6 (28)

2. Designed purpose of use

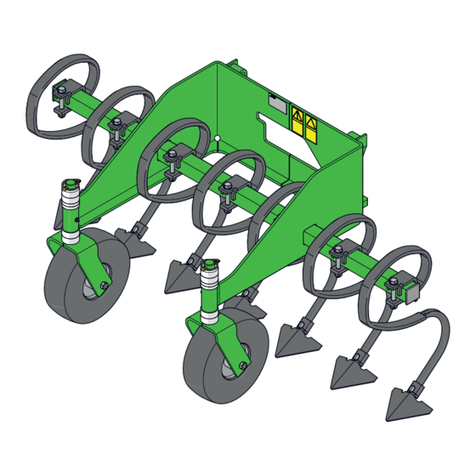

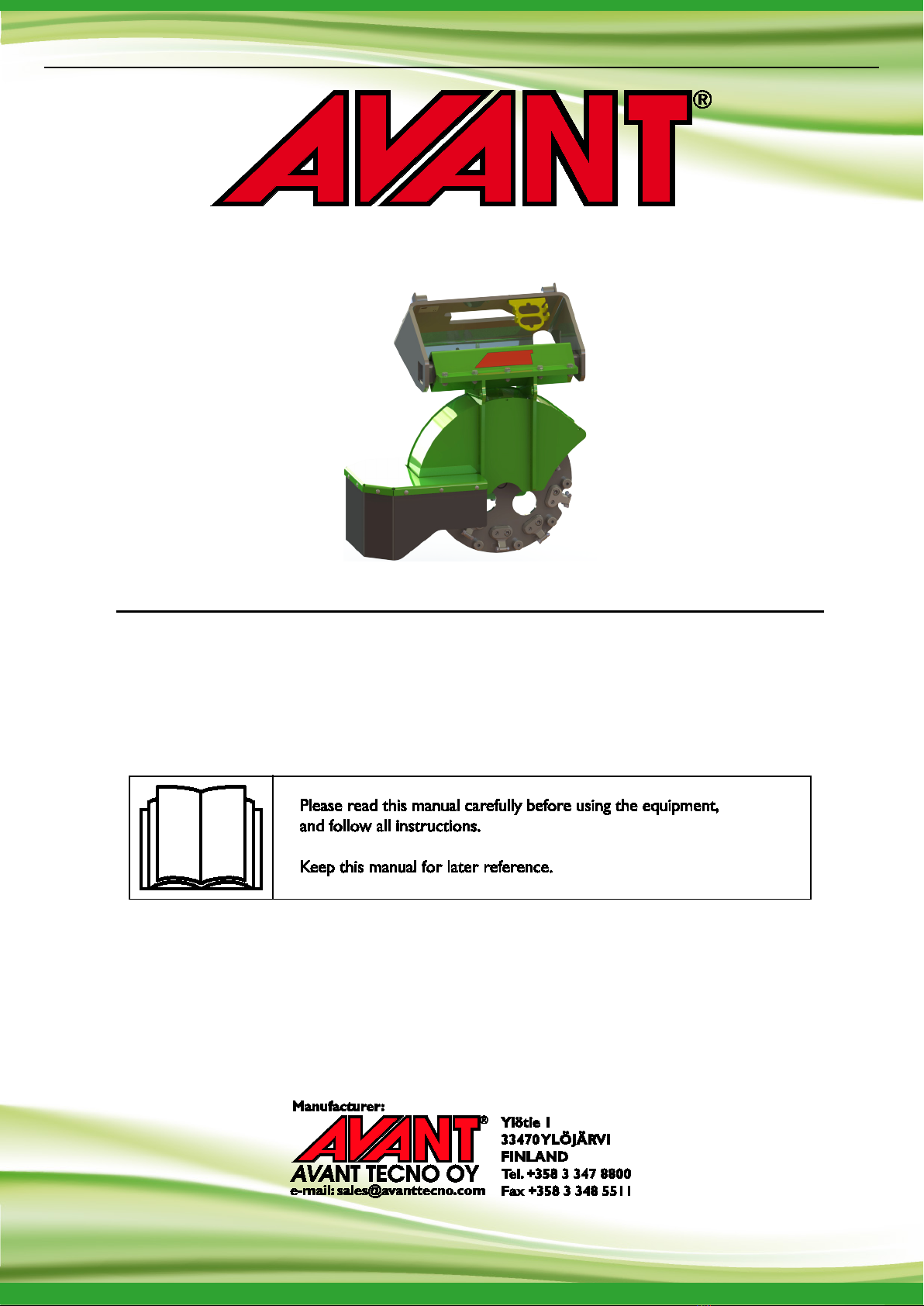

The AVANT Stump grinder is an attachment that is designed and manufactured to be used with AVANT multi

purpose loaders that are listed in Table 1. It is an efficient and easy to operate attachment for removal of tree

stumps with an Avant loader.

The cutting disc is mounted sideways, which gives excellent visibility to the working area. The cutting disc

discharges wood waste on the right side of the loader.

The stump grinder is operated from the driver's seat of the loader, and the controls and movement of the

loaders are used to remove a tree stump.To move the grinder back and forth, either the forward and backward

drive movement of the loader can be used, or by tilting the attachment. The Stump grinder is intended to be

used in near vertical position close to the ground. The tree stump must be sawed to as close to the ground as

practical before using the stump grinder.

There are three cutting edges on the individual cutting teeth of the stump grinder. Once a tooth becomes

blunt, it is easy to take into use a sharp edge by loosening the fastening bolt and turning the tooth. In addition,

the stump grinder is equipped with a protective rubber cover which prevents the wood from flying around.

The stump grinder is not intended to be used in lifted position. It is not designed for and must not be used for

any other purpose than removal of stumps of trees that are cut as short as possible. The stump grinder must

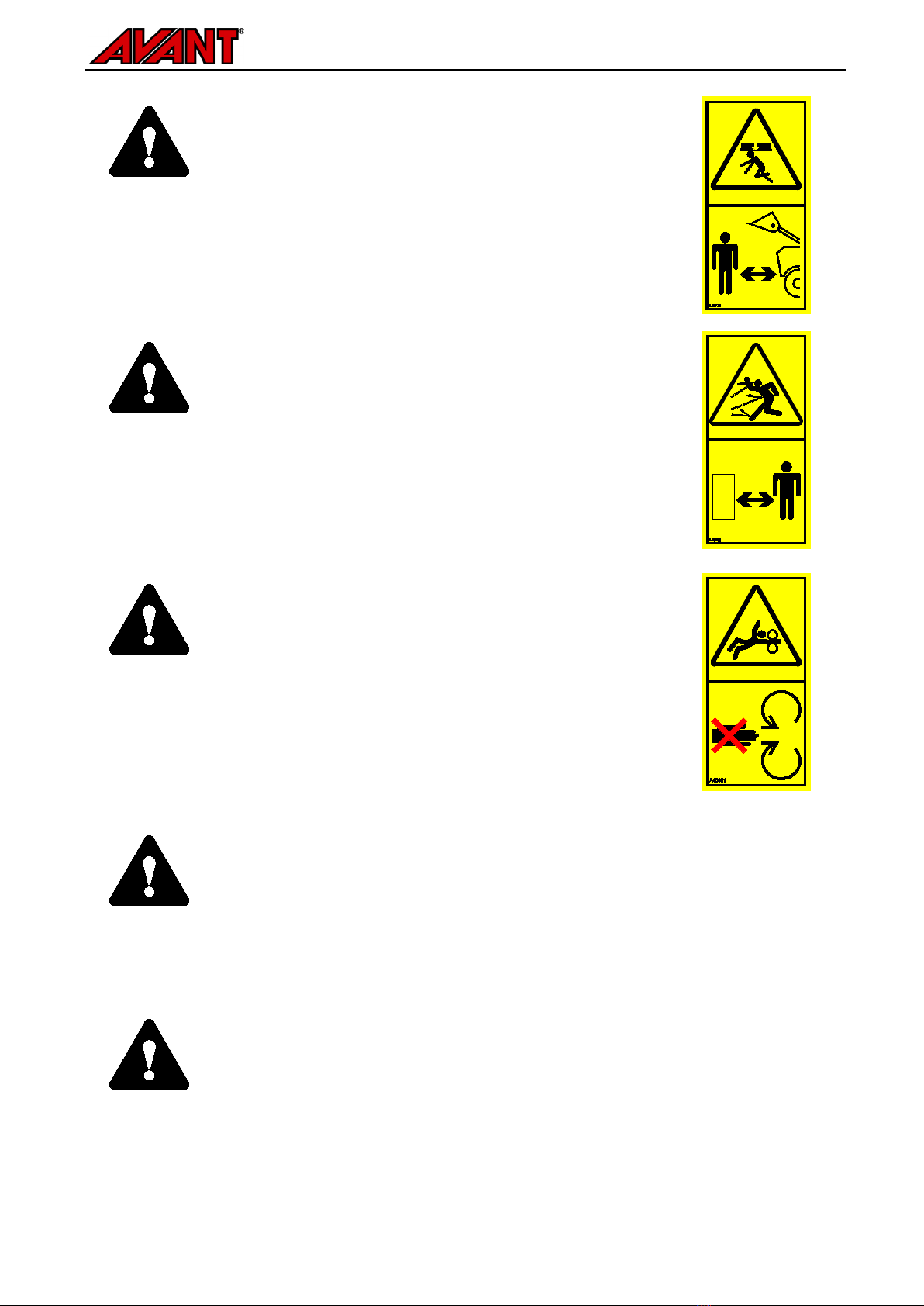

be operated by a single operator who seated on the driver's seat, and all assisting people must stay clear from

the work area. All protective covers must be in place and personal protection equipment must be used.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional maintenance. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT retailer if you have additional questions about the operation or maintenance of the equipment, or if

you require spare parts or maintenance services.

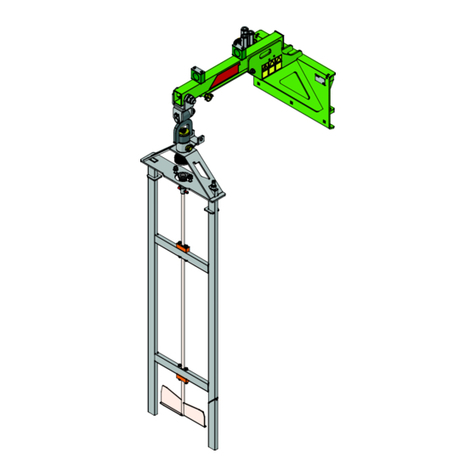

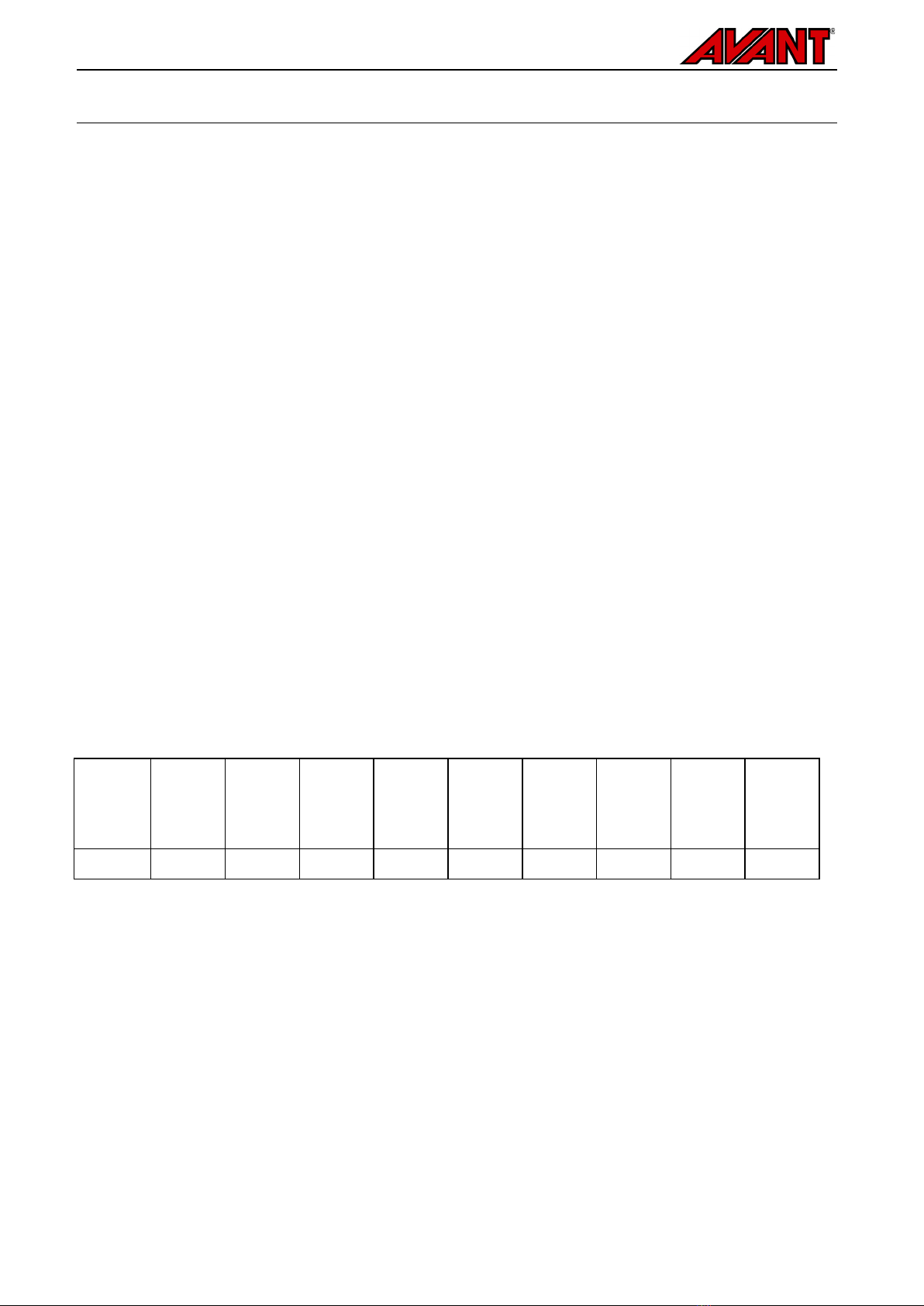

Table 1 - Stump grinder - Compatibility with Avant loaders

Avant 216

218

220

220 series 2

225

225LPG

313S

320S

320S+

419

420

520

R20

423

523

e5

e6

525LPG

R28

528

530

630

R35

635

640

745

750

755i

760i

A37265 - - - - (•) - (•) ••

It is recommended to use the attachment only with loaders marked with •in Table 1. When using with models

marked with (•), full performance may not be achieved. Additional counterweights may also be required. For

compatibility with a model not shown in table, contact your Avant dealer.