CHINT NJBK6 Series Installation instructions

NO:2020.09

Standard: IEC/EN 60947-4-1

NJBK6 Series

Motor Protector

User Instruction

Only professional technicians are allowed for installation and

maintenance.

Installation in any damp, condensed-phase environment with

inflammable and explosive gas is forbidden.

When the product is being installed or maintained, the power

must be switched off.

You are prohibited from touching the conductive part when the

product is operating.

The product shall be stored, installed and used in accordance

with the rated control power supply voltage and specified

conditions indicated in the user instructions.

1

2

3

4

5

Safety Warning

01

Use Purpose

1

Key Technical Parameters

2

NJBK6-36 motor protector (hereinafter referred to as the protector) is

applicable to the protection of overload, loss of phase, three-phase current

unbalance and blocking of none-stop or intermittent duty AC motors with

AC frequency 50Hz, rated insulation voltage below 690V and rated

operating current 1A~36A.

Table 1 Ambient Conditions

Normal use

conditions

Atmospheric

conditions

Installation category

Transport and

storage conditions

Ambient temp.: -5℃~+40℃; average value within 24h

not exceeding +35℃; altitude not exceeding 2000m.

RH shall not exceed 50% when maximum temperature is

+40℃; in case of lower temperature, higher RH is allowed.

Measures should be taken against occasional condensation

due to temperature change.

Ⅲ

-25℃~+55℃

Table 2 Product Specifications and Main Technical Parameters

Model

Setting current (A)

Current setting range (A)

Motor power (kW)

NJBK6-36/3 NJBK6-36/9 NJBK6-36/24 NJBK6-36/36

3

1~3

0.5~1.5

9

3~9

1.5~4.5

24

8~24

4~12

36

12~36

6~18

Plug installation (supported by a contactor of specified model)

Knob

Indicator (green light is on in normal operation;

red light is on in phase loss; red light is on in overload)

Installation method

Setting method

Display method

Protection of overload, loss of phase,

three-phase current unbalance and blocking

1 group of change-over

Protection function

Number of contacts

02

Table 3 Main Circuit Technical Parameters

Product Model NJBK6-36/3 NJBK6-36/9 NJBK6-36/24 NJBK6-36/36

NT00-4 NT00-10 NT00-25 NT00-40

CJX2-32/NC1-32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Rated insulation

voltage (V)

No.

690

AC220V、AC240V、AC380V,50Hz

85%Us~110%Us

4

3

Type 2

Rated control supply

voltage Us (V),

frequency (Hz)

Allowable fluctuation

range of rated control

power supply voltage

Rated impulse

withstand voltage

Uimp (kV)

Rated conditional

short-circuit current

(kA)

CPD type

SCPD model

Contactor model

CJX2-25/NC1-25

Enclosure protection

class (if applicable)

IP20

M3

0.5

Size of terminal

tightening screw

(or nut)

Torque of terminal

tightening screw (N·m)

Class 3

8h duty or non-stop duty

B

Pollution class

Rated duty

Electromagnetic

environment

03

No.

1

2

3

4

Motion time

No motion within 2h

Motion within 2h

Motion within 2min

2s<Tp≤10s

Table 4 Auxiliary Circuit Technical Parameters

Product model NJBK6-36/3, NJBK6-36/9,

NJBK6-36/24, NJBK6-36/36

1

2

3

4

5

6

Rated insulation voltage (V)

Rated impulse withstand voltage Uimp (kV)

Agreed free air heating current Ith (A)

Rated operating voltage Ue(V)

No.

380

2.5

5

240V 380V

AC-15

1.5 0.95

Use type under rated operating voltage and

rated operating current Ie(A)

SCPD model 6A Gg

2.1 Motion characteristic

2.1.1 See Table 5 for the motion characteristic of overload protection

Table 5 Motion Characteristic of Overload Protection

Setting current

multiple

1.05

1.2

1.5

7.2

Cold

Thermal

Cold

Starting

condition

Ambient air

temperature (℃)

+20

2.1.2 Motion characteristic of phase loss protection: When any one of the

three-phase currents of the main circuit is open, the protector motions for

3s, with a relative error of ± 20%.

2.1.3 Motion characteristic of three-phase unbalance protection: When the

three-phase current of the main circuit conforms to the following formula,

the protector motions for 3s with a relative error of ± 20%.

30%100%

|| i

3

1i >×

-

=

avg

avg

I

II

Max

Where:

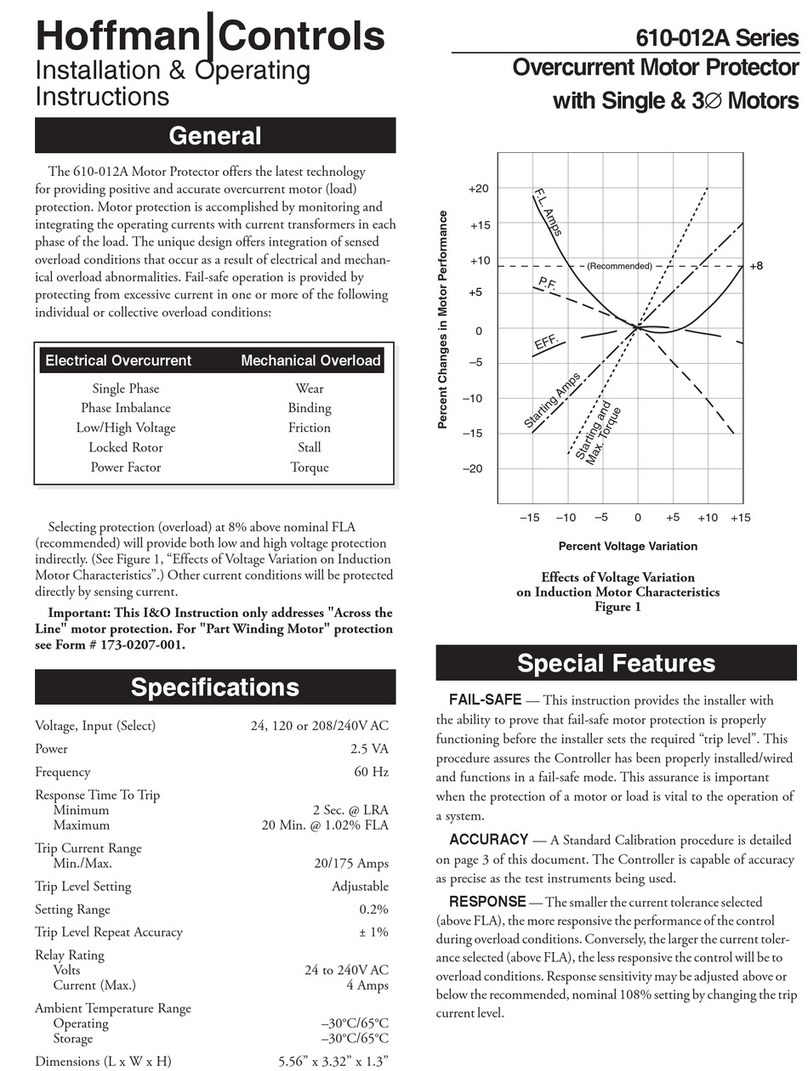

Figure 1 Outline and Installation Size of the Protector

04

Installation

3

3.1 Outline and installation size: see Fig. 1

Unit:mm

Effective current value of each phase.

Mean value of effective three-phase current values.

2.1.4 Motion characteristic of blocking protection: The blocking current set

in the protector is 6Ie. When the current of the main circuit is greater than

the blocking current, the protector motions for 3s with a delay and a relative

error of ± 20%.

2.2 Reset characteristic

i

I

avg

I

After the protector motions, the protector’s reset mode is manual

reset when the rated control power supply voltage is normal; the protector

is immediately reset when the rated control power supply voltage is

disconnected.

54.5max 82max

88max

L3 L2 L1 N

FU1

W1 V1 U1

QS

FU2

W2 V2 U2

W3 V3 U3

W4 V4 U4

QF1

KM

KM

STP ST

QF1

KM

95

96

A1

A2

M

3~

L3 L2 L1 N

FU1

W1 V1 U1

QS

FU2

W2 V2 U2

W3 V3 U3

W4 V4 U4

QF1

KM

KM

STP ST

QF1

KM

95

96

A1

A2

M

3~

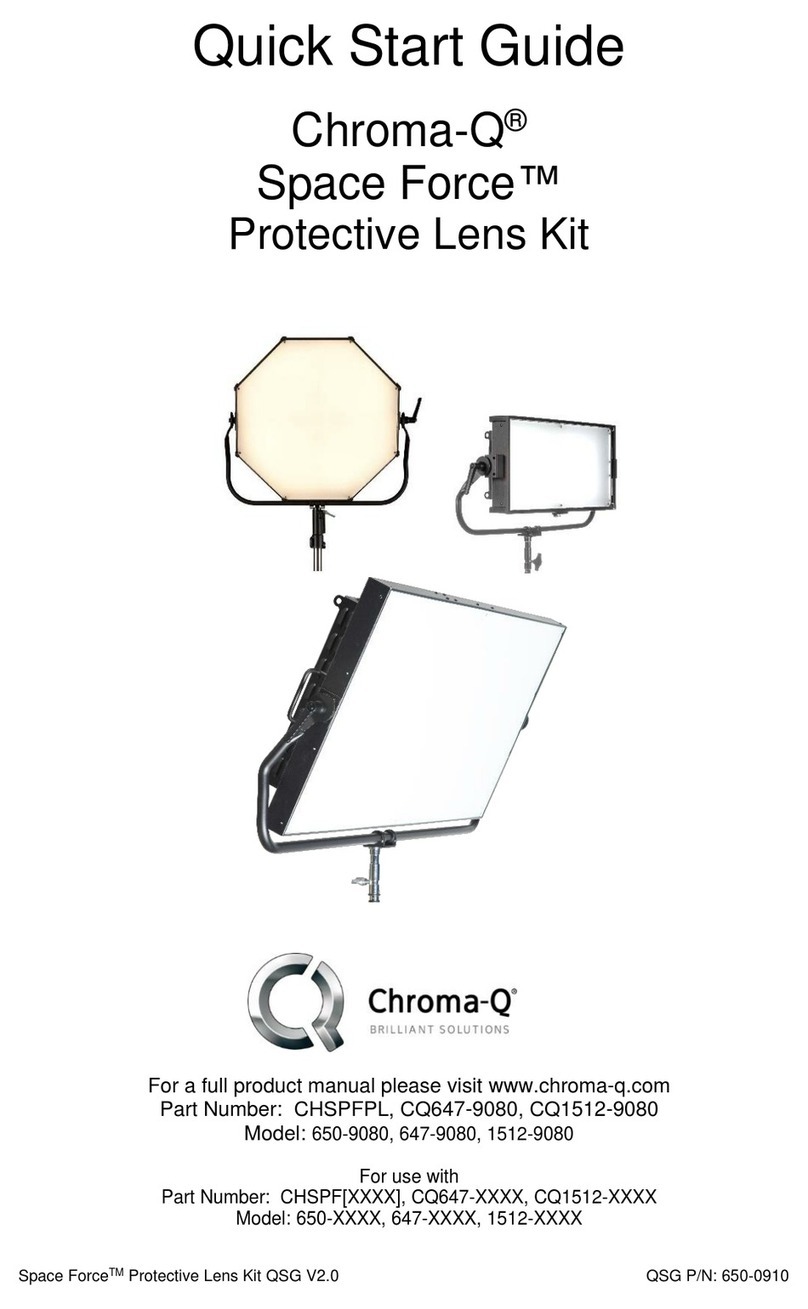

Figure 2 Wiring Diagram of the Protector with the

Control Power Supply Voltage of AC220V/AC240V

05

3.2 Wiring diagram: See Fig. 2 ~ Fig. 3.

Figure 3 Wiring Diagram of the Protector with the

Control Power Supply Voltage of AC380V

06

3.3 Test/reset button instructions: “TEST/RST” on the protector is the

test/reset button. Press it when the product is working normally, the

protector motions and the red light flashes; press it after a fault, the

protector is reset.

3.4 Adjustment of the setting current value: the protector uses the setting

knobs with indicating arrows. Based on the setting current value on the

nameplate, set the current according to the rated current and motor load

condition marked on the nameplate of the motor. Adjust the setting current

value of the protector to a scale equal to the rated current value marked on

the motor nameplate.

3.5 Commissioning: After confirming that the wiring and setting are correct,

power on the product and press the start button, then the motor should be

able to run normally and the (green) operation indicator on the panel

should be on. If the red indicator flashes, fine tune the setting value until

the red indicator light just does not flash.

Notes:

1 Check the performance of the protector on a regular basis. Perform overload

and loss of phase testing. The testing should be performed by professional

technicians to ensure the safety of electricity use.

2)The setting error of the protector shall not be greater than 5%. When the

current of the main circuit is within this range, the overload indicator may be on.

3)If the motor stops during its operation, the motor should be checked for loss

of phase or overload. First, check whether the temperature rise of the motor is

too high. If the temperature rise is too high, the stop may be caused by

overload; if not, the motion of the protector may be caused by the loss of phase

of the circuit. Check whether the three-phase power supply is normal, whether

the dynamic and static contacts of the AC contactor are in good contact, and

whether the three-phase power line of the motor has loosened; if everything

goes well but the motor still cannot be started, then carefully check whether the

self-locking contact of the AC contactor and the terminal wiring of the protector

have loosened. The motor cannot be started until the fault is eliminated. When

the fault is not eliminated, it cannot be started forcibly for fear of accidents.

4)Do not open the protector without permission, so as to avoid danger or

affecting the normal operation of the protector.

)

07

Maintenance

4

Table 6 Analysis and Troubleshooting of Common Faults

Symptoms Cause analysis Troubleshooting method

Whether the wire and the

terminal are in reliable

contact, and whether the

power terminal is correctly

wired.

The power indicator

light is off.

The motor stops in

operation

Environmental Protection

5

In order to protect the environment, the product or product parts

should be disposed of according to the industrial waste treatment process,

or be sent to the recycling station for assortment, dismantling and recycling

according to local regulations.

4.1 The terminal of the protector should be tightened on a regular basis.

4.2 Avoid squeezing the product; the product should be stored in a well-

ventilated place.

Connect wires reliably

according to the user

instructions.

Whether the motor has

phase loss or overload.

Trouble shooting according

to Note 3) under No. 3.5.

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO.,LTD.

NJBK6 Series

Motor Protector

IEC/EN 60947-4-1

JDQ Check 10

09

NJBK6 Series

Motor Protector

User Instruction

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

This manual suits for next models

4

Table of contents

Popular Protection Device manuals by other brands

Vega

Vega SOURCE 82 operating instructions

Tractel

Tractel FABA System AL2 Installation and operating manual

Siemens

Siemens TPS4 13 Installation, operation and maintenance manual

ABB

ABB Relion REG670 Commissioning manual

i4Technology

i4Technology BugHunter DAudio bda-4 Voice user manual

Intermatic

Intermatic IG2TM installation instructions