Table of contents

3

Tabl e of conten ts

Preface..............................................................4

Target group for this operating manual 4

Symbols used 5

Safety instruction ............................................6

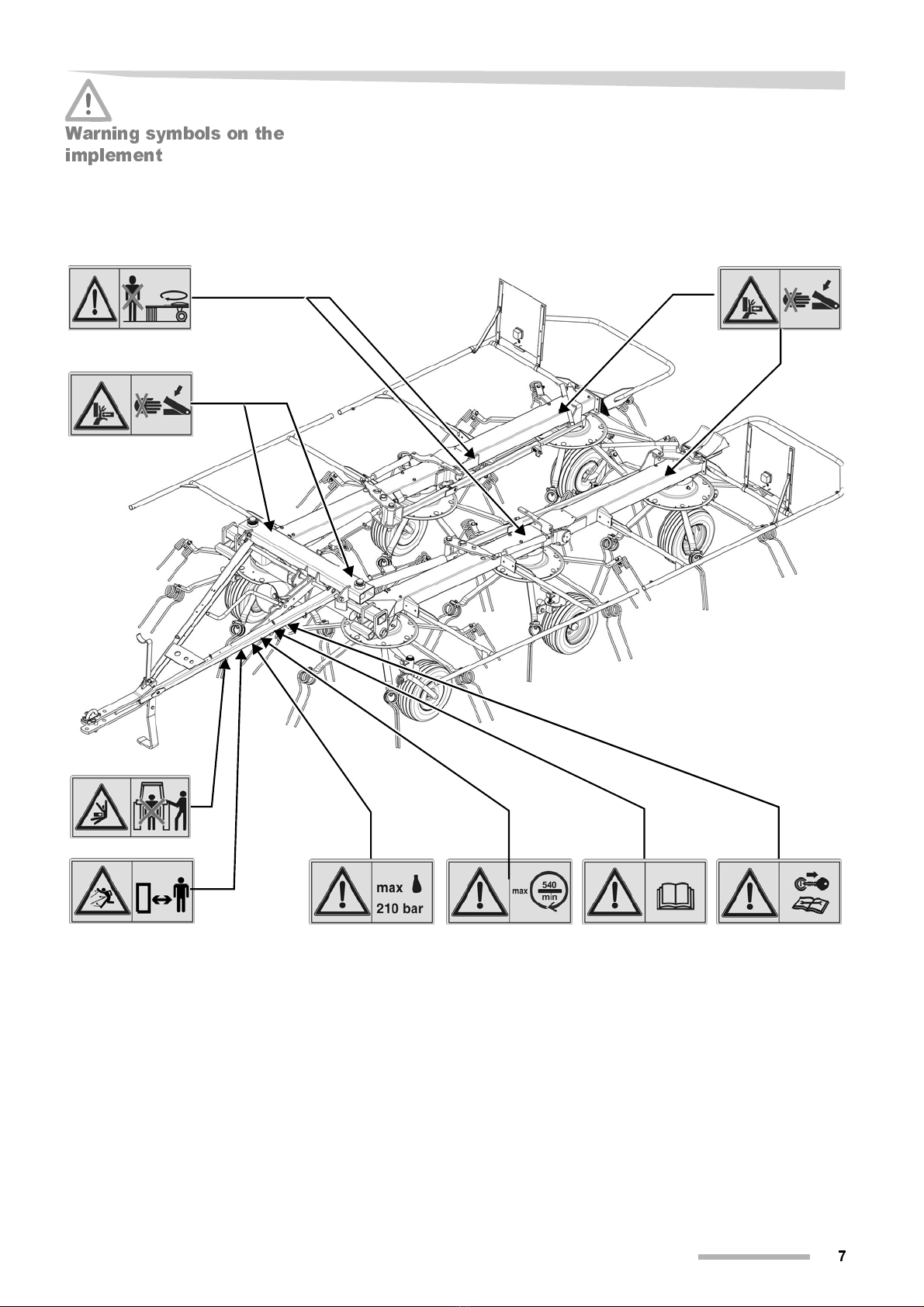

For your safety 6

Who is allowed to operate the implement 9

General 9

Coupling 10

Road travel 12

Operation 13

Uncoupling 14

Care and Maintenance 15

Further regulations 16

Familiarise yourself with the device............17

Work area of the implement 17

Features of the implement 17

Component designations 18

Specifications 19

Delivery and assembly..................................21

Checking the scope of supply 21

Coupling the implement................................22

Coupling the lift link drawbar 22

Coupling the pending attachment 22

Coupling the cardan shaft 22

Wheel wedges 23

Connections 24

Preparing for operation.................................26

Safety 26

Road transport...............................................29

Safety 29

Prior to road transport 30

Road transport 32

Operation........................................................33

Safety 33

Harvest processing 34

Implement Usage 35

Cleaning and care..........................................39

Safety 39

Cleaning 40

Care 40

Parking and storage......................................41

Safely setting down the implement 41

General 41

After the end of the season 41

Maintenance...................................................42

Safety 42

General 44

Screw connections 46

Lubrication points for grease lubrication 48

Lubricating the cardan shafts 49

Adapting the cardan shaft 50

Friction clutch 50

Lubrication points for oil lubrication 51

Filling volumes 52

Tyres 53

Hydraulic 53

Tine position 54

Accessory equipment ................................... 55

Tine anti-loss device 55

Swathing gear 55

Anti-wrapping plate 55

Hydraulic angled position 56

Fault recovery................................................ 57

Circuit diagrams............................................ 58

Hydraulic diagram, standard version 58

Hydraulic diagram with hydraulic angled posi-

tion 59

Lighting circuit diagram 60

Environmental protection............................. 61

Disposal 61

EU Declaration of Conformity ......................62

Index ............................................................... 63