5

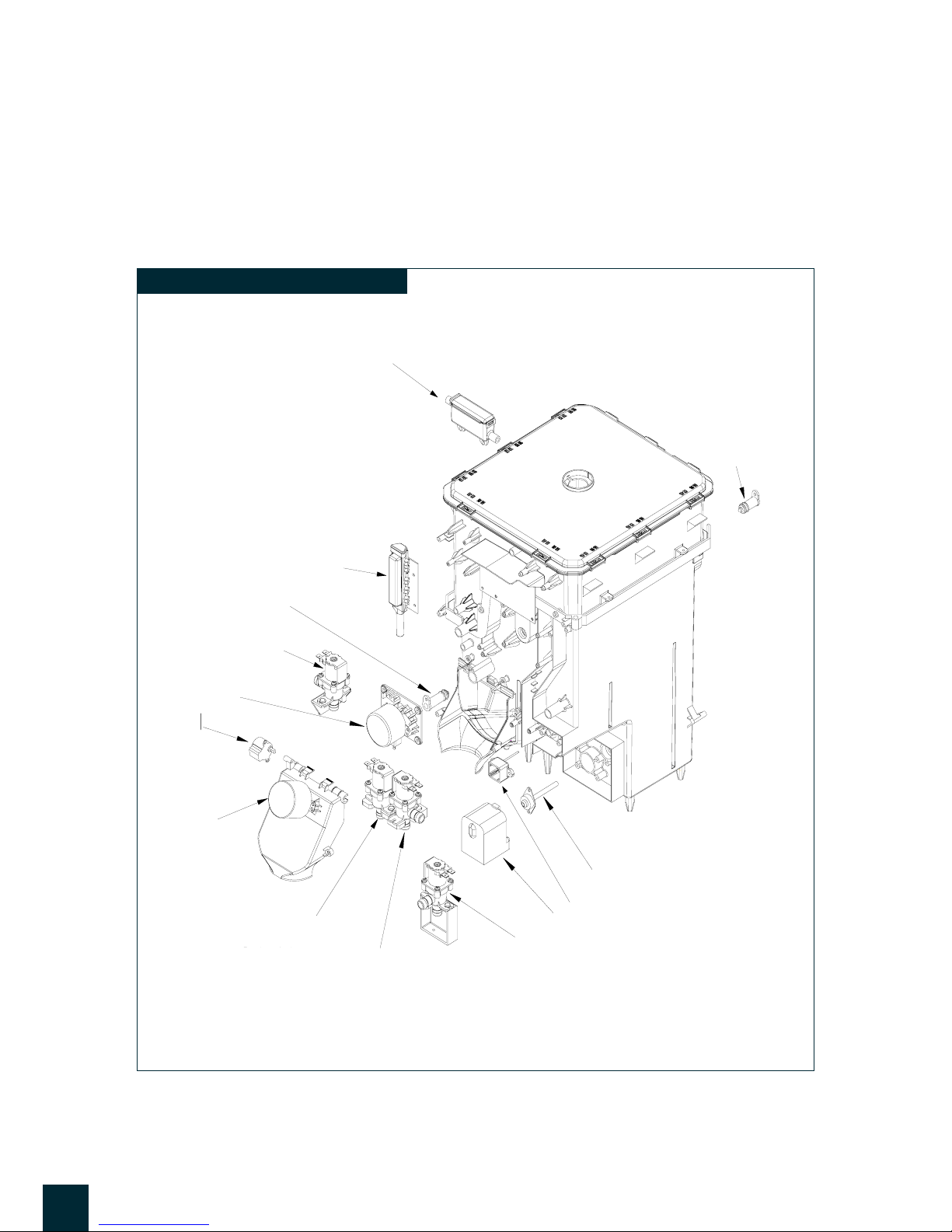

Product

Features

Infrared Water Level Detection Sensor

Infrared OLC sensor is applied in IGUASSU ICE 500. It provides more improved detection accuracy

than traditional mechanical detection types, thus allowing stable water level detection. The signal is

connected to a controller in order to automatically adjust puried water levels.

(Patent: No.426182)

Safety Function (Ice Dispensing & Hot Water Locking Function)

Setting the safety function using the LOCK/ICE touch sensor button prevents ice cube and hot water

being dispensed from the unit. It helps to prevent burns and other unwanted injuries for children, the

elderly and any other vulnerable user.

Continuous Water Dispensing Mode*

IGUASSU ICE 500 has continuous water dispensing function, which allows users to dispense cold/

ambient water continuously. The system maximizes user convenience since a set volume of water,

either 0.5l or 1l, can be dispensed with a touch of buttons. *Not available for hot water.

Automated Operation via Sensor and Micom

This system internally provides temperature control for the ice making process/cold water process by

way of an ice detection sensor, so that ice making, ice removal, and cold water operation, via Micom,

may be automatically controlled in order to maintain an optimum operation.

4 H2O(Ambient Water/Cold Water/Hot Water/Ice) 1 Product!

With improved convenience, IGUASSU ICE 500 oers more production and supply power by providing

puried ambient water, cold water, hot water, and ice from one product.

Separate Water Delivery from a Single Spout

Ambient, cold, and hot water come out from a single spout, but independent water hoses are applied

so that each water is not mixed, thus improving overall satisfaction in preferred temperature from the

rst drink.