E5EX–H E5EX–H

10

Level 1

In this level, the upper- and lower-limit values of the temperature

range, control period, hysteresis, heater current, and heater burn-

out

alarm can be set.

When pin 1 on the operating mode selector (SW201) is set to the

OFF position (PID action), the temperature setting range limit val-

ues,

control period, heater current, and heater burnout alarm value

can

be set or changed. Any of these

parameters can be selected by

pressing

display key the required number of times as follows:

Upper-limit value of tem

-

perature setting range

Lower-limit value of temper

-

ature setting range

Control period

Press a.

Press a.

Press a.

Press a.

Press a.

5l-l

5l-h

cp

ct

hb

Heater current

Heater burnout alarm

Lower/Upper Limits of T

emperature Range:

sl-l

,

sl-h

–200 0 400 1,300

SL–L SL–H

Basically, the temperature range that can be measured is deter-

mined

by the temperature sensor to be

used. For example, when a

K-type (chromel-alumel thermocouple) temperature sensor is se-

lected,

the measurable range is from –200

°

C to 1,300

°

C. However

,

this

temperature range can be narrowed, say

, to 0

°

C to 400

°

C. T

o do

this, set the lower-limit value of the temperature setting range, in this

case to 0°C, on the SV display by using the up or down key while

5l-l is displayed on the PV display. Similarly, set the upper-limit

value, 400°C, while 5l-h is displayed. If the process temperature

falls below the set lower-limit value or exceeds the set upper-limit

value,

it is displayed on the PV display provided it is

within the tem

-

perature

range of the temperature sensor

.

Control Period: cp

To use a control period, pin 1 on the operating mode selector

(SW201)

must be set to the

OFF position. When

cp

is displayed on

the

PV display

, the control period can be set or changed

in a range

from

1 to 99 seconds in units of 1 second. The factory setting is 20

seconds. When a Voltage Output Unit is used, it is recommended

that

the control period be set to 20 seconds or less (ideally

, about 2

seconds), so that the control action can be performed more accu-

rately.

Control

output

ON

OFF 20 seconds

When control period is

set to 20 seconds

Heater Burnout Alarm: ct

,

hb

Set

a

burnout current value to determine disconnections of the heat

-

er. Firstly, a current measured in the heater current value mode is

displayed

in amperes. The normal current value is the current value

with

the control output ON. Disconnect the

heater and read the cur

-

rent

value and obtain the set value from the following:

Normal

current value + Current value

with disconnected heater

2

Use display key and set the PV display to hb. The difference be-

tween

the normal current

and the one with the disconnected heater

should

be 2.5 A minimum. If it is less than 2.5 A, the operation to de

-

tect the disconnection of the heater may be not stable. The value

can

be set with in increments of 0.1 A from 0.0 to 50.0 A.

Note

1:

Do

not allow a current of more than 50 A to flow in the Con

-

troller;

the maximum continuous heater current is 50 A.

2: Set

the value to 0.0 A if the heater burnout alarm is not used,

in

which case the alarm will not function at all.

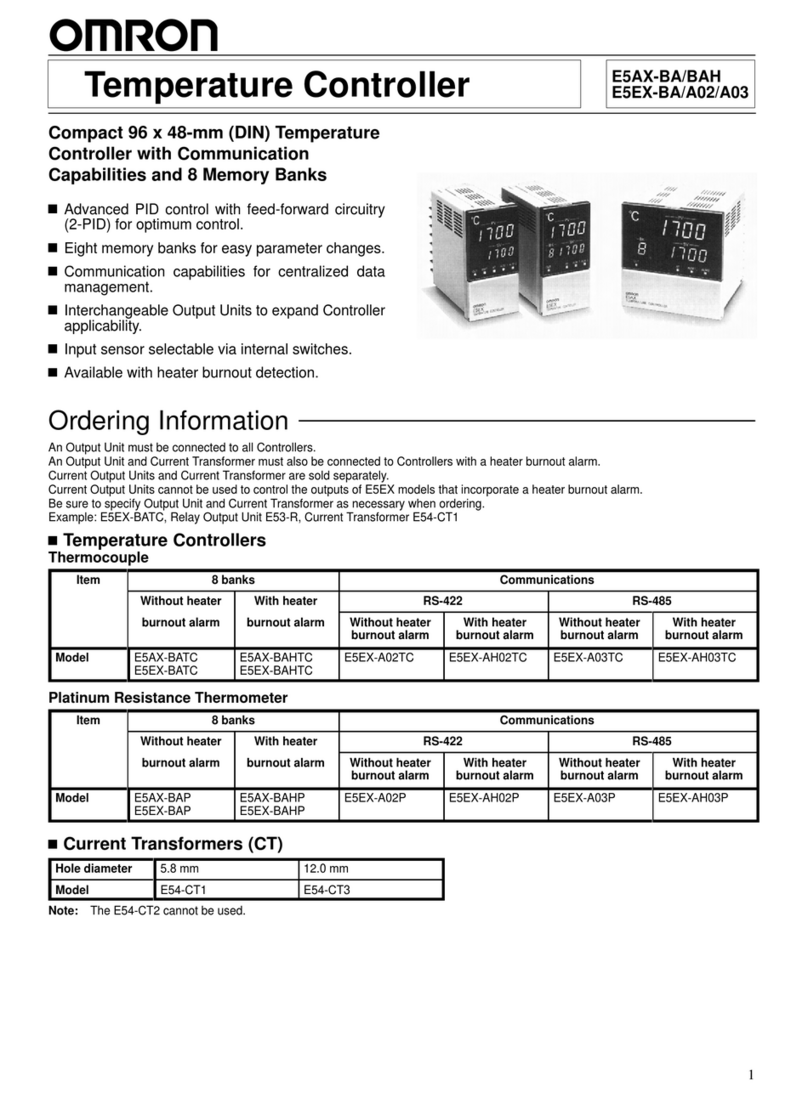

Heater Burnout Alarm and Sensor Abnormality Alarm

Alarm Heater burnout

alarm Sensor

abnormality

alarm

Output terminal

T

erminal output is ON when either alarm

is ON.

Output ON When a heater

burnout

is

detected.

When sensor is in

error.

Output

display

monitor hb

on front panel is

lit. 5en5

on front panel

is lit.

Output retention

function Yes No

Output reset

Set heater burnout

alarm value to 0.0

A or switch power

OFF and then turn

on power

.

Output is OFF

when sensor ab

-

normal condition is

solved

Influence on con

-

trol output/alarm

output

None

Control output:

OFF; Alarm output:

ON (proportional

alarm output is

OFF)