A + K AstroBeam X310 BIBM iL V300 B

A + K AstroBeam X311 BIBM Value Based A

ASK C100 EInfocus LP 240 D

ASK C105 EInfocus LP 250 D

ASK C200 CInfocus LP 340 A

ASK C300 BInfocus LP 340B A

ASK C40 DInfocus LP 350 A

ASK C420 CInfocus

A

ASK C50 DInfocus LP 530 A

ASK C80 EInfocus LP 650 C

ASK C90 EInfocus LP 690 E

ASK C95 EInfocus LP 790 B

Boxlight 12SF AInfocus LP 790HB B

Boxlight CD-454m AInfocus LP 820 C

Boxlight CD-455m AInfocus LS 110 A

Boxlight CD-555m AInfocus

A

Boxlight CD-600m AInfocus

B

Boxlight CD-750m AInfocus

C

Boxlight CD-850m CInfocus

C

Boxlight CD-875m CInfocus

C

Boxlight Cinema 12SF AInfocus X1 B

Boxlight SP-45m DKnoll HD-101 B

Boxlight XP-55m DKnoll HD-110 A

Dataview E200 EKnoll HD-177 C

Dataview E220 EKnoll HD-272 C

Dataview E221 EKnoll HT-202 A

Dataview E231 EProxima DP 2000s D

Dataview M320 BProxima DP 2000x D

Dream Vision Dream Weaver CProxima DP 6150 E

Dream Vision Dream Weaver II CProxima DP 6155 E

Dukane ImagePro 7100HC BProxima DP 6500x C

Dukane ImagePro 8043A DProxima DP 8000 B

Dukane ImagePro 8048 AProxima DP 8000HB B

Dukane ImagePro 8750 AProxima DP 8200x C

Dukane ImagePro 8753A DToshiba TDP-MT100 B

Dukane ImagePro 8757 CToshiba TDP-MT5 A

Geha Compact 105 DToshiba TDP-MT8U C

Geha Compact 107 BToshiba TDP-S2 A

Geha Compact 205 DToshiba TDP-S2V A

Geha Compact 210 Plus EToshiba TDP-S3 A

Geha Compact 211 Plus EToshiba TDP-T1 A

Geha Compact 280 AToshiba TDP-T3 A

Geha Compact 290 CYokogawa D-1500X E