Important Notice regarding Product Liability

According to the since 01.01.1990 valid EU-Guidelines, the manufacturer is only then liable for

the product when all parts of the device originate from the manufacturer and the device was

correctly assembled and operated.

With the use of foreign accessories or parts, the liability and guarantee of the manufacturer

either falls away entirely or partly.

By using the Carbon Cleaner 5 accessories and parts, you have the guarantee that all the safety

requirements are adhered to and you also prot from the continual product development.

Safety Guidelines and Requirements

The Cleaner can only then be operated risk-free when all the safety guidelines are read and

adhered to in its entirety.

1. The use of the Cleaner is only permissible in the commercial and industrial area.

2. Keep the workplace tidy. Untidy workplaces favours the possibility of an accident.

3. Protect your eyes with safety goggles or a face shield.

4. To protect your hands from allergies (e.g. Nickel), use Latex, Vinyl gloves or similar.

5. Ensure that there is sucient air ow. Use an extraction system if possible.

6. Take your environment into consideration. Ensure good lighting. Do not use the cleaner near

ammable substances or where a spark can ensure.

7. Keep away from children. The chemicals contain partly poisonous substances.

8. The person operating the devise must be at least 18 years old. Trainees must be at least 16 years

old und be under supervision.

9. Electromagnetic elds can interfere with pacemakers. Persons using such, are prohibited from

using the Cleaner.

10. Do not overwork the Cleaner. Do not cause any shorts. You operate much better and safer within

the given performance parameters.

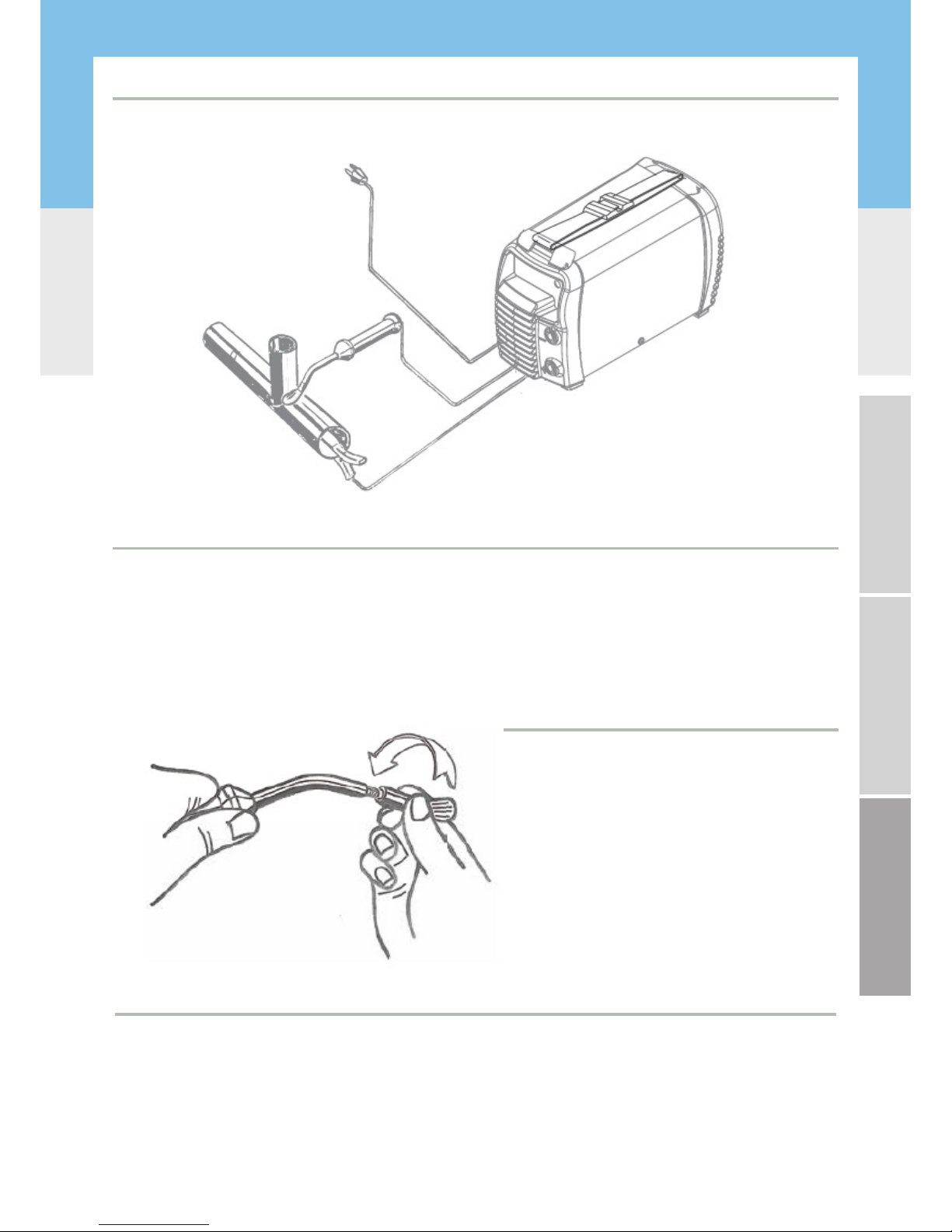

11. Use the correct tools. Use the attachments purposefully (carbon brushes / electrodes).

12. Wear suitable clothing. The chemicals can cause colouration on your clothes.

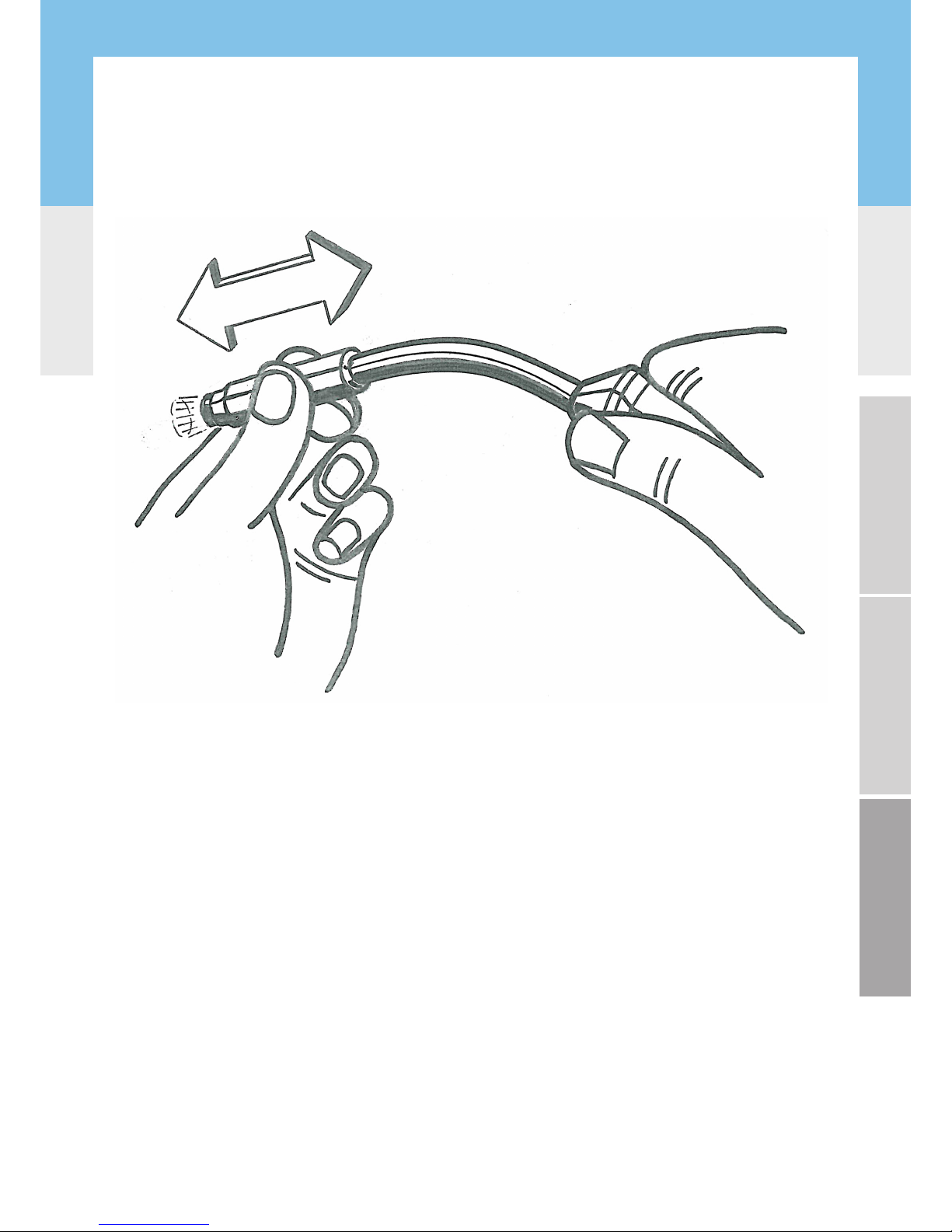

13. Use the cable and pipes for its intended use. Do not carry the Cleaner by the cable. Check the

cable and pipes regularly for any damages and replace them timeously.

14. Secure the work piece. Use holding devices to secure the work pieces as this is safer than holding

it with your hand.

15. Keep a normal body position and do not overstretch yourself.

16. Keep your balance at all times.

17. Take special care of your Cleaner.

18. Keep the device clean. Wash it with soap water or Carbon Cleaner 5 N.

19. Unplug the device from the mains when not using it.

20. Avoid the unintentional use of the device.

21. Make sure that the device is not in contact with tools, materials, tables etc. and starts working on

its own.