Nozzle Assembly S22693-118

Retainer (Standard spacing for .045 and .052 dia electrodes) S22693-152

Retainer (Wide spacing for special applications) S22693-135

Retainer “0” ring S22693-136

Nozzle Retainer Insulator (Standard spacing) S22693-117

Nozzle Retainer Insulator (Wide spacing) S22693-146

Wire liners:

.035-.045 6 ft. S22693-9

.035-.045 15 ft. S22693-158

.052-.062 6 ft. S22693-10

.052-.062 15 ft. S22693-159

Diffuser (non-taper lock) S22693-120

Short diffuser (non-taper lock) S22693-206

Contact Tips:

.030” dia. Heavy Duty S22693-1

.035” dia. Heavy Duty S22693-2

.045” dia. Heavy Duty S22693-3

.052” dia. Heavy Duty S22693-4

.062” dia. Heavy Duty S22693-5

Taper Lock Diffuser S22693-207

Taper Lock Contact Tips:

.030” dia. Taper Lock S22693-191

.035” dia. Taper Lock S22693-129

.045” dia. Taper Lock S22693-181

.052” dia. Taper Lock S22693-194

.062” dia. Taper Lock S22693-195

TOTAL:

EXPENDABLE REPLACEMENT PARTS FOR TANDEM MIG 800 AMP WELDING TORCH

Parts Description Part Number Quantity Price

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our

customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to our customers based

on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or

advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of

practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has been given, nor does the provision of information or

advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change — This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

EXPENDABLE REPLACEMENT PARTS

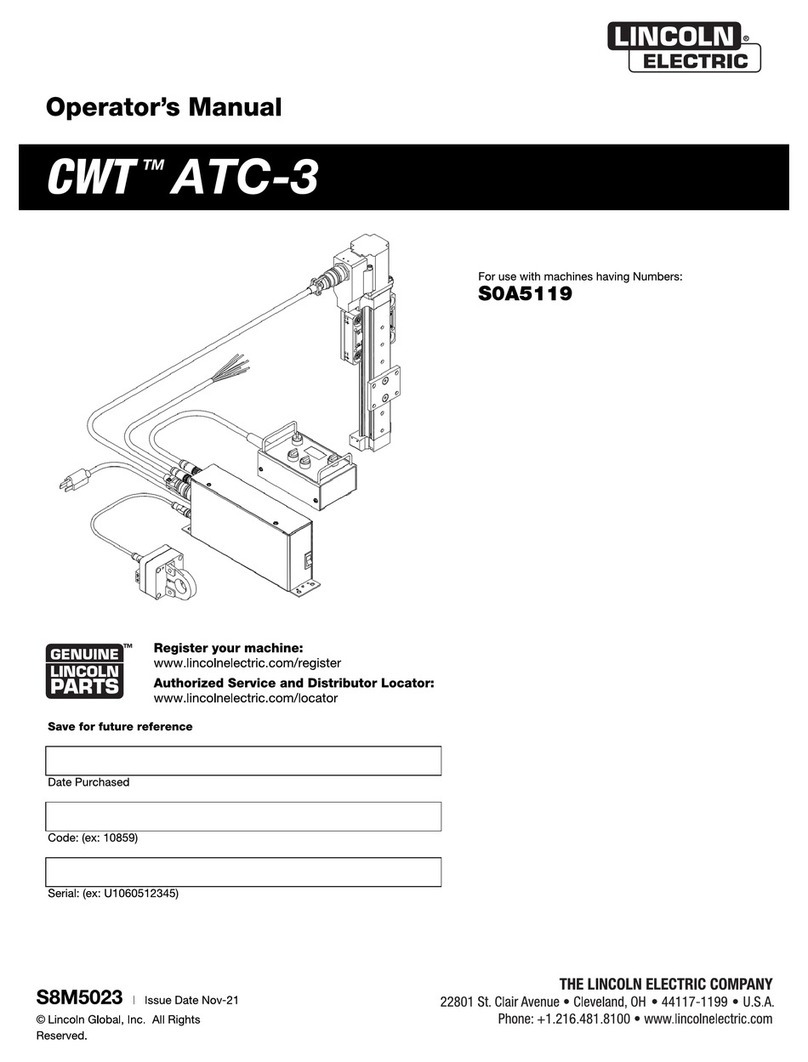

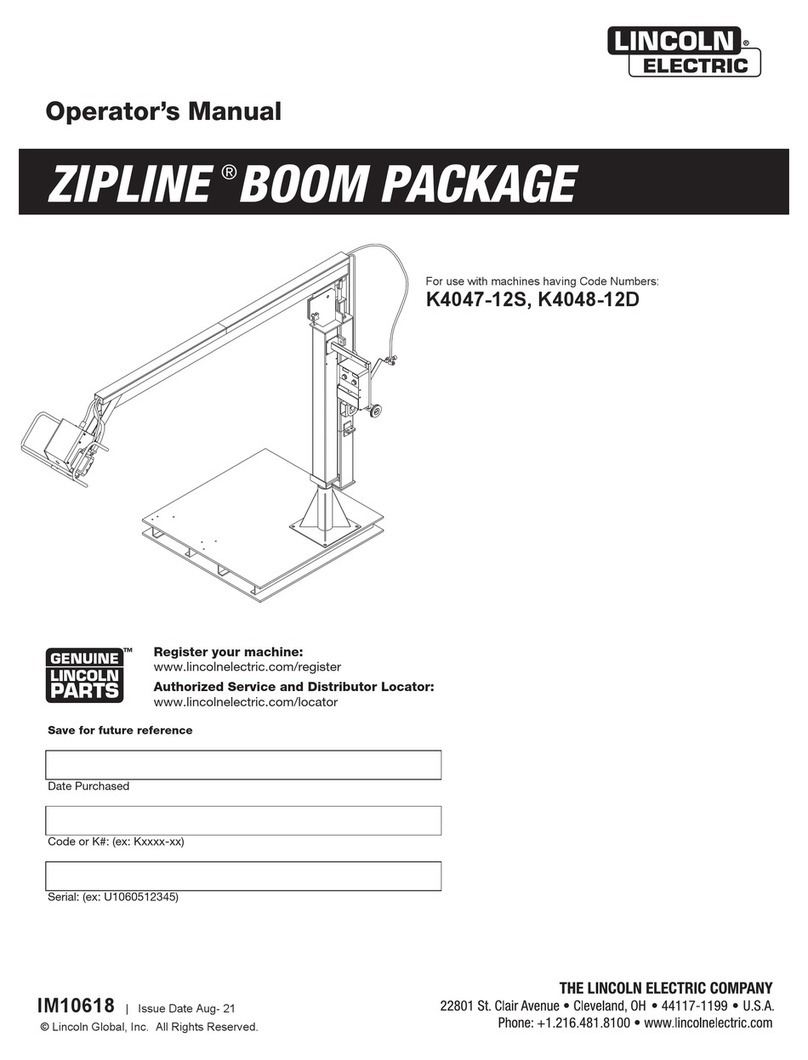

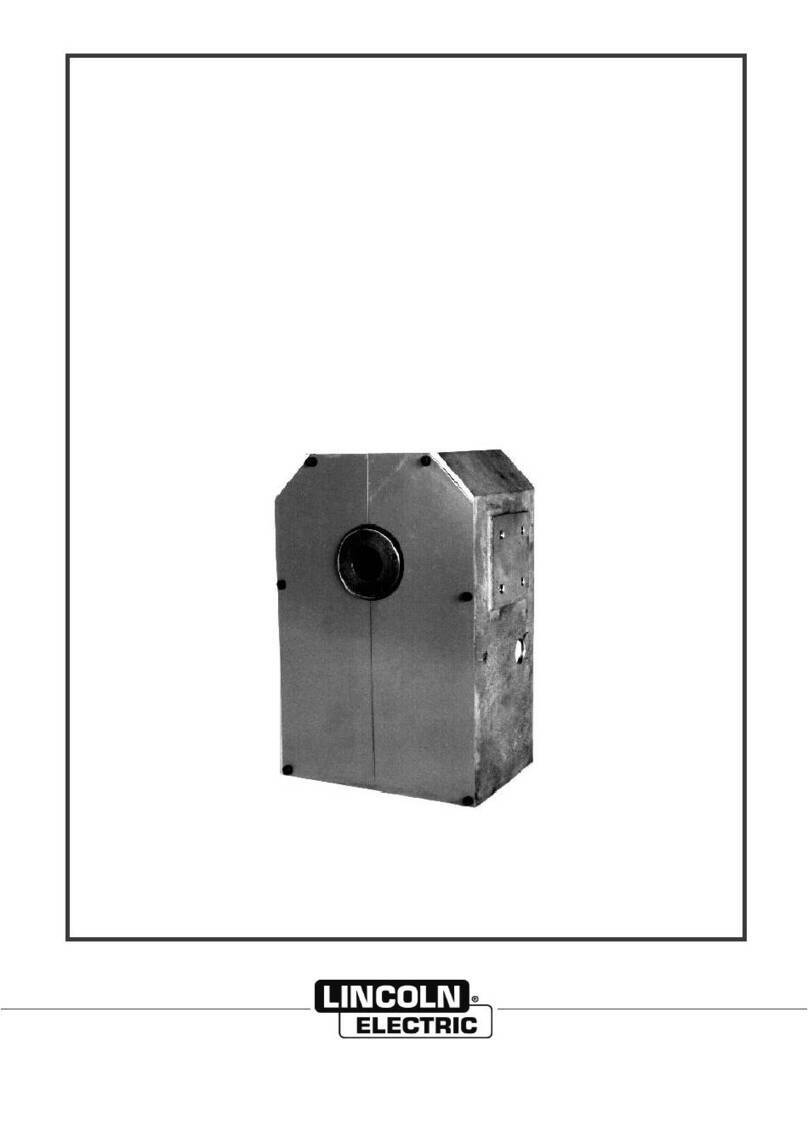

Diffuser and contact tips:

High current capacity taper lock contact tips and diffuser

As standard, the Tandem MIG 800 Amp Welding Torch is supplied with Taper Lock

Diffusers (S22693-207) and Taper Lock Contact Tips. Diffusers are designed to provide a

larger seating surface for the contact tips. The enlarged seating surface provides better

current carrying capacity over conventional diffuser designs. Better current carrying

capacity means less heating of the contact tips, longer tip wear and fewer tip changes.

The diffuser design is complimented with a taper lock contact tip design providing a

generous contact mating surface, fewer screw threads and dual thread starting points to

speed tip replacement time.

Conventional heavy duty contact tips and diffuser

Industry standard contact tips and diffuser design are available for end users that have

established a plant standard. The diffuser design is unique to the Tandem MIG torch,

however the contact tip can be used on compatible semiautomatic welding torches.

Taper Lock Diffuser and Contact Tip

Conventional Diffuser

and Contact Tip