HEAT PUMPS -AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 12.65 D

4

Horizontal package air conditionners

HCompact2 HA

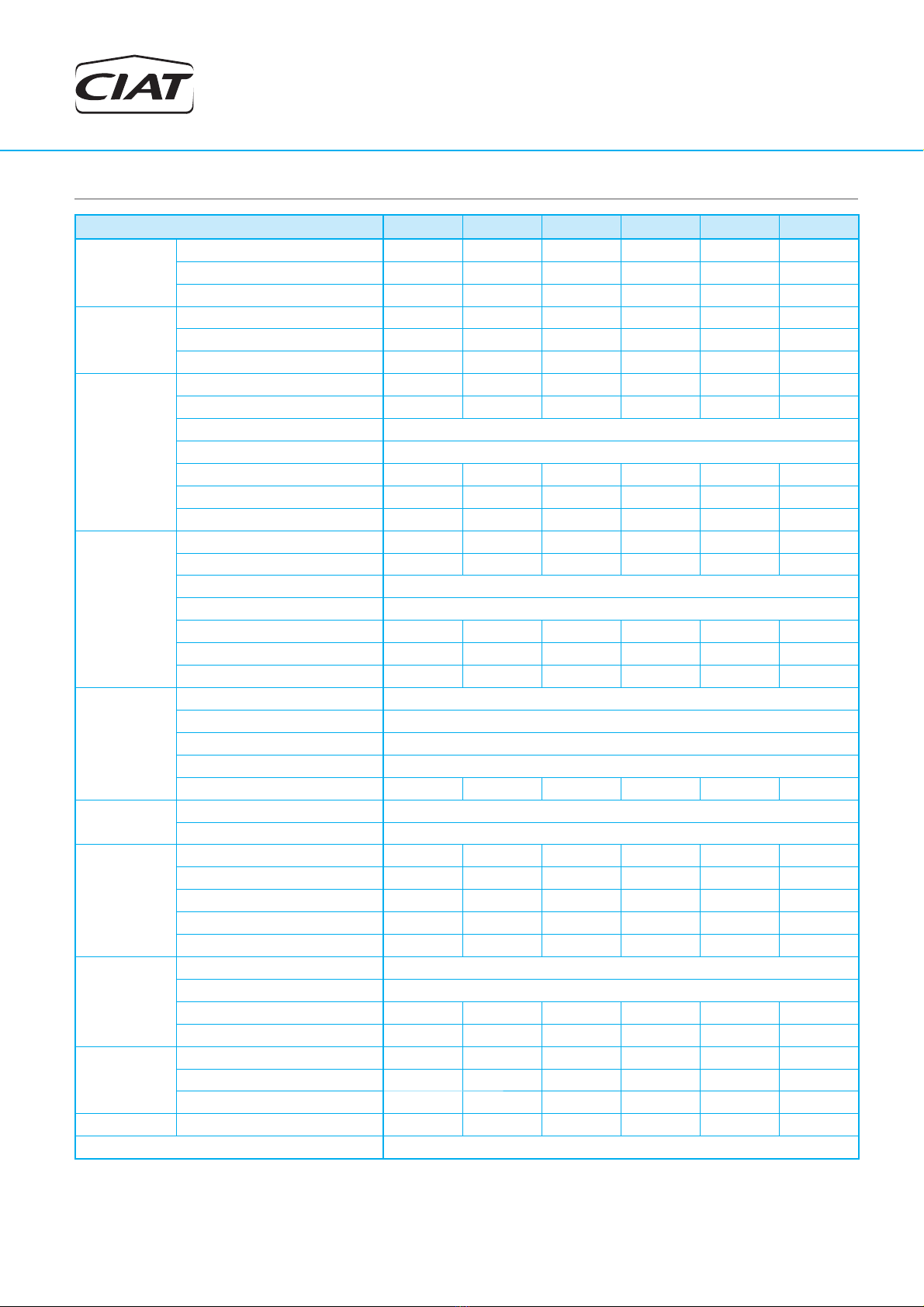

3. TECHNICAL CHARACTERISTICS (EN-14511-2013)

HCompact2 HA 55 65 80 90 120 160

Cooling

capacities

Cooling capacity (kW) 12,5 15,3 20,1 21,5 27,1 35,9

Power input (kW) 5,2 6,6 7,4 8,5 11,0 15,4

EER performance 2,38 2,30 2,70 2,53 2,47 2,33

Heating

capacity

Heating capacity (kW) 14,2 16,9 21,1 23,1 30,5 41,0

Power input (kW) 4,8 5,7 6,4 7,4 9,3 13,3

COP performance 2,93 2,96 3,29 3,13 3,28 3,10

Outdoor

circuit

fan

Nominal air flow (m3/h) 4.100 4.600 6.500 7.000 10.000 12.200

Available static pressure (mm.w.c) 9 9 10 10 12 12

Type Centrifugal

Number 1

Motor output (kW) 1,1 1,5 1,5 2,2 2,2 3,0

Power input (kW) 0,77 1,01 1,14 1,33 1,37 2,03

Speed (r.p.m.) 1.125 1.207 828 859 589 630

Indoor

circuit

fan

Nominal air flow (m3/h) 2.500 3.100 4.000 4.600 6.000 7.000

Available static pressure (mm.w.c) 5,0 5,0 6,2 6,2 6,2 7,5

Type Centrifugal

Number 1

Motor output (kW) 0,55 1,1 1,1 1,5 1,5 3,0

Power input (kW) 0,35 0,63 0,67 0,94 1,20 1,94

Speed (r.p.m.) 1.115 1.340 1.051 1.150 988 1.168

Compressor

Type Scroll

Compresor number 1

Circuit number 1

Oil type Copeland 3MAF 32cST, Danfoss POE 160SZ, ICI Emkarate RL 32CF, Mobil EAL Artic 22CC

Voulme of oil (l) 1,6 1,6 1,6 3,0 3,3 3,3

Electrical

characteristics

Electrical power supply 400 V / III ph / 50 Hz (±10%)

Power supply 3 Wires + Ground

Maximum

absorbed

current

Compressor (A) 15,0 19,0 19,0 22,0 29,0 35,0

Outdoor fan (A) 2,7 3,6 3,6 5,0 5,0 6,9

Indoor fan (A) 1,6 2,7 2,7 3,6 3,6 6,9

Control (A) 2,0 2,0 2,0 2,0 2,0 2,0

Total (A) 21,3 27,3 27,3 32,6 39,6 50,8

Refrigerant

Type R-410A

Global warming potential (GWP) 2.088

Charge (kg) 2,5 3,0 4,5 4,9 5,0 6,2

Environment impact (t CO2e) 5,2 6,3 9,4 10,2 10,4 12,9

Dimensions

Length (mm) 1.420 1.420 1.760 1.760 2.300 2.300

Width (mm) 1.065 1.065 1.414 1.414 1.820 1.820

Height (mm) 576 576 701 701 824 824

Weight (kg) 245 253 332 375 472 521

Ø Condensate evacuation 3/4”

Cooling capacity calculated in accordance withthe EN-14511-2013 standard given for indoortemperature conditions 27ºC, 50% RH and 35ºC outdoor temperature.

Heating capacity calculated in accordance with the EN-14511-2013 standard given for indoor temperature conditions 20ºC and 6ºC WB outdoor temperature.

Total power input by compressor and motorised fans under nominal conditions calculated in accordance with the EN-14511-2013.

Climatic warming potential of a kilogram of fluorinated greenhouse gas in relation to a kilogram of carbon dioxide over a period of 100 years.