CHISAGE CE-3P6KEG-Pro User manual

Copyright © Zhejiang Chisage New Energy Technology Co., Ltd.

Without written permission, any information of this document (partly or

entirely) cannot be extracted, copied or transmitted in any form or by any

means. All right reserved.

Notice:

The information in this document is subject to change without notice. Please

adhere to the actual products in case of any discrepancy. Any statements,

description, and recommendations in this manual do not constitute a

guarantee or warranty of any kind, explicitly or implicitly.

Warranty:

Warranty terms and conditions can be downloaded from the Internet at

www.chisagess.com.

1

Contents

1. About the Manual .............................................................................................................. 3

2. Product Overview ...............................................................................................................4

3. Safety ..................................................................................................................................7

4. Mounting ............................................................................................................................8

4.1 Installation Location .................................................................................................8

4.2 Inverter Mounting ....................................................................................................9

5. Electrical Connection ....................................................................................................... 11

5.1 DC Side Connection of Inverters ............................................................................11

5.2 AC Side Connection of Inverters ............................................................................ 13

5.3 External Grounding Connection ............................................................................ 14

5.4 Earth Fault Alarm ................................................................................................... 15

5.5 Over Current Protection Device .............................................................................16

5.6 Communications Connection ................................................................................ 16

5.7 Electrical Connection Overview .............................................................................17

5.8 Meter and CT Installation (optional) ..................................................................... 18

5.9 Residual Current Device (RCD) ...............................................................................19

5.10 DRM (Demand Response Mode) ......................................................................... 19

6. Operation ......................................................................................................................... 20

6.1 Start and Stop Inverters ......................................................................................... 20

6.2 LCD Operation ........................................................................................................ 21

6.2.1 Main Menu ..................................................................................................21

6.2.2 Basic Info. ....................................................................................................22

6.2.3 Basic Setup ..................................................................................................24

6.2.4 Detail Info - Maintenance Personnel Only ................................................. 25

6.2.5 Technical Set – Maintenance Personnel Only ............................................ 30

7. Maintenance and Troubleshooting ..................................................................................42

8. Specification ..................................................................................................................... 49

2

3 4

1. About the Manual

2. Product Overvie

The manual describes product information, mounting, installation, operation,

maintenance, troubleshooting and specification of Zhejiang Chisage inverters.

Validity

The document is valid for the following inverter models: CE-3P5KEG-Pro, CE-

3P6KEG-Pro, CE-3P8KEG, CE-3P10KEG, CE-3P12KEG, CE-3P15KEG, CE-3P18KEG

,and CE-3P20KEG.

Target Group

The target group of this manual are end users and qualified persons who

have knowledge of inverters or skills of inverter installation, maintenance, etc.

Only qualified persons are allowed to perform the installation and activities

marked in this document under the guidance of safety instructions. Please

read this manual carefully before conducting any kind of work on the

inverters.

Valid Region

This manual applies to the operation of Zhejiang Chisage inverters in

Australia, New Zealand, the UK, EU, South America, North America, and

Southeast Asia.

w

2.1 Product Description

Zhejiang Chisage CE-3P5KEG-Pro, CE-3P6KEG-Pro, CE-3P8KEG, CE-

3P10KEG,CE-3P12KEG, CE-3P15KEG, CE-3P18KEG, and CE-3P20KEG

three phase on-grid inverters convert DC power generated by

photovoltaic panel arrays into AC power and feed theconverted AC

power into utility grid.

Product Appearance:

No. 1 2 3 4 5 6 7

Name DC

Switch

PV

Input

Ports

CT

Port

Wifi/GPRS

stick Port

COM/Me

ter/DRM

Port

Grounding

Port

AC

Output

Port

5 6

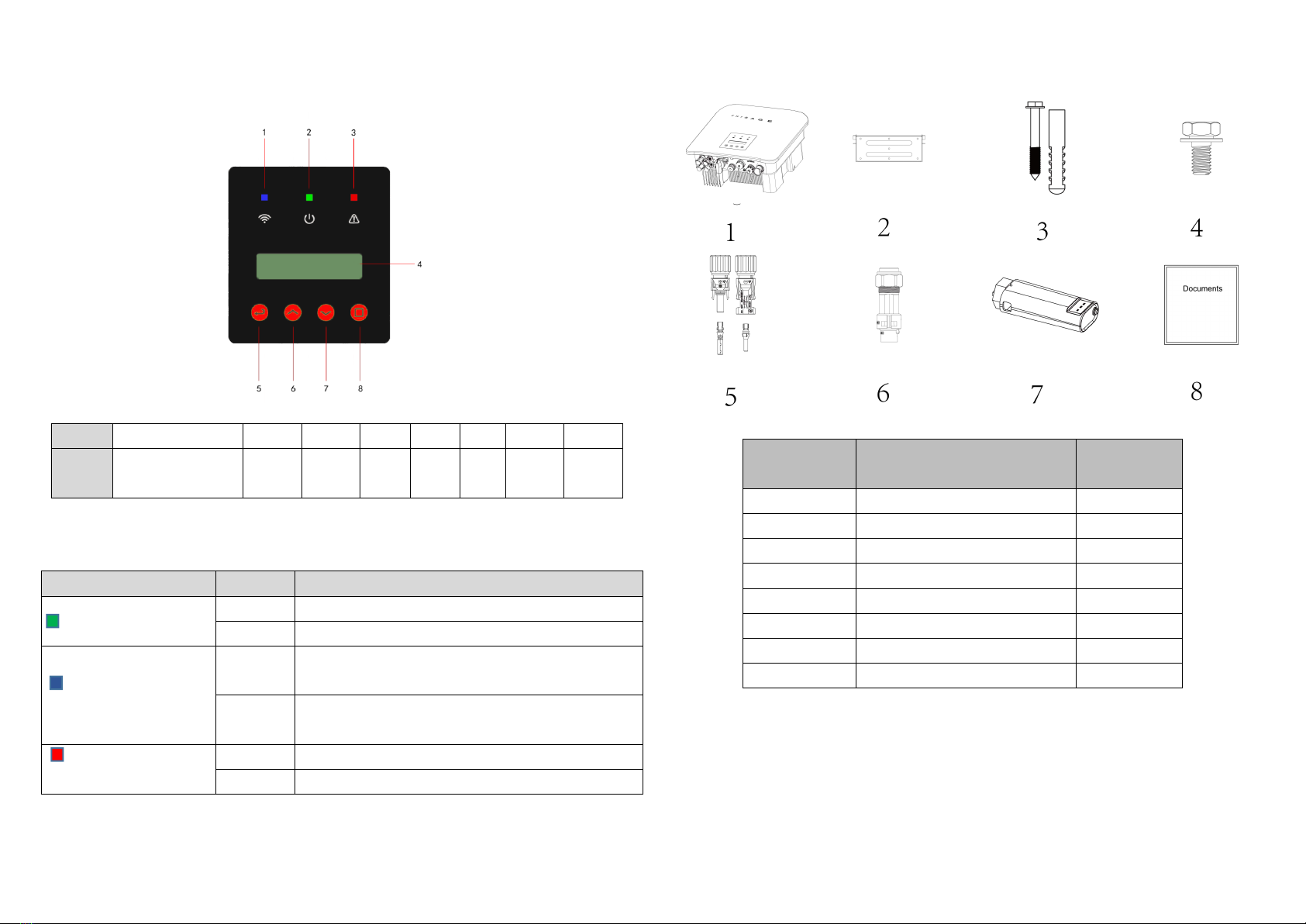

2.2 Front Panel

Operation Panel:

LED Light:

Light Status Explanation

O

POWER N The inverter is generating power

OFF The inverter is not generating power

COMMUNICATIONS

ON The inverter has been connected to the

Internet

OFF The inverter has not been connected to the

Internet

ALARM ON Alarm or fault has been detected

OFF The inverter is operating normally

2.3 Scope of Delivery

No. Description Quantity

1 Inverter 1

2 Wall Bracket 1

3 Expansion Screws 3

4 Fastening Screws 3

5 DC Connectors 3 / 4 (pairs)

6 AC Connectors 1

7 WiFi/GPRS Stick 1

8 Documents 1

No. 1 2 3 4 5 6 7 8

Name Communications

Light

Power

Light

Alarm

Light

LCD ESC Up Down Enter

7 8

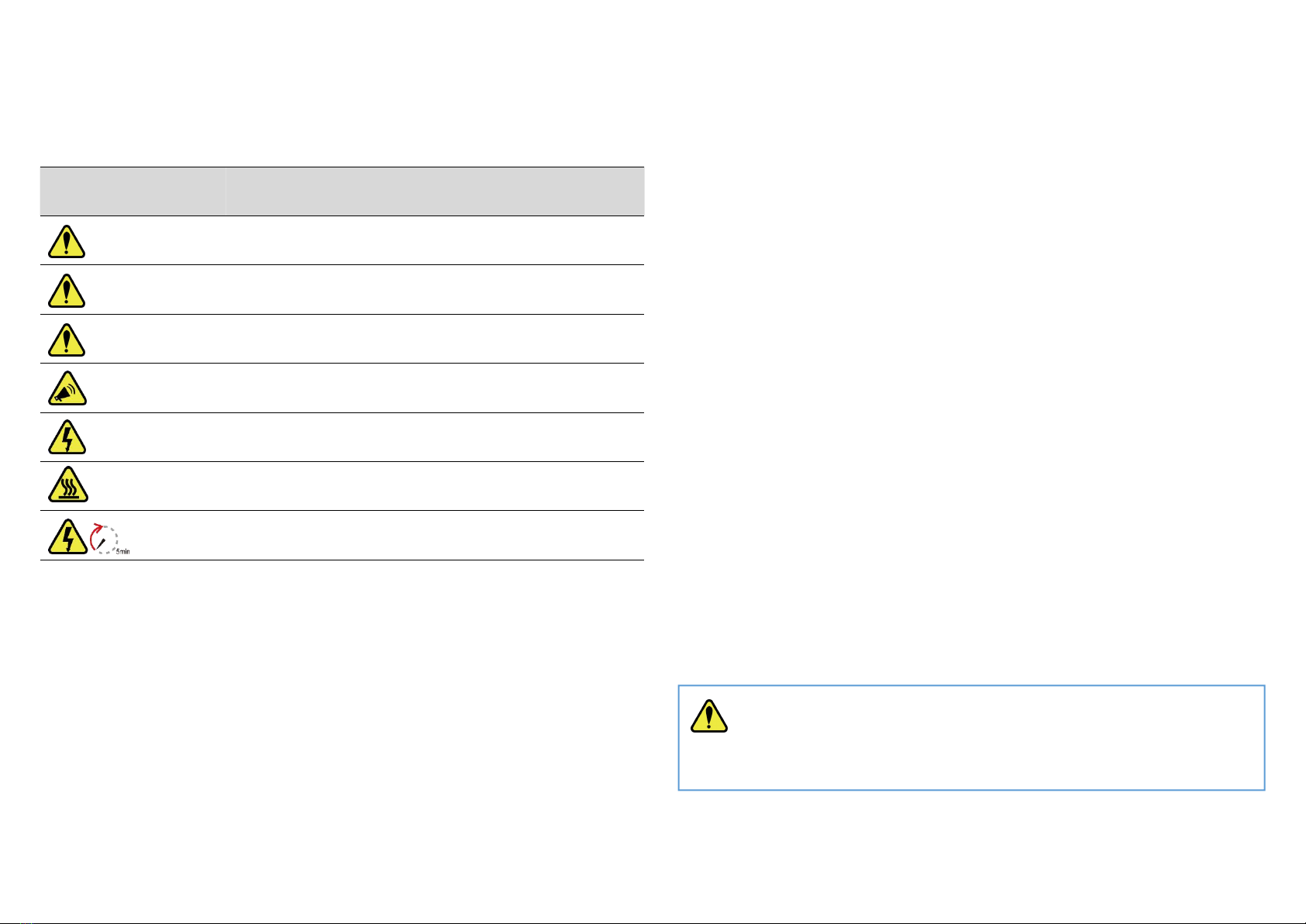

3. Safety

3.1 Safety Symbols

Symbol Explanation

Indicates a high level of risk which, if not avoid, may

result in death or serious injur

DANGER y

Indicates a medium level of risk which, if not avoid,

may result in death or serious injur

WARNING y

Indicates a low level of risk which, if not avoid, may

result in minor or moderate injur

CAUTION y

Indicates a situation which, if not avoided, may

result in device damage or property damag

NOTE e

ELECTRIC SHOCK Indicates a danger of electric shock or high voltage

Indicates hot surface, do not touc

HOT SURFACE h

Notice of waiting at least 5 minutes before operatio

WAIT

n

3.2 Safety Instructions and Notice for Use

The inverters involved in this manual comply with applicable safety and

technical regulations in design and test. To avoid personal injury and property

damage and to ensure longer service life of the machines, please read this

manual carefully and observe all safety information during operation.

Improper operation may result in risk of person injury or damage to the

machine and to other property, so please ensure that the following

requirements are met before or during operation.

Installation of inverters must be performed by qualified technicians, and

be in compliance with applicable electrical standards, regulations and the

requirements of local power authorities.

Wear protective equipment for all work on the machines: helmet,

insulated footwear, gloves, etc.

Ensure that unauthorized persons and children have no access to the

machines.

Do not open the housing of the machines at any time. Unauthorized

opening will void guarantee and warranty and may damage the

machines.

Do not touch non-insulated parts or cables, disconnect the machines

from voltage sources and guarantee no possible re-connection before

working on the machine.

Use measuring devices with a DC input voltage range of 1100 V or higher

only.

High voltage is present in the live parts and cables inside the product

during operation, wait at least 5 minutes after disconnecting voltage

sources.

The temperature of some parts of the inverter may exceed 60 ℃during

operation. To avoid being burnt, do not touch the inverter during

operation.

Pack inverters properly during transportation, and do not transport them

together with flammable material.

4. Mounting

4.1 Installation Location

The following points should be considered when selecting an installation

location.

or ex

p

losion

WARNING

Do not select locations storing flammable material which may cause fire

!

9 10

The wall bearing inverters shall be able to hold the weight of at least 4

times of the weight of the inverters.

The location shall be convenient for electrical connection, operation and

maintenance.

The ingress protection of the inverter is IP66, so it can be installed both

indoors and outdoors.

The temperature of the cooling fin may exceed 75 ℃, so select safe

locations.

The location must be well ventilated and sheltered from direct sunlight,

rain or snow.

Ensure the visibility of the LED lights and LCD display on the front panel

of inverters.

Install inverters vertically or with a backward tilt within 15 degrees. No

lateral tilt is allowed.

If more than one inverter are installed in one location, a minimum 150

mm clearance should be kept between two inverters and a minimum 300

mm clearance between inverters and the ground.

The Inverter is to be installed in a high traffic area where the fault is likely

to be seen.

4.2 Inverter Mounting

Dimension of the mounting bracket:

Unit: mm

Procedures:

1) Ensure that the bracket is horizontal. Mark the position of the drill holes.

For brick walls, the position of the holes should suit expansion screws.

2) Use a 10 mm drill bit to drill mounting holes of 40 mm deep.

3) Insert the expansion tubes into holes.

4) Screw the expansion screws into expansion tubes with a cross

screwdriver to fix the bracket on the wall.

5) Lift up the inverter, and hang it on the mounting bracket securely.

6) Lock the inverter to the mounting bracket with screws.

NOTE: To protect your hands from scratch, please wear gloves!

11 12

5. Electrical Connection

5.1 DC Side Connection of Inverters

5.1.1 PV Array Configuration

This inverters are compatible with monocrystalline silicon, polycrystalline

silicon, and thin-film PV panels. The recommended PV array matching the

inverters are listed below:

1.25 × Isc of each PV string ≤PCE(Inverter) DC input Isc (18A)

Voc of each PV string ≤ 1100 V

PV strings should be connected to the inverter through special PV connectors

that are in the scope of delivery.

It is recommended to use the DC cable of 4 mm2or 6 mm2.

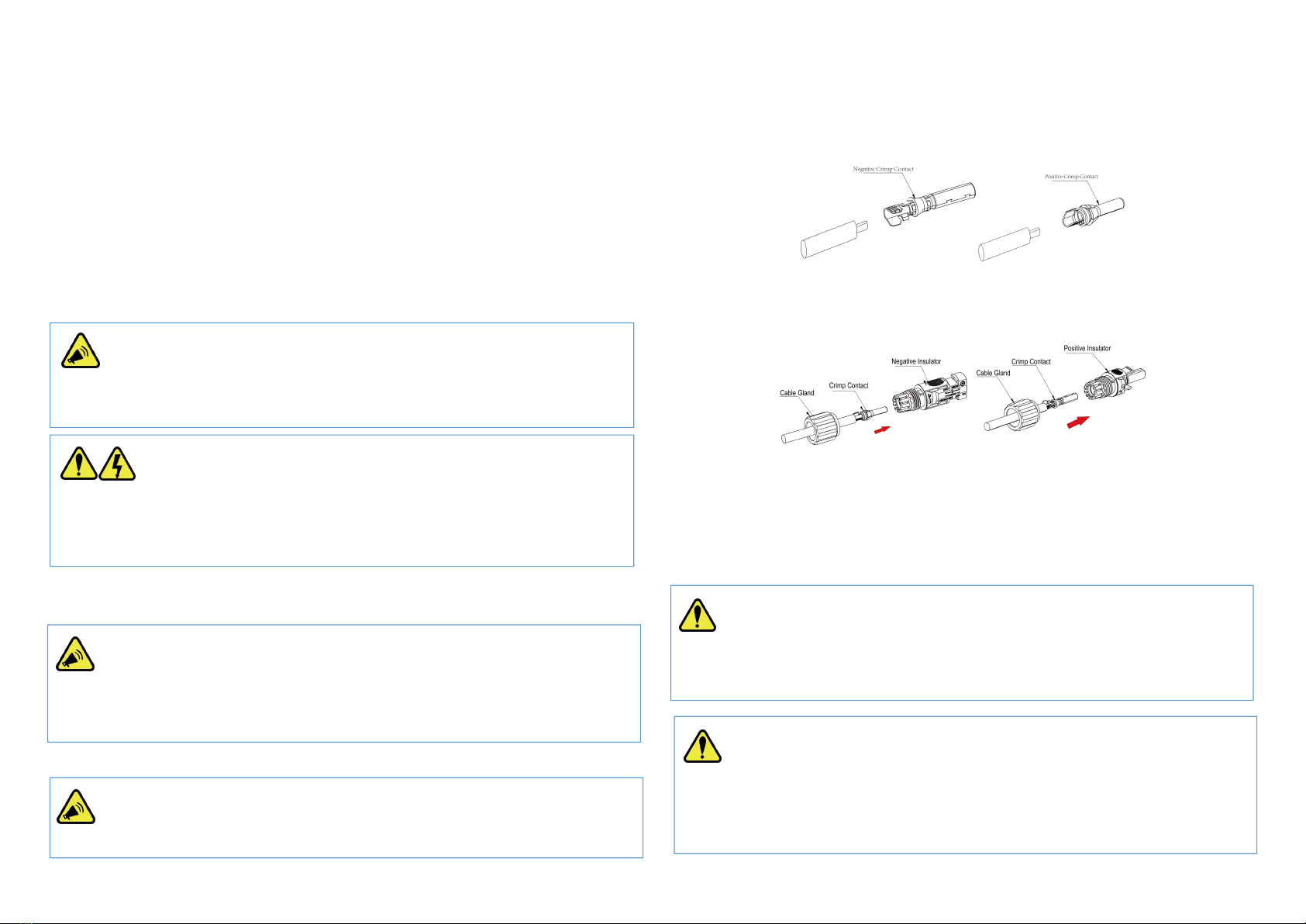

5.1.2 Assemble DC cables to DC connectors:

1) Strip the insulation layer off the DC Cable for a little length.

2) Insert the wire into the Crimp Contact and crimp them with an electrical

crimp-er.

3) Thread the cable through the Cable Gland, insert it into the insulator, and

gently pull backward the cable to ensure firm connection. Then screw up

the Cable Gland to the Insulator.

5.1.3 Install the DC connectors to the Inverter:

1) Turn the Grid Supply Main Switch OFF.

2) Turn the DC switch OFF.

3) Connect the DC connectors to the Inverter, small click confirms

connection. Please guarantee the correct polarity of the connection.

Lethal high voltage will be generated by PV arrays under sunlight, so

please disconnect DC and AC breakers and ensure no possibility of

re-connection before conduct electrical connection

DANGER ELECTRICAL SHOCK

!

Ensure that the open circuit voltage of PV array is within the max. input

voltage of the inverter

WARNING

!

NOTE: Use DC cables specialized for photovoltaic systems Only!

WARNING: Do not turn off DC switch directly for accident reverse

connection of DC inputs or any fault of inverters as it may damage

inverters. In that case, turn off the DC switch only when the DC current is

below 0.5 A.

NOTE: Use only the supplied connector or the connector with IP 65

or above to guarantee that the protection ingress of the whole inverter is

IP66!

NOTE: PV arrays should be under the protection of over voltage

classⅡ. For the grounding of the PV array, the frame of panels should

contact the rail

,

and the the

g

roundin

g

cable connect the rail.

13 14

5.2 AC Side Connection of Inverters

For the sake of safety, it is recommended to use the AC cable of 4 mm2.An AC

Connector is supplied together with the inverter.

AC Connector

Procedures:

1) Strip the insulation layer off the AC cable about 8 to 15 mm.

2) Thread the AC cable through the Nut, Sealing Plug and the Housing.

3) Connect wires to the Terminal Block:

insert yellow green wire to the grounding (PE) terminal, red or brown

to live line (L) terminal and blue or black to zero line (N) terminal;

screw up screws on the connectors with socket head wrench and pull

back wires to ensure firm connection.

4) Connect the Nut, Sealing Plug, Housing and Terminal Block together, a

small click confirms secure connection.

5) Connect the AC connector to the inverter, a small click confirms

connection.

5.3 External Grounding Connection

The external grounding port is located beside the AC connection terminal of

the inverter. The parameters of designed external protective earthing

conductor and screw are as below:

M4 screw with the cross-sectional area of 6.1 mm2;

AWG8 conductor with the cross-sectional area of 6 mm2.

Procedures:

Prepare an OT terminal M4, crimp a grounding cable to the terminal, insert a

fastening screw into the OT terminal, insert them to the grounding port on

the inverter, and screw them tightly (the torque is 1.1 N.m.).

15 16

5.5 Over Current Protection Devic

5.4 Earth Fault Alarm

The inverters are designed with an earth fault alarm function. If an earth fault

occurs, the inverters will stop generating power, the red alarm light will be on

and the LCD will display ‘ISO Out Range’ or ‘PEN No Connect’. In that case,

please refers to Chapter 7 for troubleshooting or contact Zhejiang Chisage for

help.

e

It is recommended to install a breaker (over current protection device (OCPD))

to protect the AC grid connection conductors. The table below is the

recommended parameter of an OCPD ratings for the Inverter.

5.6 Communications Connection

5.6.1 Communications overviews

The inverters have remote communications functions with the help of Wifi

sticks. The performance of inverters can be monitored remotely through a

specified APP or website.

WiFi/4G Stick Installation

Assemble WiFi/GPRS stick to the corresponding port on inverter as shown in

the diagram.

1) Plug the stick to the Wifi port on the inverter

2) Rotate the front operative part of the stick clockwise till the secure

connection of the stick

More detailed information about communications can be found in

corresponding manuals.

Inverter Rated output

voltage (V)

Rated output

current (A)

forCurrent

protection

device (A)

CE-3P10KEG 230/400 14.5 25

WARNING: The external grounding connection cannot replace

the connection of PE terminal in AC connection. Ensure that both the

external grounding connection and the PE connection are done properly!

DANGER ELECTRICAL SHOCK

When the PV array is exposed to light, it supplies a d.c. voltage to the PCE.

CE-3P6KEG-Pro

CE-3P8KEG

CE-3P5KEG-Pro 230/400

230/400

16

7.2

230/400

8.7

11.6 16

25

CE-3P12KEG

CE-3P15KEG

CE-3P18KEG

CE-3P20KEG

230/400

230/400

230/400

230/400

17.4

21.7

26.1

29.0

25

32

32

40

17 18

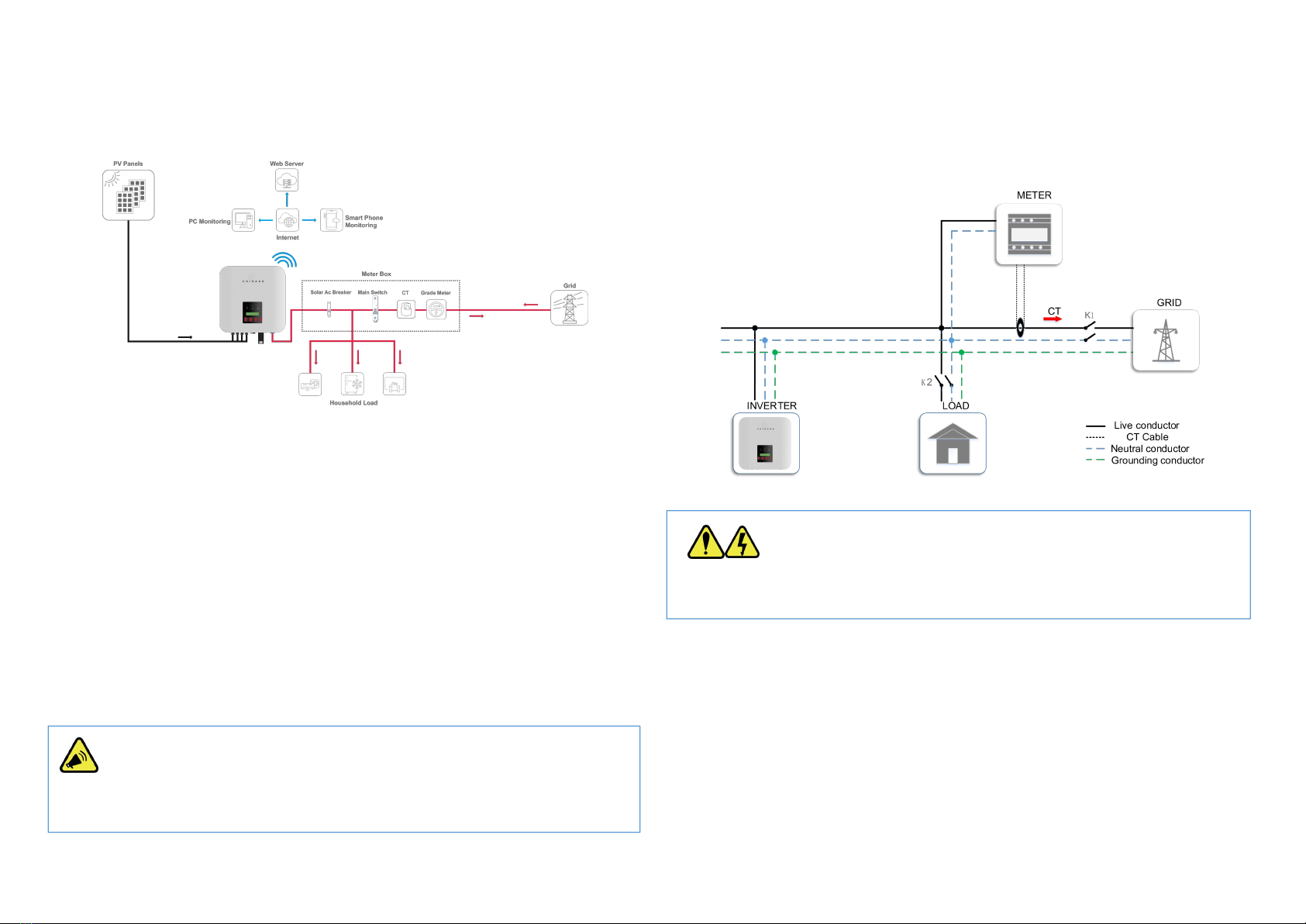

5.7 Electrical Connection Overview

The following is a diagram of a typical solar system for your reference to

install inverters.

5.8 Meter and CT Installation (optional)

A meter and CT(current transformer) can be connect to corresponding ports

on inverter to monitor electricity parameter such as current, voltage, power,

etc. and to realize export power management.

The suggested parameter:

Max input current for meter: 80A

Max measuring current for CT: 100A/phase

Detail specifications of meter and CT can be found on Zhejiang Chisage

Website and a customer can purchase a suitable meter and CT for inverters

on the website.

Meter and CT connection:

For more information about meter and CT connection, please refer to

corresponding manuals on Zhejiang Chisage website.

The following is schematic diagrams for reference.

CT Installation Electrical Diagrams

Single Phase Meter Installation Electrical Diagrams

5.9 Residual Current Device (RCD)

An internal residual current device is integrated in the inverter to protect

against any potential residual current. If the residual current that exceeds a

set limit is detected, the inverter will stop working, the warning light will be

on and the LCD will display ‘GFCI Device Fault’ or ‘GFCI Out Range’.

The inverter can cause a d.c. current in the external protective earthing

conductor. Where a residual current-operated protective (RCD) or monitoring

NOTE

No need to change any parameter of the meter as it has been preset in the

factor

y

!

DANGER ELECTRICAL SHOCK

Turn off upstream and downstream electrical connection before the

meter installation!

19 20

(RCM) device is used for protection in a case of direct or indirect contact, only

an RCD or RCM of Type B is allowed on the supply side of this product.

5.10 DRM (Demand Response Mode)

The DRM port is only applicable to installations in Australia and New Zealand

as requires by the standard of AS/NZS 4777.2:2020. The inverter detects and

initiates a response to the demand response modes listed in the following

table.

Mode Functions

DRM 0 Operate the disconnection device

DRM 5 Do not generate power

DRM 6 Do not generate at more than 50 % of rated power

DRM 7 Do not generate at more than 75 % of rated power AND absorb reactive

power if capable

DRM 8 Increase power generation (subject to constraints from other active

DRMs)

Ways to connect a DRED (demand response enabling device) to inverters

1) Assemble a RJ45 connector by connecting a network cable to the RJ45

according to the international conventional method;

2) Plug the RJ45 connector to the DRM port of the inverter.

Power rate limit modes as required by AS/NZS 4777.2:2020 is supported in

this inverters. When a demand response mode (except for DRM 0) is asserted

or unasserted the power rate limit will apply to the increase or decrease in

power generation or consumption and the transitions between power levels.

When a DRED is connected to an inverter, the inverter will receive and

shown in the BASIC INFO in the LCD menu

response to the outside signal directly. And the DRM working mode will be

.

6. Operation

6.1 Start and Stop Inverters

6.1.1 Inverter Turning-on

The following procedures have to be followed exactly to start an inverter.

1) Turn on the AC breaker.

2) Turn on the DC Switch.

3) After a compulsory delay of 30 to 300 seconds, the inverter will start to

work and the POWER light will be on.

6.1.2 Inverter Turning-off

The following procedures have to be followed exactly when stop an inverter.

1) Switch off the AC Switch.

2) Wait around 30 seconds for the capacitor to dissipate energy. Then turn

the DC switch OFF.

3) Be sure that all LED light is OFF (around 1 minute).

CAUTION WAIT

Beware of the risk of electrical shock! Wait at least 5 minutes before

touching the machine although the DC switch has been turn off!

WARNING

Ensure that the open circuit voltage of PV array is within the max. input

voltage of the inverter!

DANGER ELECTRIC SHOCK

High voltage may present, please beware of the risk of electric shock and

take protection precautions!

21

22

6.2 LCD Operation

6.2.1 Main Menu

When the inverter has been started, the LCD screen shows operation status

and power of the inverter alternately every 10 seconds (refer to below figure).

You can press UP and DOWN keys to scroll the screens and press ENTER key

to access the main menu. The main menu includes four sub-menus: BASIC

INFO, BASIC SETUP, DETAIL INFO, and TECHNICAL SET.

6.2.2 Basic Info.

The table below explains the meaning of information displayed in the

sub-menu of Basic Info.

No.

Displays

Duration

Explanation

1

10 S

Total energy: total energy generated

2

10 S

This Month: total energy generated

this month

Last Month: total energy generated

last month

3

10 S

This Day: total energy generated today

Previous Day: total energy generated

yesterday

4

10 S

DC voltage1: the DC voltage of the PV

input 1

DC current1: the DC current of the PV

input 1

5

10 S

DC voltage2: the DC voltage of the PV

input 2

DC current2: the DC current of the PV

input 2

6

10 S

DC voltage3: the DC voltage of the PV

input 3

DC current3: the DC current of the PV

input 3

7

10 S

DC voltage4: the DC voltage of the PV

input 4

DC current4: the DC current of the PV

input 4

8

10 S

AC voltage A: the voltage of the utility

grid live line A

AC current A: the current of the utility

DC VOL1: 401.5V

DC CUR1: 18.6A

DC VOL2: 408.5V

DC CUR2: 18.6A

AC VOL A: 230.6V

AC CUR A: 38.8A

TOTAL ENERGY

50000 Kwh

ThisMon: 255Kwh

LastMon: 254Kwh

TODAY: 52 Kwh

PRE_DAY : 54Kwh

DC VOL3: 401.5V

DC CUR3: 18.6A

DC VOL4: 401.5V

DC CUR4: 18.6A

23

24

grid live line A

9

10 S

AC voltage B: the voltage of the utility

grid live line B

AC current B: the current of the utility

grid live line B

10

10 S

AC voltage C: the voltage of the utility

grid live line C

AC current C: the current of the utility

grid live line C

11

10 S

the frequency of phase A: 50.2 Hz

Output Power: 1200 W

12

10 S

the frequency of phase B: 50.2 Hz

Output Power: 1200 W

13

10 S

the frequency of phase C: 50.2 Hz

Output Power: 1200 W

14

10 S

The total output power

3600W

15

10 S

Cumulative energy generation time

16

10 S

Inverter SN: The SN of the Inverter

EE00S005000001A1

17

10 S

Working Mode:

DRM(Demand response mode)

Number:

18

10 S

This menu indicates the current

country grid code or safety standards

selected

Customers are able to view those info without password including country

grid code. cAUSAS4777_2A, cAUSAS4777_2B, cAUSAS4777_2C and

cNZS4777_2 represent Australia A, Australia B, Australia C and New Zealand

standard respectively. Another standards such as cEN50549_1 and

cABNT_NBR_16149 are also included in the menu.

6.2.3 BASIC SETUP

You can set time and address in this sub-menu.

No.

Display

Explanation

1

To set up time

2

To set up RS485 address

3

To set up language

6.2.3.1 Time Setting-up

When the sub-menu of ‘SET TIME’ is selected, the LCD will display the screen

as below.

Press ENT to move the cursor from left to right, Press UP/DOWN to select a

number for a selected digit. Press ESC to save the setting and return to the

main menu.

6.2.3.2 Address Setting-up

The inverter RS 485 address communicating with a monitoring platform can

TOTAL RUNTIME:

152 H

INVERTER SN

EE00S005000001A1

SET TIME

SET RS485 ADDR

NEXT = ENT OK = ESC

25-01-2022 18:23

FREQ C :50.2Hz

POWER C: 1200 W

SET LANGUAGE

MODLE:

Volt-Watt

Standard

cAusas4777_2A

AC VOL B: 230.6V

AC CUR B: 38.8A

AC VOL C: 230.6V

AC CUR C: 38.8A

TOTAL POWER

3600 w

FREQ A :50.2Hz

POWER A: 1200 W

FREQ B :50.2Hz

POWER B: 1200 W

25 26

be set here, the address ranges from ‘01’ to ‘99’, and the default address is

‘01’.

Press UP/DOWN to scroll through numbers for a selected digit, press ENT to

save the setting and return to the main menu, and press ESC to return to the

main menu without saving the setting.

6.2.3.3 Language Setting-up

Working language of the inverter can be set here, and the default language is

English.

6.2.4 Detail Info - Maintenance Personnel Only

Select ‘Detail Info’ from the main menu and the LCD screen will display the

following information:

Steps to view the menu of the Detail Info.:

1) Enter the password:

Please contact your inverter supplier for the default password. When finishing

password entering, press ENT to verify the password. If the password is

correct, the sub-menu will be displayed, and if wrong, the LCD will display

‘Wrong Password’ and return to the previous menu. Press ESC to return to

the main menu.

2) Access the sub-menu:

After enter the correct password, the sub-menus will be displayed:

1. Operation Info, 2. Fault Info, 3. Flash Version, 4. Warning Info, 5. SW

Version, 6. Rated Power, 7. Rated Voltage, 8. Daily Energy, 9. Monthly

Energy, 10. Yearly Energy, 11. Export Total, 12. Export Today

Press UP/DOWN to scroll the screen, press ENT to go into the selected

sub-menu and press ESC to return to the main menu.

6.2.4.1 Operation Information

This information is for maintenance personnel to get the operation

information, and the information is as below:

No.

Display Duration Explanation

110 S This menu indicates:

GFCI RMS: Leakage current

protection

ISO: Ground fault

protection/Insulation Resistance

210 S This menu indicates:

The temperature of heat sink of

inverters

310 S This menu indicates:

Inverter inner temperature

410 S This menu indicates:

Bus voltage

AC direct component

510 S This menu indicates:

Power factor ratio

Output power limit

610 S Half Voltage of Bus

Grid filter grade

YES = ENT EXIT = ESC

Slave Add: 01

NEXT = ENT EXIT = ESC

Password: 0000

GFCI RMS: 10 mA

ISO : 1.25 kΩ

Heatsink Temp

65.5 ℃

Inv Inner Temp

45.0 ℃

BusVol: 385.5V

DCI : 0 mA

PF:+1.00 ac

Pac Limit: 80%

BusHalfVol:

GridFilter: ON

27 28

7

10 S This menu indicates:

Residual current protection

Insulation Resistance/Ground

fault protection

810 S This menu indicates:

All PV in parallel mode

MPPT shadow mode

910 S This menu indicates:

Self examination of AC relay

Output direct component

protection

10 10 S This menu indicates the apparent

power

11 10 S This menu indicates the active

power

12 10 S This menu indicates the reactive

power

13 10 S This menu indicates the power

exported to grid

The operation info of inverter and part of protection info. can be view after

password has been input and all the info. is included in the above table. Press

UP/DOWN to scroll the screen to view.

6.2.4.2 Fault Info.

When a fault happens, the Alarm Light will be on, and the LCD will display a

brief description of the fault. Please refer to Chapter 7 for troubleshooting or

contact after-sales department if a fault info. is displayed.

6.2.4.3 Flash Version

The flash version can be checked here.

6.2.4.4 Warning Info.

If a adverse condition presents in the inverter, the LCD will display a warning

information. The inverter will work normally with such warning conditions.

When a warning info. is displayed, please refer to Chapter 7 for

troubleshooting.

6.2.4.5 Software Version/Firmware Version

The software version or firmware version of the inverter is displayed and is

accessible for technicians only.

6.2.4.6 Rated Power

The rated power of the inverter is displayed here.

6.2.4.7 Rated Voltage

The rated voltage of the inverter is displayed here.

NOTE: This operation is for maintenance personnel only. Password

is required to access this part!

ACHCT Device

Fault

Warning Info

0x00000400

Rated Power

5KW

SW Version

V01.05

RCD(GFCI): ON

PVISOGuard: ON

AllPVParal: ON

MPPTShadow:

RelayCheck:OFF

DCI Prot : ON

Apparent Power

2000 VA

Active Power

2000 W

Reactive Power

2000 Var

Export Power

4800W

Rated Voltage

220V

Flash Version

ES 3.0

29

30

6.2.4.8 Daily Energy

The energy generated for a specified day can be checked here.

6.2.4.9 Monthly Energy

The energy generated for a specified month can be checked here.

6.2.4.10 Yearly Energy

The energy generated for a specified year can be checked here.

6.2.4.11 Export Total

Total energy exported to grid can be checked here.

6.2.4.12 Export Today

The energy exported to grid today can be checked here.

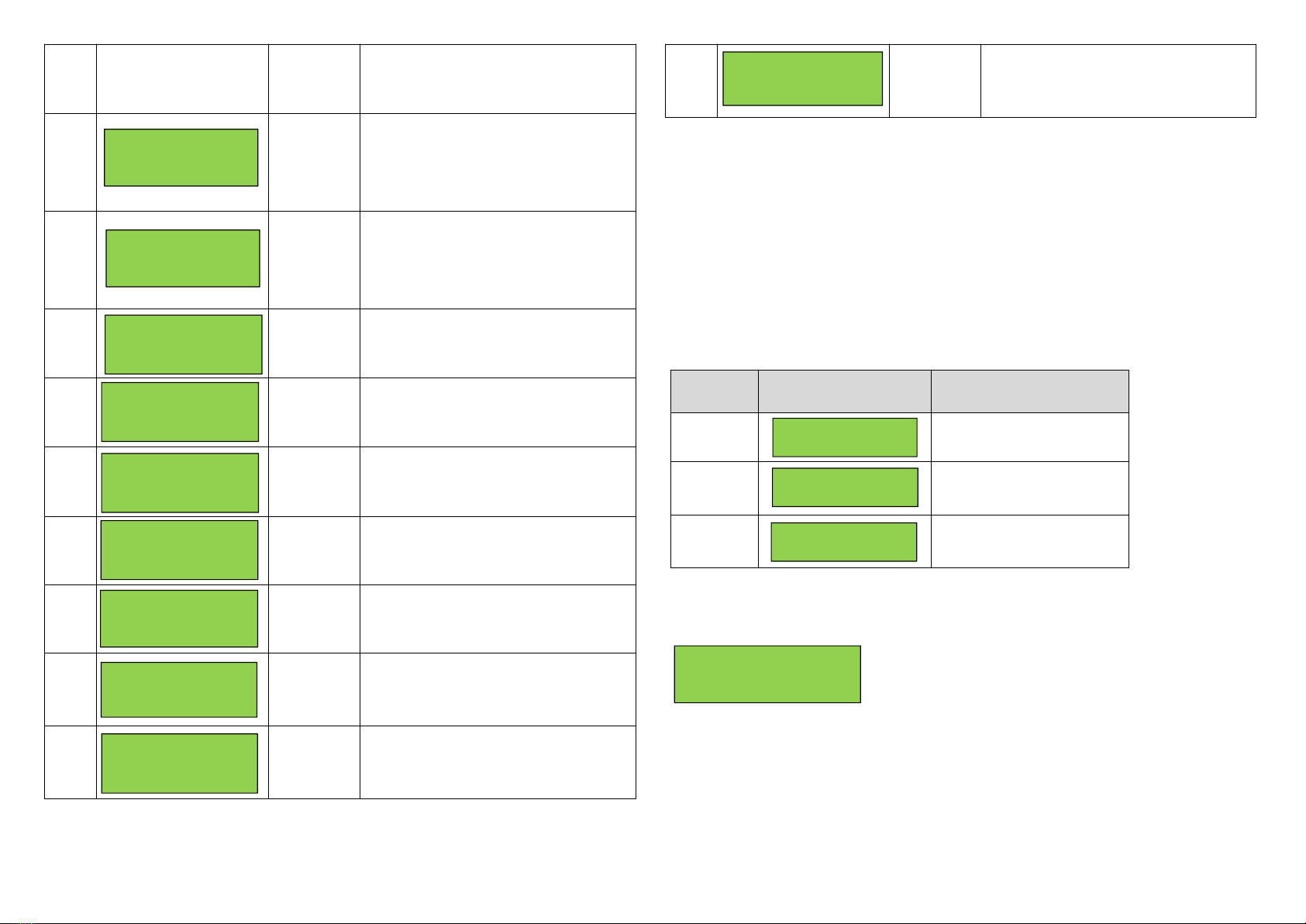

6.2.5 Technical Set – Maintenance Personnel Only

This section is for maintenance personnel only, enter password to access the

sub-menu as guided by Chapter 6.2.4.

The sub-menu:

No.

Display

Explanation

1

To enable the setting-up of all

functions under the menu of

Technical Set

2

To set up safety standard or

country grid code for the inverters

3

To set up the rated voltage

4

To set up the high limit of AC

output voltage

5

To set up the low limit of AC

output voltage

6

To set up the high limit of AC

output frequency

7

To set up the low limit of AC

output frequency

8

To set up the max generation

power

9

To set up the AC instant voltage

limit

Pmax Limit

VAC L Limit

VAC H Limit

Standard Set

ALL Set Enable

Select Day

2020-02-22

Select Month

2020-02-22

Select Year

2020-02-22

FAC H Limit

FAC L Limit

AC Inst Limit

Rated VAC Set

31 32

10

To set up the power control

11 To set up the increase power rate

limit and decrease power rate limit

12 To set up special functions

13 To set up passwords

14 To restore factory settings

15 To adjust the total power

generated

16 To clear the power generation

record

17 To enable the grid connection

18 To set up export power limit

Press UP/DOWN to scroll the menu, press ENT to access the sub-menu, and

press ESC to return to the previous menu.

6.2.5.1 All Set Enable

This function is to enable all the setting-up functions under the menu of

‘Technical Set’. Before enabling or setting up any of the function under this

menu, please turn the ‘All Set Enable’ on.

6.2.5.2 Standards Set

The safety standard for different countries can be selected in this sub-menu.

Australia A, Australia B, Australia C and New Zealand grid codes can be

selected here. cAUSAS4777_2A, cAUSAS4777_2B, cAUSAS4777_2C and

cNZS4777_2 represent Australia A, Australia B, Australia C and New Zealand

standard respectively.

Procedures:

Step1: go to ‘All Set Enable’ in the menu of ‘TECHNICAL SET’ and turn the

status to ‘ON’.

Step2: move to ‘Standard Set’ and get inside

Step3: select the country grid code needed.

Press UP/DOWN to scroll through the national standards, press ENT to

confirm the safety standard, and press ESC to return to the previous menu.

6.2.5.3 Rated VAC Set

Rated AC output voltage can be set up here. Only when there are more than

Standard Set

cAusas4777_2A

Export Limit

ALL SET Enable

ON

Factory Reset

Special Func

Set Passwords

Standard Func

Power Control

Adjust Total E

Reset Total E

Export ON/OFF

NOTE: This part is accessible for qualified and accredited

technicians only!

NOTE: This operation is for maintenance personnel only.

Passwordis required to access this part!

33

34

one type of applicable voltage will this function be used.

6.2.5.4 AC Output Voltage Limit

This section is to set up the high and low limit of AC output voltage as

permitted by local grid company if the grid voltage is beyond the range

specified by national standards.

The detailed procedure is described in a separated document named ‘Voltage

Adjustment’.

6.2.5.5 AC Output Frequency Limit

This section is to set up the high and low limit of AC output frequency as

permitted by local grid company if the grid frequency is beyond the range

specified by national standards.

The method to set up the AC output frequency limit is similar to that of AC

voltage adjustment.

6.2.5.6 Max Generation Power Setup

The max output power can be set up here.

The detailed procedure to set up the Max generation power is described in a

separated document named ‘Power Generation Limit’.

6.2.5.7 Power Control

No.

LCD Display

Explanation

1

To set up reactive power

2

To set up power factor

3

To restore reactive power

4

To restore power factor

Reactive power and power factor can be set up and restored here.

The power quality response modes as required by the standard of AS/NZS

4777.2:2020 can be activated or controlled under this menu combined with

the menu of special function. The detail procedure will be described in the

following part.

6.2.5.8 Standard Function

Power increase slope and decrease slope can be set up here.

This part is for the setup of power rate limit modes as required by AS/NZS

4777.2:2020. Soft ramp up after connect, reconnect or soft ramp up/down

following a response to frequency disturbance is available in those inverters.

Procedures to set up the gradient of power rate limit:

Step1: Go to ‘All Set Enable’ in the menu of ‘TECHNICAL SET’ and turn the

status to ‘ON’.

Step2: Go to ‘Standard Func’ and then get inside.

VAC H Limit Set

270V

VAC L Limit Set

180V

Pmax Limit

70% of Prated

Q Set

+60%

YES=ENT EXIT=ESC

Are You Sure?

YES=ENT EXIT=ESC

Are You Sure ?

PF Set

+80%

Q Reset

PR Reset

FAC H Limit Set

52Hz

FAC L Limit Set

47Hz

Pwr UpSlope

90%

Pwr DownSlope

20%

35 36

6.2.5.9 Special Function Setu

Step3: Go to set up the ‘Pwr UpSlope’ or ‘Pwr DownSlope’ for the soft ramp up/down

of rated power per minute.

.

p

No.

LCD Display Explanation

1To set up the constant PV voltage

2To set up the multiple MPPTs parallel

mode

3To enable the High Voltage Ride Through

4To enable the Low Voltage Ride Through

5To enable the bus mid-point voltage

protection

6To enable the DC component inspection

7To enable the GFCI protection

8To enable the ISO protection

9

To enable the island protection

10 To enable the buzzer

11 To enable the relay

12 To enable the QU curve

13 To enable the PF curve

14 To enable the Q curve

15 To enable the PU curve

16 To enable the shadow MPPT mode

6.2.5.9.1 Island Protection

The active anti-islanding protection of the inverters is achieved by shifting the

frequency of the inverter away from nominal conditions in the absence of a

reference frequency (frequency shift). It is enabled by default.

6.2.5.9.2 Volt-var Response Mode

1/2BUS Prot

LVRT

Shadow MPPT:

PF CURVE

QU CURVE

ISO Prot

DCI Prot

GFCI Prot

Set CV MPPT

All PV Paral

HVRT

Island Prot

Buzzer Enabled

Relay Check

Q CURVE

QU CURVE ON

PU CURVE

NOTE: This operation is for maintenance personnel only.

Passwordis required to access this part!

37 38

The QU Curve is enabled by default. The volt-var response mode changes the

reactive power absorbed or supplied by the inverter in response to the

voltage at its grid-interactive port. The diagram and table below are the

response mode required for the volt–var response according to the standard

of AS/NZS 4777.2:2020.

Region

Default Value VV1 VV2 VV3 VV4

Australia A Voltage 207 V 220 V 240 V 258 V

Inverter reactive

power level

(Q)% of Srated

44%

supplying

0% 0% 60%

absorbing

Australia B Voltage 205 V 220 V 235 V 255 V

Inverter reactive

power level

(Q)% of Srated

30%

supplying

0% 0% 40%

absorbing

Australia C Voltage 215 V 230 V 240 V 255 V

Inverter reactive

power level

(Q)% of Srated

44%

supplying

0% 0% 60%

absorbing

New

Zealand

Voltage 207 V 220 V 235 V 244 V

Inverter reactive

power level

(Q)% of Srated

60%

supplying

0% 0% 60%

absorbing

Procedures to enable or disable the Volt-var Response Mode:

Step1: go to ‘All Set Enable’ in the menu of ‘TECHNICAL SET’ and turn the

status to ‘ON’.

Step2: go to ‘Special Func’ and then go to ‘QU Curve’

Step3: enable or disable the ‘Volt-var Response Mode’ by changing the status

to ‘ON’ or ‘OFF’.

6.2.5.9.3 Volt-watt Response Mode

The PU Curve is enabled by default. The volt-watt response mode varies the

maximum active power output level of the inverter in response to the voltage

at its grid-interactive port. The diagram below is the response curve required

for the volt–watt response according to the standard of AS/NZS 4777.2:2020.

PU CURVE ON

NOTE: This operation is for maintenance personnel only.

Passwordis required to access this part!

This manual suits for next models

7

Table of contents

Other CHISAGE Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual