ENGLISH

V.I.P. 150 PFC

SAFETY INFORMATION

1

UNPACKING AND PREPARATION

2

INSTRUCTIONS MANUAL

Carefully read this instructions manual in its entirety and keep it safe for future

reference.

It is essential to know the information and comply with the instructions given

in this manual in order to ensure the fitting is installed, used and serviced

correctly and safely.

CLAY PAKY S.p.A. disclaims all liability for damage to the fitting or to other

property or persons deriving from installation, use and maintenance that have

not been carried out in conformity with this instructions manual, which must

always accompany the fitting.

CLAY PAKY S.p.A. reserves the right to modify the characteristics stated in

this instructions manual at any time and without prior notice.

Congratulations on choosing a Clay Paky product! We thank you for your

custom. Please note that this product, as all the others in the rich Clay Paky

range, has been designed and made with total quality to ensure excellent

performance and best meet your expectations and requirements.

HQI-T 150

•Maximum ambient temperature

For the fitting to operate well and reliably, the ambient temperature should not

exceed 35°C (95°F).

•IP20 protection rating

The fitting is protected against penetration by solid bodies with a diameter of over

12 mm (0.47”) (first digit 2), but not against dripping water, rain, splashes or jets of

water (second digit 0).

•Protection against electrical shock

This fitting is classified, in accordance with the type of protection against electrical

shock, in Class I.It must therefore be connected to a power supply system with

efficient earthing.

It is, moreover, recommended to protect the supply lines of the projectors from

indirect contact and/or shorting to earth by using appropriately sized residual current

devices.

•Hooking up to the supply mains

The operations for connecting to the electricity mains must be carried out by a

qualified electrical installer.

Check that the mains frequency and voltage correspond to the frequency and

voltage for which the projector is designed, given on the electrical data label.

This label also gives the input power. Refer to this to evaluate the maximum number

of fittings to connect to the electricity line in order to avoid overloading.

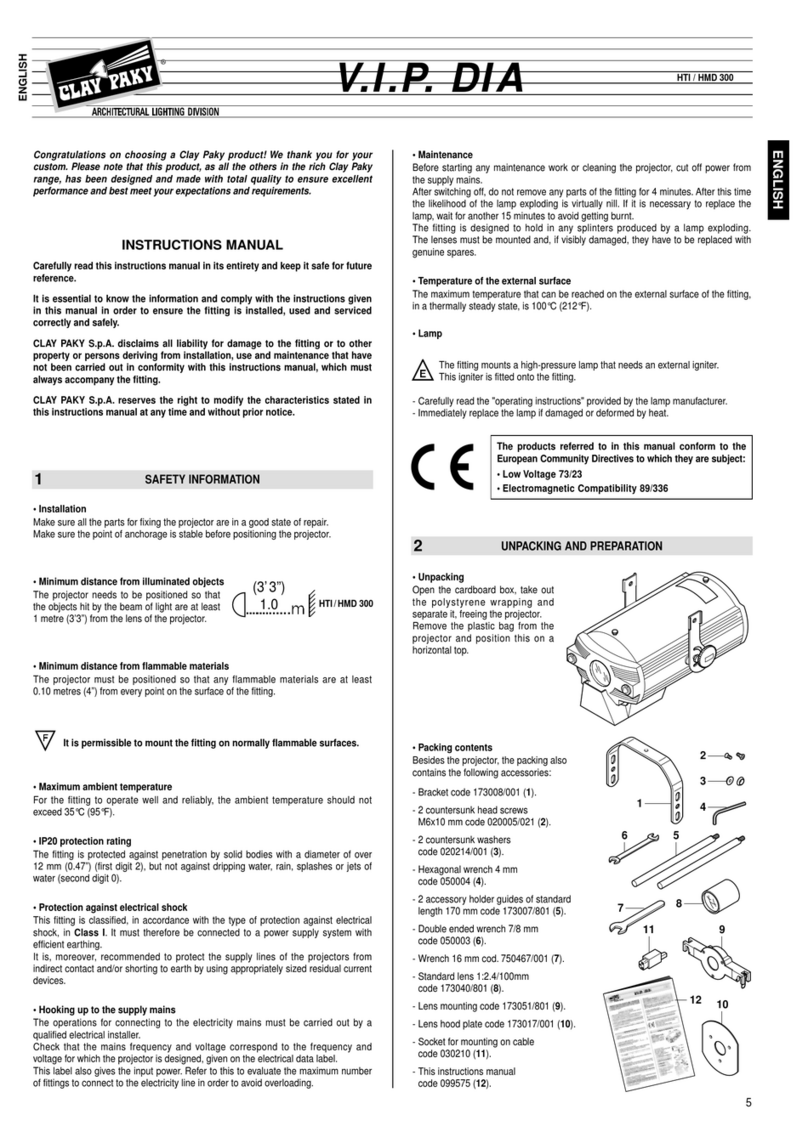

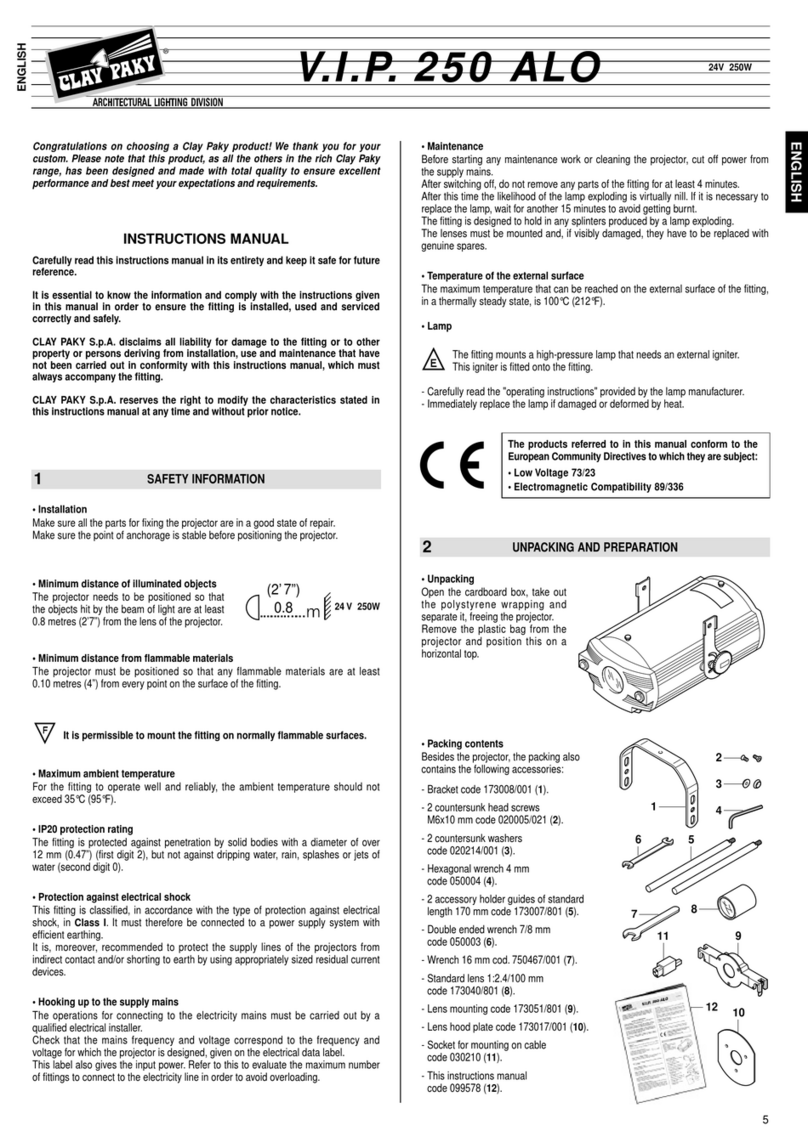

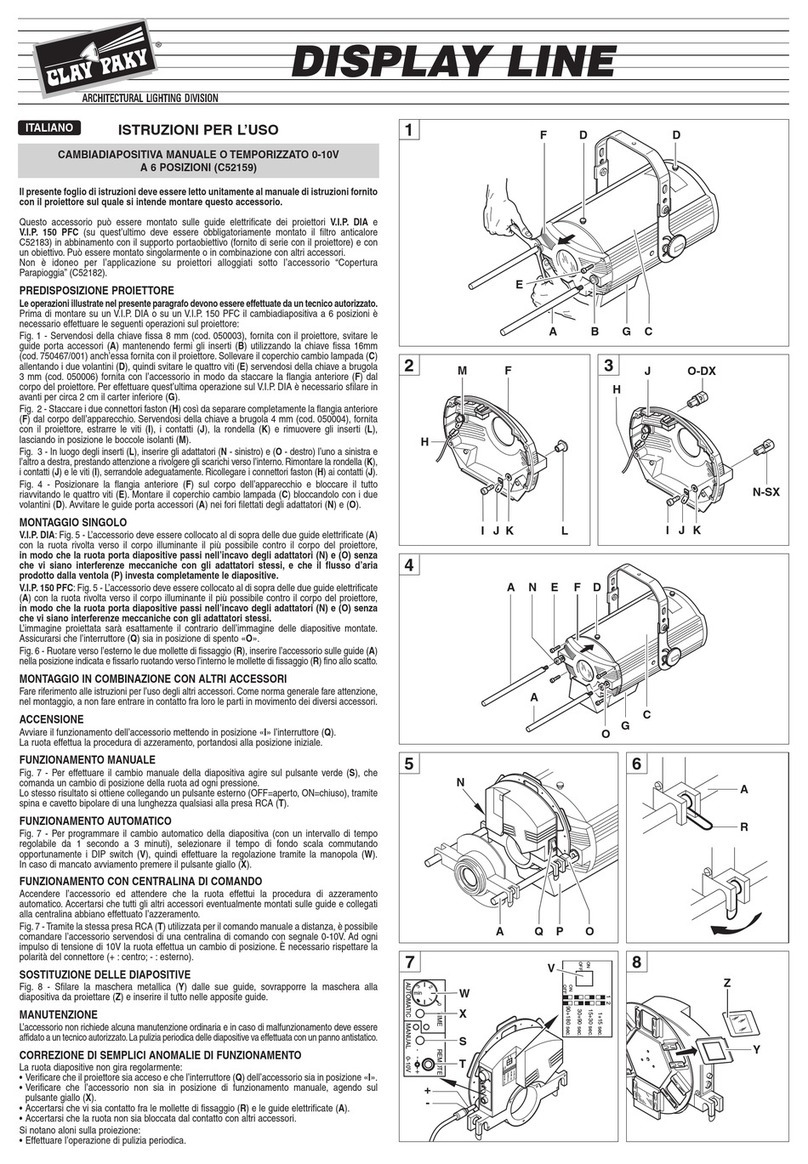

•Unpacking

Open the cardboard box, take out

the polystyrene wrapping and

separate it, freeing the projector.

Remove the plastic bag from the

projector and position this on a

horizontal top.

•Packing contents

Besides the projector, the packing also

contains the following accessories:

-Bracket code 173008/001 (1).

-2countersunk head screws

M6x10mm code 020005/021 (2).

-2countersunk washers

code 020214/001 (3).

-Hexagonal wrench 4mm

code 050004 (4).

-2accessory holder guides of standard

length 170 mm code 173007/801 (5).

-Double ended wrench 7/8mm

code 050003 (6).

-Wrench 16 mm cod. 750467/001 (7).

-Standard lens 1:2.4/100mm

code 173040/801 (8).

-Lens mounting code 173051/801 (9).

-Lens hood plate code 173017/001 (10).

-Socket for mounting on cable

code 030210 (11).

-This instructions manual

code 099577 (12).

It is permissible to mount the fitting on normally flammable surfaces.

•Maintenance

Before starting any maintenance work or cleaning the projector, cut off power from

the supply mains.

After switching off, do not remove any parts of the fitting for at least 2 minutes.

After this time the likelihood of the lamp exploding is virtually nill. If it is necessary to

replace the lamp, wait for another 15 minutes to avoid getting burnt.

The fitting is designed to hold in any splinters produced by a lamp exploding.

The lenses must be mounted and, if visibly damaged, they have to be replaced with

genuine spares.

•Temperature of the external surface

The maximum temperature that can be reached on the external surface of the fitting,

in a thermally steady state, is 80°C (176°F).

•Lamp

The fitting mounts a high-pressure lamp that needs an external igniter.

This igniter is fitted onto the fitting.

-Carefully read the "operating instructions" provided by the lamp manufacturer.

-Immediately replace the lamp if damaged or deformed by heat.

The products referred to in this manual conform to the

European Community Directives to which they are subject:

•Low Voltage 73/23

•Electromagnetic Compatibility 89/336

HQI-T 150