MI00/10056 rev. 8 — 05/2006-- p ge

1.0 INTRODUCTION

1.1 Summary of the manual

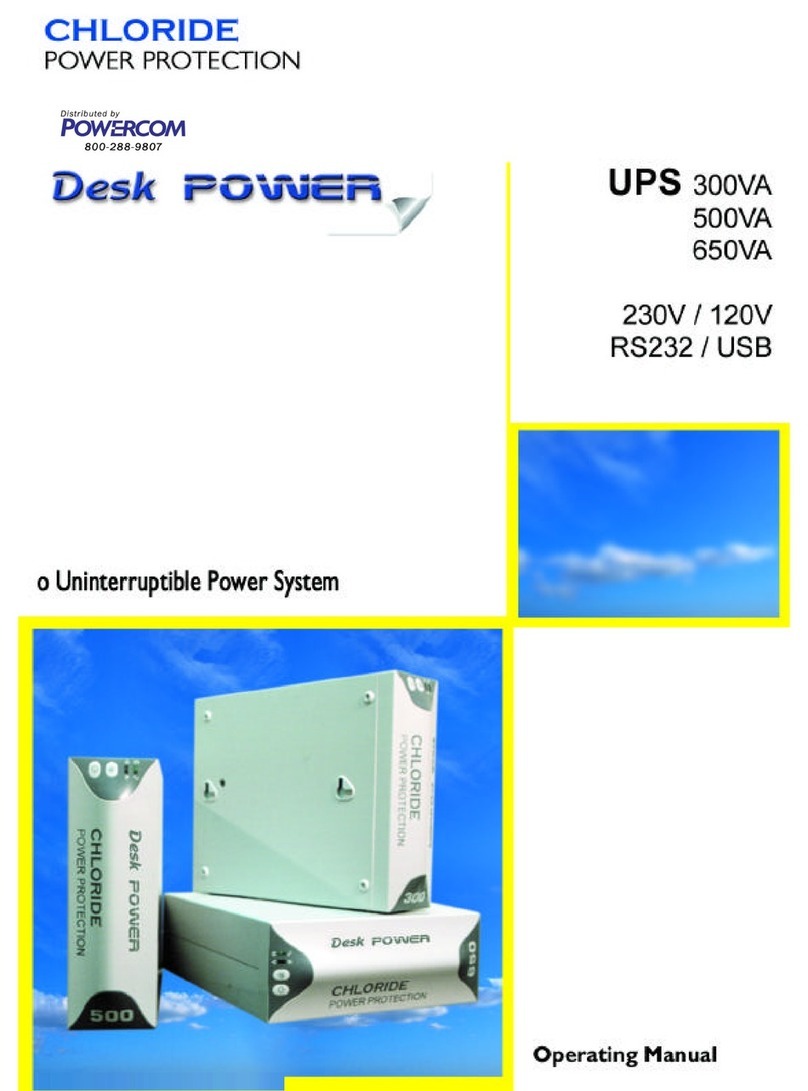

This handbook provides for the safe installation, startup and use of the EDP70 PLUS Uninterruptible Power System

(UPS). The Company recommends that the equipment be installed and regularly maintained by a Chloride

Authorized personnel.

DO: - read the User Handbook before operating the EDP70 PLUS UPS.

- keep a log of all incidents.

- protect the batteries from damage. Batteries leak acid; avoid contact with skin,

clothes or eyes.

DO NOT: - operate the control switches.

- operate the EDP70 PLUS UPS with any covers removed.

- obstruct the ventilation grilles.

1.2 Summary of the equipment

The EDP70 PLUS Uninterruptible Power System (UPS) totally isolates the load from voltage drops, spikes, transients

frequency variations in the utility supply.

In the event of failure or brownout of the AC utility supply, an internal audible alarm sounds and an LED on the control

panel illuminates, the EDP70 PLUS UPS will continue to provide safe, clean continuous power, without interruption, from

the battery, for a duration dependent on battery capacity and output load.

The audible alarm alerts the user to start a safe orderly shutdown of the load. hen the AC utility supply returns to

normal, the EDP70 PLUS UPS automatically recharges the battery ready for any future power failure.

The microprocessor display panel provides access to very detailed information regarding the status of the supplies and

EDP70 PLUS UPS. Refer to current publication for detailed specification.

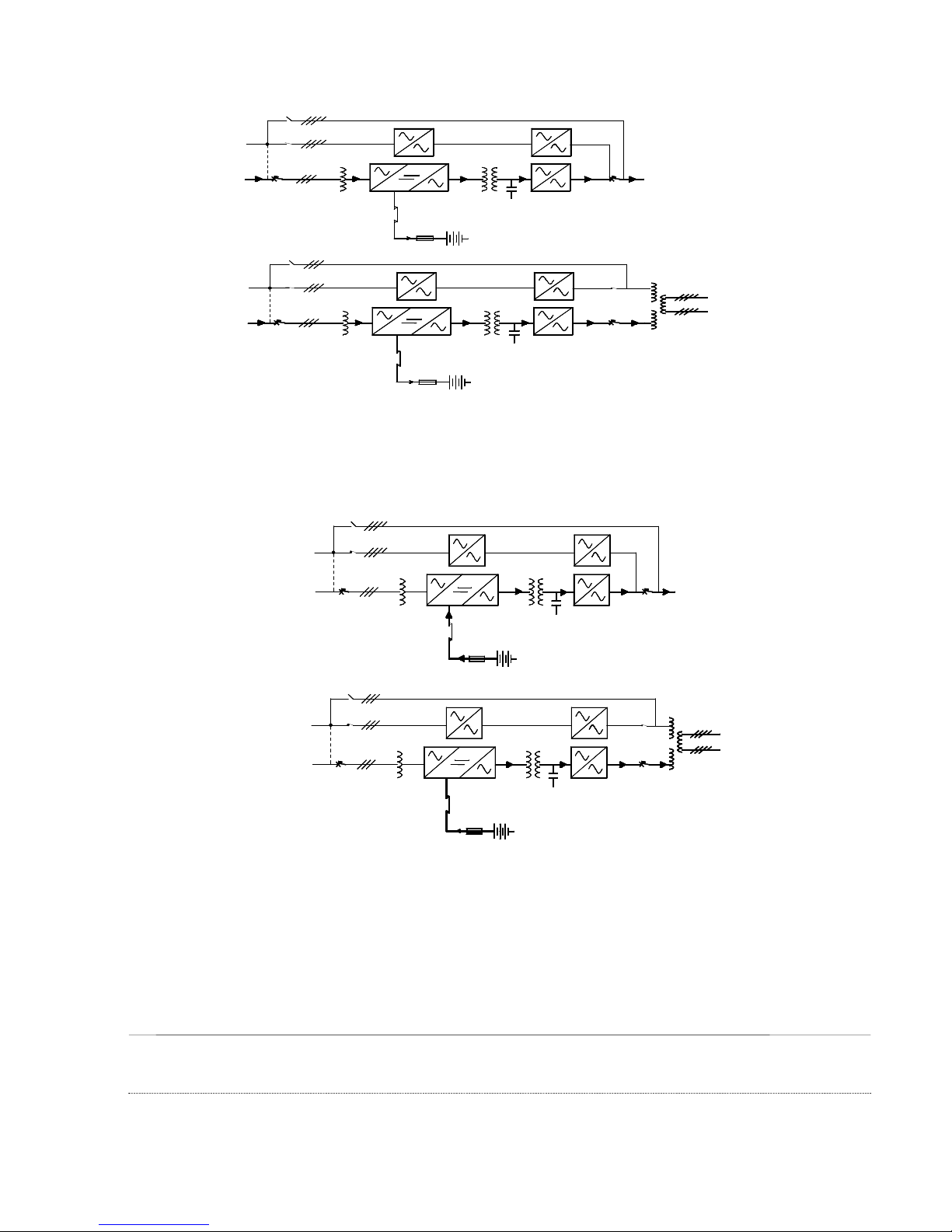

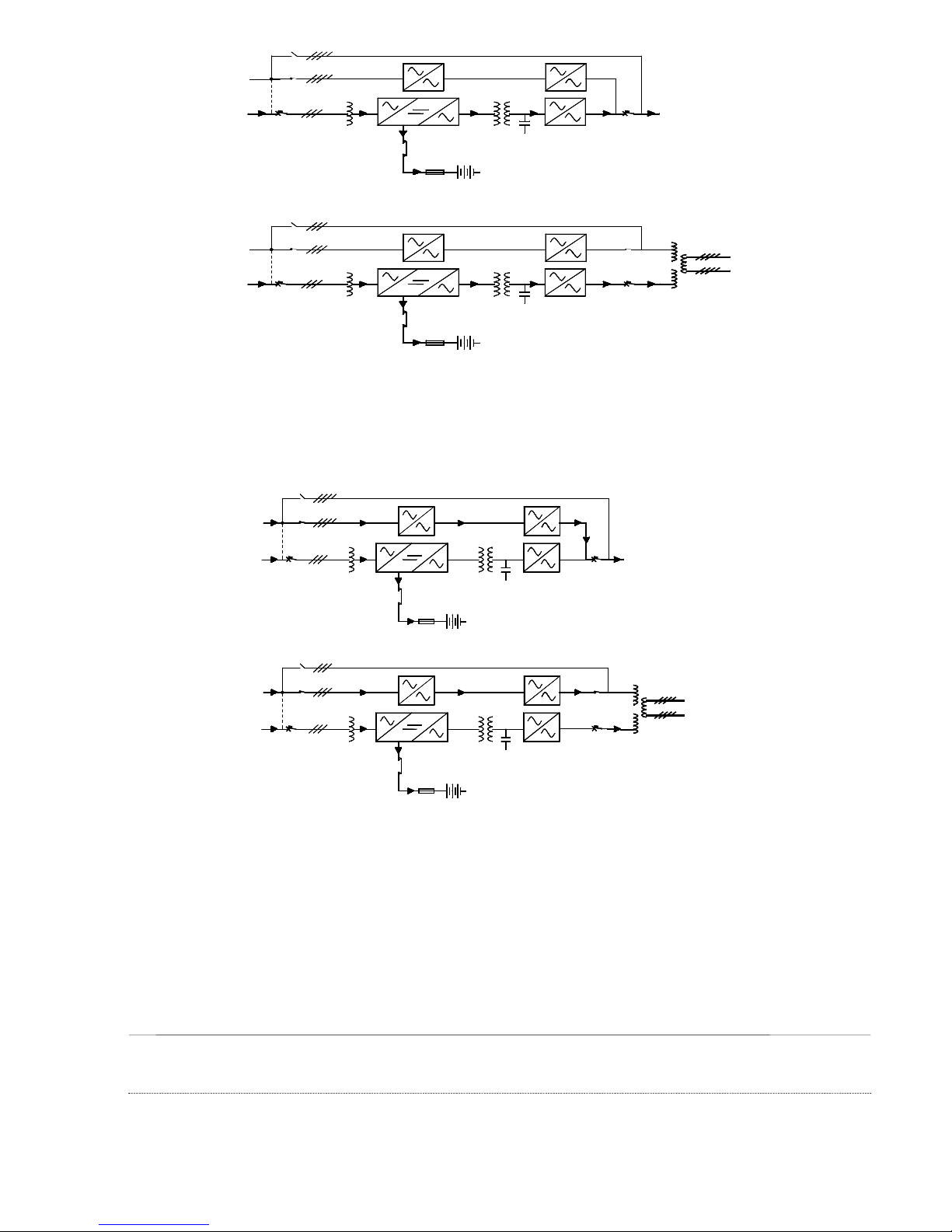

The block diagram, shows the main functional sub-assemblies of the EDP70 PLUS UPS. The AC three phase utility

supply is rectified to provide direct current, which maintains the battery in a fully charged state and also supplies the

inverter, which provides the three phase output via an electronic static switch.

Normally the supply of the reserve line is taken from the AC utility input, but special units, with a separate reserve input

supply, are available. This allows the inputs to be supplied from independent three phase sources.

Provided the reserve supply is within limits, the inverter will match the output frequency with the reserve supply

frequency. The inverter has its own internal crystal control to stabilize the output frequency if the reserve supply

frequency is out of limits. The electronic static switch switches the output from the inverter to the reserve supply, without

interruption, to meet any load current surges, or to supply the load if the battery is discharged during an AC utility supply

failure.

Maintenance and testing can be carried out on the EDP70 PLUS UPS without interrupting the output, by switching the

load from the reserve supply to the maintenance bypass circuit. This work should only be carried out by Chloride-trained

personnel.