Inspection instructions

If over pressurizing of the equipment is

believed to have occurred contact the factory

authorized warranty and service center

nearest you for inspection of the pump.

Specialized equipment and knowledge is

required for repair of this pump. Contact the

factory authorized warranty and service

center nearest you for repairs or adjust-

ments other than maintenance specified in

this manual.

Annual inspection is recommended by the

factory authorized warranty and service

center nearest you.

A list of factory authorized warranty and

service centers is available upon request.

Damaged pumps

Any pump that appears to be damaged in

anyway, is badly worn or operates abnor-

mally, shall be removed from use until

repairs are made.

Contact the factory authorized warranty

and service center nearest you for repairs.

Operation

Flushing

The pump was tested in lightweight oil,

which was left in to protect the pump from

corrosion. Flush the supply lines and hoses

with compatible solvent and blow dry with

air before connecting them to the system.

This is to purge any contaminates such as

dirt, moisture or metal shavings that could

damage the pump or system components

In a circulating system, the pump runs

continuously and slows down or speeds up

as supply demands, until the air supply is

shut off.

In a direct supply system, with adequate

air pressure supplied to the motor, the pump

starts when the gun or dispensing valve is

opened and stalls against pressure when it

is closed.

If the pump accelerates quickly or is run-

ning too fast, stop it immediately. Check the

fluid supply and refill it if necessary. Prime

the pump to remove all air from the system,

or flush the pump and relieve pressure.

Maintenance

If you are pumping fluid which dries,

hardens or sets up, flush the system with a

compatible solvent as often as necessary to

prevent a buildup of dried fluid in the pump

or hoses.

Corrosion protection

for carbon steel pumps

Always follow the pressure relief

procedure warning whenever you

stop spraying and before checking or

repairing any part of the system, to

reduce the risk of serious bodily injury.

WARNING

Do not exceed the maximum working

pressure of any component or accessory

used in the system.

This pump can develop 1,000 psi

(68,9 bar) maximum working pressure,

at 200 psi maximum incoming air

pressure.

Verify all equipment and accessories

are rated to withstand the maximum

working pressure of this pump.

WARNING

Do not clean this system without proper

grounding.

When flushing the pump with sol-

vents, to reduce the risk of injury from

splashing or static sparking, always hold

a metal part of the dispensing valve

firmly to the side of a grounded metal

pail, and use the lowest possible fluid

pressure when flushing.

WARNING

Installation

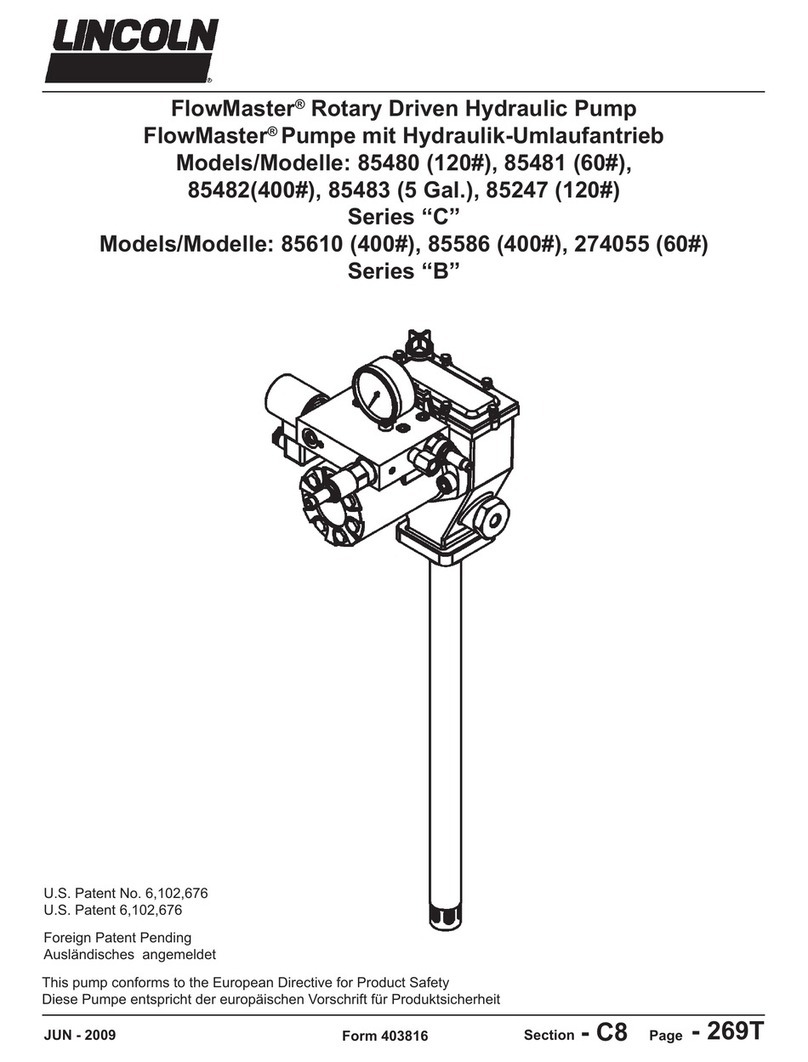

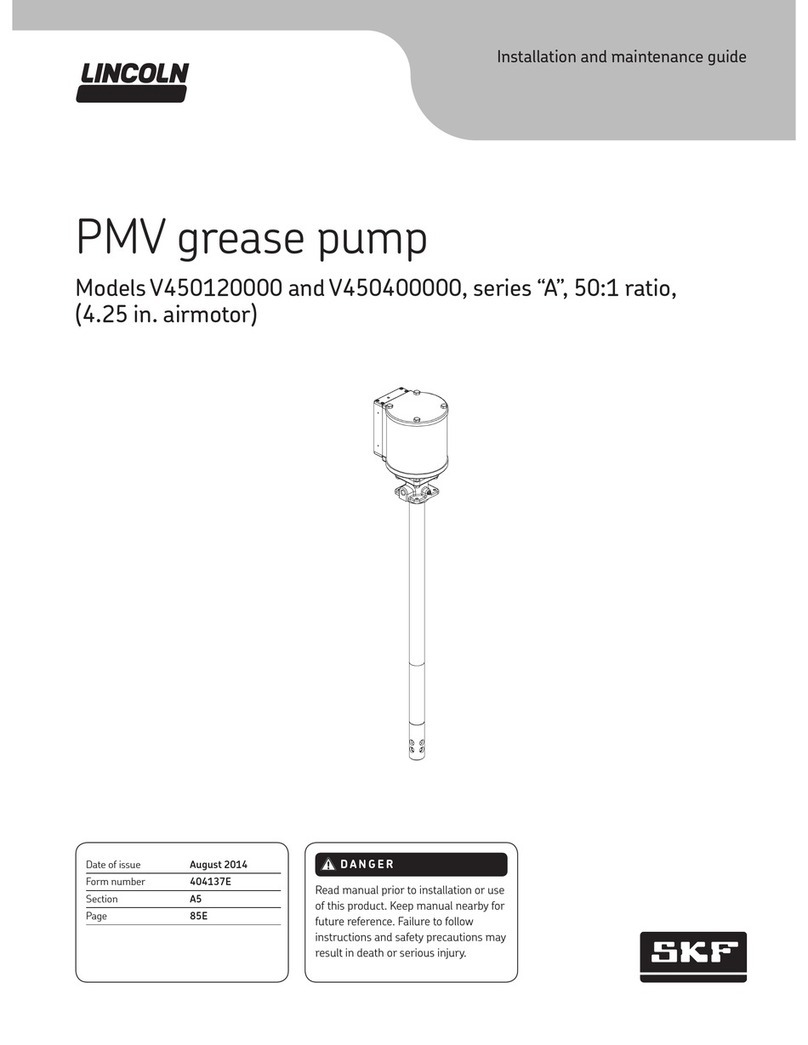

The typical installation and pump mountings

shown are only a guide for selecting and

installing system components.

Contact your Lincoln representative for

assistance in designing a system to suit your

particular needs.

Mount the pump to suit the type of

installation planned. Refer to the pump

dimensional drawing for mounting layout.

An air line filter/regulator/lubricator is

recommended for use with your Lincoln

pump to remove harmful dirt and moisture

from the compressed air supply, and to

provide automatic air motor lubrication.

Use correct air and fluid hoses for your

system.

Tighten all fluid connections securely

before using this equipment.

!Notice Water and moist air, can

cause your pump to corrode. To

help prevent corrosion, never leave the

pump filled with water or air.

After normal flushing, flush the pump

again with mineral spirits or oil-based

solvent, relieve pressure, and leave the

mineral spirits in the pump.

Follow all steps of the pressure relief

procedure warning.

4