Page 2

Description

Positive trigger lock-out

Quick make-and-brake contacts, which

directly handle the motor circuit, are

locked in position until tripped. The

roller-type trigger lockouts prevent

positively any operation of the Limit

Switch until the full power of the high-

tensile, oil-tempered, magnafluxed

spring is available to assure extremely

fast operation for either tripping or re-

setting. Operation in any intermediate

position of the operating lever is im-

possible.

Direct contact opening and closing

In the remote possibility of spring fail-

ure, the contacts are operated by the

direct drive action of the tripping and

reset weights. In tripping, as the reset

weight causes the trip pin to engage

the operating pin to operate the con-

tacts. In resetting, the reset-pin does

the job.

One piece movable contacts

The low inertia of these contacts prac-

tically eliminates any contact bounce.

Exclusive arc transfer system

This arc transfer system combined with

the shape of the arc chamber allows

greater arc interrupting in a smaller

space. The arc is confined to a con-

trolled path for more efficient extin-

guishing. No destructive burning of the

contacts can occur as the arc is trans-

ferred to the rearmost part of the mag-

netic blowout coil guards and to the

central rod conductor in the arc shield.

A smaller Limit Switch is made possi-

ble.

Sturdy Housing

Size 4, 5, 6, & 6A cases are of cast

iron. Size 2 and 3 cases are molded

fiberglass. The cover is of tough glass-

reinforced polyester resin. It is easily

removed for ready access to the con-

tacts.

Safety chain

The insulated cover is securely fas-

tened to the case by means of a safety

chain to prevent loss when removed

from the case.

Clearly marked leads

Flexible leads for external connections

extend through snug-fitting neoprene

bushings in the back of the cast-iron

case. They are clearly marked to

speed installation.

Rugged Construction

High-quality materials reduce mainte-

nance. All parts are of non-corrosive

materials. Contacts are hard-drawn

copper, except for sizes 3 & 6A which

use silver faced tips. The shaft is

stainless steel. All current-carrying

parts are copper or brass. Contact and

shunt fastening screws are stainless

steel.

Ball Bearings

Four oversize, double-sealed ball

bearings are permanently lubricated to

minimize friction and reduce mainte-

nance.

Early Break Auxiliary (EBA)

The EBA option is available for crane

hoists that are controlled with AC or

DC drives. The EBA contacts (DPDT)

operate prior to the power contacts,

thus providing a signal to turn off the

drive before motor power interruption.

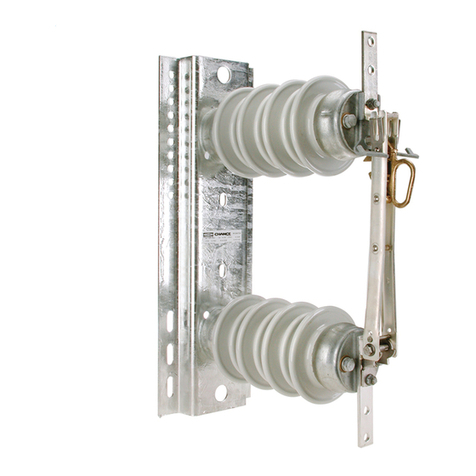

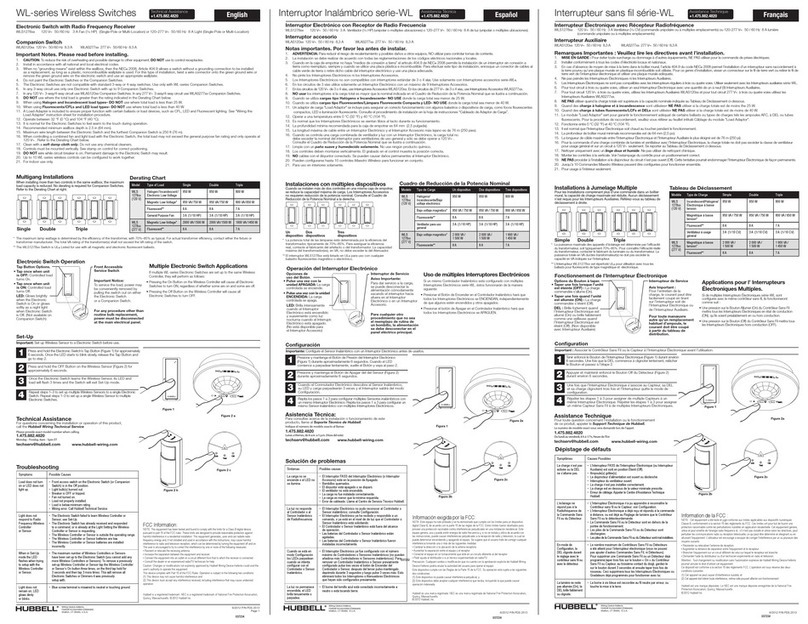

Installation

Euclid™ Type 4220 Crane Power Limit

Switches are easily field installed.

Mount horizontally on top of the trolley

frame of the hoist, with mounting feet

down. Install the split-sleeve sus-

pended weight guide around the deed-

ended cable. A bracket or striker plate

may be attached to the hook block, if

necessary, to lift the suspended weight

when hoising. Steel cable is furnished

for connection the suspended weight to

the operating lever.

D-C Units Only

The operating lever is adaptable for

either right or left-hand operation. Un-

less otherwise specified, right-hand

operation is furnished. Change in in-

stallation for left-hand operation can be

made either at the Factory or in the

field. Terminal markings only are af-

fected. Refer to wiring diagram for

correct connections.

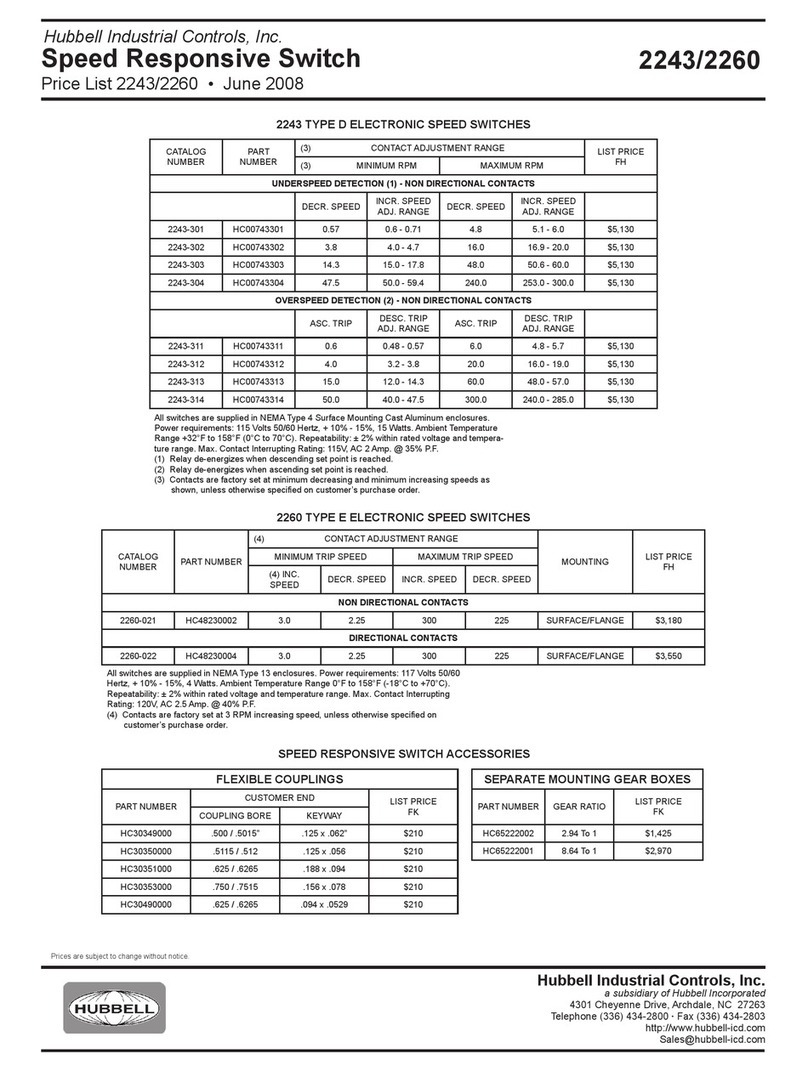

Resistors For D-C Limit Switches

Euclid™ Type K-exclusive continuous

wound, corrosion resistant, non-

breakable resistors, are specifically

designed for use with Euclid™ Type

4220 Hoist Limit Switches. See Price

List 4220.