Metkon VACUMET 52 Administrator Guide

1

metkon.com

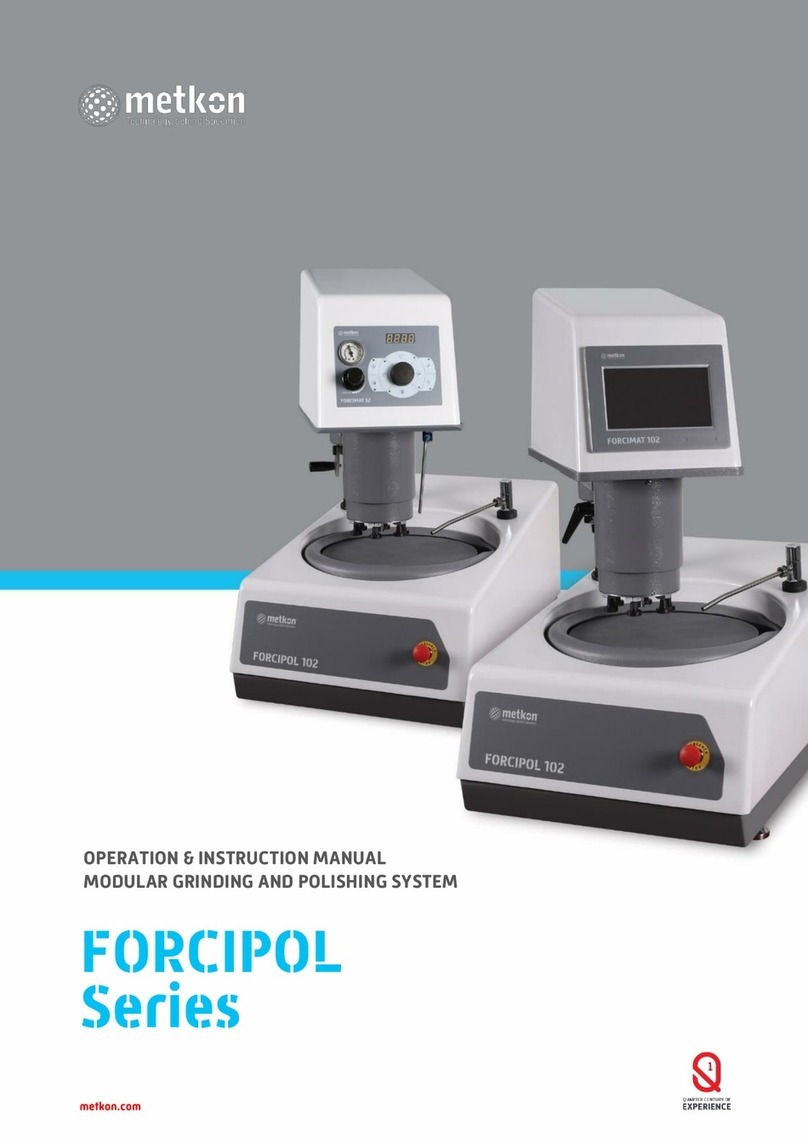

OPERATION & INSTRUCTION MANUAL

VACUUM IMPREGNATION UNIT

2

EC Declaration of Conformity

Manufacturer : Metkon Instruments Inc.

Address : Demirtas Dumlupinar Organize Sanayi Bolgesi

Ali Osman Sonmez Cd. No: 14 Bursa / TURKEY

Model No : VACUMET 52

Herewith declares that;

Vacuum Impregnation Unit

is in conformity with the provisions of the Machinery Directive (directive 2006/42/EEC), as amended, and with national

implementing legislation;

And furthermore declares that

the following (parts/clauses of) standards have been applied

EN ISO 12100:2010, TS EN 60204-1

Authorized Person: ERCIN SENAY

Position: Manager of Research and Development Department

Year: 2019

Bursa / Turkey

3

Index

DESCRIPTION ............................................................................................................................ 4

Design .....................................................................................................................................................................................4

Technical Data ........................................................................................................................................................................5

Warranty .................................................................................................................................................................................5

Safety Precautions ..................................................................................................................................................................5

INSTALLATION & SET UP........................................................................................................... 6

Unpacking & Checking Contents of Package ...........................................................................................................................6

Installation and Set-Up ...........................................................................................................................................................6

CONTROL PANEL....................................................................................................................... 7

Control Button Functions ........................................................................................................................................................7

OPERATION ............................................................................................................................... 7

Without Sucking Function ........................................................................................................ 7

With Sucking Function.............................................................................................................. 7

SERVICE AND MAINTENANCE ................................................................................................... 7

Maintenance ...........................................................................................................................................................................7

ACCESSORIES AND CONSUMABLES.......................................................................................... 8

Accessories .............................................................................................................................................................................8

Consumables...........................................................................................................................................................................8

TECHNICAL DOCUMENTATION ................................................................................................. 9

Recommended Spare Part List ................................................................................................................................................9

Customer Service ....................................................................................................................................................................9

4

DESCRIPTION

Design

Compact and simple

Built-in vacuum sytem with Gauge

Efficient impregnation

Multi-specimen application.

VACUMET 52 is designed for embedding and impregnation of

porous materials. It removes the trapped air from the

mounting material and eliminates the gaps between the

specimen and the resin.

Most mineralogical specimens have porosities, cavities,

cracks, and ther fore need to be under vacuum. VACUMET 52

fulfills this requirement easily and efficiently. In addition,

VACUMET 52 can also be used for glueing the specimens on

the glass slides for further processing in thin section

preparation.

METKON offers wide range of cold mounting consumables

high quality embedding forms for different types of

mineralogical application.

Only air connection is necessary to operate VACUMET 52. No

electric or water connection is needed.

Embedding mineralogical specimens is very easy with

VACUMET 52. Just place your specimen inside the embedding

form, fill it with cold mounting resin, place it inside the

VACUMET 52, close cover and turn on vacuum. That's all!

Two different operation is possible with VACUMET 52;

embedding with sucking function or without sucking function.

It is also possible to mount specimens with VACUMET 52, if

the specimen has very low density and floating inside the

resin material. VACUMET 52 has feature for fixing low-density

materials.

VACUMET 52

5

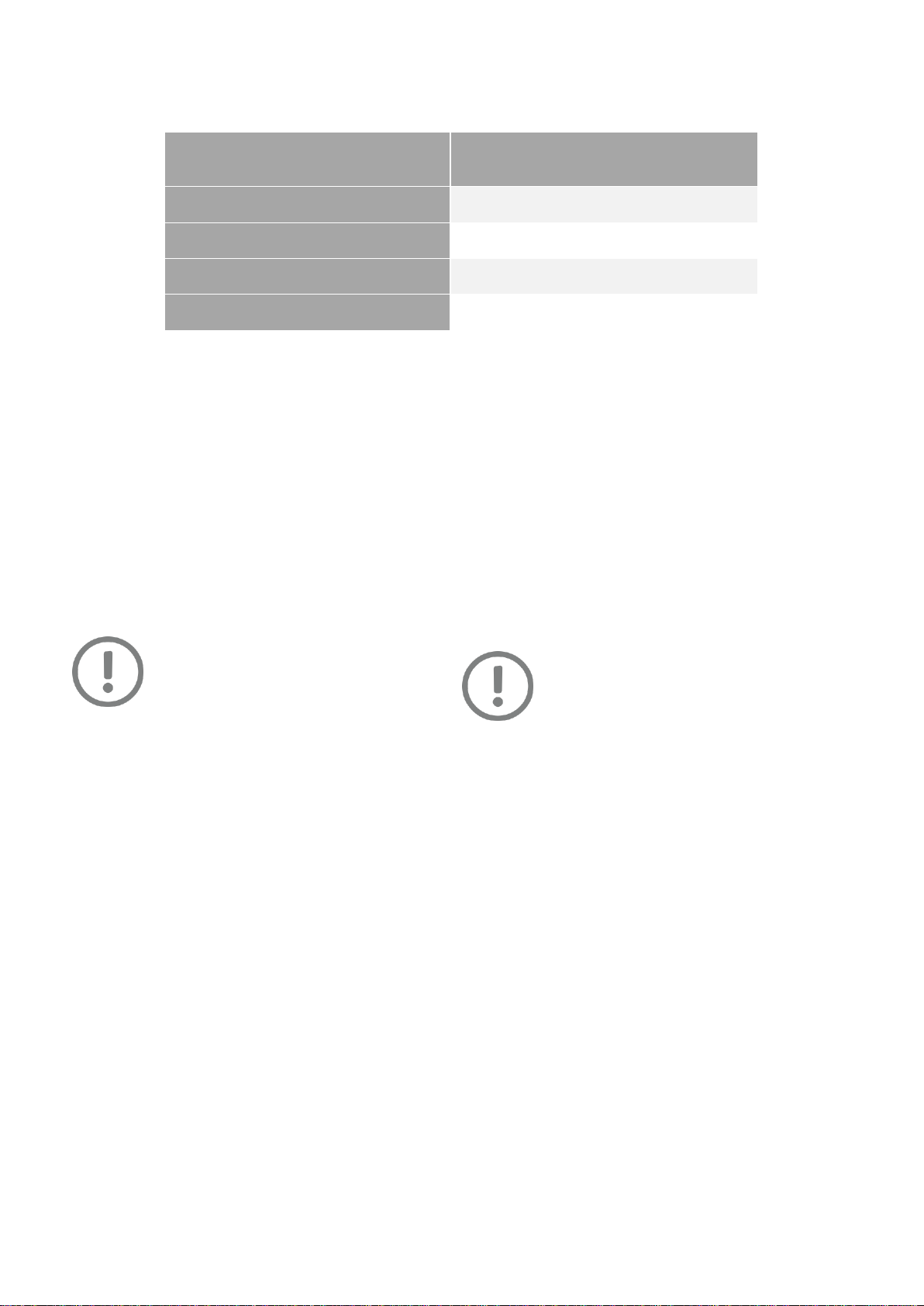

Technical Data

Warranty

The VACUMET 52 is guaranteed against defective material or

workmanship defects for a period of 12 months from the date

of receipt by the customer or latest 18 months after the

shipping date. The warranty is not valid if inspection shows

evidence of misuse or unauthorized repair. Warranty covers

only replacement of defective materials. If this unit need to be

returned to our factory for service, please contact your

distributor for authorization and include the following details:

Serial Number of the unit, Invoice number and date. Transport

costs belong to the customer.

NOTE

The equipment is designed to be used with

METKON accessories and consumables. In case

of misuse of equipment, improper installation,

alteration, use of different source parts,

improper repair, METKON will accept NO responsibility for

any damages to the operator or the equipment.

Disassembling of any part should always be performed by a

qualified technician

Safety Precautions

Read the below instructions carefully before use.

Place the machine on a sturdy and safe table.

The equipment must be installed in compliance with

local safety regulations.

Only use approved METKON accessories and

consumables to achieve maximum safety and lifetime.

Follow the instructions and safety regulations when

lifting and carrying the equipment.

Using gloves is recommended when working with cold

mounting consumables.

Follow the periodically maintenance.

NOTE

METKON Instruments Inc. can make any changes

without notice on the equipment, accessories,

consumables and miscellaneous products.

Consequently; visual or written information on

the instruction manuals, technical materials, catalogues,

website, product videos and other marketing materials may

show inconsistencies and may be different from the product.

Model

Order No

VACUMET 52

25 06

Vacuum System

0,65 bar

Air Pressure

4,5 - 6 bar

Dimensions, WxDxH, cm.

30 x 31 x 35

Weight, kgs

8 kgs

Table of contents

Other Metkon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual