ThermOweld CRE-1 User manual

The Contractors Choice

thermOweld®

+1 (918) 627-5210 • 1-800-558-1373 • WWW.THERMOWELD.COM

ELECTRICAL GROUNDING • CATHODIC PROTECTION • ELECTRIC UTILITY • RAIL

thermOweld®Tel. +1.800.558.1373

4102 South 74th East Ave Tel. +1.918.627.5210

Tulsa, OK 74145 USA www.thermoweld.com

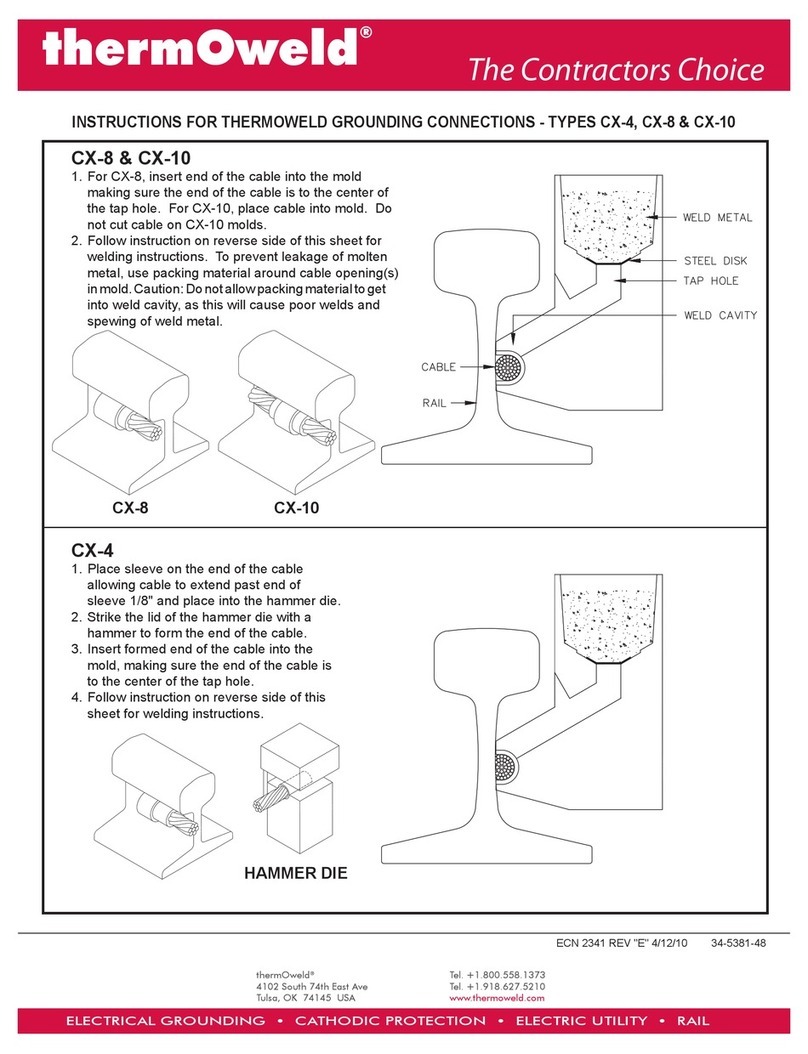

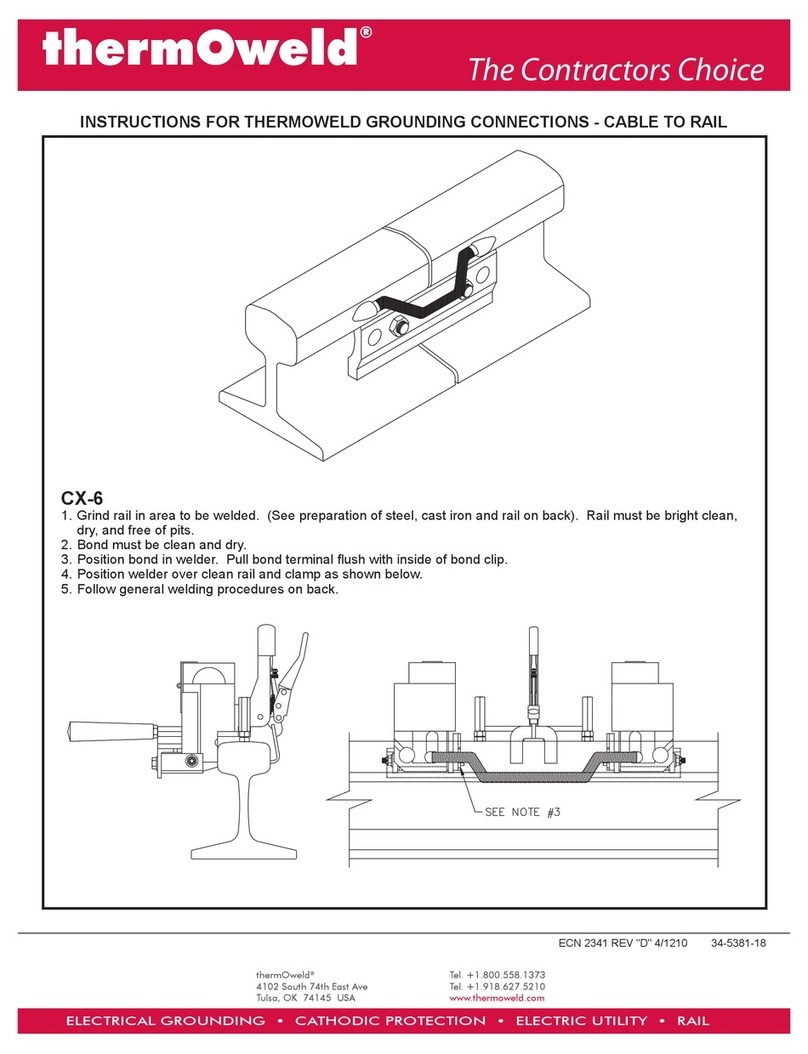

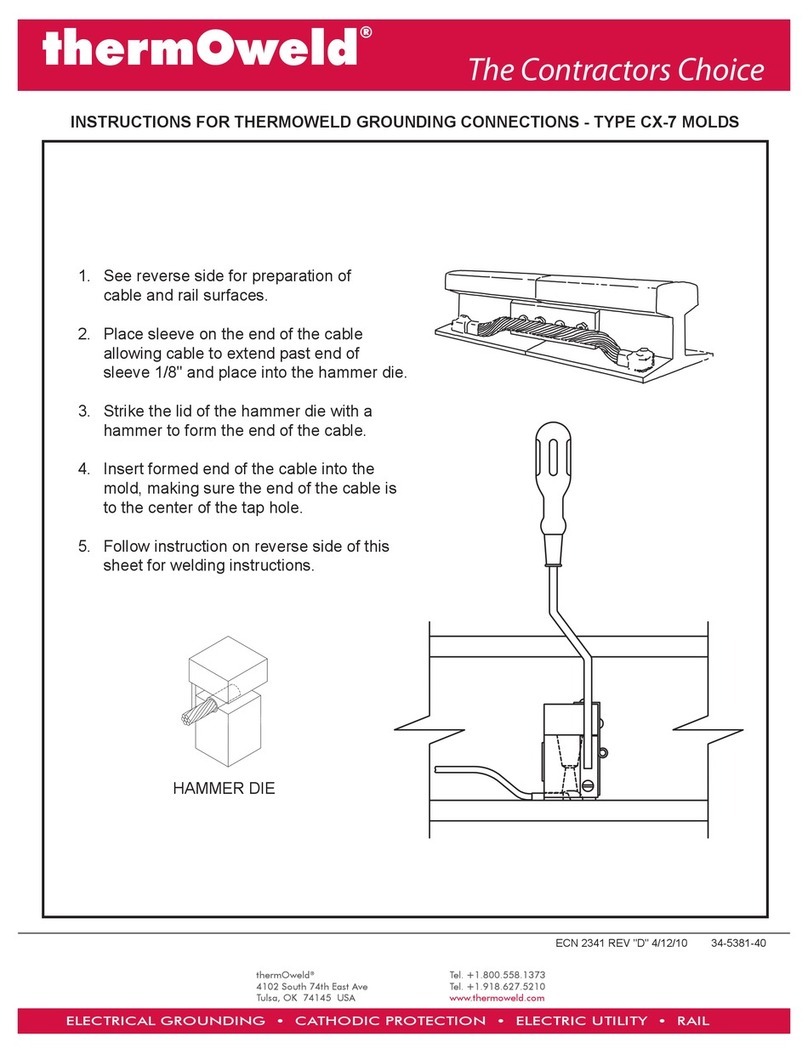

INSTRUCTIONS FOR THERMOWELD GROUNDING CONNECTIONS - CABLE TO REBAR

CRE-1†

Place end of cable to center of tap

hole. Follow instructions on reverse

side for proper use of copper shim

stock or packing pad.

CRE-2

Butt end of cable against rebar. Follow instructions on

reverse side for proper use of copper shim stock.

CRE-3†

Place cable and rebar into mold. Do not cut run cable.

Followinstructionsonreversesideforproperuseofcopper

shim stock or packing pad.

CRE-4†

Place cable and rebar into mold. Follow instructions on

reversesideforproper useof coppershim stockor packing

pad.

CRE-5†

Place cable and rebar into mold. Do not cut run cable.

Followinstructionson reversesideforproper useofcopper

shim stock or packing pad.

CRE-6†

Buttcableagainstrebar. Followinstructionsonreverseside

for proper use of copper shim stock or packing pad.

ECN 2422 REV "J" 1/5/11 34-5381-10

† Depending on weld type and rebar size, mold may go

around or be placed onto rebar.

1-800-558-1373 • SALES • SERVICE • TECHNICAL SUPPORT • VISIT www.thermOweld.com

t

h

e

r

m

O

w

e

l

d

®

Z

Z

E

E

Patented

E

Z

L

i

t

e

®

M

o

l

d

GENERAL SAFETY INSTRUCTIONS

1. Always wear proper clothing, safety glasses and gloves when

exothermic welding.

2. Only weld items mold is designed for.

3. Do not use worn or broken molds which could cause leakage

of molten weld metal.

4. Make sure that the material being welded fits in the mold

properly and that the mold will close tightly around them.

5. Do not alter molds or accessories without factory

authorization.

6. Avoid breathing concentrations of smoke, as it may be

hazardous to your health.

7. Avoid contact with hot materials.

8. Remove or protect fire hazards in the welding area.

9. Avoid moisture and contaminants in the mold and materials

being welded. Contact of molten weld metal with moisture or

contaminants may cause weld metal to spew out of mold.

10. When welding to pipe or vessels, you should consider

the following:

a.the effect welding may have on structural members

and thin wall pipe or vessels.

b.pipe or vessels that are pressurized or contain (or

have contained) flammable, explosive or hazardous

materials should be evaluated in the case of a melt-

through or hot molten weld metal coming in contact

with any flammable, explosive or hazardous materials.

11. Failure to abide by the above and follow welding procedures

may result in improper welds, damage to the material being

welded or create hazardous situations for the individual.

PREPARATION OF CABLE

1. Cable must be bright, clean and dry.

2. Cable that is saturated with oil or grease must be cleaned.

Cable may be cleaned by burning it off with a torch (gasoline

blow torch, butane torch, acetylene torch) After burning off oil

or grease, a wire brush should be used to remove residue.

Wet cable must be dried out. Use a hand torch.

3. Corroded cable must be cleaned. Use the 38-0135-00

cablecleaningbrushoracardclothbrush. Itisimportantthat

the ends of the individual strands are clean. This can best be

accomplished by making a fresh cut on the end of the cable.

4. Cable should be straightened before clamping mold in place.

Bent or out of round cable will hold mold open and cause leaks.

5. For hard drawn cable or cable under tension, use 38-0330-00

cable clamp.

6. Remove insulation from insulated cable before cutting with

hacksaw. Otherwiseendsofstrandswillbecomecoatedwith

insulating material which may cause defective welds.

7. FLEXIBLE CABLE

A sleeve must be used when welding flexible cable.

38-0329-00 wrap sleeves are recommended for 300 MCM

and smaller cable.

PREPARATION OF REINFORCING BAR

NOTE: The use of ThermOweld exothermic connections on

rebar can have an effect on the rebar’s structural

strength. Consideration as to weld location should

be made before actual welding. Area under minimum

stress is preferred.

1. Surface to be welded must be bright, clean and dry.

2. Remove rust and mill scale with coarse file or grinder.

3. Remove oil, grease or pitch coatings with solvent or torch.

USING COPPER SHIM STOCK AND PACKING PAD

1. For molds requiring copper shim stock, wrap one copper

shim tightly around rebar on each side of area to be welded.

2. For molds requiring packing pad, form pad to rebar with hole

running lengthwise over cleaned area of rebar. Press mold

over pad with ends of pad even with edges of the mold.

Secure backing plate when required.

WELDING PROCEDURE

1. Checkmoldtagformaterialtobeweldedandpropercartridge

size to use.

2. Make sure all surfaces and conductors are clean, dry and are

the proper sizes for the molds application per mold tag.

3. Molds can be dried by heating to approximately 250ºF. Molds

may be dried with a hand operated butane torch or by firing a

charge in the mold before making the desired weld.

4. Position mold onto conductor(s). See front of this sheet for

positioning of conductors into mold. Lock mold with handle

clamps or frame, whichever is the case.

5. Insert steel disk being sure it is directly centered over the

tap hole. Failure to insert disk into mold or failure to seat the

disk properly can create an improper weld and may cause

mold to spew weld metal.

6. Pour proper weld cartridge(s) into crucible being careful not to

loosen all the starting powder while pouring weld metal into

mold. Use of wrong weld cartridge can cause improper welds

or damage to molds.

7. Close the lid of the mold and place a small amount of starting

powder in the ignition pocket.

OR

Insert the EZ Lite®ignitor in the connector of thermOweld EZ

Lite Remote™ Unit. Close the lid and place the ignitor in the

top opening of the EZ Lite®Lid allowing the connector to rest

on the lid.

8. Before igniting, verify conductor positioning and that mold is

closed completely.

9. Ignite the starting powder with the flint ignitor. Pull flint ignitor

away from starting powder right after trigger is pulled to keep

from fouling flint ignitor. (Do not place any exposed body part

directly over lid or in front of lid opening.)

OR

Turn the power button to the “ON” position on the EZ Lite

Remote™ Unit followed by the “operate” button until the

exothermic reaction is initiated.

10. Wait for 15 seconds before opening mold to allow weld metal

to cool.

11. To clean the mold, use a natural bristle brush, soft cloth or

newspaper before making next weld. On horizontally split

molds, use a small diameter rod or screw driver to remove

slag from tap hole. Caution should be used when cleaning

molds to avoid burns from contact with hot mold.

DO NOT USE WIRE BRUSH TO CLEAN MOLD!

NOTE: 1.A fouled flint ignitor may be cleaned by soaking in

house hold ammonia.

2.Proper cartridge size is marked on mold tag and

shown on the bottom of the cartridge tube.

3.Cartridge size is the approximate weight of the powder

in grams. When the cartridge size specified is not

available, two or more smaller cartridges or part of a

larger cartridge may be used. Care should be taken

not to mix starting material in-between cartridges.

4.HandleClampadjustmentsmaybemadebyremoving

cotter pin and clevis pin and turning eye bolt one turn

clockwise to tighten or one turn counter clockwise to

loosen.

This manual suits for next models

5

Other ThermOweld Welding Accessories manuals

Popular Welding Accessories manuals by other brands

GULLCO

GULLCO 50 Operating instructions & safety information

Rothenberger

Rothenberger P63-S6 instruction manual

PROFAX

PROFAX WP-500 operating instructions

Leister

Leister WELDING PEN S operating instructions

Kemppi

Kemppi MTP 350 operating manual

Inverter Fusion

Inverter Fusion Fusion MultiClean operating instructions

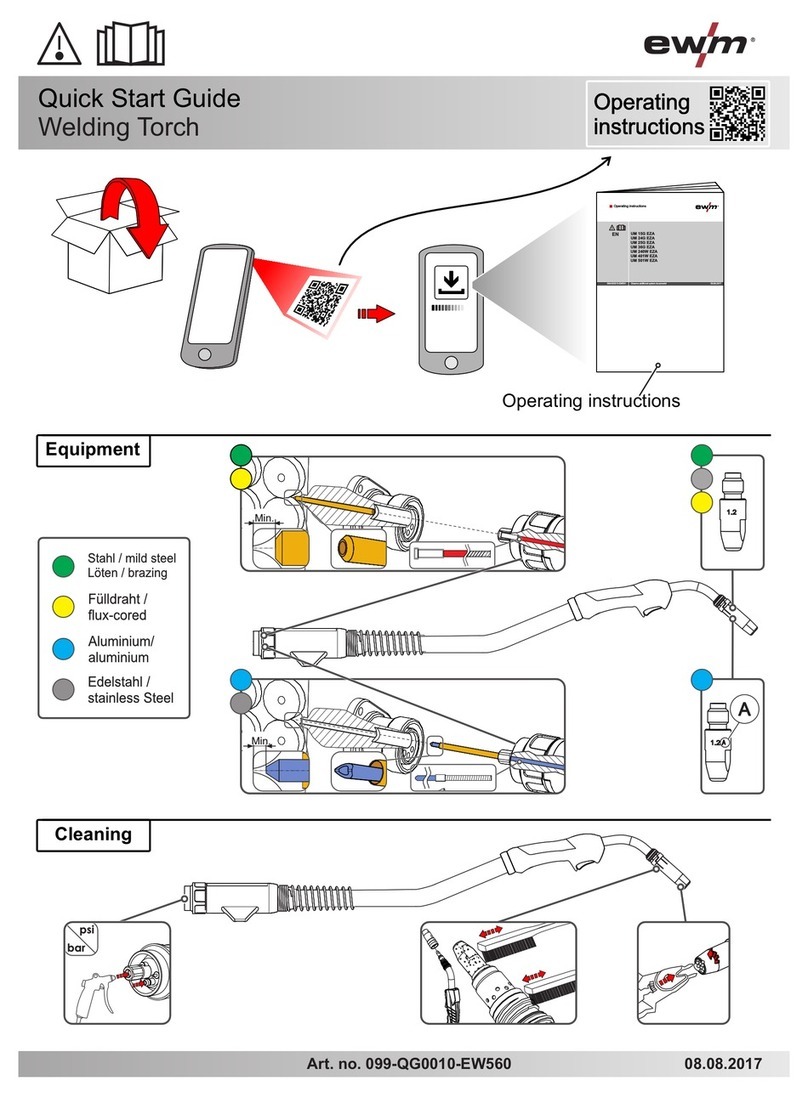

EWM

EWM UM 24 G EZA quick start guide

COWLEY INDUSTRIES

COWLEY INDUSTRIES LM05 Installation and operating instructions

Leister

Leister FUSION 1 operating instructions

FRONIUS

FRONIUS MTG 250i operating instructions

Welbilt

Welbilt SOLAR POWEREDAUTO-DARKENING WELDING HELMET owner's manual

FRONIUS

FRONIUS WF 25i Case D200 operating instructions