3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

SAFETY PRECAUTIONS

1. The tyre changer should be bolted firmly to the workshop floor using the

pre-drilled holes in the base plate before use.

2. Do not allow personnel to use the tyre changer unless they have read

these safety precautions.

3. Never tamper with the product or modify it in any way, as this could prove

to be dangerous and will invalidate the guarantee. Only use the product

for the purpose for which it is intended.

4. Ensure that the tyre changer is in good working order. Have any damaged

parts repaired or replaced immediately. Use genuine Clarke parts only. The

use of unauthorised parts may be dangerous and invalidate the

guarantee.

5. Do not use the tyre changer if it is damaged.

6. Always use the tyre changer in a suitable, well lit work area.

7. Keep the work area clean and tidy and free from unrelated items.

8. Do not use the tyre changer when you are tired or under the influence of

alcohol, drugs or intoxicating medication.

9. Ensure all bystanders keep at a safe distance whilst the tyre changer is in

use.

10. Never climb on the tyre changer.

11. Take care not to trap your fingers in the adjustable parts.

12. Do not over-reach. Keep your proper footing and balance at all times.

13. Safety equipment such as gloves and non-skid shoes will reduce personal

injuries.

14. Failure to heed these warnings may result in damage to the equipment, or

serious personal injury.

15. Always visually inspect the tyre changer before use, to ensure that all parts

are correctly located and secure. Check for cracks, deformation or other

signs of damage or worn parts.

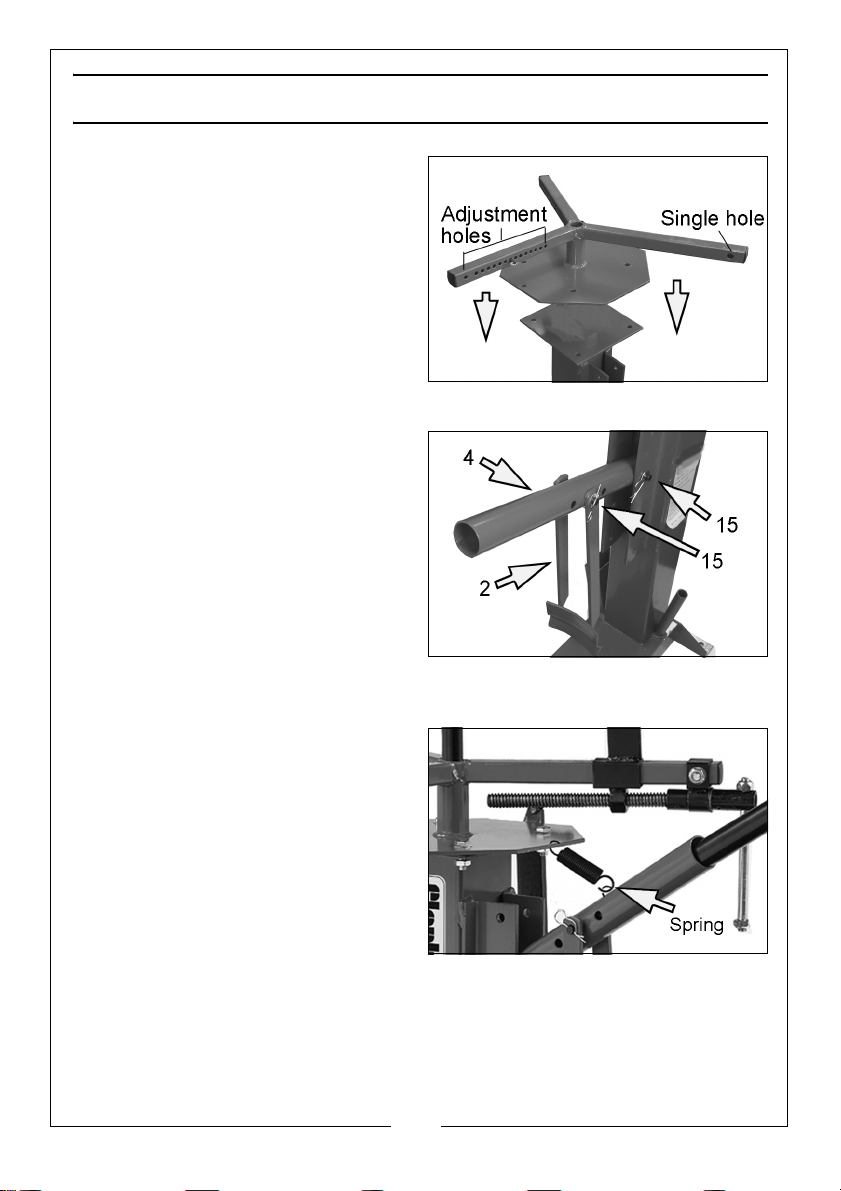

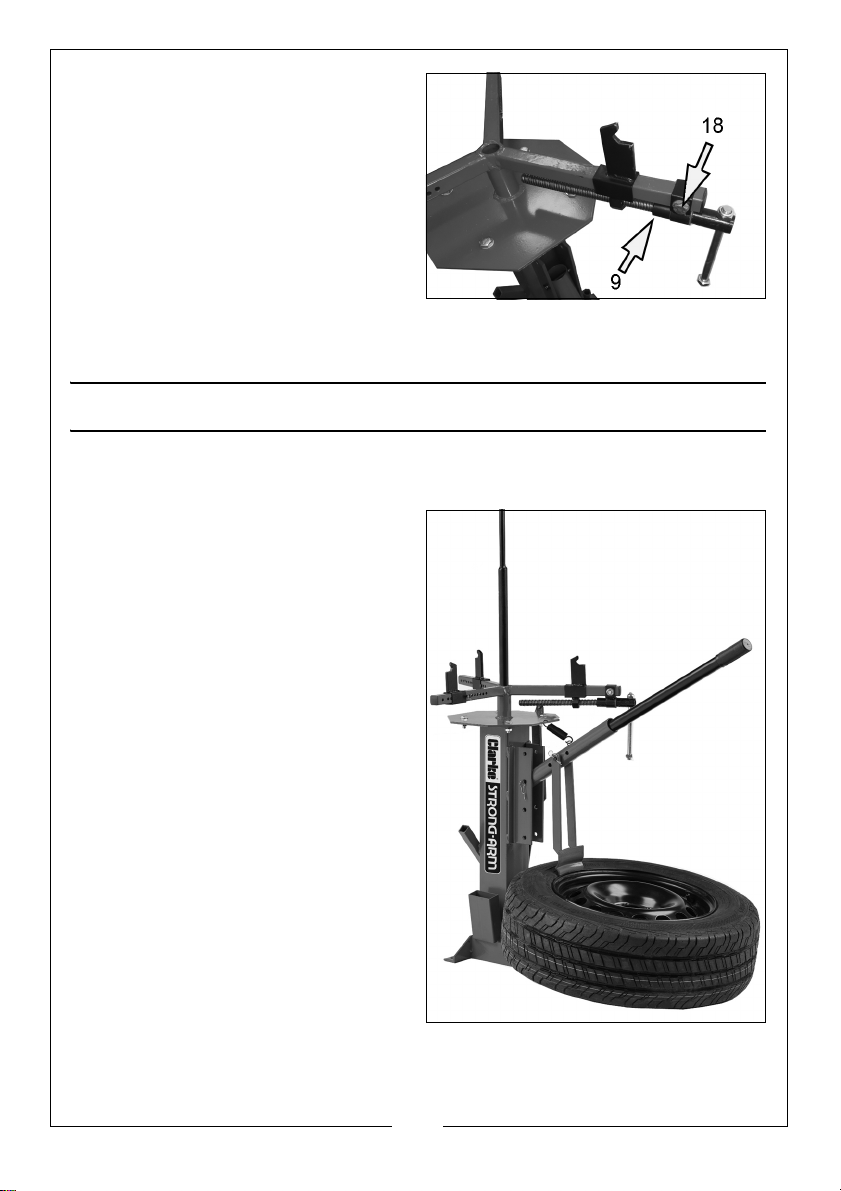

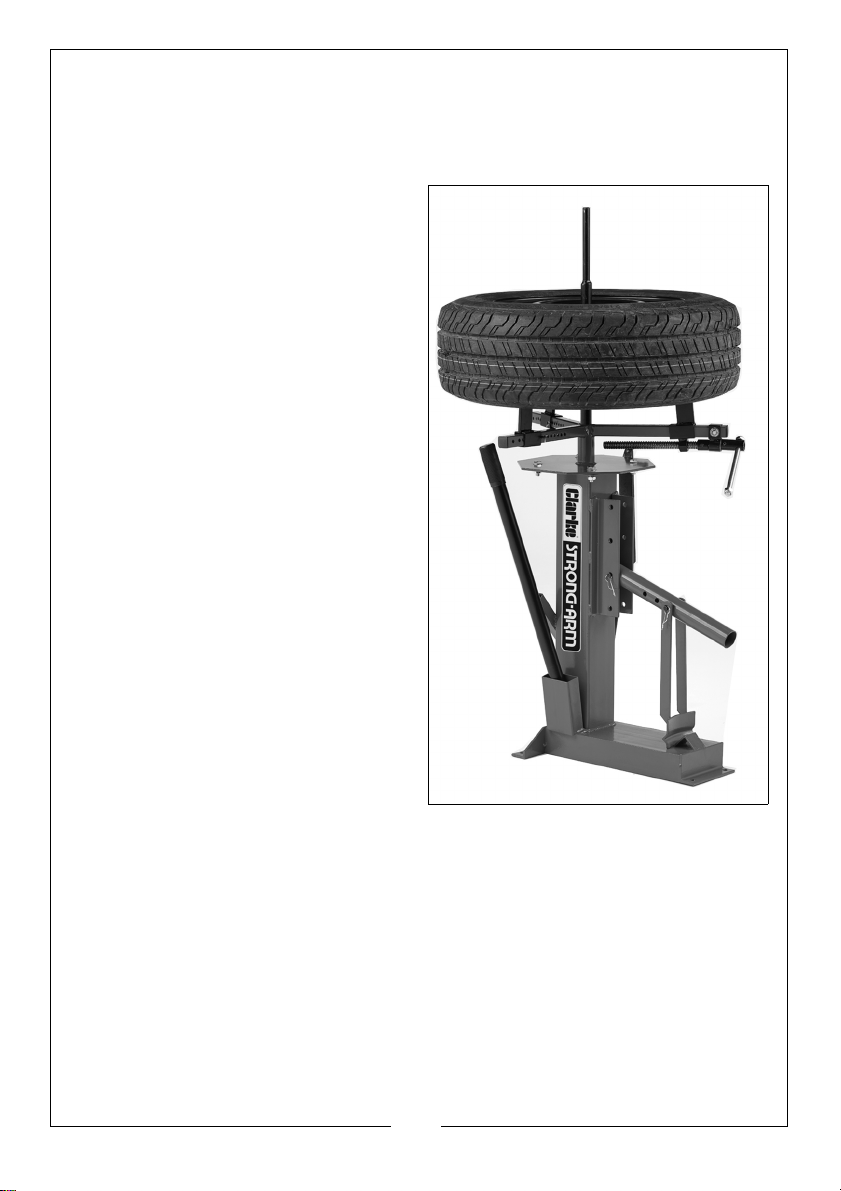

UNPACKING PRIOR TO ASSEMBLY

Unpack the components on a clean flat area of hard standing and ensure

that all parts are present. Identify all components according to the illustration.

Open or ring spanners (17 mm) or an adjustable wrench will be required for

assembly.