clare G2000 User manual

CLARE G2000

Comprehensive Test Station

for

The Lighting Association Code of Practice

Operator Manual

February 1999

1999 Clare Instruments Ltd.

Table of Contents

Section 1 – Notices 5

Warranty 6

Copyright Notice 6

E & OE 6

Declaration of Conformity 7

Section 2 - General Guidance Notes 9

Safety 10

Safe Application of Test Equipment 11

Maintenance 12

Summary of Safety Information 13

Section 3 - Introducing the CLARE G2000 15

Front Panel Controls 16

Rear Panel Connections 19

Accessories 20

Section 4 – Operating Procedures 23

Instrument Set-Up 24

Test Procedure A – Basic Earthed (Class I) Products 27

Test Procedure B – Basic Double Insulated (Class II) Products 31

Test Procedure C – Earthed (Class I) Products plus Light-Up Test 35

Test Procedure D – Double Insulated (Class II) Products plus Light-Up Test 39

Section 1

Notices

Notices

Limited Warranty & Limitation of Liability

CLARE Instruments Limited guarantees this product for a period of 1 year. The period of warranty will come into

effect on the day of delivery.

Copyright 1999

All rights reserved. Nothing from this edition may be multiplied, or made public in any form or manner, either

electronically, mechanically, by photocopying, recording or in any manner without prior written consent from

CLARE Instruments Limited. This also applies to any accompanying drawings, diagrams or illustrations.

E&OE

The information contained within this manual is given in good faith and is provided for guidance only. Although all

reasonable care has been taken to ensure accuracy of the information, CLARE Instruments Limited, their agents

and distributors, accept no responsibility for any errors or omissions within this document, nor for any

misinterpretations by the user. For clarification on any part of this document please contact CLARE Instruments

Limited, or your local agent, before operating the instrument.

Due to a policy of continuous development CLARE Instruments Limited reserve the right to alter or amend

equipment specifications and descriptions outlined in this publication without prior notice. No part of this

publication shall be deemed to form, or be part of, any contract for the equipment unless specifically referred to as

an inclusion within such contract.

6

Notices

Declaration of Conformity

For the

Clare G2000 Test Station

Manufactured by:

Clare Instruments Ltd. Dominion Way, Worthing, West Sussex. BN14 8NW

Millennium Statement

This product is Millennium compliant and conforms fully to the BSI DISC PD2000-1 document.

Statement of Conformity

Based on test results using appropriate standards, the product is in conformity with

Electromagnetic Compatibility Directive 89/336/EEC and Low Voltage Directive 73/23/EEC.

Standards Used:

EN 61010-1 (1993) Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use.

EN 50081-1 (1992) Electromagnetic Compatibility. Generic Emission Standard: EN55022 Class B.

EN 50082-1 (1992) Electromagnetic Compatibility. Generic Immunity Standard: IEC1000-4-2, -4-3, -4-4, -4-5.

The tests have been performed in a typical configuration.

Conformity is indicated by the symbol - , for ‘Conformité Européenne’

7

Section 2

General Guidance Notes

General Guidance Notes

SAFETY

The design of the CLARE G2000 Test Station meets the European Commission Directive No. 73/23/EEC, relating

to the “Low Voltage Directive”. This is in accordance with BS EN 61010-1: 1993 – Safety requirements for

electrical equipment for measurement control, and laboratory use. This unit is also compliant with the draft

European Standard prEN 50191:1997.

The design of the equipment is intended for use under the following conditions:

Indoors;

Altitude up to 2000 m;

Temperature 5°C to 40°C;

Maximum relative humidity 80% for temperatures up to 31°C to 50% at 40°C;

Mains supply voltage fluctuations of ±10% of the nominal voltage.

The user MUST follow the remainder of this section on safety, installation, guidance and maintenance to

guarantee safe operation and to maintain the equipment in a safe condition.

WARNING! This equipment requires a protective earth conductor. Do not use the equipment without a protective

earth conductor or intentionally interrupt the protective earth conductor.

10

General Guidance Notes

Do not remove or open the instrument cover - When connected to the mains supply, internal terminals of the

equipment will be live and the opening of covers or removal of parts is likely to expose live parts and create a risk

of electrical shock. The user must disconnect the equipment from ALL voltage sources before any adjustment,

replacement, maintenance or repair.

Fuse Ratings – For replacement purposes, the rated current and type of any internal, panel mounted or plugtop

fuses, where fitted, must be as specified. Typically these will be of the Mains Quick Blow Type F style. The user

must not use makeshift fuses or attempt to short-circuit fuse holders.

SAFE APPLICATION OF TEST EQUIPMENT

Any person operating electrical test equipment must be 18 years old or over and should have had adequate

training in the use of the particular piece of equipment. The degree of training should be appropriate for the

competence and experience of the operator and should be documented.

Site the test equipment in a clearly defined test area, with access limited to the operator only. Where possible

power outlet sockets should be of plastic construction and the test area should be free of steel conduit, trunking

and such like. Construct test benches of insulated material, preferably wood. The operator must stand on an

insulated, Earth free, surface such as British Standard approved rubber matting or nail-free duckboard. Provision

should also be made to allow the test item to be placed on an insulated surface.

DO NOT TOUCH OR CONTACT THE TEST ITEM WHILST OPERATING THE TEST EQUIPMENT.

KEEP THE TEST AREA CLEAN AND TIDY

11

General Guidance Notes

MAINTENANCE

Clare Instruments Ltd. supplies a guarantee against defective material and faulty manufacture for a twelve-month

period from the date of delivery.

Prior to despatch the equipment undergoes careful inspection and comprehensive testing. Report any defect

discovered with the equipment in respect of materials or workmanship within the guarantee period. We undertake

to put right the defect at our expense subject to our standard conditions of sale.

Our responsibility is in all cases limited to the cost of making good the defect in the equipment. This does not

apply to defects caused by abnormal conditions of working, accident, misuse, neglect or wear and tear.

In the event of difficulty or apparent malfunction, it is advisable to contact Clare Instruments Ltd. On –

Telephone 01903 502551 or Fax 01903 244258.

We recommend that the complete instrument be returned to us for repair or annual re-calibration:

The Service Department

Clare Instruments Ltd

Dominion Way

WORTHING

West Sussex

BN14 8NW

12

General Guidance Notes

Please take adequate care with packing and arrange insurance cover against transit damage or loss when

returning the instrument – if possible use the original packing box and supports.

Regularly calibrate all test equipment to meet internal quality or regulatory licensing authority requirements and to

keep the equipment in a safe working condition. Return the equipment to Clare Instruments for this purpose.

Keep the equipment in a clean condition. Examine all input and test output leads and connectors regularly to

guarantee they are in a safe working condition.

The equipment contains parts that are specific to the equipment only, therefore, order spare parts from the above

address. Clare Instruments Ltd. strictly forbid any use of spare parts, other than those acquired from the original

manufacturer.

SUMMARY OF SAFETY INFORMATION

Should there be any doubt about location, setting up procedure or operation of the test equipment, contact Clare

Instruments Ltd. Report any apparent malfunctions immediately.

Maintain the test equipment in accordance with Health and Safety at Work Act and the Electricity at Work

Regulations. The supply socket used for connection to the incoming mains system should undergo earth loop

impedance measurements in keeping with the regulations to guarantee safe operation.

NOTE: Your Health and Safety Inspector may, with the benefit of on-site observations, offer alternate or additional

instructions to the above recommendations.

13

Section 3

Introducing the CLARE G2000

Introducing the CLARE G2000

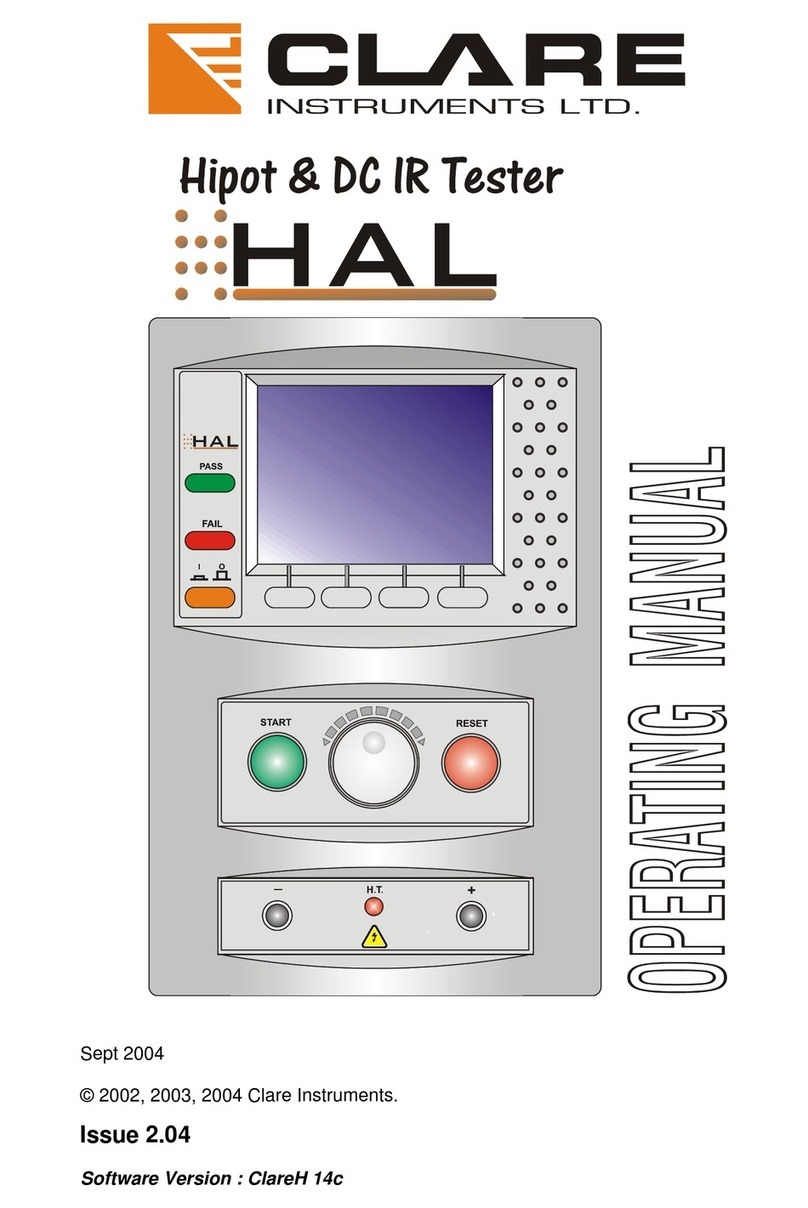

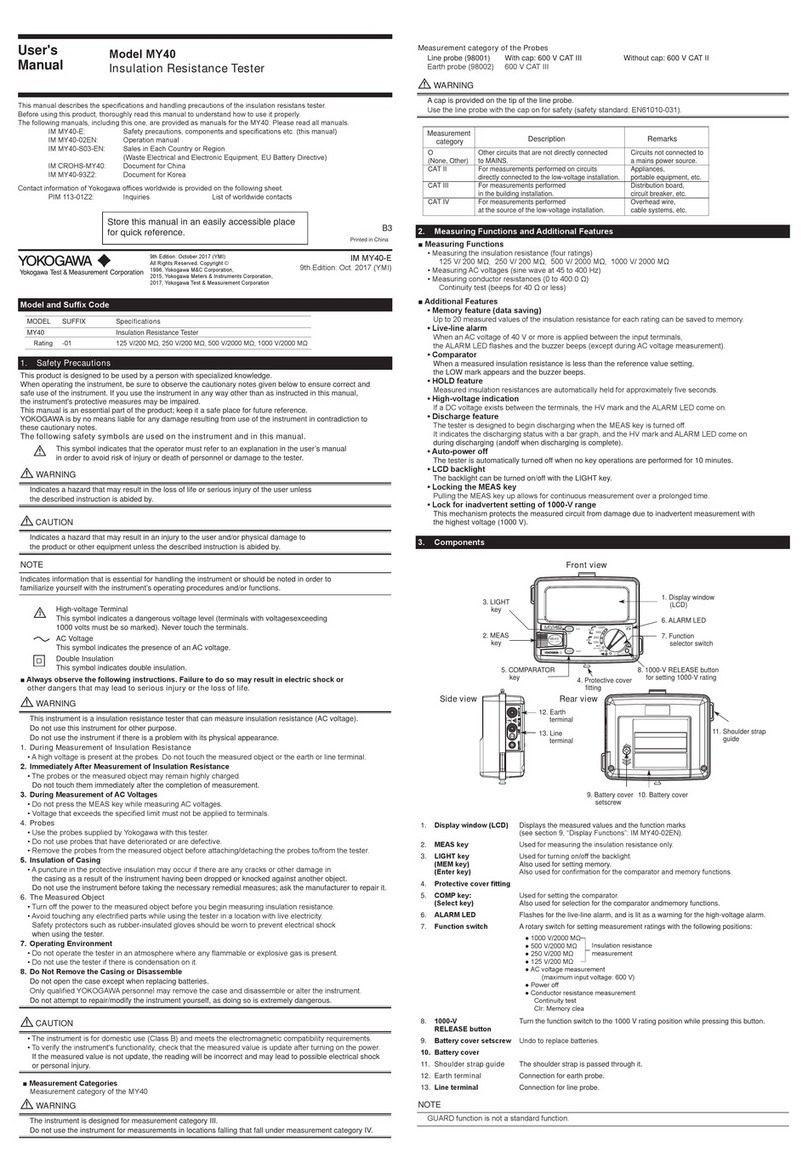

Facia Controls and Indicators

FIG.1 Facia Controls & Indicators

16

Introducing the CLARE G2000

Descriptions

1. Supply Switch - Rocker switch for switching the instrument on or off, illuminated in the ON position.

2. Earth Circuit meter – displays the ohmic value of the measured Earth path. A satisfactory reading will be

below 0.5 ohms (in the amber or uncoloured zones). Readings in the red zone, or beyond, may indicate a

poor or broken earth connection.

3. Set Zero control – used to set mechanical zero of the meter during factory build & calibration procedures. Not

normally required for user adjustment.

4. Set Inf. control – used for setting the full scale (INF) reading of the meter to compensate for mains

fluctuations, or differences, from location to location. Refer to Set-Up procedures for adjustment details.

5. Flash LN-E push button – used to apply 1500Va.c. Flash Test between Line + Neutral to Earthed parts for

Class I products or, in conjunction with the Flash Probe, for applying 4000Va.c. between L + N to outer

surfaces of Class II products.

6. Flash L-N push button – used to apply 1500Va.c. Flash Test between Line and Neutral circuits of both Class

I and Class II products.

Note

It is not advisable to apply a L-N Flash test to any product that requires a Light-Up test, particularly those that may

incorporate electronic control circuits or in-line transformers, the test may damage sensitive electronic

components. The Test Inhibit circuit should detect a L-N short and prevent the Light-Up test being applied.

17

Introducing the CLARE G2000

7. Flash Fault lamp – lights to show that the product has failed the applied Flash test, an internal audible alarm

will also sound and the test voltage will be removed automatically. This lamp also acts as the Fault Reset

button, which must be momentarily depressed to cancel the fault indication and reset the safety trip circuit.

8. Safety push button – used in conjunction with the Light-Up test to minimize accidental operation.

9. Light-Up test keyswitch – applies mains voltage to the item under test, used as an alternative to the low

voltage continuity/polarity test for products that include ballasts, filter networks, in-line transformers and the

like, and therefore require full mains voltage to check correct operation.

THIS TEST SHOULD ONLY BE APPLIED FOLLOWING SATISFACTORY EARTH AND/OR FLASH TESTS.

10. Test Inhibit lamp – lights to indicate that internal protection circuitry has operated to prevent operation of the

Flash or Light-Up tests. Check that Continuity probes have been removed from lamp holders and/or that total

lamp load does not exceed 600 Watts.

18

Table of contents

Other clare Test Equipment manuals