Page 8

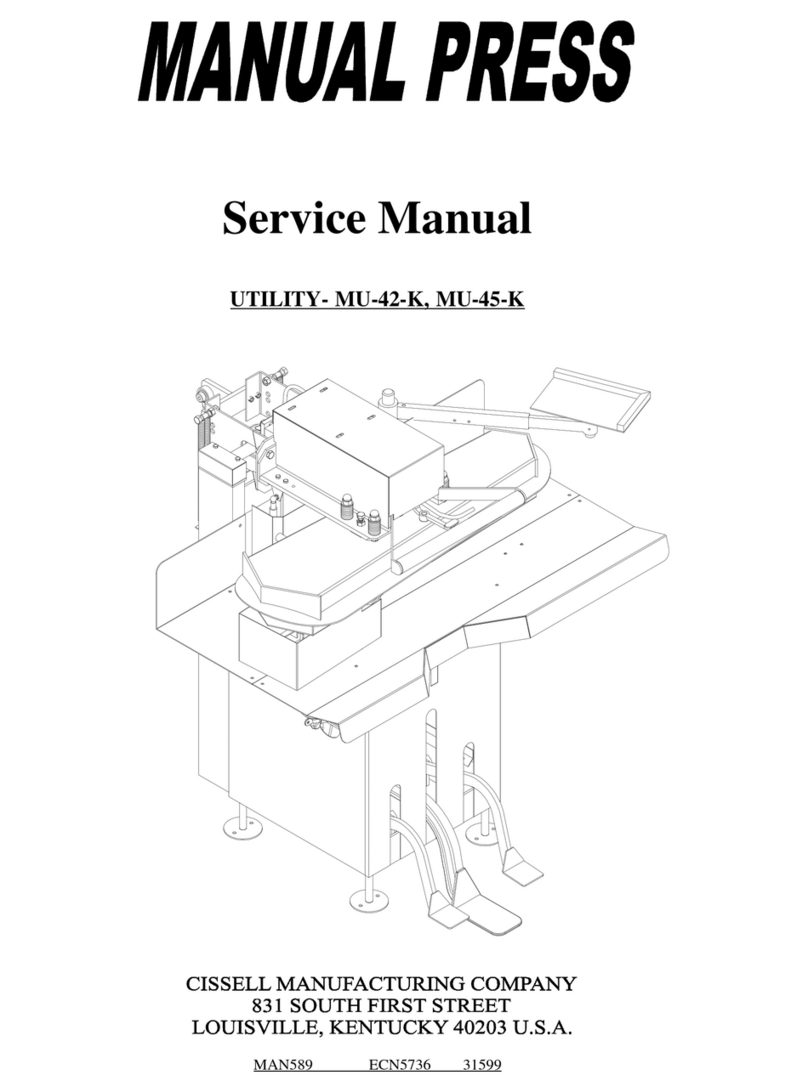

STRAIGHT FLOOR MODEL “L” FLOOR MODEL

NO. CONVEYOR

OF LENGTH

LINKS LOADED

NO. CONVEYOR

OF LENGTH

LINKS LOADED

NO. CONVEYOR

O F A & B

LINKS LOADED

NO. CONVEYOR

O F A & B

LINKS LOADED

14 8’-0” 58 30’-0” 58 34’-6”

15 8’-6” 59 30’-6” 59 35’-0”

16 9’-0” 60 31’-0” 60 35’-6”

17 9’-6” 61 31’-6” 61 36’-0”

18 10’-0” 62 32’-0” 62 36’-6”

19 10’-6” 63 32’-6” 63 37’-0”

20 11’-0” 64 33’-0” 64 37’-6”

21 11’-6” 65 33’-6” 65 38’-0”

22 12’-0” 66 34’-0” 22 16’-6” 66 38’-6”

23 12’-6” 67 34’-6” 23 17’-0” 67 39’-0”

24 13’-0” 68 35’-0” 24 17’-6” 68 39’-6”

25 13’-6” 69 35’-6” 25 18’-0” 69 40’-0”

26 14’-0” 70 36’-0” 26 18’-6” 70 40’-6”

27 14’-6” 71 36’-6” 27 19’-0” 71 41’-0”

28 15’-0” 72 37’-0” 28 19’-6” 72 41’-6”

29 15’-6” 73 37’-6” 29 20’-0” 73 42’-0”

30 16’-0” 74 38’-0” 30 20’-6” 74 42’-6”

31 16’-6” 75 38’-6” 31 21’-0” 75 43’-0”

32 17’-0” 76 39’-0” 32 21’-6” 76 43’-6”

33 17’-6” 77 39’-6” 33 22’-0” 77 44’-0”

34 18’-0” 78 40’-0” 34 22’-6” 78 44’-6”

35 18’-6” 79 40’-6” 35 23’-0” 79 45’-0”

36 19’-0” 80 41’-0” 36 23’-6” 80 45’-6”

37 19’-6” 81 41’-6” 37 24’-0” 81 46’-0”

38 20’-0” 82 42’-0” 38 24’-6” 82 46’-6”

39 20’-6” 83 42’-6” 39 25’-0” 83 47’-0”

40 21’-0” 84 43’-0” 40 25’-6” 84 47’-6”

41 21’-6” 85 43’-6” 41 26’-0” 85 48’-0”

42 22’-0” 86 44’-0” 42 26’-6” 86 48’-6”

43 22’-6” 87 44’-6” 43 27’-0” 87 49’-0”

44 23’-0” 88 45’-0” 44 27’-6” 88 49’-6”

45 23’-6” 89 45’-6” 45 28’-0” 89 50’-0”

46 24’-0” 90 46’-0” 46 28’-6” 90 50’-6”

47 24’-6” 91 46’-6” 47 29’-0” 91 51’-0”

48 25’-0” 92 47’-0” 48 29’-6” 92 51’-6”

49 25’-6” 93 47’-6” 49 30’-0” 93 52’-0”

50 26’-0” 94 48’-0” 50 30’-6” 94 52’-6”

51 26’-6” 95 48’-6” 51 31’-0” 95 53’-0”

52 27’-0” 96 49’-0” 52 31’-6” 96 53’-6”

53 27’-6” 97 49’-6” 53 32’-0” 97 54’-0”

54 28’-0” 98 50’-0” 54 32’-6” 98 54’-6”

55 28’-6” 99 50’-6” 55 33’-0” 99 55’-0”

56 29’-0” 100 51’-0” 56 33’-6” 100 55’-6”

57 29’-6” 57 34’-0”

1-5025-36

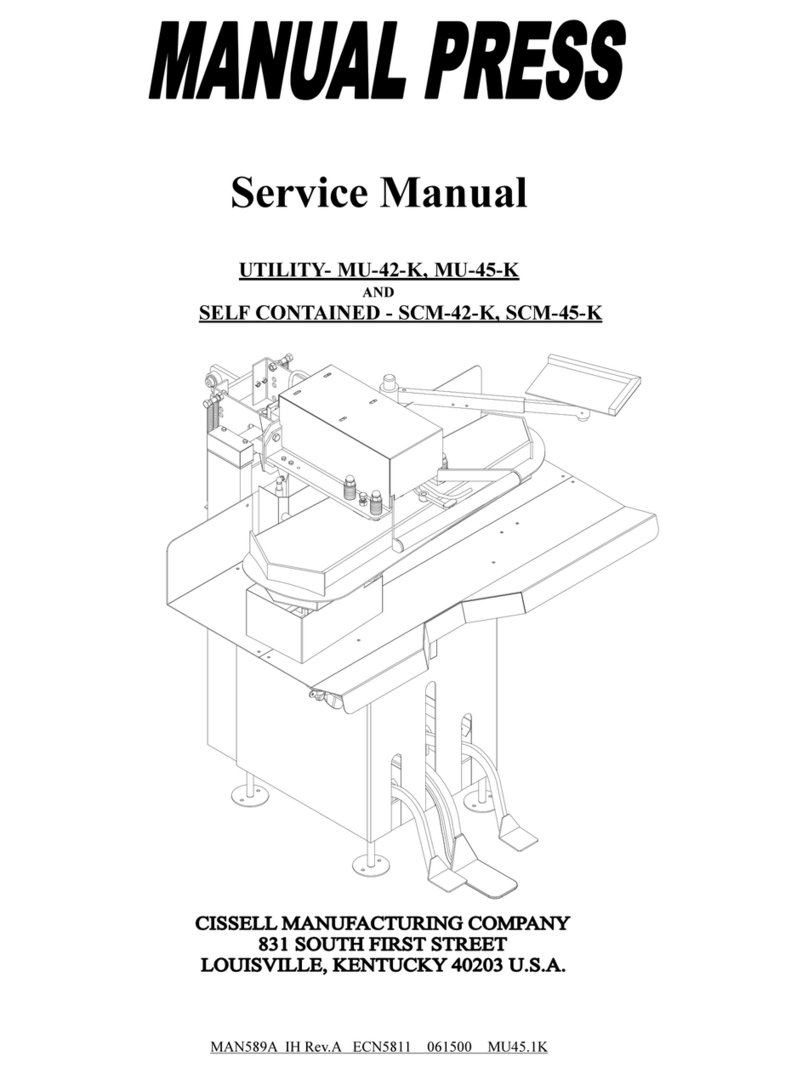

CISSELL

CONVEYORS