0-6

WARNINGS

This paragraph covers important warning for safety to be observed before reading the instructions.

Fully understand the following warnings before reading this manual.

These warnings are important for preventing the danger to human bodies as well as accidents.

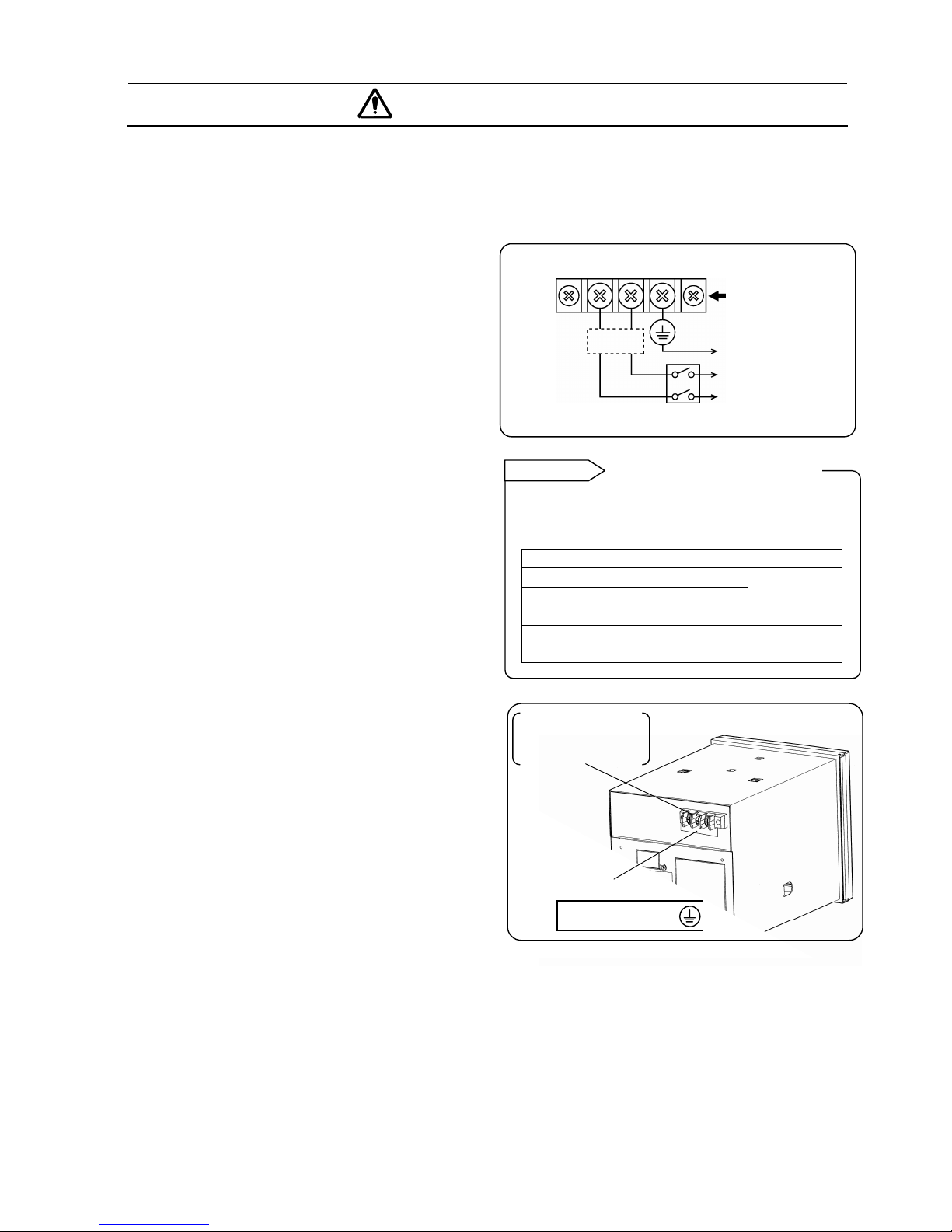

1. Switch and overcurrent

protective device

This instrument is not provided with any power

switch and any replaceable overcurrent protective

device. Mount a switch and an overcurrent

protective device (breaker, circuit protector or the

like) for the power supply within 3m where the

operator can reach them handily. Use these switch

and overcurrent protective device conforming to

IEC947-1 and IEC947-3.

2. Connect the instrument to

the ground without fail.

Connect the protective conductor terminals of this

instrument to the protective conductor of the

power supply equipment. Don't disconnect them

during use for the purpose of preventing an

electric shock accident.

3. Before turning on the power

supply first

Make sure that the feed voltage is within the

range indicated on the power label for safety

before turning on the external power switch.

4. Don't repair or modify the

instrument.

Don't repair or modify the instrument by replacing

parts by any persons other than servicemen

approved by our company, otherwise the

instrument may be damaged or the instrument

does not function normally, and also, accidents like

an electric shock accident may occur.

The internal unit and case are provided with

electric circuits and moving parts.

Don't put your hands, etc. into them, otherwise an

electric shock accident or injuries may result.

5. Use the instrument according to the instruction manual.

Use the instrument correctly and safely according to this instruction manual.

You should understand that we are not responsible for any injuries, damage, lost profits, and any other

demands which may be caused by wrong uses.

6. Stop feeding power supply, if an abnormal symptom occurs.

If abnormal odor, noises, or smoke occurs, or if the instrument is hot to such an extent as it cannot touch

by hand, a dangerous trouble may occur. Turn off the power supply at once, and inform CHINO's sales

agent of it.

Overcurrent

protective

device

(250V 3A)

Switch

Feed power

To protective

conductor of power

supply equipment

Power terminals

and protective

conductor terminal

LN

Power terminals

Protective

conductor terminal

100-240V AC

50/60Hz 45VA MAX

Power label

The following fuse is mounted in the power

supply unit of this instrument for safety use.

However, this fuse is not replaceable.

Manufacturer Model Ratings

SCHURTER SPT001.2508

LITTEL FUSE 21502.5

WICKMANN 19181

250V AC

2.5A

LITTEL FUSE 215002P 250V AC

2A

Fuse in power supply unit

Reference