Repair or Warranty Contact Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

Page 9

5.

•

•

–If it is not, turn it clockwise until it comes in contact with the underside of the power head.

6. Replace the primary power head.

• Carefully position the primary power’s head on the primary tank.

• Rotate the primary vacuum’s Compressed Air Control valve to the OFF position.

• Rotate the power head until the Compressed Air Control valve is aligned with the inlet port on the vacuum tank.

• Latch the power head to the tank.

• Rotate the support vacuum’s Compressed Air Control valve to the OFF position.

7. Disconnect the vacuums.

• Disconnect the SFC hose from the primary vacuum’s SFC port.

• Disconnect the SFC hose from the support vacuum’s inlet port.

I

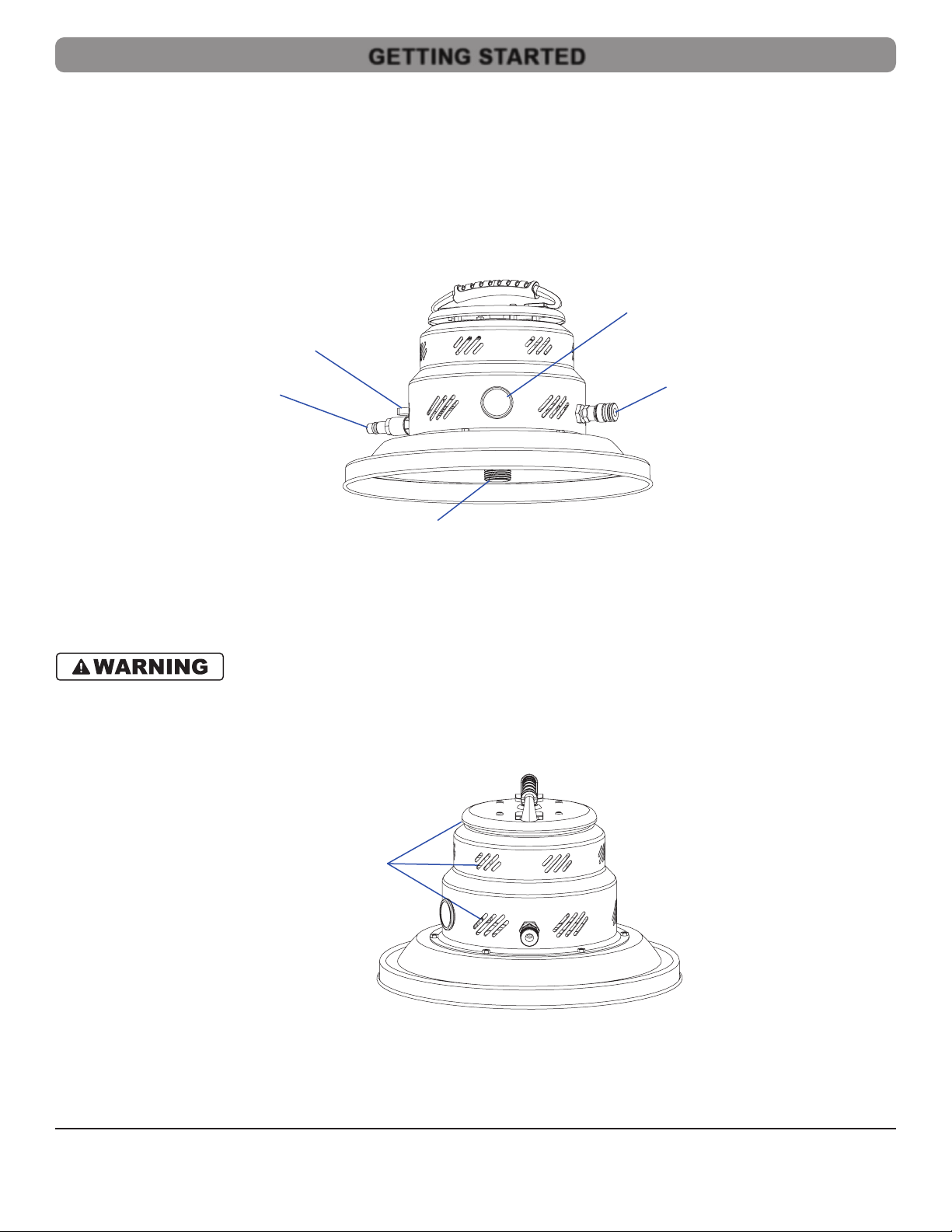

1. Safe the vacuum.

• Disconnect the vacuum from the power source.

• Remove all hoses from the vacuum.

2. Remove the power head.

• Unlatch the power head from the tank.

•

•

3.

•

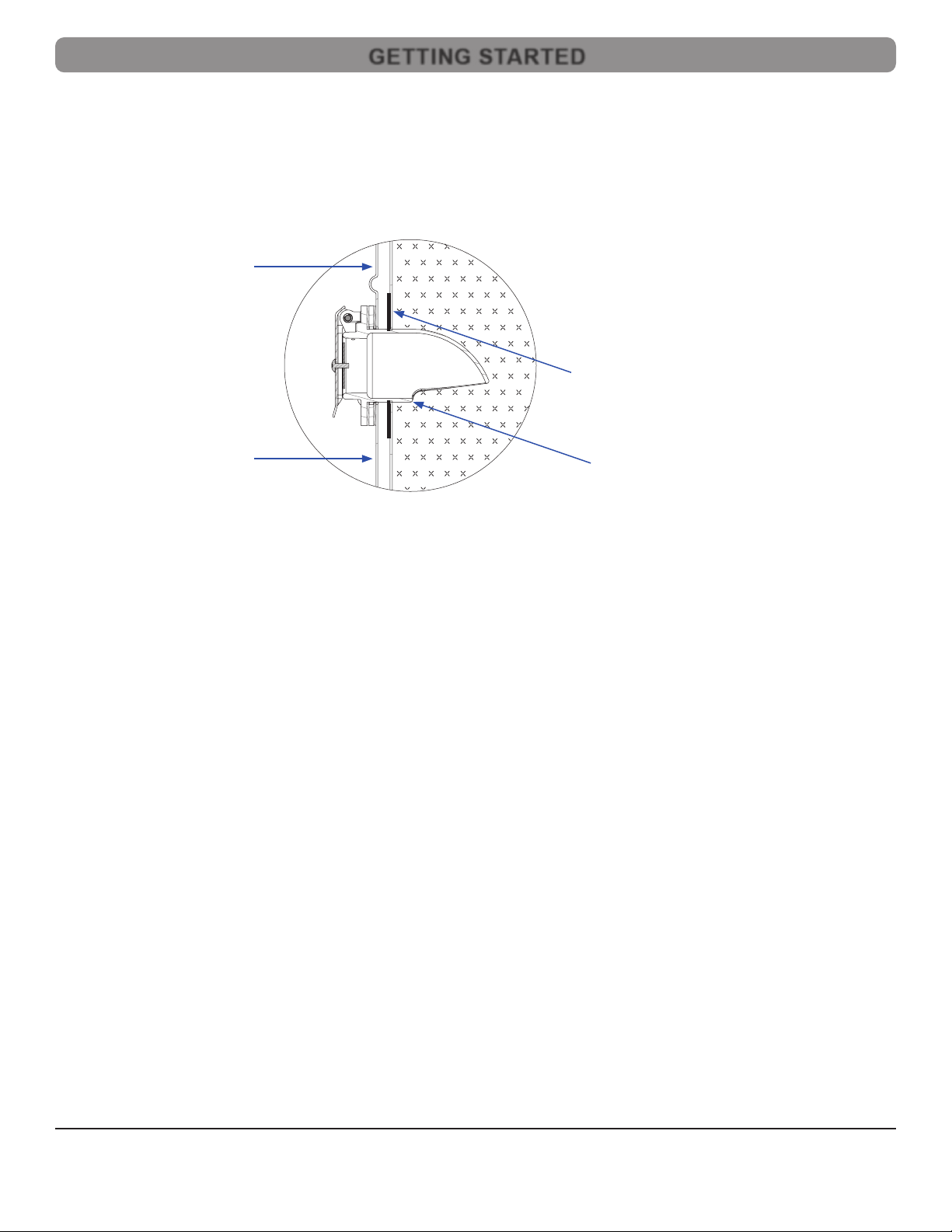

• Find the seam and carefully peel the Velcro apart.

•

4.

•

•

•

5.

• Holding the power head on its side, examine the HEPA Filter.

•

–If it is not, rotate it clockwise until fully seated.

6. Replace the power head.

• Position the power head on the vacuum tank.

• Rotate the power head so that the Compressed Air Control valve on the power head is aligned with the inlet port on the vacuum tank.

• Latch the power head to the tank.

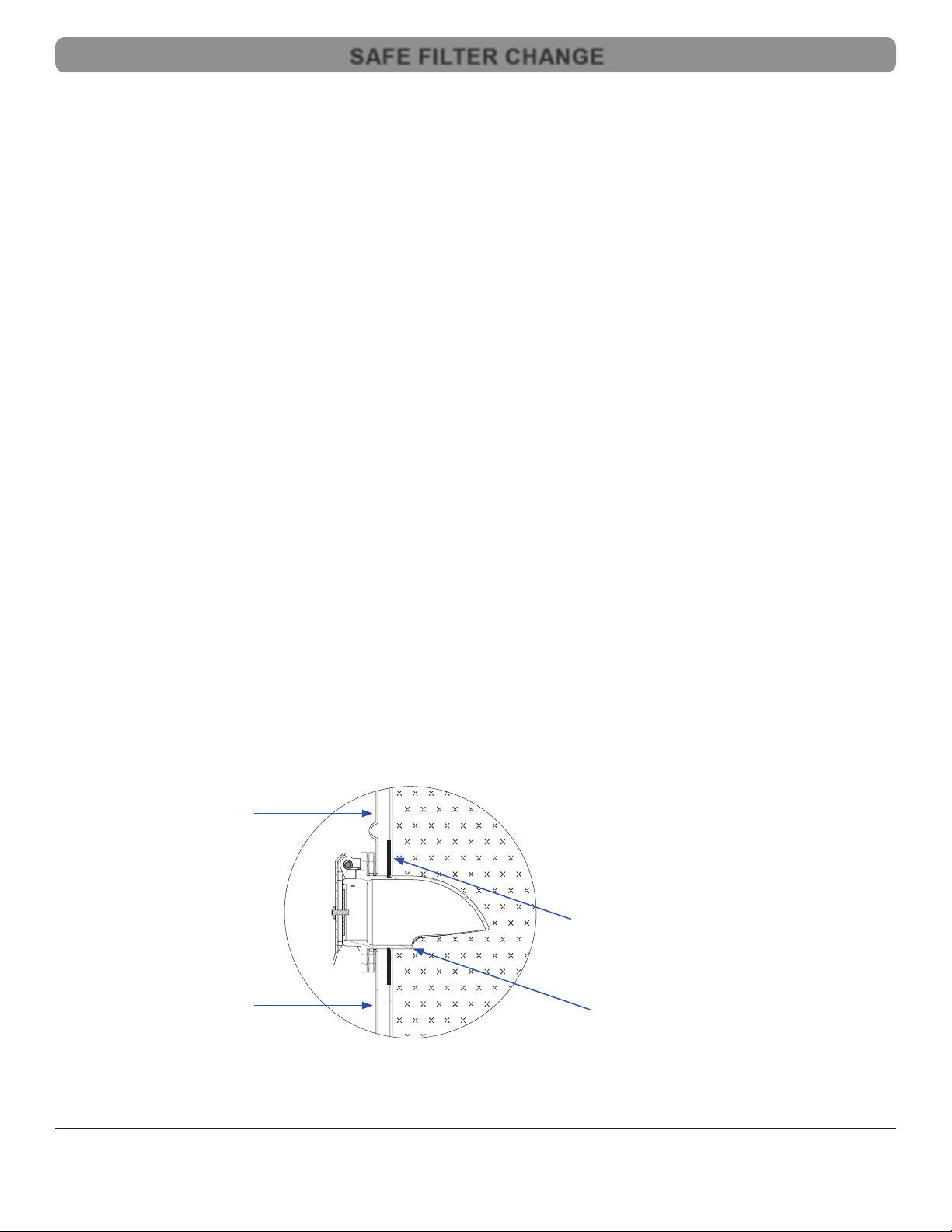

SAFE FILTER CHANGE

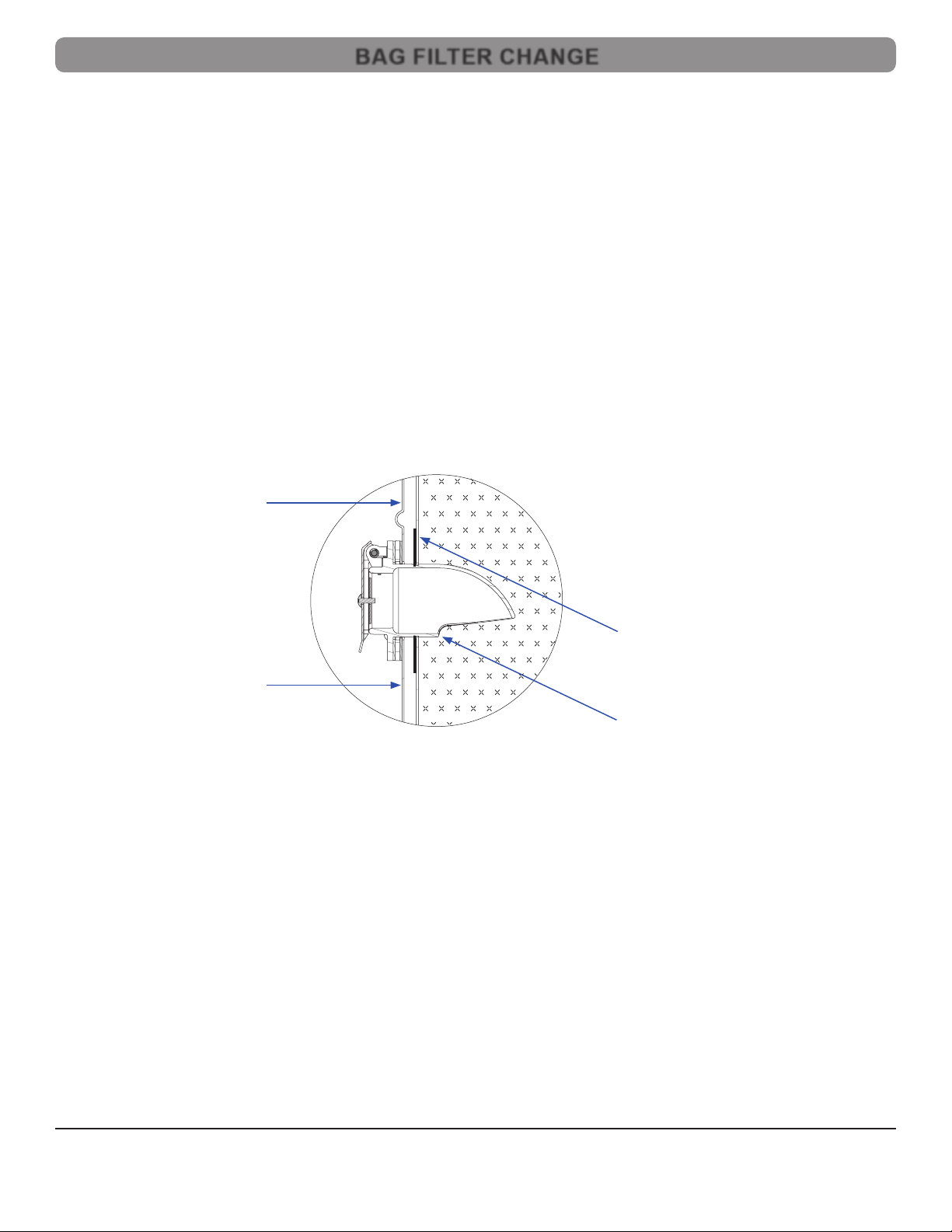

PRE-FILTER CHANGE