2110 Temperature Controller

Chromalox 2110

Table of Contents

1–Quick Setup ................................................................................................... 1

2–Introduction ................................................................................................... 2

3–Installation and Wiring .................................................................................. 4

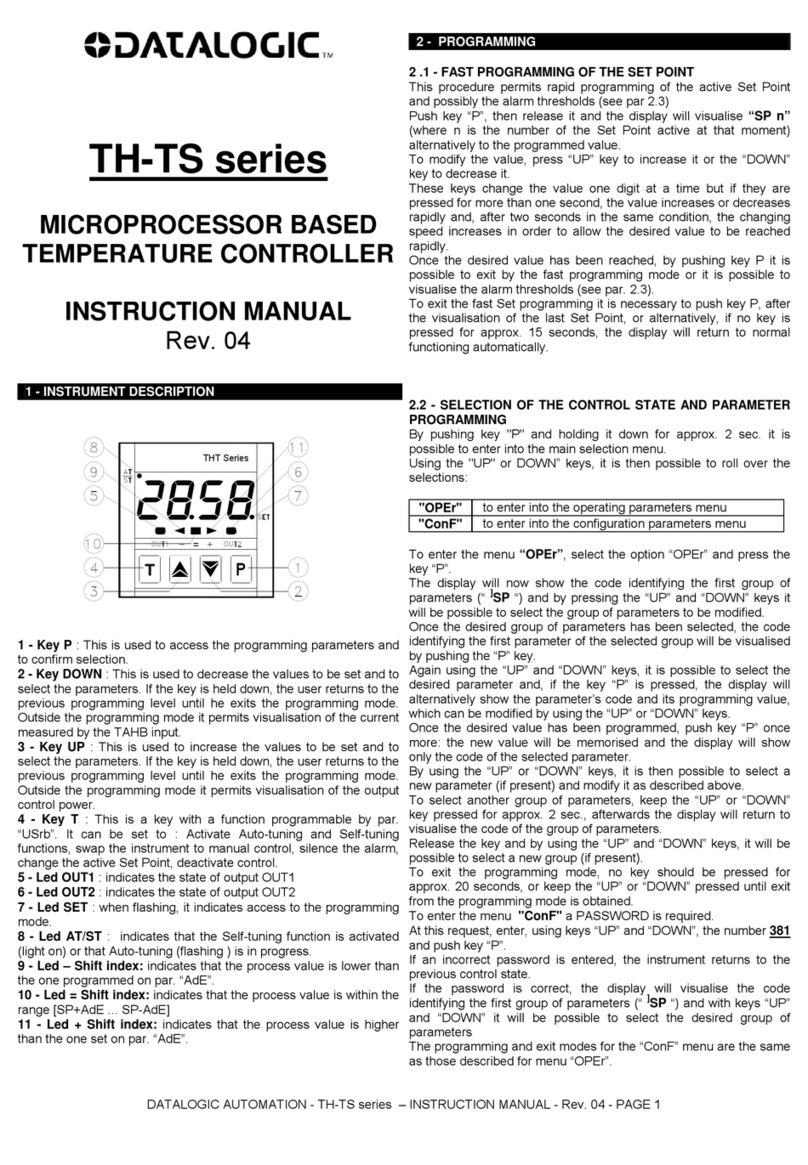

4–Adjusting Setpoint and Configuration ......................................................... 12

5–Controller and Alarm Operation .................................................................. 16

6–Replacing Output Modules .......................................................................... 17

7–Calibration ................................................................................................... 19

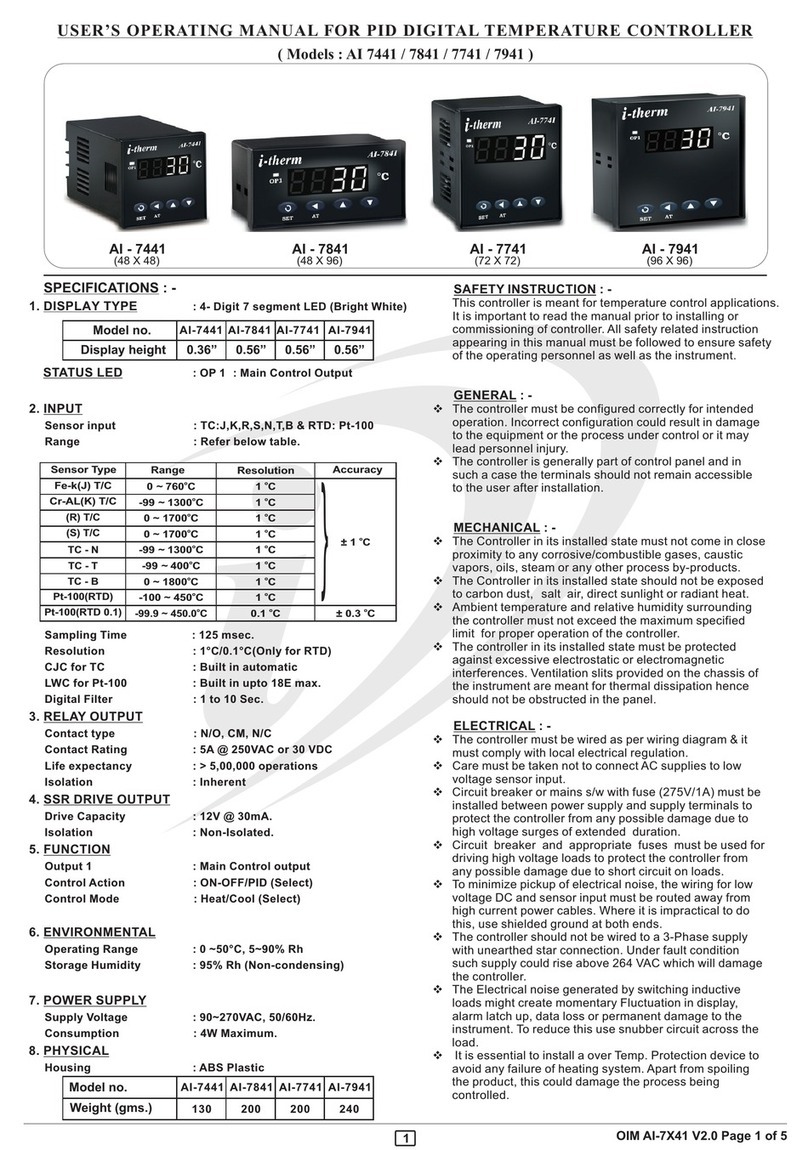

8–Specifications............................................................................................... 21

9–Troubleshooting ........................................................................................... 22

10–Warranty and Return .................................................................................. 24

Manual Sections

Illustrations

iii

1.1 Dip Switch Settings .................................................................................. 1

1.2 Establishing the Set Point ......................................................................... 1

1.3 Adjusting the Set Point ............................................................................. 1

2.1 Front Panel Identification ......................................................................... 2

2.2 Typical Application................................................................................... 3

2.3 Model Identification ................................................................................. 3

3.1 Default Dip Switch Settings ..................................................................... 4

3.2 Removing Mounting Collars .................................................................... 5

3.3 Mounting Dimensions .............................................................................. 6

3.4 Mounting the 2110 ................................................................................... 6

3.5 Wiring Terminal Identification ................................................................. 7

3.6 Thermocouple Connections with Shield .................................................. 8

3.7 Three-Wire RTD Connections with Shield............................................... 9

3.8 Two-Wire RTD Connections .................................................................... 9

3.9 Control Output Wiring–R1 and S0 ......................................................... 10

3.10 Control Output Wiring–R3 ..................................................................... 10

3.11 Control Output Wiring–V0 ..................................................................... 10

3.12 Control Output Wiring–S1 and S2 ......................................................... 11

3.13 90-260 VAC Instrument Power Connections .......................................... 11

3.14 Alarm Connections ................................................................................. 11

4.1 Establishing the Set Point ....................................................................... 12

4.2 Adjusting the Set Point ........................................................................... 12

4.3 Configuring 2110.................................................................................... 13

4.4 Configuring 2110.................................................................................... 13

4.5 Configuring 2110.................................................................................... 13

4.6 Configuring 2110.................................................................................... 13

4.7 Configuring 2110.................................................................................... 13

4.8 Configuring 2110.................................................................................... 13

6.1 Replacing Output Module ...................................................................... 18