Civemasa AACRP User manual

AACRPAACRP

OPERATOR'S MANUAL

Civemasa Implementos Agrícolas 1

AACRP

Introduction

The AACRP plow has a modern and rugged structure with a better

weight distribution. This equipment allow operations with the tractor

over unworked ground, far from the furrow. It can be normally used

on tractors with dual wheelset.

Equipped moldboards with two cutting faces that provides

excellent penetration, clod breaking and stubble incorporation.

The moldboards have a cylindrical shape with high capacity of

land fragmentation and also have an automatic retrieving set that is

activated by an elastic deformation of the flat spring, returning the

moldboards to working position instantly, being just necessary to lift

the equipment.

Special coating with high density polyethylene that reduces the

effort and the friction with the ground and also has a superior wear

resistance.

This operator's manual contains the necessary information for

the best performance of this plow. The operator must carefully read

the entire manual before working with the equipment. Also, read and

understand the safety recommendations.

For any further clarification or in the event of technical problems

that may arise during the service, consult your dealer and the

Technical Support department of the factory. They can ensure the

fully functioning of your Civemasa plow.

Civemasa Implementos Agrícolas

2AACRP

Table of contents

1. To the owner 3

2. To the operator 4 to 9

3. Data sheet 10 & 11

Dimensions for transportation and storage 11

4. Components 12

5. Assembly 13 to 18

Frame assembly 13

Moldboard carrier frame and shock absorbers 14

Moldboard assembly 15

Adapter to change the number of moldboards assembly 16

Wheelset fixation support assembly 16

Wheelset and rear tire assembly 17

Front tires assembly / Hoses and cylinder assembly 18

6. Set-up instructions 19

Preparing the tractor / Quick coupling (Hanger type) 19

7. Adjustments and operations 20 to 25

Plow leveling 20

Depth adjustment of the moldboard 21

Automatic retrieving and pressure adjustment 22

Important recommendations / Plow operations 23

Ways to start the plowing / Troubleshooting guide 24

Operations - Important points 25

8. Maintenance 26 to 33

Lubrication / Lubrication points 26

Replacement of the blades and polyethylene plates 27

Wheelset hubs lubrication 28

Hydraulic cylinder maintenance / assembly 29 & 30

Plow maintenance 31

Tires inflation 32

Hydraulic safety 33

9. Important data 34 to 36

Calculation of hourly income 34

Average income table 35

Torque table 36

10. Important 37

Civemasa Implementos Agrícolas 3

AACRP

To the owner

General information

Important

NOTE

The acquisition of any Civemasa product assures to the original purchaser the following

rights:

• Warranty certificate;

• Operator's manual;

• Technical assistance by the dealer on equipment delivery.

However, the owner must check the condition of the equipment on delivery, as well as

knowing the warranty terms.

Special attention should be given to the safety recommendations, operation precautions

and maintenance of the equipment.

The instructions in this manual indicates how to get the best performance and allow

the operator to get maximum income, increasing the equipment lifetime.

This manual should be read by operators and maintenance staff.

• Only people who own a full knowledge of the tractor and equipment must

transport, operate and carry out any maintenance on them;

• Civemasa is not responsible for any damage caused by accident on

transporting, maintenance, incorrect utilization or inadequate storage,

either by negligence and/or lack of experience from any person;

• Civemasa is not responsible for any damage caused by unpredictable

situations or the incorrect use of the equipment.

Right and left hand side indication are made observing the equipment from the rear.

To order any parts or request technical assistance services, it is required to provide

the data contained on the nameplate, which is located on the equipment frame.

The warranty shall not be applied to any equipment, or any parts thereof,

which has been altered elsewhere than at the place of manufacture or which

the original purchaser thereof, at retail, has used or allowed to be used parts,

not made or supplied by Civemasa.

Civemasa Implementos Agrícolas

4AACRP

To the operator

Dear operator!

Respect the ecology. Do not throw trash away. This gesture

of goodwill helps to protect our environment.

Be careful with the environment

Working safely

U

U

s

s

o

o

d

d

e

e

E

E

.

.

P

P

.

.

I

I

.

.

O

O

B

B

R

R

I

I

G

G

A

A

T

T

Ó

Ó

R

R

I

I

O

O

Uso de

E.P.I.

OBRIGATÓRIO

Read and understand the information before making any

adjustment or maintenance.

Have extreme caution when operating with the power take-off

(PTO). Do not get closer during operation.

• Security aspects must be carefully observed to avoid accidents.

• This symbol is a warning used to prevent accidents.

• The instructions under this symbol refers to the safety of the

operator, mechanician or third parties, therefore they should be

carefully read and observed. When the safety instructions are

not being followed, a serious accident or even death may occur.

The AACRP plow is simple to operate, requiring however the

basic and essential cautions to its handling.

Always keep in mind that safety requires constant attention,

observation and prudence during working, transportation,

maintenance and storage.

Products such as oil, fuel, filters, batteries and others are spilt

over the soil and can penetrate to the underground layers, thus

compromising nature. Ecological and conscious disposal of them

should be done.

Civemasa Implementos Agrícolas 5

AACRP

To the operator

Always use the safety locks to carry out maintenance operations

and to transport the equipment.

Always use the seat belt.

XX

The presence of any other people on the tractor or equipment

is stricly forbidden.

Have extreme caution when driving under electrical power lines.

For your protection and safety, always wear adequate clothes

and footwear while operating the equipment.

Never use your bare hands to check hydraulic leaks, the high

pressure can cause injuries.

Never attempt to change the adjustments, clean or lubricate the

equipment when the same is switched on or in movement.

Be careful while driving on slopes. Risk of overturn.

Prevent that chemical products (i.e.: fertilizers, treated seeds)

make any contact with your skin or clothes.

Keep access and work places clean or free from oil and grease.

Risk of accidents.

Civemasa Implementos Agrícolas

6AACRP

To the operator

• Only trained and qualified personnel are allowed to operate the equipment.

• While working or during transportation, only the presence of the operator is

allowed on the tractor.

• Do not allow children to play or to get over the equipment while it is operating,

during transportation or storage.

• When setting the equipment to transport position, check if there are no people

or animals close or under the equipment.

• Use personal protective equipment (PPE).

• Wear appropriate clothes and footwear. Avoid clothes that are either loose or

hanging from the body, which may become entangled in moving parts.

• Wear protective gloves to work near the cutting parts.

• Never operate the equipment without its protective devices.

• Have full knowledge of the soil before starting to work. Use the speed which is

suitable to the conditions of the ground. Provide the delineation of obstacles

or hazardous locations.

• Carefully check the transport width on narrow locations.

• Be careful when hitching the equipment to the tractor.

• Only pull the equipment using a tractor with appropriate power.

• Do not drive the equipment under the influence of alcohol or any soothing/

stimulating medicine, as it may result in a serious accident.

• In case of a fire outbreak or any possible hazard, the operator must leave the

area as fast as possible and look for a safe place. Always have emergency

numbers at hands.

• In case of emergency, know how to stop the tractor and equipment quickly.

• Always shut down the engine, remove the key and activate the brake before

leaving the tractor seat.

• Never attempt to change the adjustments, clean or lubricate the equipment

while it is moving.

• Whenever you unhitch the equipment, either in the field or shed, do it on a flat

and firm surface. Make sure the equipment is properly supported.

• We suggest that you carefully read the manual, as it will be a guide for

periodic verifications that need to be done and will allow that you assure the

maintenance of your equipment.

• If there is any doubt after reading it, ask your dealer. For more complicated

operations, there will be the right person to help you there.

• Please check the general safety instructions on the back cover of this manual.

Civemasa Implementos Agrícolas 7

AACRP

Transportation over truck or trailer

To the operator

Civemasa does not advise the equipment traffic on highways, because this

practice involves serious security risks in addition to being prohibited by the

current existing traffic law. The transportation for long distances should be

done on truck, trailer or other by following these safety guidelines:

• Use adequate ramps to load or unload the equipment. Do not make the loading

on ditch banks, it can cause a serious accident.

• When lifting with a hoist, use the appropriate points to lift.

• Underpin the equipment appropriately.

• Use chock blocks and safety chains to secure the equipment to the truck or

trailer during the transport.

• Make sure the SMV (Slow Moving Vehicle) sign, and all the lights and reflectors

that are required by the local highway and transport autorithies are in place,

are clean and can be seen clearly by all overtaking and oncoming traffic.

• After 8 to 10 km transporting, please inspect the load condition. Repeat this

procedure every 80 to 100 km. Give more attention when transporting the

equipment on rough roads, slopes and other adverse conditions.

• Always be careful with the load height, especially when passing under electrical

power lines, bridges and others.

• Check all laws and regulations regarding the height limits and load width while

transporting the equipment to the truck or trailer. If necessary use banners,

lights and other devices in order to give adequate warning to the other drivers.

Civemasa Implementos Agrícolas

8AACRP

To the operator

Lifting points

Use chains, of at least 3 meters long, to lift the equipment safely.

Use the adequate points for lifting and be sure that the equipment is safe.

Avoid accidents.

Always keep a safe distance from the equipment.

Minimum - 3 metersMinimum - 3 meters

longlong

This moldboard plow has adequate lifting points located on the frame. When lifting with

a hoist, it is essential to hitch the cables to all of these points.

Civemasa Implementos Agrícolas 9

AACRP

To the operator

Safety decals

Decal set

Qty. Model Serial number

1Civemasa logo 05.03.03.3238

1Danger decal 05.03.03.1739

1Read the manual decal 05.03.03.1428

1Lubricate and tighten daily decal 05.03.03.1827

The safety decals warn about the equipment points that require more attention and they

should be kept in good repair. If these decals become damaged or illegible, replace them.

Civemasa provide decals, upon request and indication of the respective serial number.

Civemasa Implementos Agrícolas

10 AACRP

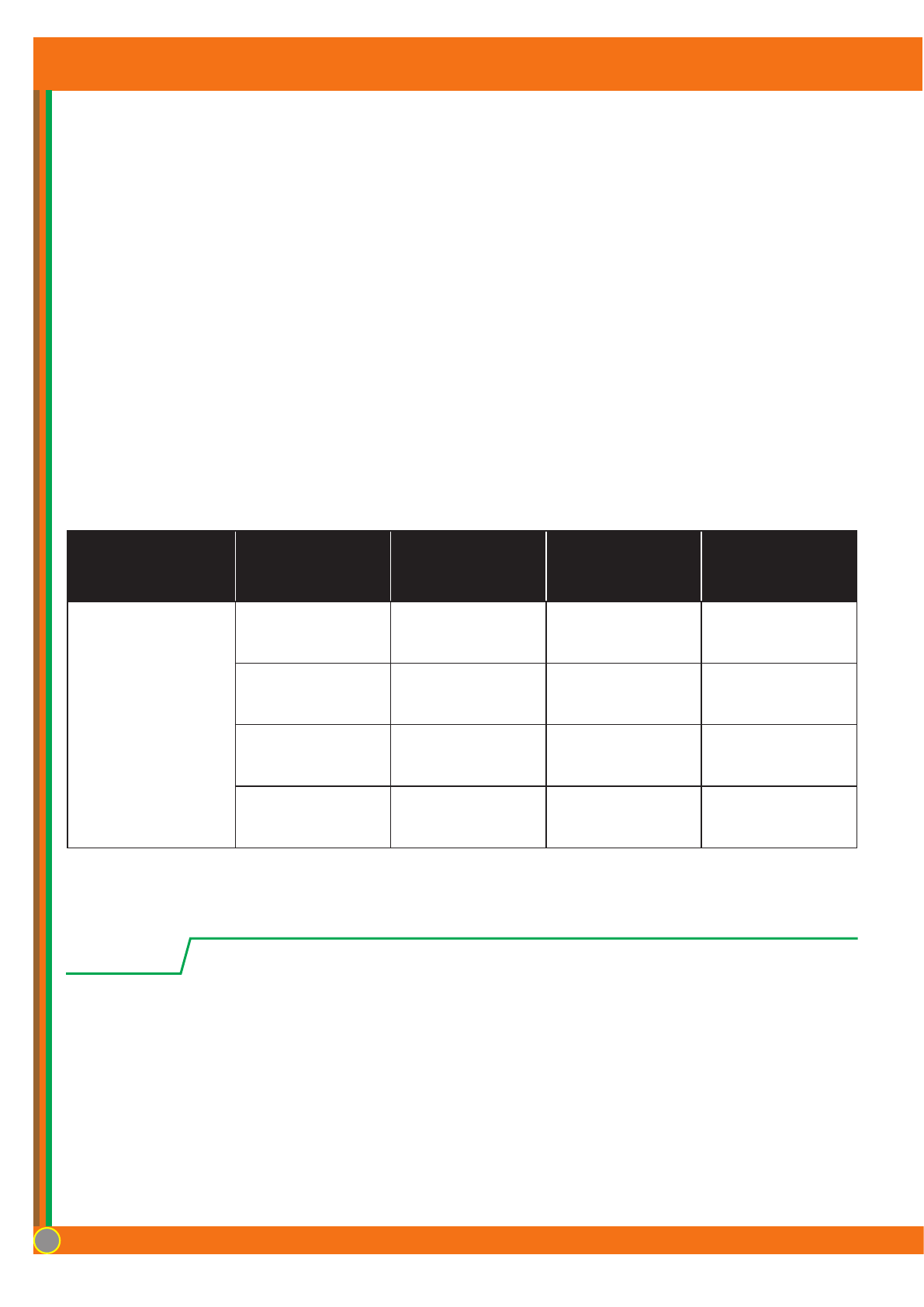

Data sheet

Model Number of

moldboards

Cutting width

(mm)

Total weight

(kg)

Tractor engine

required power

(hp)

AACRP

05 2400 2335 220 - 240

06 2880 2530 240 - 260

07 3360 2820 260 - 300

08 3840 3010 300 - 340

ATTENTION

Type: ......................................................................................................................... Plow

Model: ...................................................................................................................AACRP

Spacing between moldboards: .............................................................................. 810 mm

Number of moldboards:...........................................................................05, 06, 07 and 08

Hitching type: ......................................................................Three-point hitch - Category II

Working speed:.................................................................................................5 to 8 km/h

Height:.................................................................................................................. 950 mm

Tires:........................................................................................................6.00 x 16 - 6 ply

The working speed of the plow may vary between 5 and 8 km/h, depending

on conditions and soil type.

The tractor engine required power must be observed regarding depth,

soil type and working speed.

Civemasa Implementos Agrícolas 11

AACRP

Data sheet

Dimensions for transportation and storage

Model Number of

moldboards A B C D

AACRP

05 1510 810 4100 5940

06 1510 810 4100 6420

07 1510 810 4100 7130

08 1510 810 4100 8040

Measures in millimeters.

NOTE

AA

BBBB

CC

DD

Civemasa Implementos Agrícolas

12 AACRP

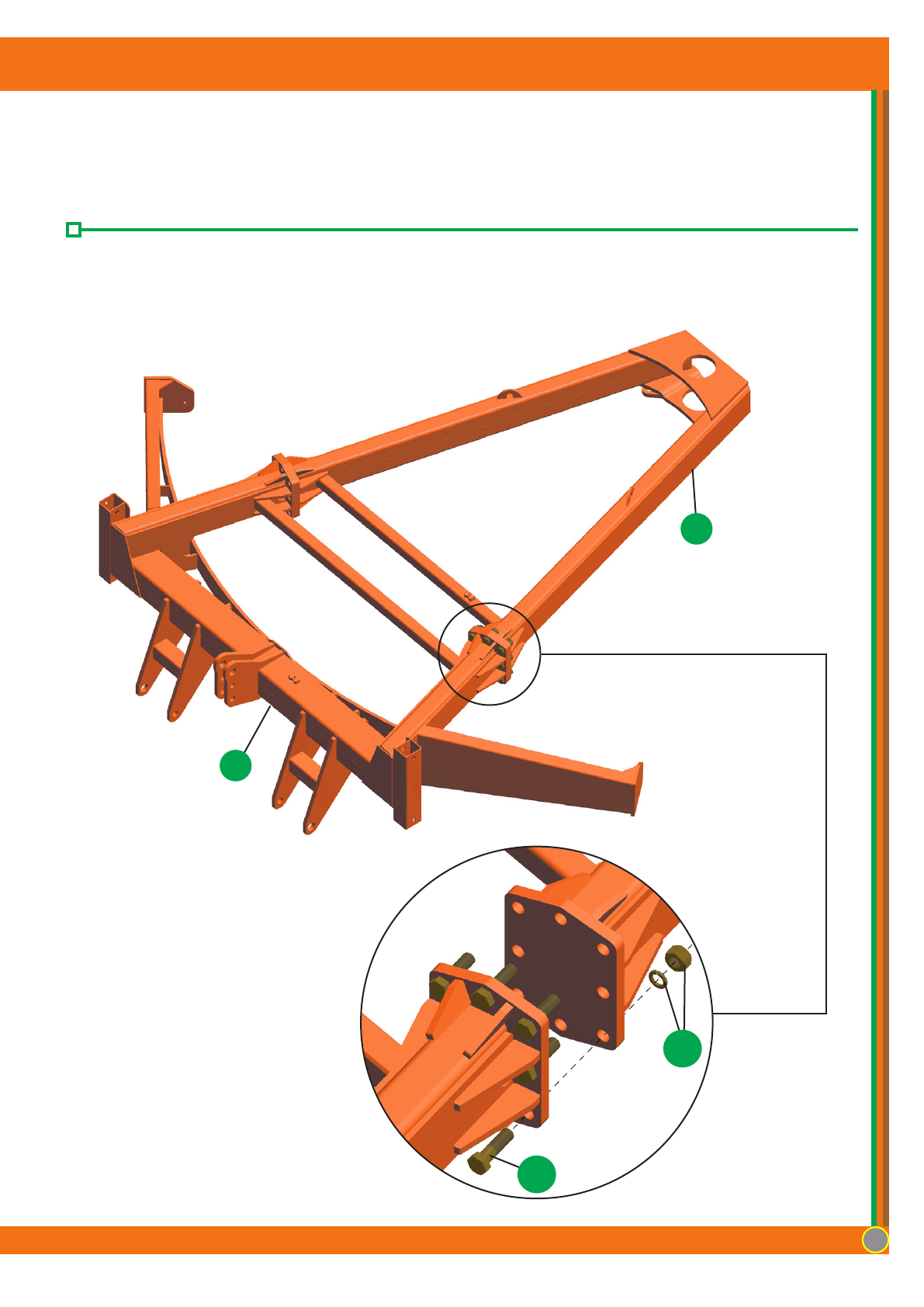

Components

AACRP - On-land reversible moldboard plow

0707

0101

0202

0808

0404

0505

0303

0606

0606

01 - Frame 05 - Moldboards

02 - Drawbar 06 - Gauge wheels

03 - Hydraulic cylinder 07 - Stabilizer

04 - Polyethylene plates 08 - Tractor hitch

Civemasa Implementos Agrícolas 13

AACRP

Assembly

Frame assembly

DD

CC

BB

AA

The plow usually leaves the factory assembled, but to facilitate loading and

transportation, the plow may leave unassembled in some cases. Follow the instructions

below for the correct way to assemble your plow:

Connect the front part of the frame (A) to its rear part (B) using bolts (C), spring

washers and nuts (D), as detailed below.

Civemasa Implementos Agrícolas

14 AACRP

Assembly

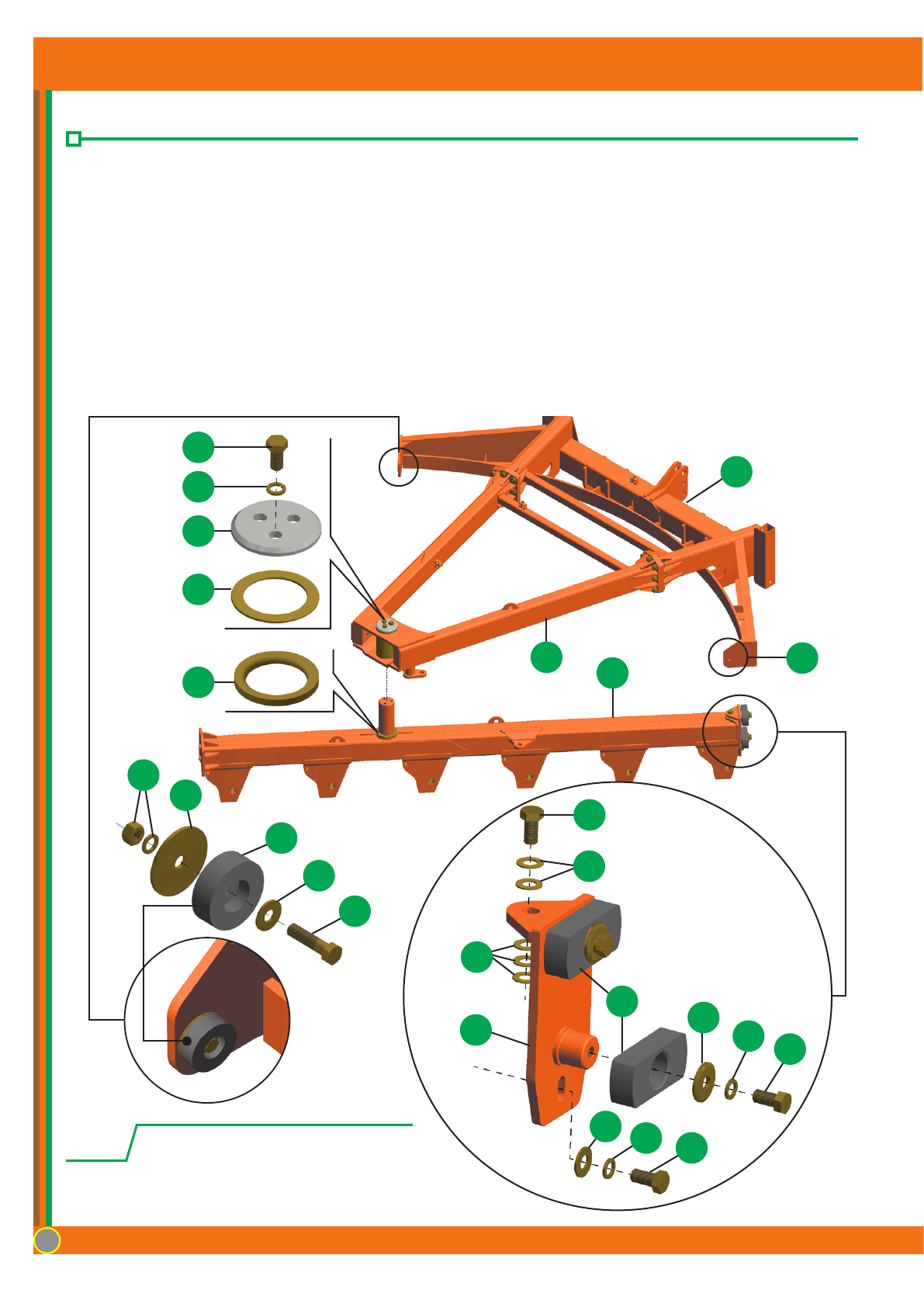

Moldboard carrier frame and shock absorbers

GG

EE

FF

DD

CC

BBAA

II

JJ

JJ

HH

KK

LL

MM

NN

OO

PP

QQ

WWTT

RR

VV

UU

SS

RR

NOTE

Assemble the moldboard carrier frame (A) on the rear part of the drawbar (B) using

bolts (C), spring washers (D), upper frame fixation flange (E), flat washer (F) and axle

bushing (G).

Place the guide fastener (H) on the moldboard carrier frame using a bolt (I) and flat

washers (J) on the upper part; on the lateral, use a bolt (K), spring washer (L) and flat washer

(M). Place the frame guide plates (N) on the fastener using bolts (O), spring washers (P)

and flat washers (Q), as shown below.

Fasten the lateral shock absorbers (R) to the front frame (S) with a flat washer (T)

using a bolt (U), flat washer (V), spring washer and nut (W).

The washers (J) are used to

adjust the frame guide plates

(N) so that they can slide as

smooth as possible.

Civemasa Implementos Agrícolas 15

AACRP

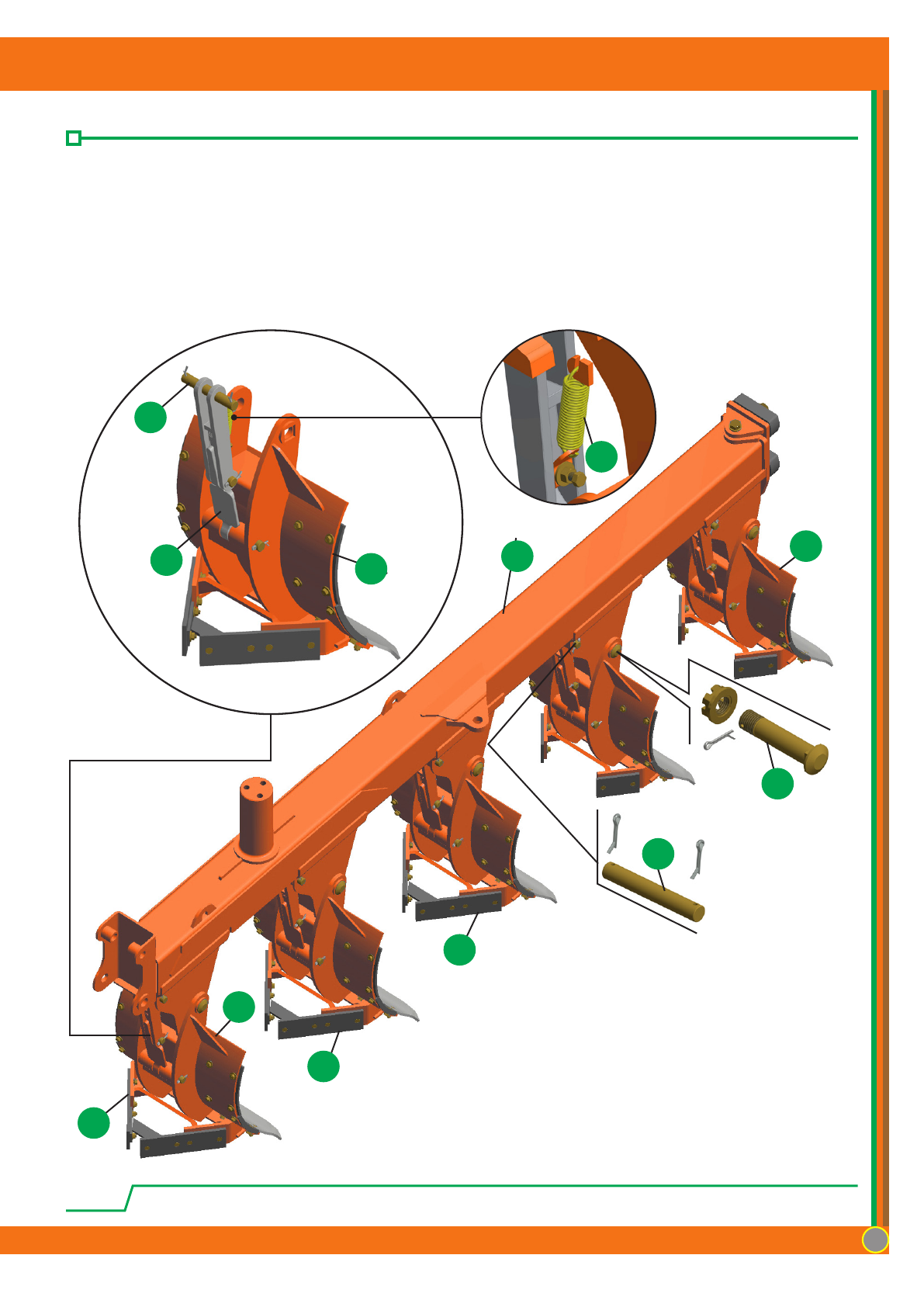

Assembly

Moldboard assembly

NOTE The three last moldboards have long guides (G) to help stabilizing the plow.

EE

DDAA

FF

GG

AA

GG

GG

EE

CC

AA

BB

Couple the moldboards (A) to the moldboard carrier frame (B) using a pin (C), castle

nut and cotter pin.

Then, couple the automatic retrieving set (D) with junction axle (E) and cotter pin.

Lastly, lock the traction spring (F) to the automatic retrieving set (D). Repeat this

operation for every moldboard.

Civemasa Implementos Agrícolas

16 AACRP

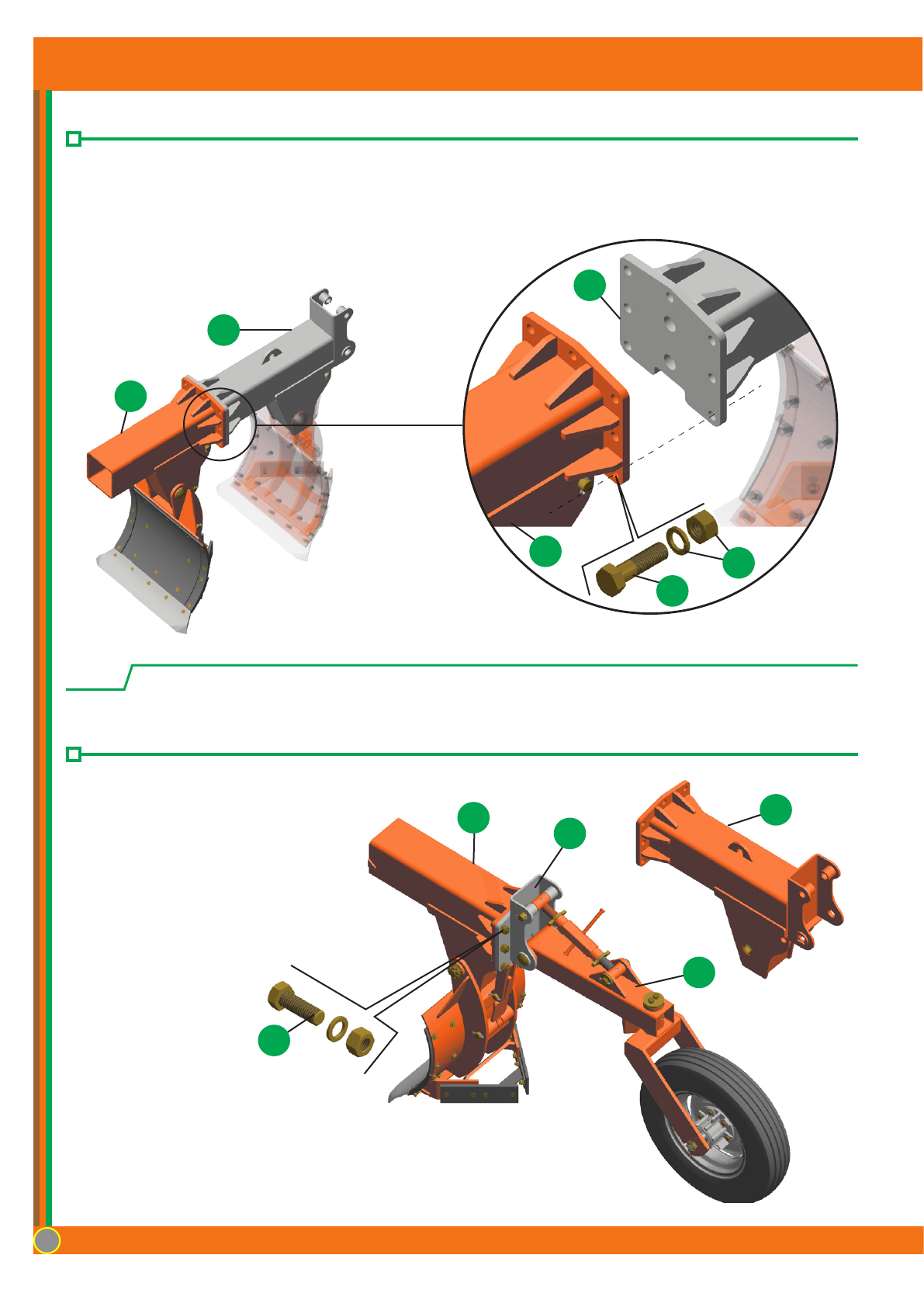

Assembly

Adapter to change the number of moldboards assembly

BB

AA

AA

BB

CC

DD

Wheelset fixation support assembly

NOTE The adapter (A) is an optional part for the 6/5, 7/6 and 8/7 models.

To add a moldboard on some equipment models, use the adapter (A), which must be

fastened to the moldboard carrier frame (B) using bolts (C), spring washers and nuts (D).

AA

BB

CC

EE

DD

When the adapter is

not being used to change

the number of moldboards

(A), use the wheelset fixation

support (B), fastened to the

moldboard carrier frame

(C) using bolts (D), spring

washers and nuts to couple

the rear wheelset (E).

Civemasa Implementos Agrícolas 17

AACRP

Assembly

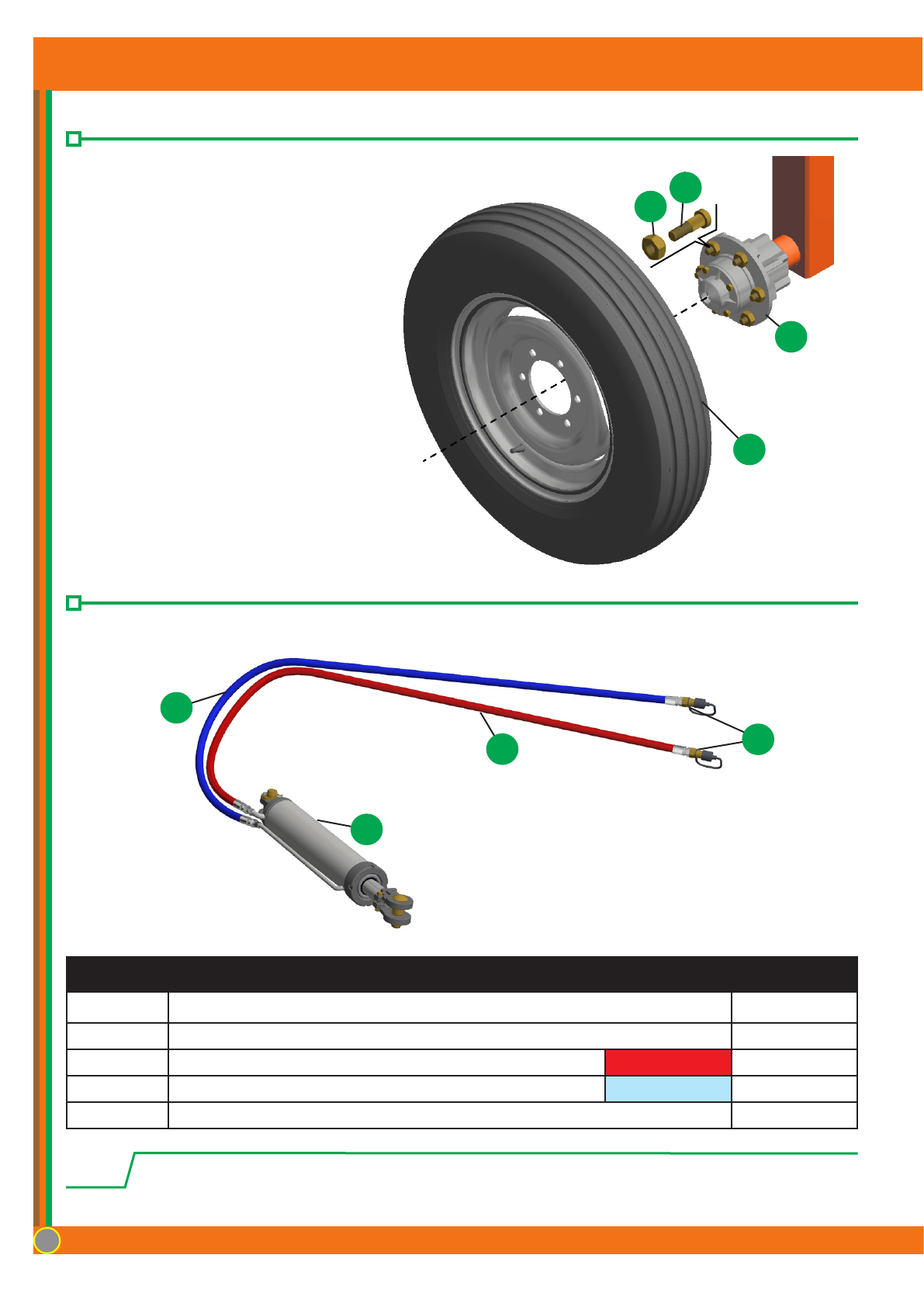

Wheelset and rear tire assembly

BB

GG

FF

AA

DD

CC

EE

NN

OO

MMPP

IIPP

JJKK

HH

LL

MM

OO

To couple the rear wheelset (A), fasten it to the moldboard carrier frame (B) using a

junction axle (C), castle nut (D), flat washer and cotter pin. Place the stabilizer (E) to the

wheelset (A) with junction axle (F) and cotter pin. On the other end, use the junction axle

(G) and cotter pin.

Fasten the wheel (H) to the

wheelset hub (I) using a bolt (J)

and conical nut (K).

On the axle hub (I), place

flat washer (L) and locks (M).

Couple the set on the fastener

(N) and tighten the castle nuts

(O). To finish, lock the cotter

pins (P) on the hub.

Civemasa Implementos Agrícolas

18 AACRP

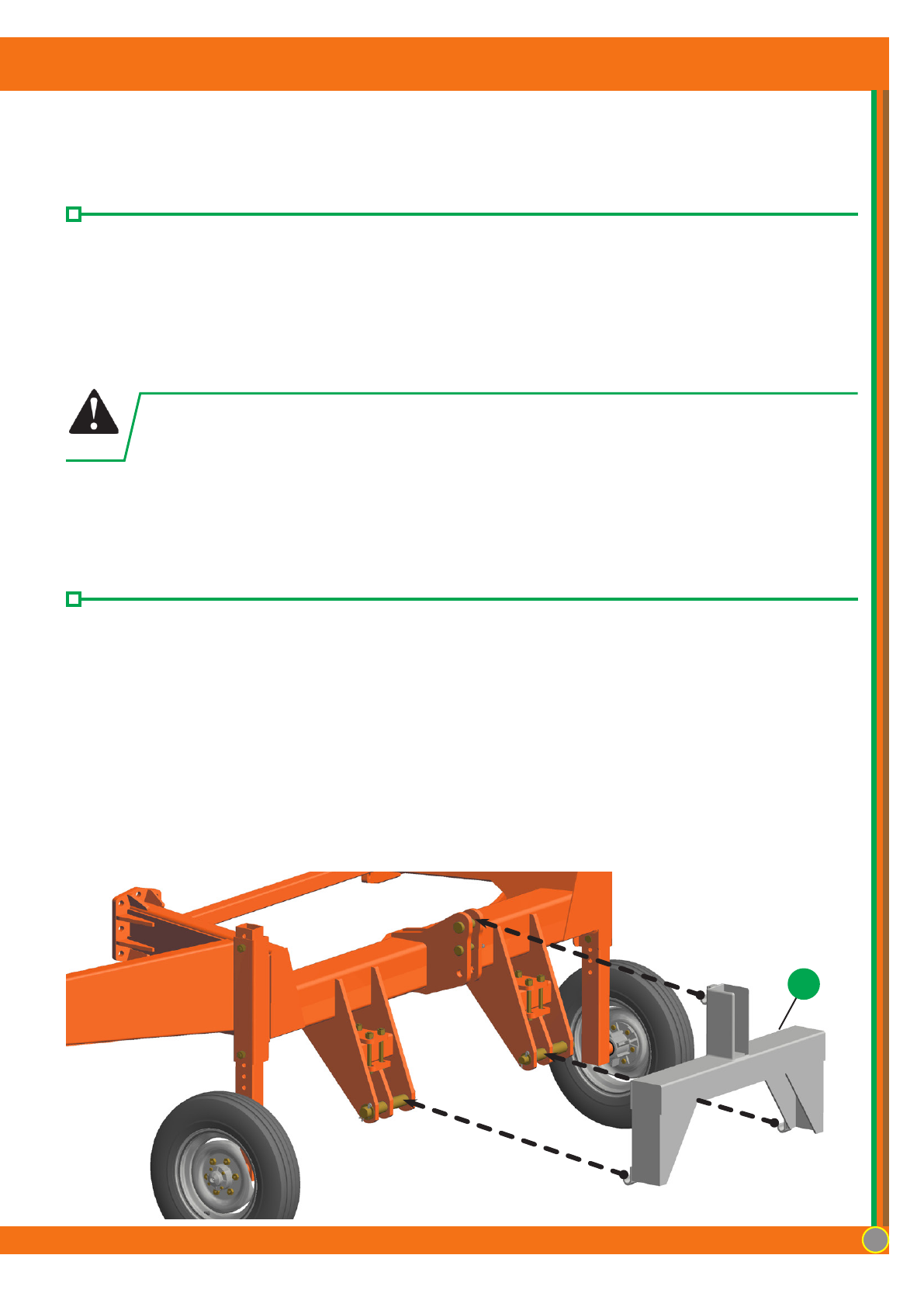

Assembly

Front tires assembly

Hoses and cylinder assembly

NOTE Assemble the set with enough tightening to avoid leakages.

Always use thread sealing tape to couple the male quick couplers to the hoses.

AACRP

Item Description Quantity

AHydraulic cylinder 01

B3/8 x 6000 TR-TM hose Pressure 01

C3/8 x 6000 TR-TM hose Return 01

DMale quick coupler with cap 02

Identify the hoses as shown on the illustration and also the specifications below:

CC

AA

BBDD

DDCC

BB

AA

Fasten the wheel (A) to the

wheelset arm hub (B) using a bolt

(C) and conical nut (D).

Check how to assemble and

unassemble the wheelset hub (B)

for a correct lubrication.

Civemasa Implementos Agrícolas 19

AACRP

Set-up instructions

Preparing the tractor

The following instructions must be carefully observed in order to get the best working

performance.

NOTE

Quick coupling (hanger type)

AA

Check the general conditions for using the tractor, especially the good functioning of

the hydraulic system (three-point hitch).

The addition of water ballasts on the tires or a set of weights on the front part/rear

wheels of the tractor are the most used ways to increase the traction over soil and to give

a greater stability to the tractor.

When transporting the plow or lifting it for maneuvers, check the tractor

manual to be sure about the necessary weight to not affect the stability of the

tractor-plow set. Without this proper weight distribution, serious accidents

or even death may occur.

Civemasa is not responsible for the incorrect use of the equipment.

The quick coupling (hanger type) (A) comes equipped to the tractor to facilitate and

give greater security.

With the fast coupling, the operator can perform the plow hitching from the seat.

Choose a place as flat as possible for hitching.

Drive the tractor slowly in reverse gear in order to get closer to the plow and be ready

to brake. After hitching, lift the plow until it clicks lock.

For a perfect coupling, the plow must be centralized with the tractor.

Align the tractor quick coupling with the plow drawbar.

Table of contents

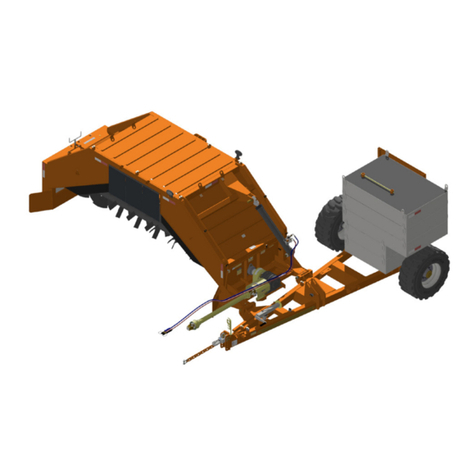

Other Civemasa Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Hanskamp

Hanskamp PipeFeeder HighSpeed Installation and operating instruction

LEMKEN

LEMKEN POLARIS 12/1.900 operating instructions

Sovema

Sovema FC-2 Series Operation & maintenance manual

360 YIELD CENTER

360 YIELD CENTER 360 BANDIT installation instructions

J&M

J&M Torsion Flex manual

GSi

GSi Cumberland Hi-Lo Installation and operation manual