Claind Hydro200 User manual

User’s manual

Hydrogen

generator

Hydro200

2

Sommario

1. Introduction 3

2. Safety 4

3. Description of the generator 6

4. Installation 9

. Disassembly and transport 12

6. Use 13

7. Maintenance 20

8. Troubleshooting 23

9. Guarantee 2

10. Declaration of conformity 26

11. Note 27

Hydrogen generator Hydro200

3

1.

Introduction

This document is aimed at the User of a hydrogen generator model in the series

Hydro200, and provides all information regarding installation use and mainte-

nance.

As regards the operations of installation and maintenance, it is presumed that

the manual user is experienced in the use of pneumatic components, and in par-

ticular is aware of all safety aspects linked to the use of hydrogen.

The margin of the text contains the following symbols, indicating:

m

compulsory safety standards to be observed

c

electrical hazard

e

recommendations and important information

It is strongly recommended to carefully read all safety warnings (par. 2.1.) be-

fore carrying out any operation on the generator.

Safety

4

2.

Safety

The generators in this series can be installed in the vicinity of the utilities without

the requirement for classification of the surrounding area as “hazardous”, provi-

ded that all necessary measures have been taken to guarantee the maximum

safety.

The unit must be installed and used in observance of the instructions in this boo-

klet. Failure to observe these instructions will render the guarantee null and void

and release CLAIND from all liability for direct or indirect damage or physical

injury.

2.1.

Warnings

m

Hydrogen is an extremely flammable gas that forms EX LOSIVE MIX-

TURES WITH AIR. If not aware of all safety aspects linked to the use

of this gas, consult the relative safety datasheet

m

lace the generators FAR FROM SOURCES OF HEAT

m

The generator must operate with its safety guard fitted: this guaran-

tees the correct circulation of air and prevents the formation of gas

pockets. For the same reason, NEVER LACE OBJECTS ON THE TO

VENTILATION GRILLE

m

lace the generators in an environment ROTECTED AGAINST RAIN

AND WIND

c

NEVER O EN the generator while it is connected to the electrical

mains. RISK OF FATAL INJURY BY ELECTROCUTION

e

Repairs and inspections must be carried out exclusively by S ECIALIST ER-

SONNEL: in the event of faults impossible to solve according to one of the pro-

cedures in the TROUBLESHOOTING chapter, contact exclusively a CLAIND

technical service centre

e

If the generator is not to be used for a prolonged period of time, it must be ade-

quately depressurised (see par. 6.4. and par. 6. .)

Hydrogen generator Hydro200

2.2.

Safety devices

MAXIMUM RESSURE: The maximum volume of hydrogen that can be stored

in the generator is 100ml . Maximum operating pressure is 4 bar.

There is a double pressure control.

• One is a pressure sensor, via the control system, which shuts down the genera-

tor when pressure value exceeds by 0. bar the set value;

• The other is a pressure switch, independent from the control system, which shu-

ts down the generator when pressure value exceed 4. bar;

HYDROGEN-OXYGEN MIXTURE: The formation of potentially hazardous

hydrogen-oxygen mixtures inside the generator is prevented by:

• Special electrodes (patented) for the production of hydrogen which prevent oxy-

gen from mixing with the hydrogen.

• A forced ventilation system prevents the formation of hydrogen pockets due to

possible gas leaks. Any significant gas leaks are also indicated by the control sy-

stem.

2.3.

Technical assistance

The CLAIND technical assistance can be contacted as follows:

Tel. ++39 0344 6603

Fax ++39 0344 6627

e-mail: service@claind.it

Description of the generator

6

3.

Description of the generator

3.1.

Equipment supplied

Unless otherwise agreed upon, the supply of a generator in the series Hygen200

includes:

• hydrogen generator

• User manual

• electric power supply cable (2m) with socket type IEC3 0-Schuko

For connection to copper pipe 1/8” comprising:

• n°1 adaptor 6MB-1/8”

• n°1 nut Swagelok 1/8”

• n°1 back ferrule Swagelok 1/8”

• n°1 front ferrule Swagelok 1/8”

For connection to steel pipe 2x1mm comprising:

• n°1 coupling 6MB for steel pipe 2x1mm

• n° ferrule for steel pipe 2x1mm

For connection to vent pipe comprising:

• 2m polyamide pipe 6x4mm

• n°1 ferrule for polyamide pipe 6x4mm

• n°1 nut for polyamide pipe 6x4mm

For routine maintenance comprising:

• n°1 funnel for replenishing drier

• n°1 Allen key 8mm

Hydrogen generator Hydro200

7

3.2.

Technical specifications

3.2.1.

General

3.2.2.

Electrical

3.2.3.

Gas

Dimensions Width 40 cm

Depth 0

Height 31

Weight 19 kg

Noise <46 dB(A)

Operating temperature ÷40°C

rotection rating IP20

ower supply voltage 11 ÷230 V~ (±10%); 1ph;

0÷60Hz

Max. absorption 100 V~

Maximum hydrogen flow rate 200 Nml/min

Hydrogen pressure settable from 1 to 4 bar

Description of the generator

8

3.3.

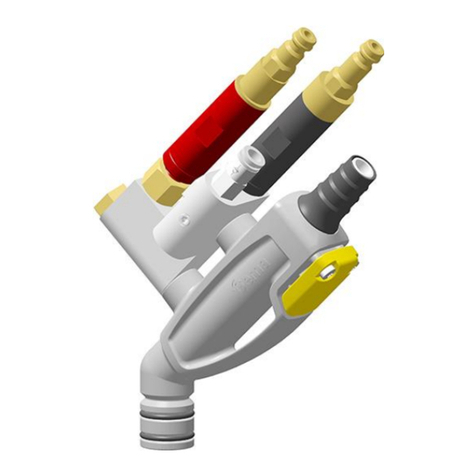

Generator components

3.3.1.

Front view

3.3.2.

Rear view

A. ALPHANUMERIC DISPLAY AND

KEYBOARD: indicates operating status

and alarms; the four keys enable the

display and modification of operating

parameters as required

B. “POWER” KEY: ON push button

A. CONNECTOR, “jack” type for control

of external pump (optional)

B. CONNECTOR for electric power cable;

includes housing for main FUSE

C. TANK for demineralised water

D. H2 OUT: coupling for hydrogen outlet

E. O2 VENT: coupling for air vent

F. WATER: coupling for demineralised

water inlet

G. HANDLE for generator lifting

H. LABEL: stating the model, serial

number (SN) and electrical

specifications

I. GRILLE for ventilation

J. DRIER tube

A B

A B C

D E F G H I J

Hydrogen generator Hydro200

9

4.

Installation

4.1.

Installation area requirements

4.1.1.

Humidity and dust

To avoid risks of damage to electronic components, install the generator in an

environment subject to limited relative humidity and low concentrations of dust.

The generator must also be protected against drips, rain and wind.

4.1.2.

Temperature

The ambient temperature in the generator installation area must be between

°C and 40°C.

Install away from heat sources. Avoid direct exposure to sunlight.

4.2.

Installation procedure

4.2.1.

Step 1: remove the packaging

Remove all packaging, taking care not to damage the generator panels.

If possible, store the packaging to ensure adequate protection when moved in

the future.

Ensure that the supply is complete (see section 3.1)

4.2.2.

Step 2: position the generator

Locate an installation area that meets the specifications listed in section 4.1.

Position the generator on a laboratory bench or on a Claind generator from the

series AirToc, AirToc SL, or NitroAir.

e

Handle with care: never tilt the generator and avoid impact with obstacles.

e

Ensure a clearance of at least 20cm cm at the rear of the generator.

e

Remember never to place objects on the top panel of the generator.

4.2.3.

Step 3: fill the demineralised water tank

• locate the demineralised water tank at the rear of the generator

• disconnect the tank by means of the quick coupling at the bottom of the tank.

• remove the tank

• unscrew the cap, fill the tank to 1 cm from the top edge and refit the cap

• refit the tank and connect the quick coupling

e

Use demineralised water with electrical conductivity no higher than

Installation

10

µS/cm (resistivity no lower than 0.2 M

Ω

cm) @ 20°C

e

The generator consumes approx. 1ml (1cc) of demineralised water per litre (Nl)

of hydrogen produced

e

On request, CLAIND can supply an external pump kit (see APPENDIX), which in

command by the generator enables automatic refilling of demineralised water.

4.2.4.

Step 4: Connect the hydrogen line.

• locate the coupling H2 OUT at the rear of the generator

• remove the cap using a 8mm hex key

• From those available in the connection kit, choose the coupling most suited to

the line used. The supply comprises couplings for connection to 1/8” copper pi-

pes or 2×1mm steel pipe

• Connect the line.

e

the hydrogen line must be able to withstand a pressure of at least 4. bar.

e

conserve the cap, as it is used in the event of future transport of the generator

(see chapter )

4.2. .

Step : connect the electrical mains;

• check that the mains specifications correspond to the data on the generator da-

taplate

• ensure that the POWER key is set to OFF.

• Make the electrical connection using the cable supplied with the generator (type

IRC3 0-Schuko, length 2m)

c

For reasons of safety, the following instructions must be strictly obser-

ved.

The electrical installation must comply with current standards, in particular re-

garding the protection line.

c

Recommendations for correct installation:

• do not use extension leads, adaptors or multiple sockets; if necessary, replace

the plug IEC3 0-Schuko with a more suitable version;

• always connect the protection wire;

• the mains socket must be located in an easily accessible position.

e

If a failure in gas supply (due to a power failure, activation of an electrical safety

device, or generator fault), even temporary, is not admissible, a pneumatic panel

should be envisaged, to enable provisional activation of a reserve gas source (to-

tally or partially automatic).

e

To ensure compliance with standards imposed by the Machinery directive, the

start-up of the generator after electrical power supply is restored cannot normal-

ly be automatic, and should be manually activated by the operator.

Hydrogen generator Hydro200

11

e

If automatic start-up of the generator is necessary, this command should be en-

tered in the set-up program

4.2.6.

Step 6: Connect the vent hose

• locate the outlet O2 VENT at the rear of the generator

• remove the plastic cap using a 12mm hex key

The O2 VENT outlet enables the oxygen (produced in parallel to the generation

of hydrogen) to be released into the atmosphere. As the released oxygen may

in some phases contain traces of electrolyte, the vent should be conveyed as fol-

lows:

• connect the polyamide pipe 6x1 mm (supplied with the generator) and route the

other end of the pipe (shortened if necessary) to a small collection tray placed

at a lower level than that of the generator.

e

avoid obstructing the vent: during use, the end of the polyamide pipe 6x1 mm

opposite the generator must never by closed off or immersed in the liquid.

e

conserve the cap, as it is used in the event of future transport of the generator

(see chapter )

4.2.7.

Step 7: set the mode parameters

In this phase the mode parameters should be checked (and modified if requi-

red), which enable the selection of the language for message display and selec-

tion of a number of operating modes, including the method for demineralised

water refilling.

For details, refer to section 6.7.1.

4.3.

ackaging disposal

All packaging materials used are compatible with the environment and may be

stored without risk, or disposed of and recycled in accordance with local legisla-

tion governing classified waste collection.

However, when possible, it is recommended to store the packaging to ensure

adequate protection when moved in the future.

Disassembly and transport

12

.

Disassembly and transport

.1.

Disassembly

• Stop the generator (see par. 6.4.).

• Wait for depressurisation.

• Switch off the generator (see par. 6. .).

• Disconnect the electric power cable;

• Close the valves downline of the generator and detach the pneumatic connec-

tions.

• Seal off outlet H2 OUT using the original cap

• Seal off outlet O2 VENT using the original cap

• Empty the demineralised water tank

e

missing caps on the outlets H2 OUT and O2 VENT can cause serious damage to

the generator and packaging during transport.

.2.

Transport

If conserved, use the original packaging; otherwise use a pallet of adequate di-

mensions to hold the generator, affixing instructions in visible locations, such as:

THIS WAY UP, FRAGILE

Hydrogen generator Hydro200

13

6.

Use

6.1.

Keyboard and display

KEYBOARD

The keyboard on the front panel of the generator enables the user to interact

with the generator, i.e. give specific commands or display and set parameters.

The table shows the function of the various keys:

DIS LAY

The display comprises 2 lines each of 20 characters

Usually the top line displays the functions or parameters and the lower line di-

splays the relative status and values

If the message exceeds 20 characters, the text scrolls on display.

6.2.

Generator start-up

To switch on the generator, press the black key “POWER” at the front of the ge-

nerator.

Key Function

Function Selects a generator function

Cursor Increases the selected value

Cursor Decreases the selected value

Operation Starts or stops the generator

Use

14

The display illuminates and, after a few seconds, a depressurisation cycle is star-

ted automatically. During this phase, lasting maximum 60 seconds, the following

message is displayed:

WAIT…

DEPRESSURISATION IN PROGRESS

At the end of depressurisation, the following message is displayed:

GENERATOR READY

In this condition, the generator is ready to receive the production start-up com-

mand (see par. 6.3.) or shutdown command (see par. 6. .).

6.3.

Hydrogen production

When the generator has completed the preparation phase (par. 6.2.) and the

message

GENERATOR READY

is displayed, hydrogen production can be

started up as follows:

Press the operation key START/STOP.

The production cycle is started up and the following message is displayed:

PRODUCTION

X.XX bar YYY Nml/min

where:

X.XX

= hydrogen pressure, expressed in

bar

Y.YY

= instant quantity of hydrogen produced, expressed in

normal millilitres

per minute

6.4.

Stop the generator

At any time during production the generator can be stopped by pressing the key

START/STOP.

Depending on the phase activated, the generator starts to depressurise imme-

diately, or awaits conclusion of the production cycle before activating depressu-

risation.

During depressurisation, which usually lasts from 30 to 60 seconds, the following

message is displayed:

WAIT…

DEPRESSURISATION IN PROGRESS

Hydrogen generator Hydro200

1

e

NOTE: if a production block alarm is active, the START/STOP key is disabled

At the end of depressurisation, the following message is displayed:

GENERATOR READY

There are then two alternatives:

1. Switch off the generator by pressing the POWER key (see par. 6. .);

2. resume the gas production by pressing the key START-STOP (see par. 6.3.)

Use

16

6. .

Generator shutdown

6. .1.

Correct shutdown

Correct shutdown of the generator starts from the condition of

GENERATOR

READY

. par. 6.4. describes how to reach this condition.

Set the "POWER" key (black) to OFF to turn off the generator.

6. .2.

Incorrect shutdown

Avoid turning off the generator directly, without first shutting down as described

in par. 6.4.

However, this may occur inadvertently or due to a power failure. In this case, on

subsequent generator restart, the following message is displayed:

WARNING

INCORRECT SWITCH OFF

To shut off the alarm, press the function key .

6.6.

arameter display

See also flow chart in APPENDIX

6.6.1.

Hydrogen and oxygen pressure display

During production, the main menu displays the message

PRODUCTION

.

For more information on generator status, press the up arrow key . The fol-

lowing page is displayed:

H2 O2

X.XX bar Y.YY bar

where:

X.XX

= hydrogen compartment pressure bar

Y.YY

= oxygen compartment pressure bar

The values are updated continuously to verify correct operation

of the generator

To exit this page and return to the main menu press up arrow key .

6.6.2.

Maintenance counters display

From the main menu (

PRODUCTION

), press the down arrow key :

The following information is displayed in sequence (approx. every seconds)

Hydrogen generator Hydro200

17

GENERATOR RUNNING TIME

XXXXX h YY min

PRODUCED HYDROGEN QUANTITY

XXXXX litres

DRIER AUTONOMY

XXXXX litres

ORDINARY MAINTENANCE

XXXXX h YY min

e

DRIER AUTONOMY displays, in countdown mode, the litres of hydrogen that can

be produced before the drier cartridge requires replacement (see Maintenance

chapter)

ROUTINE MAINTENANCE displays, in countdown mode, the operating hours re-

maining before a general overhaul is required (recommended) for the generator.

To exit this page and return to the main menu press up arrow key .

6.6.3.

Mode parameter display

From the main menu (

PRODUCTION

), press the down arrow key twice.

The following information is displayed in sequence (approx. every seconds) re-

garding the set operating modes:

PRODUCTION RESTARTED AFTER INCORRECT

SHUTDOWN

Manual/Automatic

INCORRECT SWITCH OFF ALARM

Enabled/Disabled

Use

18

INTERNAL TANK WATER REFILLING

From external tank/From external pump (optional)

To exit this page and return to the main menu press up arrow key .

e

The default values are as follows:

PRODUCTION RESTART... = Manual

...SWITCH OFF ALARM = Enabled

...REFILLING = From external tank

When modifications to these values are required (e.g. for use of the external

pump), follow the instructions in section 6.7.1.

6.7.

arameter settings

6.7.1.

Editing mode parameters

These parameters select the operating mode of the generator, They comprise:

For access to these parameters, the generator must be switched on by pressing

and holding the Function key for a few seconds.

The data will be displayed in sequence as shown in the table above.

To modify, use the arrow keys .

To acquire the set value, press and hold key and press an arrow

key; this confirms the value and moves to the next parameter.

To exit this menu, press and hold the Function key for a few seconds.

Language of messages

Italian

English

German

French

Spanish

roduction restart after incorrect switch off

Manual

Automatic

Incorrect switch off alarm

Enabled

Disabled

Internal tank watyer refilling

From external tank

From external pump

Hydrogen generator Hydro200

19

6.7.2.

Hydrogen delivery pressure settings

The default set-point for hydrogen pressure is 1 bar. To set the operating pres-

sure to the required value (from 1 bar to 6 bar), proceed as follows:

From the main menu (

PRODUCTION

), press function key : to display the

following:

HYDROGEN PRESSURE SET-POINT

X.XX bar

To modify the value, use arrow keys .

To acquire the set value, press and hold key and press the up arrow key .

To exit this menu, press and hold the Function key for a few seconds.

6.7.3.

Editing maintenance parameters

See Maintenance section.

Maintenance

20

7.

Maintenance

To facilitate observance of adequate scheduled maintenance by the user, the ge-

nerator is equipped with a list of components subject to wear, for which, during

the test phase, a working interval is set.

During operation this time interval decreases through to expiry, at which point

there is an automatic request for maintenance.

7.1.

Expiry warnings

During production, if the estimated autonomy of a device expires, a message is

displayed, an example of which is shown below

.

WARNING

FILTER IN EXPIRY PHASE

To acquire the message, press function key . The message is then removed

to proceed with normal operation.

On subsequent restart the generator requests whether the maintenance has

been performed, with display of the following message:

SCHEDULED MAINTENANCE OF FILTER COM-

PLETE?

NO

Press the up arrow key ” to select the answer “YES” or “NO” consecutively.

After selecting the answer, to acquire the message, press the function key .

If the answer is “NO”, the message is displayed again on subsequent restart,

while if “YES”, the new work time for the component is set (that set on start of

the count) for future maintenance.

If an incorrect shutdown alarm is displayed on activation of the generator, this

procedure is disabled; it will be available for subsequent start-up.

7.2.

Maintenance schedule

To maintain generator efficiency and reduce the risks of faults, strictly observe

the recommended maintenance schedule.

The following table specifies the frequency of the recommended maintenance

operations:

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific Applied Biosystems GeneChip 645 user guide

LifeSafety Power

LifeSafety Power NETPOWER NPR500-16M installation manual

BiOptic

BiOptic Qsep1 quick start

Metkon

Metkon VACUMET 52 Operation & instruction manual

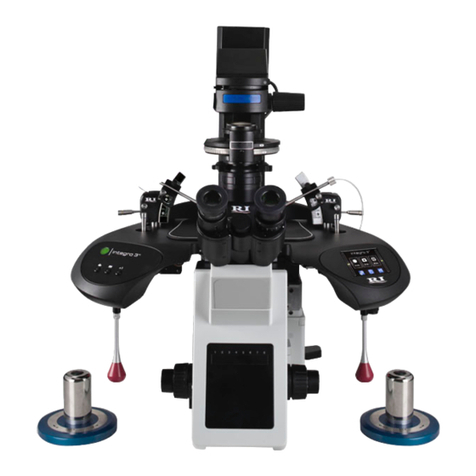

Integra

Integra MEDIACLAVE 10 quick start guide

Market Forge Industries

Market Forge Industries STM-E Installation operation & maintenance

Smith & Nephew

Smith & Nephew TRIGEN SURESHOT user manual

Gema

Gema OptiFlow IG07-PA Operating instructions and spare parts list

Swiss Pro+

Swiss Pro+ PROACQUA HRC SLIMLINE Product guide

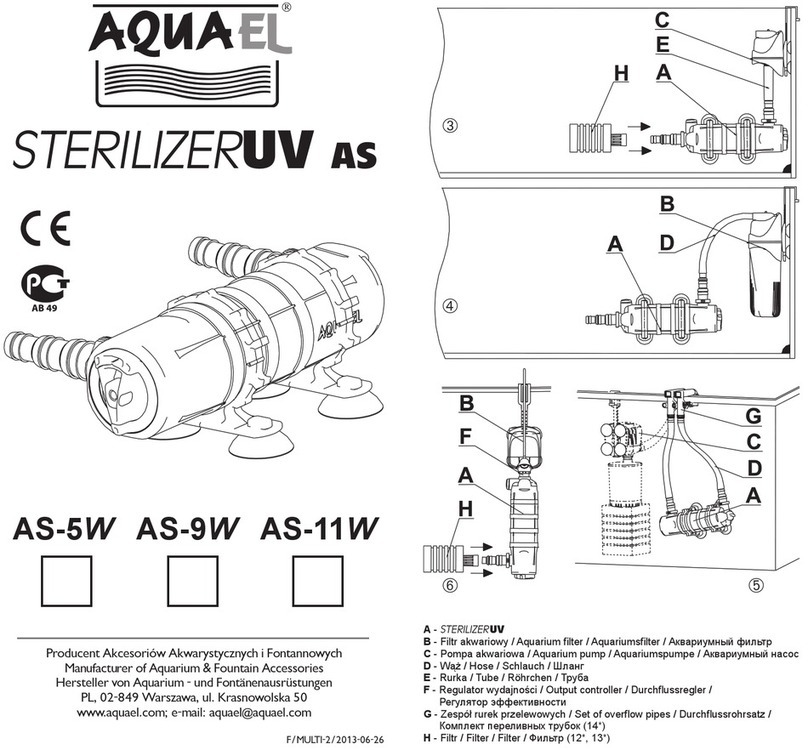

AQUA EL

AQUA EL AS Series manual

Exor

Exor JSPOU0P1 installation guide

Cooper Surgical

Cooper Surgical RI Witness 6-70-854 quick start guide