LH01793:05/00

4

S

TEP

4 - D

IAGRAM

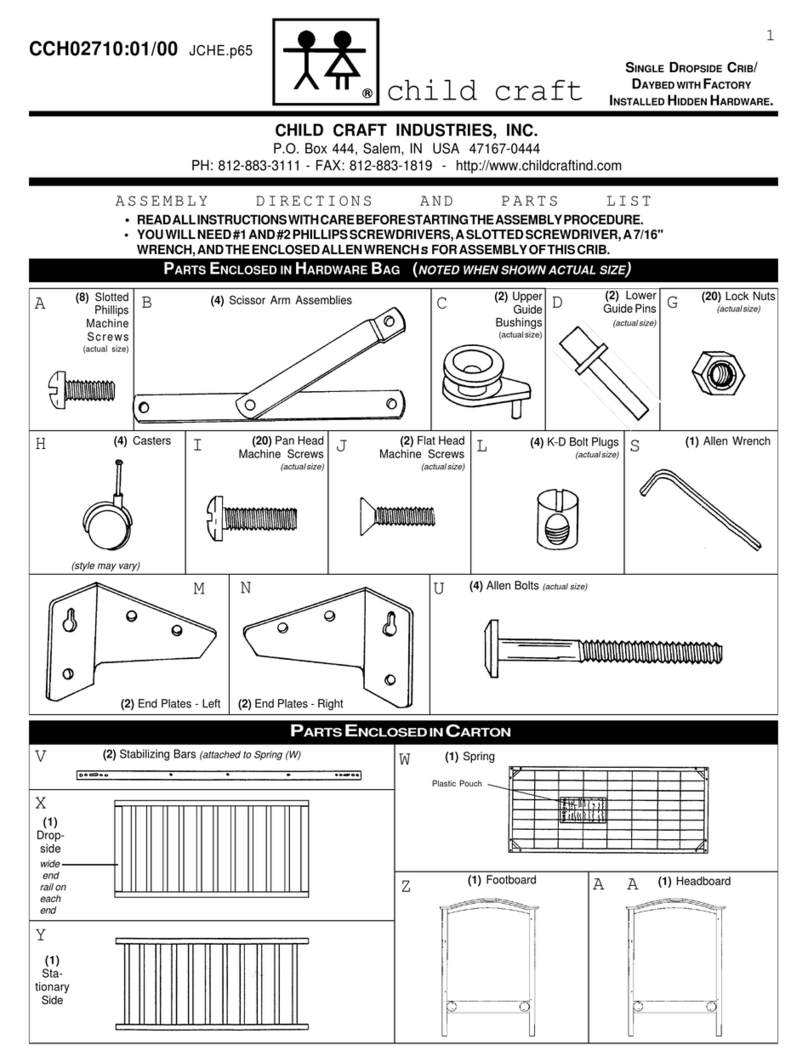

4: INSTALLATION OF DROPSIDE.

PREPARATION FOR INSTALLATION OF DROPSIDE:

Loosen the four Slotted/Phillips Screws Awhich attach

the Stabilizing Bar Tto the Headboard Yand Footboard

Xto prepare for Dropside VV

VV

Vinstallation. Back out these

(4) Screws a full (8) revolutions each, but do not remove

the screws.The Stablizing Bar Twill now be loose.

Install Dropside Vby following substeps Ithrough IV

listed below. Refer to Diagram. (It would be helpful to

have a friend assist you with this procedure.) Note: the

outside location of Dropside VV

VV

Vas shown in Dia-

gram.

I. Note: During the Dropside

V

installation procedure

use extreme caution when Top Tracks and Lower Tracks

make contact with Upper Guide Bushings

CC

CC

C

and Lower

Guide Pins

DD

DD

D

so as not to damage the finish of this crib.

II. Insert the Upper Guide Bushings CC

CC

C(mounted to

Footboard

X

and Headboard

Y

in STEP 2)into the

Upper Tracks

(metal) which were factory mounted to

Dropside.Hold the Dropside Vat approximately 30

degrees from vertical as shown in Diagram.

III. Once both ends are engaged, then carefully allow

Dropside Vto slide downward. Then rotate the bottom

end of the Dropside Vuntil it is nearly vertical. (Note:

Rotation will be stopped when the dropside

V

touches

the Lower Guide pins

DD

DD

D

.Carefully let the Dropside V

slide down until it is as low as it can go.

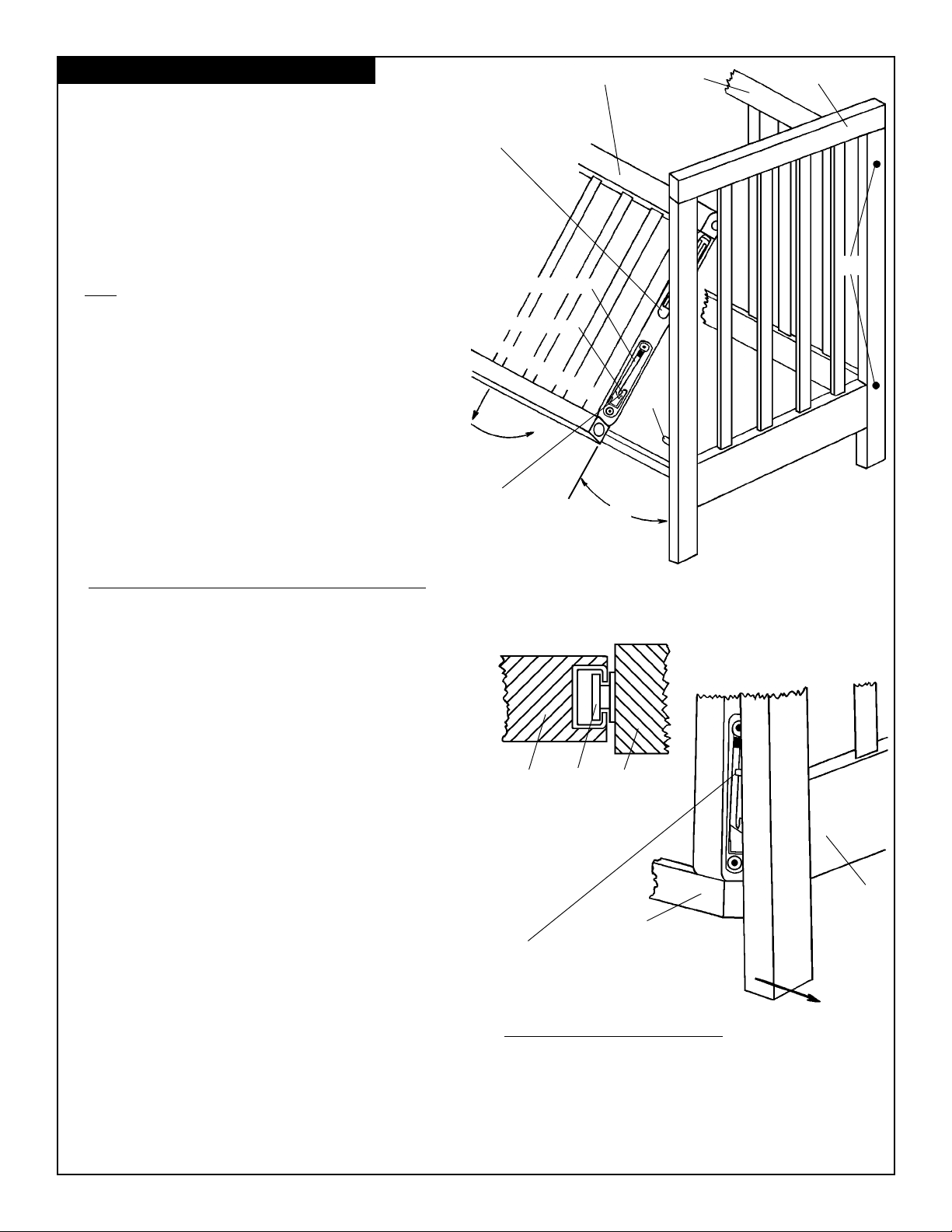

IV. READ THIS STEP COMPLETELY BEFORE PROCEEDING. Next, lift

Dropside VV

VV

Vapproximately two inches (2") vertically. This will put Dropside

Vin the proper vertical alignment with the Lower Guide Pin DD

DD

Dwhich will

be inserted into the Lower Tracks (Right & Left).

Flex the bottom end of the corner post on the Dropside side of Footboard X

away from the Dropside V. The purpose of this process is to create a gap

for the Lower Guide Pins Dto pass through so that the Lower Guide Pins

can be inserted into the long groove of the plastic Lower Tracks. As you

prepare to accomplish this please note the following:

If the Stabilizing Bar Assembly T was not loosened enough (as described

in PREPARATION FOR INSTALLATION OF DROPSIDE in the beginning

of this Step) there will not be enough slack to create the necessary gap

required for the Lower Guide Pin Dto pass through. Prematurely forcing the

pin through a gap with inadequate clearance could damage the finish on the

DropsideV. If your crib has too small of a gap, then lower Dropside Vto its

lowest position and check to verify that preparation at beginning of Step 4

was performed correctly.

If it was performed correctly, but the gap is still too small, it may be because

the Stabilizing Bar Tassembly needs to be pulled away from the bottom rails

of the Footboard Xor Headboard Y. Check to verify that the End Plates M

& Nhave been pulled away from the bottom rails until they touch the

underside of the heads of loosened Slotted/Phillips Machine Screws AA

AA

A.

After the Lower Guide Pin DD

DD

Dhas been installed into the long groove on

Footboard X, then repeat this process on Headboard Y. After both Lower

Guide Pins Dare installed, very carefully and slowly raise the DropsideV

up until it locks into its raised position. Be very careful to watch to ensure that

the Lower Guide Pins Dlocated in the grooves do not slip out during the

process of raising Dropside V.

Refer to Diagram 2. Tighten the (4) Slotted/Phillips Machine Screws AA

AA

Awhich

were installed in Step 2 to attach Stabilizing Bar Tto Headboard Yand

Footboard Xbut were loosened in Step 4. Be sure the (4) Slotted/Phillips

Machine Screws AA

AA

Aare tightened securely. Check these screws periodically

and tighten if needed.

Check the function of Dropside V. To lower the Dropside, lift

up on the Dropside top rail with your hand near the middle and

then press in with your knee on the center of the Dropside

bottom rail. The Dropside will then lower. To lock the Dropside

in the raised position, just lift it up until it locks into place.

Always verify that both ends of the Dropside are locked in the

raised position whenever child is placed in crib. Only lower

the Dropside when attending to child. Lower crib DropsideVV

VV

V

prior to proceeding with Step 5.

IIII

IIII

II.

Engagement

of Metal Top

Track and

Upper Guide

Bushing CC

CC

Cwill

start at bottom

of Metal Top

Track (see

enlarged

section view

below).

III.Lower Track

( Plastic)

NOTE: Place short groove

toward inside of crib.

long groove

short groove

Outside of Dropside VV

VV

V

30°

Corner post of Footboard

ZZ

ZZ

Z

II. ENLARGED SECTION VIEW

Engagement of Metal Top

Track and Upper

Guide Bushing CC

CC

C

IVIV

IVIV

IV.ENLARGED VIEW

IV. Then insert Lower Guide Pin DD

DD

D into

long groove in Lower Track (plastic).

Corner post to receive Dropside

VV

VV

V

FLEX

X

XCV

V

VX

W

D

R