1 Description

1.1 General

With the digital panel meter CAM 100 almost all similar DC signals are measurable. The desired measuring range (200 mV,

2V, 20V, 200 V, standard signals: 0 ... 10 V and 0 (4) ... 20 mA), including decimal place, scale themselves by solder pads

under the clamps to find. Similar input signals within the range of - 1999... + 1999 can be scaled by means of resistance at

the clamps at will. Despite the small dimensions the LED display can be read off even from larger distance well.

1.2 Safety instructions

This equipment is built and according to quality standards examined in accordance with European guidelines. It left the work

in safety-relevant perfect condition. The references and warning notes contained in this operating instructions must be con-

sidered around a safe enterprise to ensure. Without impairment of its working reliability the equipment can be operated

within the certified site conditions. See chapter 3. This equipment may be taken only by a specialist in enterprise, which is

familiar with the associated dangers and/or the relevant regulations.

1.3 Maintenance

All repairs of the device may only be carried out by a specialist workshop. In case it is inevitable to carry out repairs on the

opened device which is still supply voltage this may only be effected by trained specialist who knows about the dangers usu-

ally related to any such procedure. In case of misuse or wrong operation of the device we do not assume any liability for any

damages that might occur.

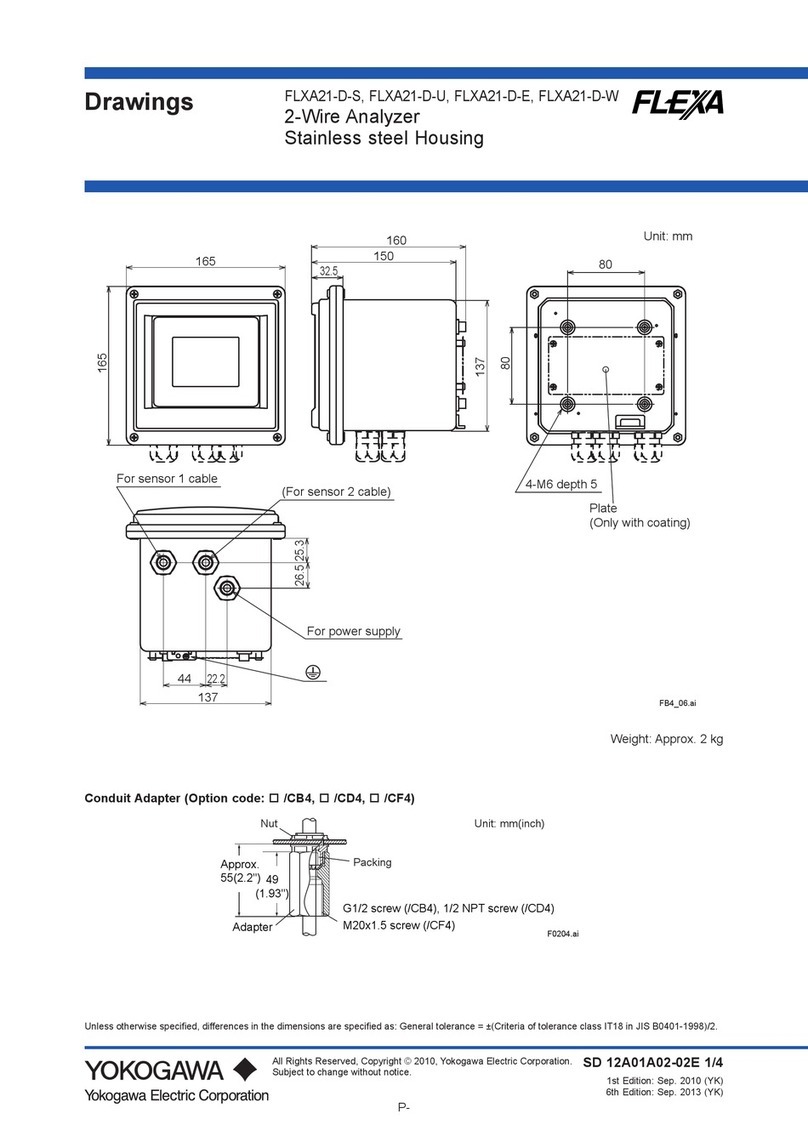

1.4 Mounting

The equipment is to be inserted from the front into the cutout planned for it (according to DIN 43,700). Dimensions of the

cutout: 45 x 22.2 [mm]. The attachment takes place with the help of enclosed fastening parts. The tightening screws are to

be tightened mutually, until the equipment sticks. During the placement of the equipment is the radiant heat of neighbouring

devices to consider (consider permissible ambient temperature!). The electrical connection is to be made according to appro-

priate regulations (e.g. VDE 0100). Supply voltage is indicated and to the clamps 5 and 6 is put on on the vehicle identifica-

tion plate.

2. Operation

2.1 Starting

Standard input & display ranges at the CAM 100 can be selected through solder pads as shown in table 1. With the resistor

Rs any display range can be realised for voltage and current measurements. Also the decimal point is selected through a sol-

der pad. The gain can be changed about ± 20% through the gain potentiometer „V“. The offset range is ± 500 digits related to

the input signal of 0 VDC or 0 mA. It can be changed by potentiometer „Np“.

2.2 Adjustment of measuring U/I

1. Standard input & display ranges can be selected through solder pads (see table 1) or calculate resistor Rs appropriate

table 2. Close solder pads (see pict. 2) and connect Rs at pin 3 / 4 at the terminal block (see pict. 1)

2. Apply the voltage or current for span start to terminal block pin 1 / 2.

3. Bring the display to the required value for span start using the zero potentiometer “NP” (see pict. 1).

4. Apply the voltage or current for span end to the input terminal.

5. Bring the display to the required value for span end using the gain potentiometer „V“ (see pict. 1).

6. Repeat step 2 to 5 until the display corresponds to the required measuring range.